Method for online calculation of number of wind field fault elimination shutdown units based on defect list

It is a technology for eliminating the downtime and defect list, which is applied in the directions of calculation, data processing application, electrical digital data processing, etc. It can solve the problems of lack of support for judgment logic, inability to apply on-site, and inability to grasp the overall situation of wind farm production, etc., to achieve improved Equipment utilization and power generation, improving operation and maintenance analysis and decision-making level, and improving the effect of defect elimination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

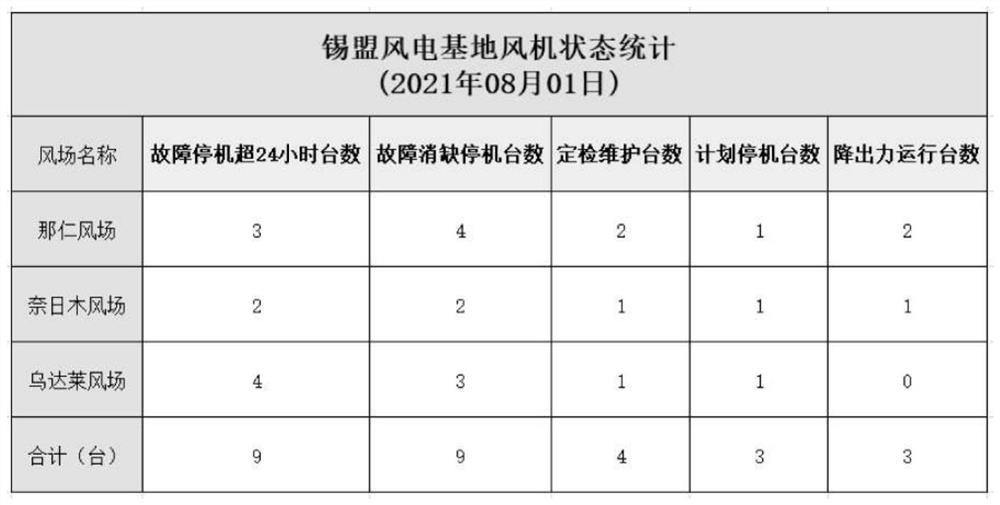

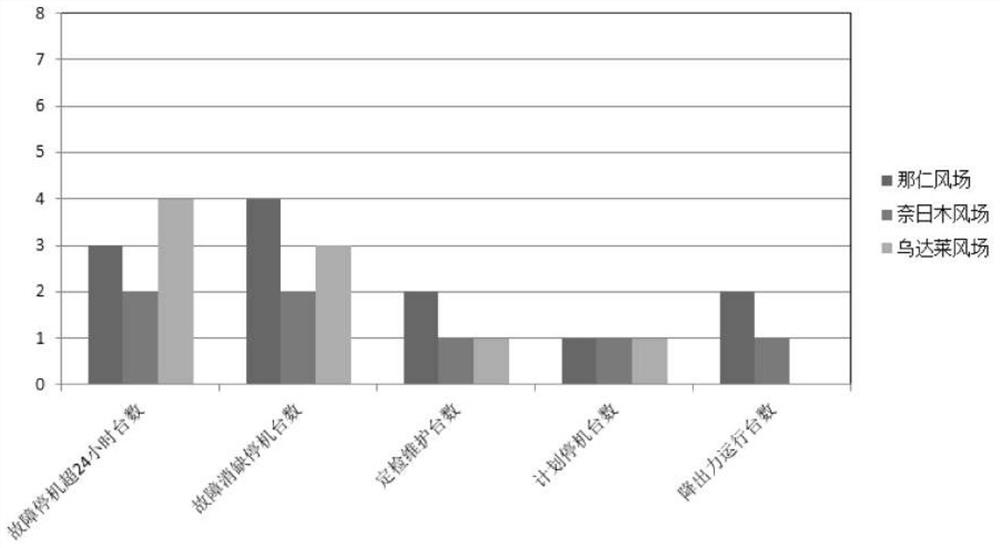

[0018] The method of this invention based on defect single-line calculation of the number of wind farm fault elimination shutdowns has been tested on the wind power smart operation and maintenance project, and the automatic calculation on the smart operation and maintenance platform has been realized. It has become a production management department to supervise the wind farm operation and An important means of field performance appraisal. Taking the headquarters of a wind power company as an example, the implementation of the method is introduced as follows:

[0019] 1) Collect and organize the field information of the three wind farm defect orders in the wind farm production management system, and extract the fields such as the status of the defect order, the number of the defective fan, the defect level, the defect phenomenon, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com