Operational use time recorder of general machine tool

A technology of working time and recorder, which is applied in the direction of time register, registering/indicating machine work, instruments, etc., can solve the problems of distinguishing between working time and effective working time of machine tools, and poor versatility, so as to improve management efficiency and The effect of decision level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

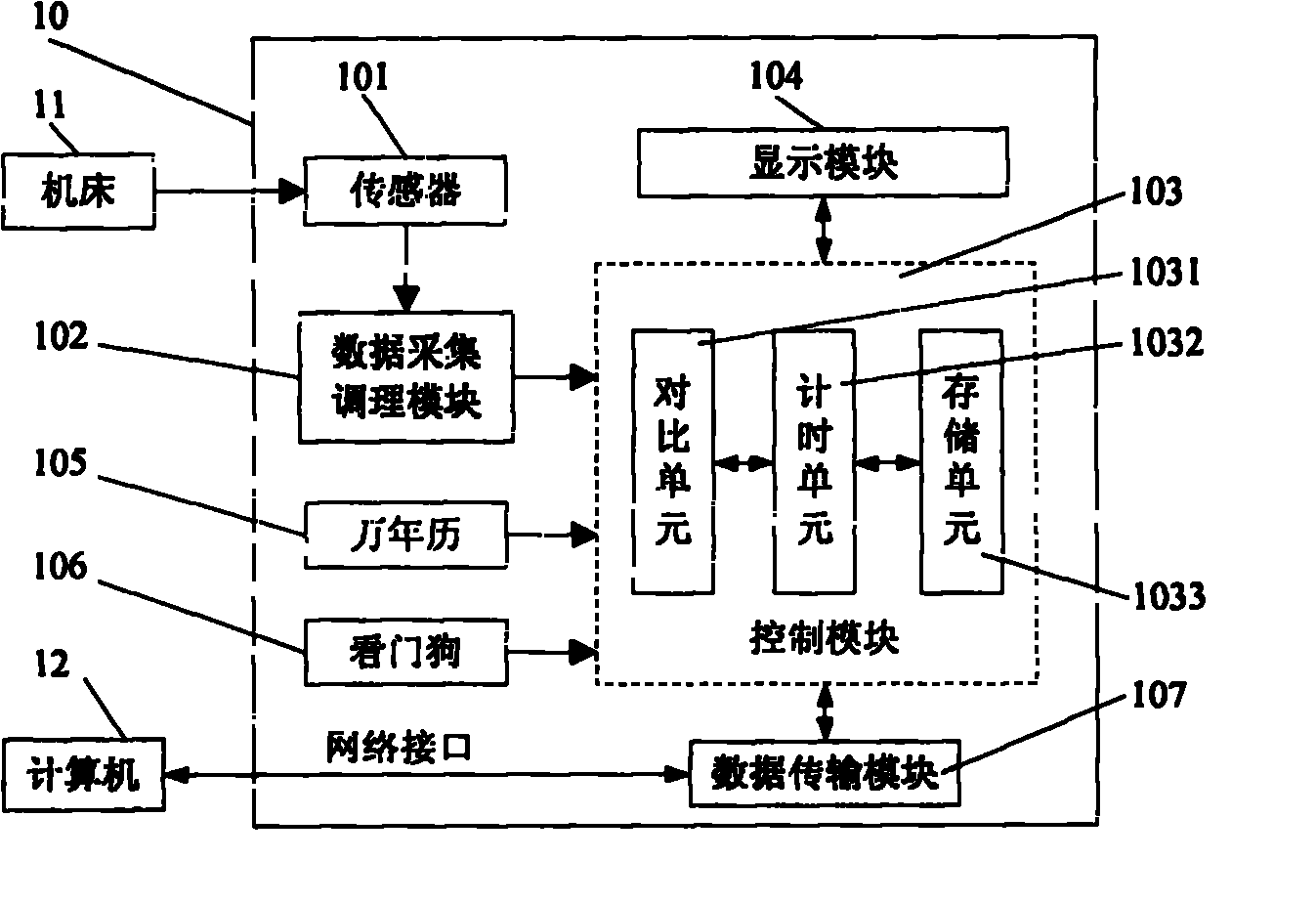

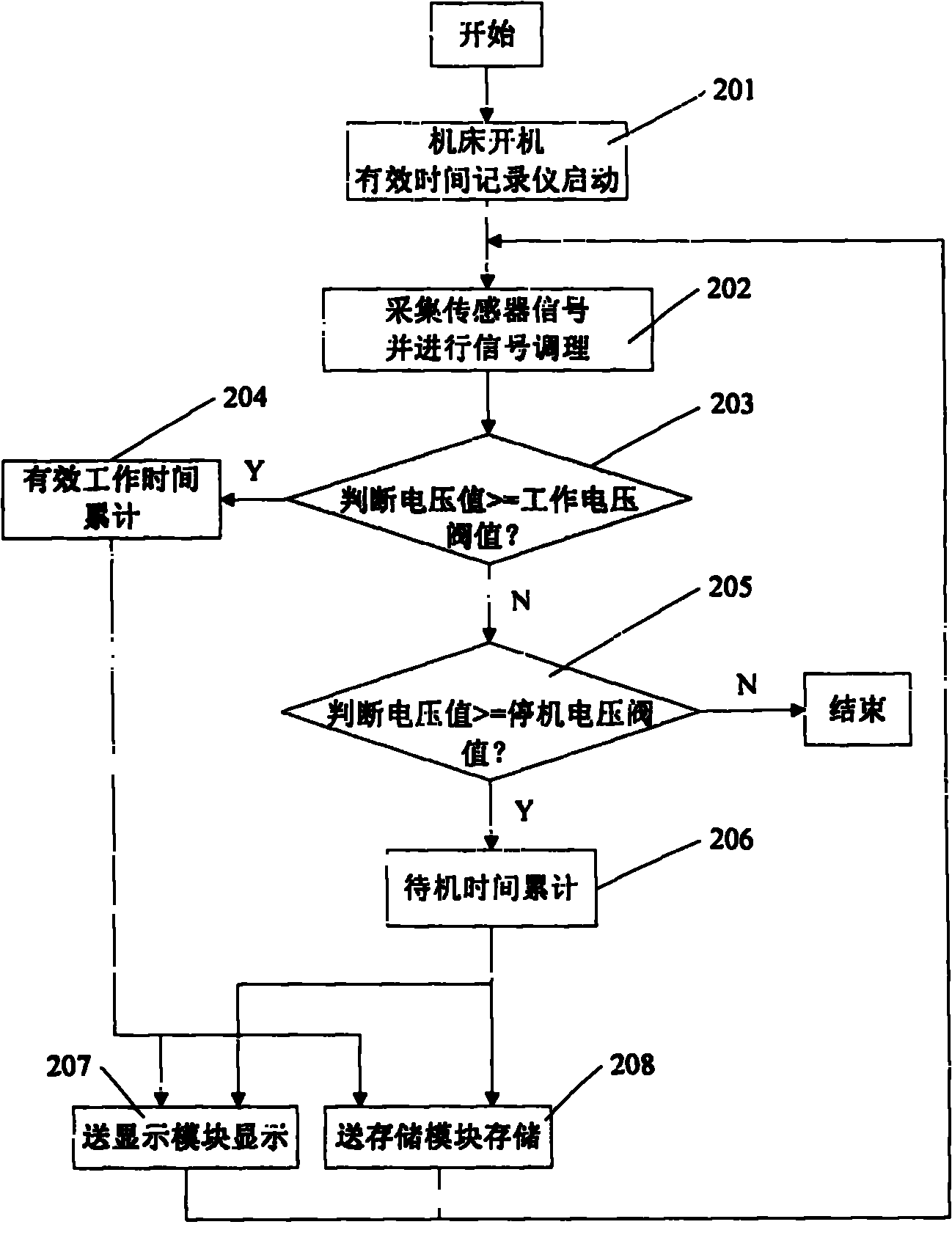

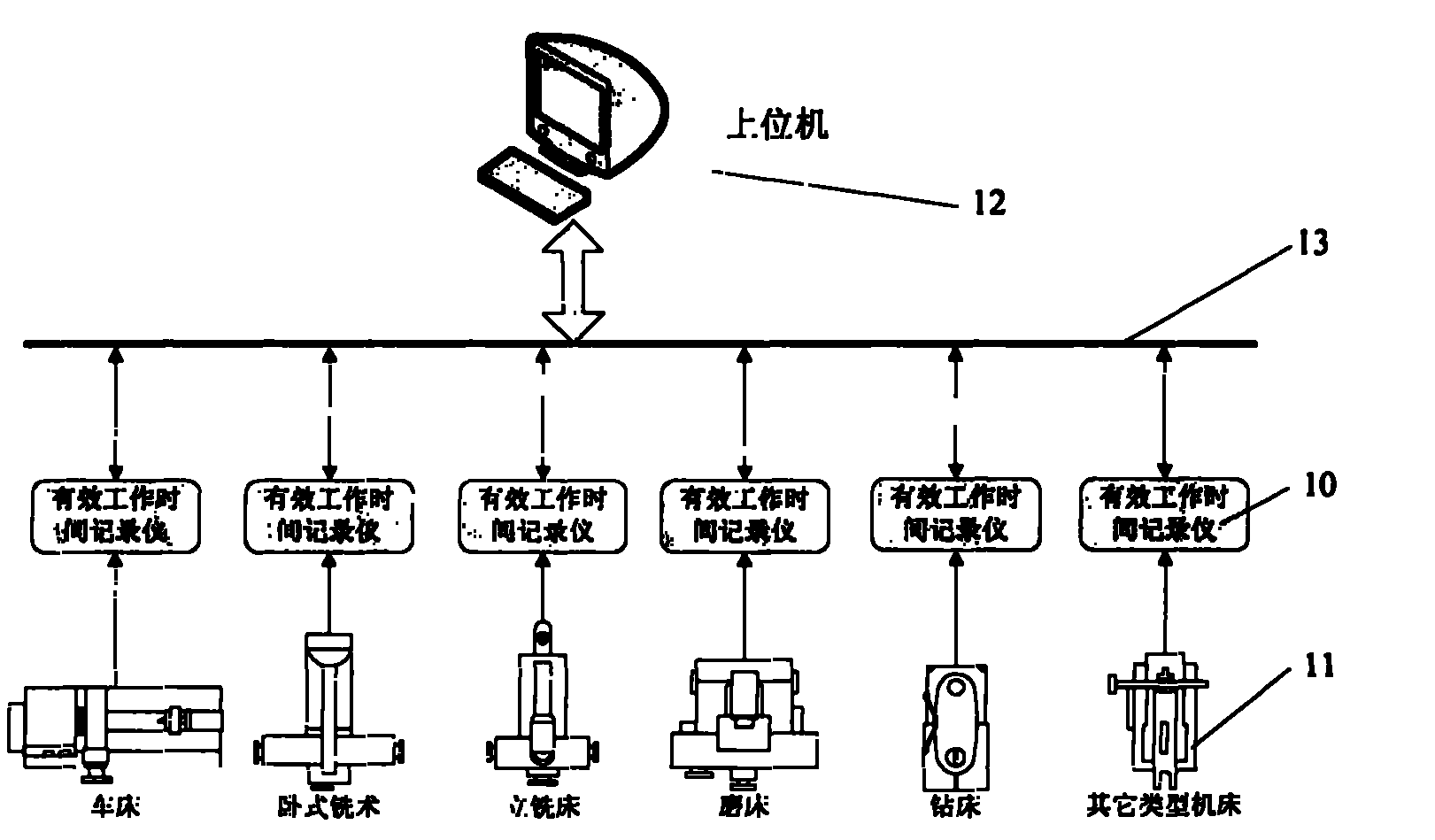

[0020] like figure 1 As shown, it is a functional block diagram of the effective working time recorder of the present invention. The machine tool effective working time recorder 10 includes a sensor 101 , a data conditioning and acquisition module 102 , a control module 103 , a display module 104 , a perpetual calendar module 105 , a watchdog module 106 and a data transmission module 107 . The sensor 101 perceives the change of the working state of the machine tool by sensing the current change of the machine tool, and converts the working state information of the machine tool into a corresponding electrical signal; the data conditioning and acquisition module 102 is used to collect the electrical signal of the sensor 101 and Perform conditioning, conditioning methods include filtering, signal amplification or reduction, analog-to-digital conversion, etc., and finally convert the analog electrical signal of the sensor into a digital electrical signal and input it into the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com