Preparation method of electrolyte containing ZIF-67 nanoparticles

A ZIF-67, electrolyte preparation technology, applied in the direction of non-aqueous electrolyte batteries, circuits, electrical components, etc., can solve the problems of little research, small local charge, etc., to inhibit dendrite growth, reduce capacity fading, uniform deposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

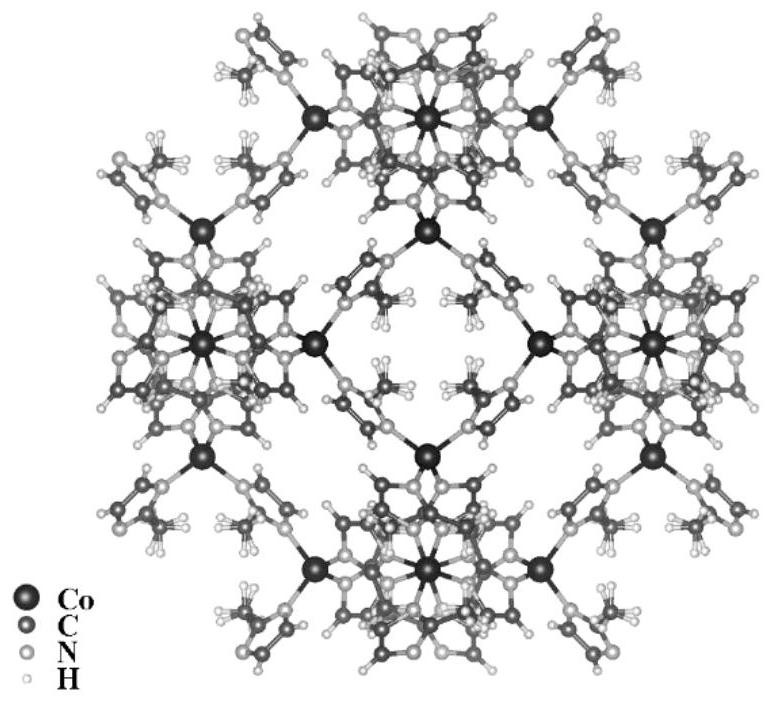

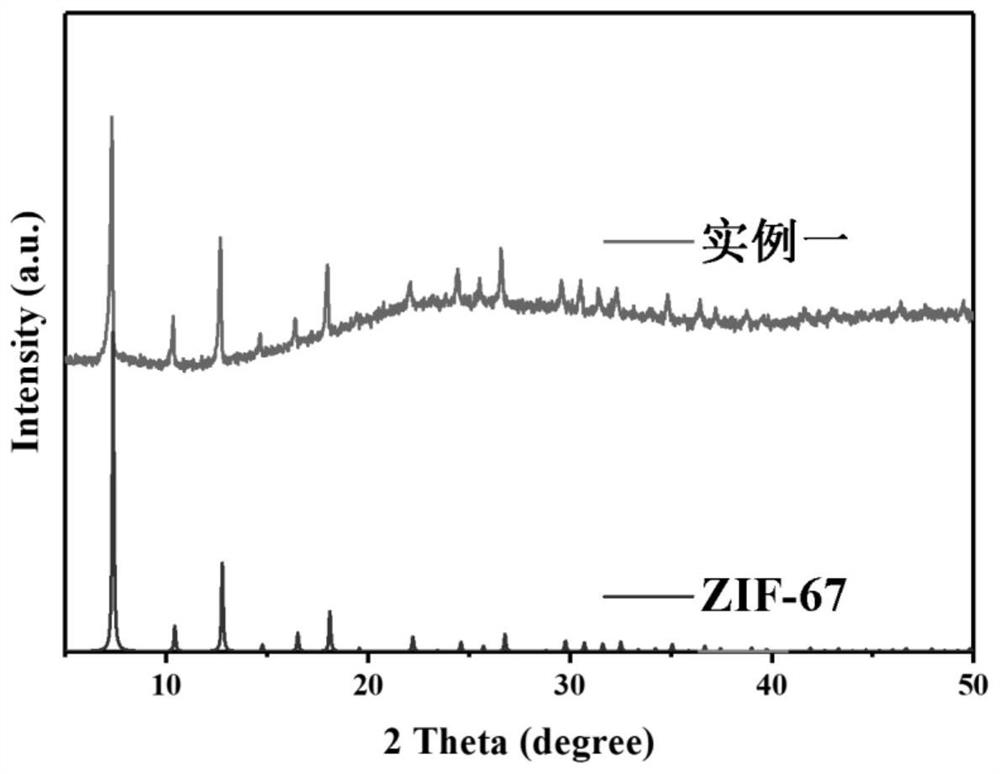

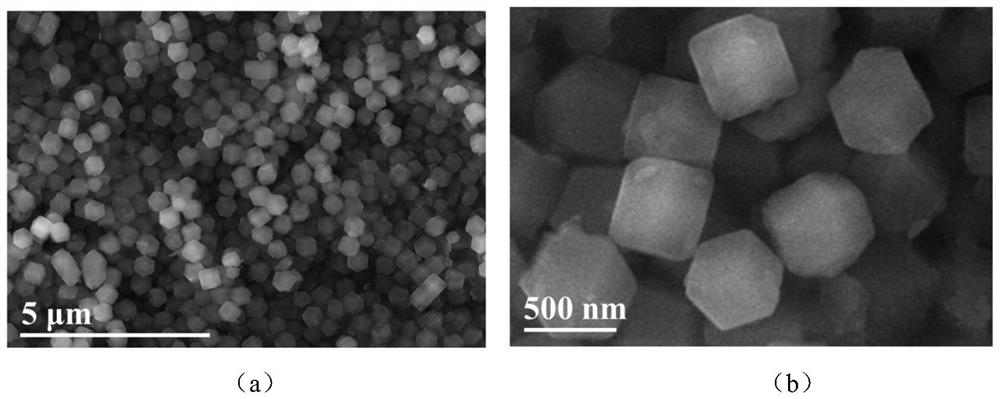

[0029] This embodiment provides a method for preparing an electrolyte solution containing ZIF-67 nanoparticles, the preparation process of which is as follows:

[0030] Step 1: Synthesis of ZIF-67 nanoparticles: 0.87g Co(NO 3 ) 2 ·6H 2 O was dissolved in 30mL methanol to obtain mixed solution A; 1.97g C 4 h 6 N 2 Dissolve in 20mL of methanol to obtain mixed solution B; mix mixed solution A and mixed solution B at a volume ratio of 1:1, leave to react at 25°C for 1 hour, and then centrifuge with deionized water and absolute ethanol After washing three times and drying in an oven at 60°C, ZIF-67 nanoparticles were obtained;

[0031] Step 2: Vacuum activation of ZIF-67 nanoparticles at 80° C. for 24 hours to remove impurities adsorbed in the pores of ZIF-67 nanoparticles;

[0032] Step 3: Add LiNO 3 Dissolve LiTFSI in a DOL / DME mixed solution with a volume ratio of 1:1 to obtain LiNO 3 The concentration of LiTFSI is 2wt%, and the concentration of LiTFSI is 1mol / L lithium-...

Embodiment 2

[0034] The electrolyte containing ZIF-67 nanoparticles was prepared according to the steps of Example 1, only the vacuum activation temperature in step 2 was adjusted from 80° C. to 100° C.; other steps remained unchanged.

Embodiment 3

[0036] Prepare the electrolytic solution containing ZIF-67 nanoparticle according to the step of embodiment 1, only the concentration 0.5g / L of ZIF-67 nanoparticle after the vacuum activation in step 3 electrolytic solution is adjusted to 0.4g / L; Other steps are unchanged .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com