Numerical control machining center clamp

A machining center and fixture technology, used in manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of automatic detachment of the workpiece, lack of anti-skid mechanism, and inability to automatically push the workpiece displacement, and achieve the effect of workpiece stabilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

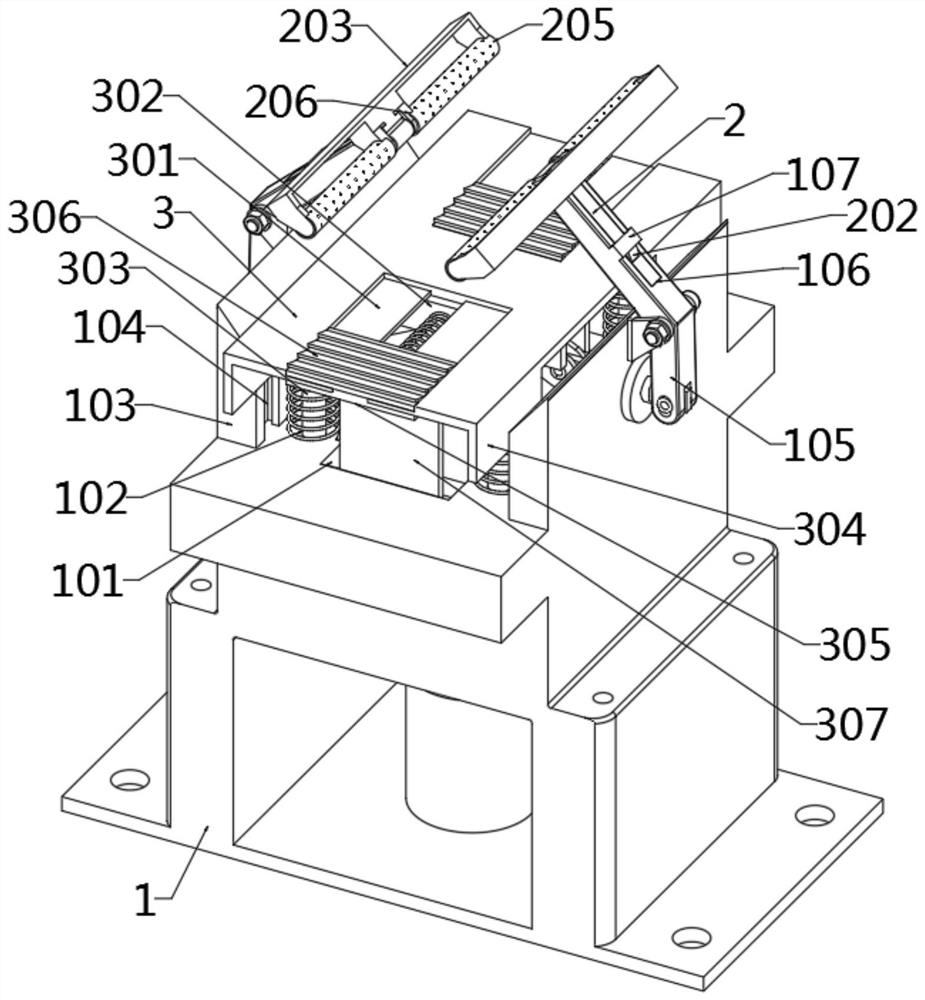

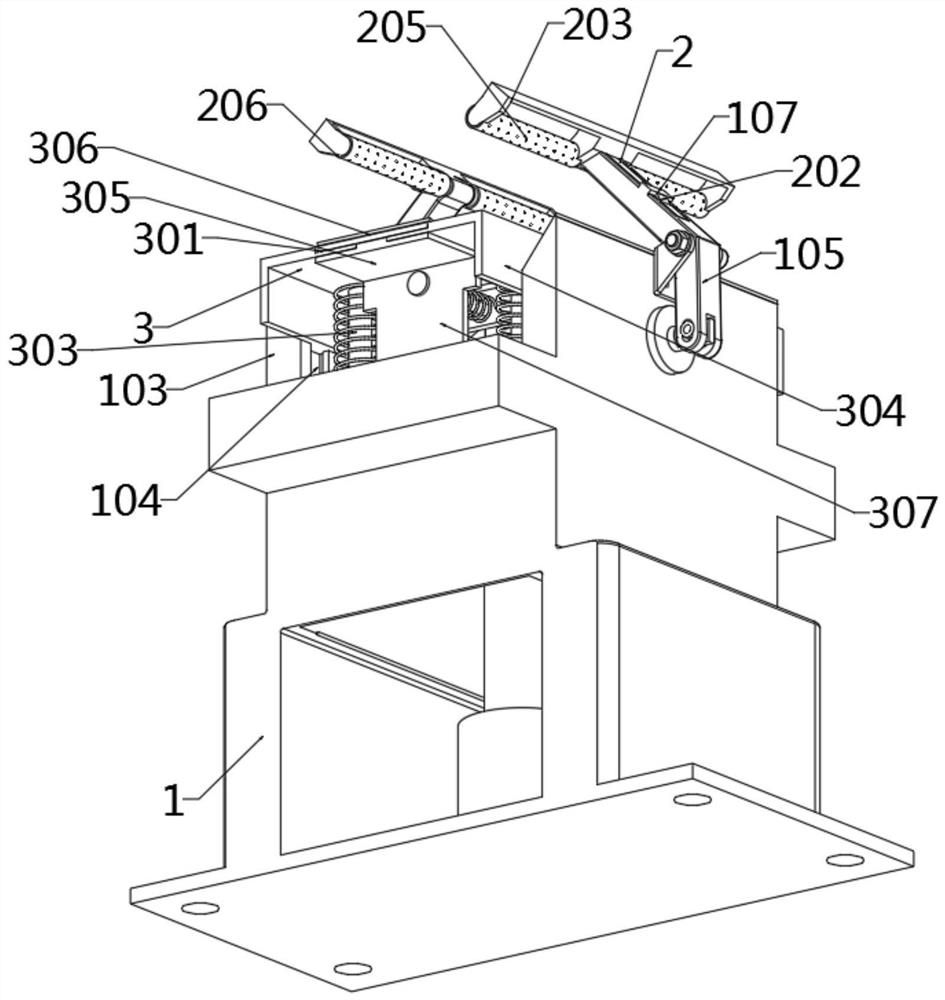

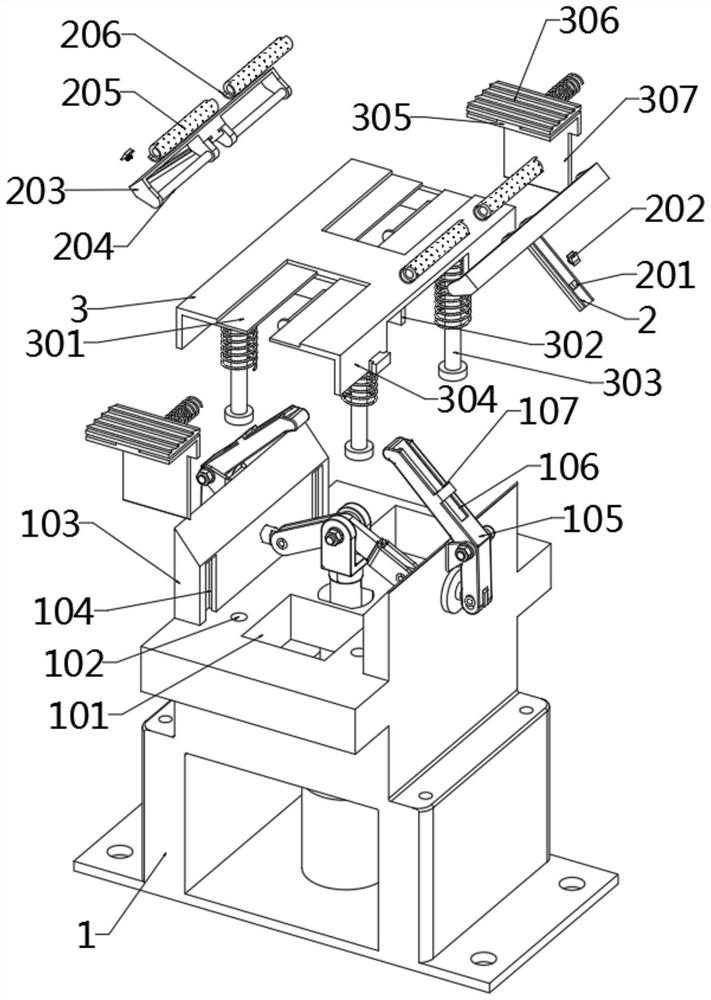

[0028] as attached figure 1 to the attached Figure 8 shown:

[0029] The invention provides a fixture for a CNC machining center, comprising a main body 1; the main body 1 is a T-shaped structure, the top of the main body 1 is provided with rectangular plates on both sides, an electric cylinder is installed inside the main body 1, and a pull rod is connected to the top of the electric cylinder, The pull rod is installed on the top of the main body 1, and the top of the main body 1 is installed with the moving plate 3; the plug-in 2, the plug-in 2 is a T-shaped structure, the plug-in 2 is inserted into the interior of the slot 106, and the plug-in 2 plays the role of connecting with the flip arm 105, And then follow the flip arm 105 to flip, so that the contact piece 205 can follow the contact and fix; the moving plate 3, the moving plate 3 includes a force displacement mechanism, the two ends of the moving plate 3 are equipped with a force displacement mechanism, and the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com