Production device for reinforced and toughened nylon modified engineering plastic product

An engineering plastic, strengthening and toughening technology, which is applied in the field of reinforced and toughened nylon modified engineering plastics production equipment, can solve the problems of unsuitability for popularization, slowing down production efficiency, low blending efficiency, etc., and achieves shortening mixing time, Good mixing effect and high blending efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

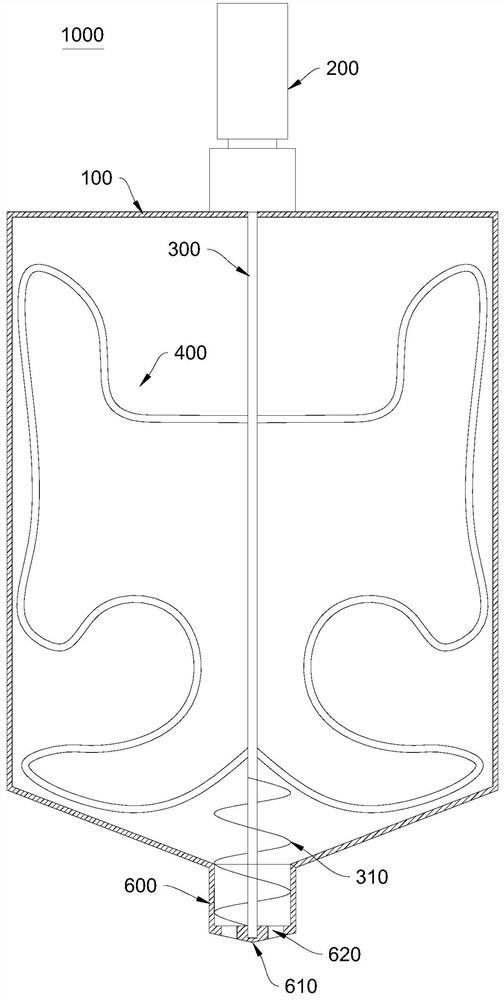

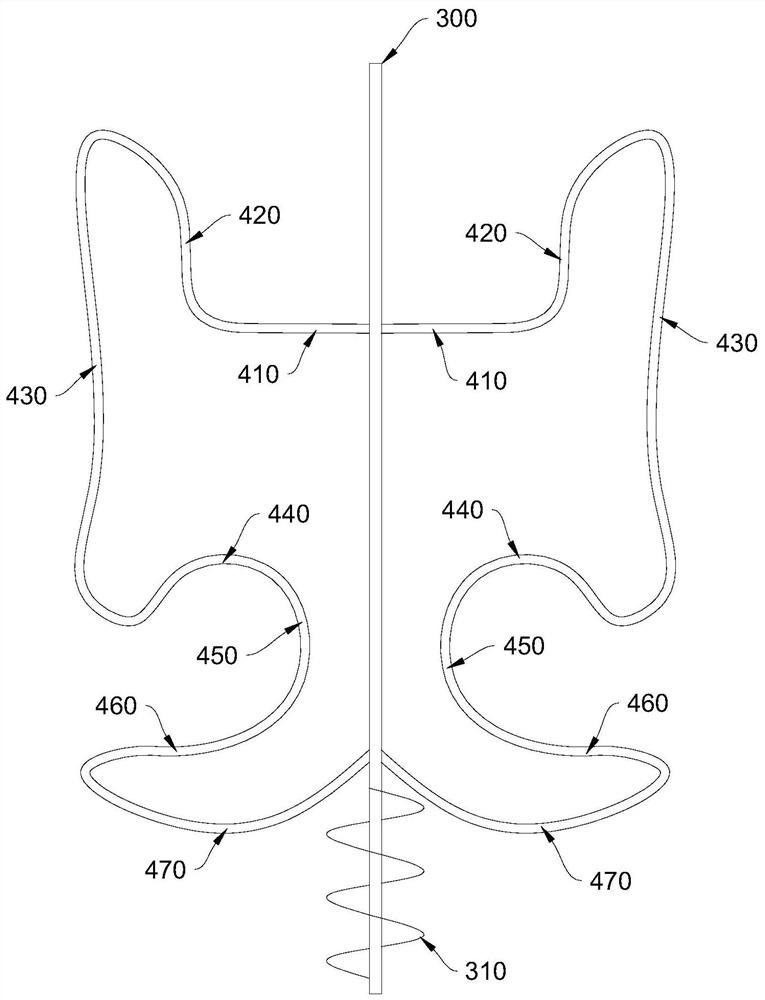

[0040] Please refer to figure 1 and figure 2 , the present embodiment provides a production device 1000 for reinforced and toughened nylon modified engineering plastic products. The production device 1000 for reinforced and toughened nylon modified engineering plastic products includes: a blending chamber 100, a drive assembly 200, a stirring shaft 300 and a stirring rod 400 .

[0041] The stirring shaft 300 is arranged along the height direction of the blending chamber 100 and driven by the driving assembly 200 , and the stirring rod 400 is fixedly connected to the stirring shaft 300 . The driving assembly 200 may be a motor installed with a reducer, but is not limited thereto.

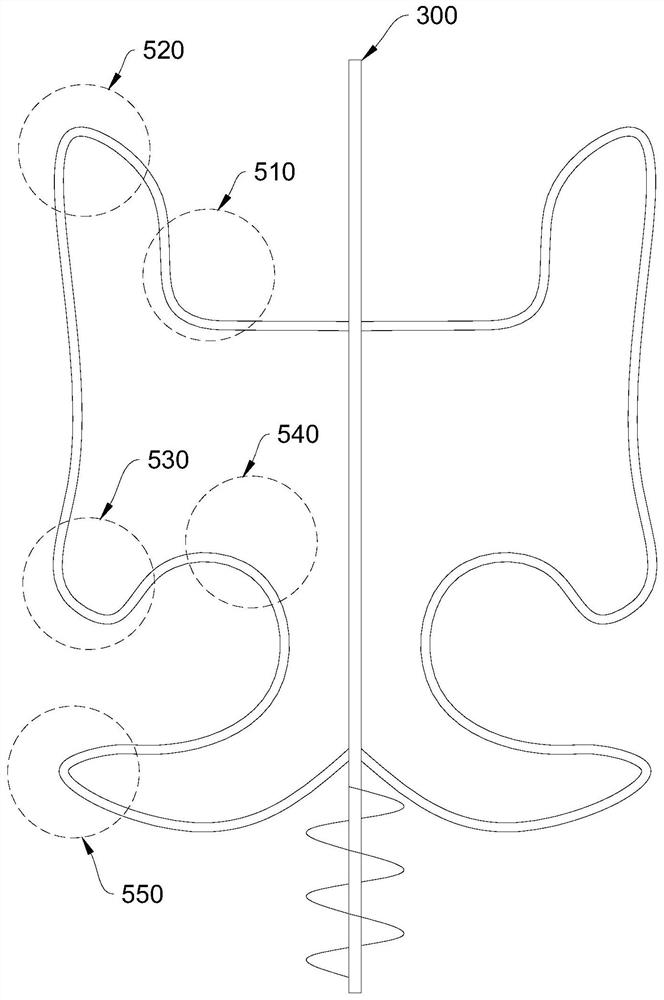

[0042] Wherein, one end of the stirring rod 400 is connected with the upper half of the stirring shaft 300 , and the other end is connected with the lower half of the stirring shaft 300 . The stir bar 400 is constructed by the following steps:

[0043] S1. Starting from the end where the stirrin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap