Profiled metal plate, assembly and profiled metal roof panel

A metal plate and plate body technology, which is applied to roofs using tiles/slate tiles, roofs using flat panels/curved panels, roofs, etc., can solve the problem that photovoltaic modules are easy to fall out, easy to be deformed by compression, and poor wind resistance performance, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

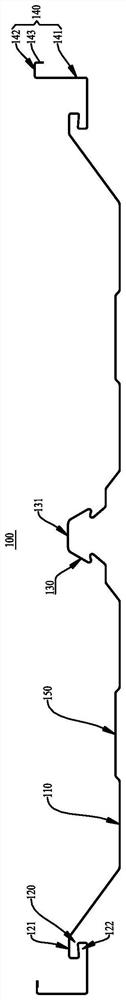

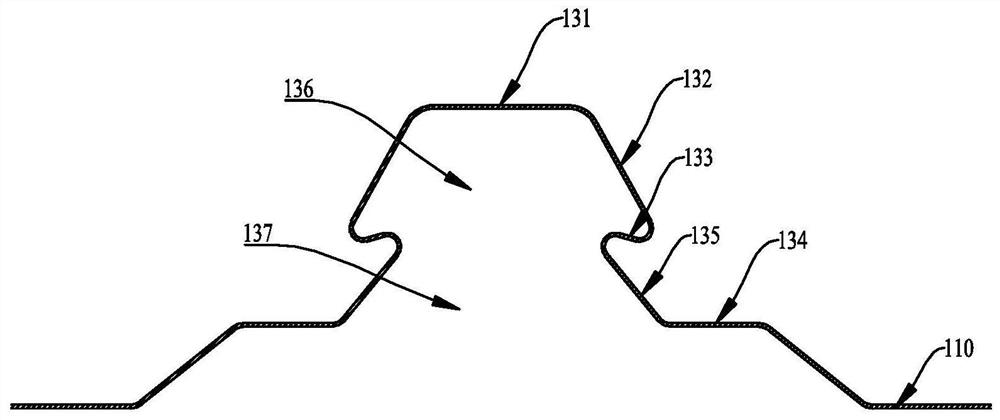

[0055] Please see figure 1 and figure 2 , the present embodiment provides a profiled metal plate 100, which includes a strip-shaped plate body 110, viewed from the cross-section in the width direction of the plate body 110, the two sides of the plate body 110 are respectively bent to form a strip extending along the length direction. The edge ribs 120, the upper surface of the edge ribs 120 is the edge support surface 121, the plate body 110 below each edge support surface 121 is bent to form a buckle groove 122, and the opening of the buckle groove 122 faces away from the other side. In the direction of one edge rib 120, the plate body 110 between the two edge ribs 120 is bent to form a middle rib 130 extending along the length direction. The upper surface of the middle rib 130 is the middle supporting surface 131, and the middle The support surface 131 and the edge support surface 121 are generally located on the same plane, and the middle rib 130 has a cavity with an open...

no. 2 example

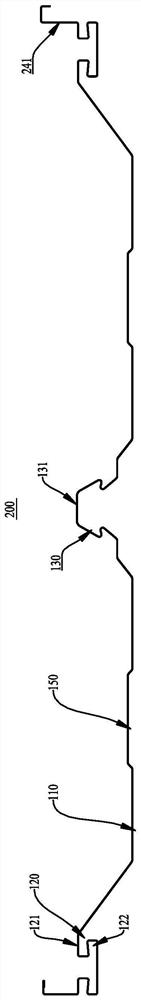

[0063] Please see figure 1 and image 3 , a profiled metal plate 200 provided in this embodiment, its structure is roughly the same as that of the first embodiment, the difference is that in this embodiment, the vertical surface 241 of each connecting portion 140 is also bent processing, but the whole is in a vertical state. This setting can ensure that after the matching connecting parts 140 are overlapped together, the bending parts of the vertical surface 241 can be overlapped and snapped together, and they can be connected without special processing. together.

no. 3 example

[0065] Please see figure 1 and Figure 4 , a profiled metal plate 300 provided in this embodiment, its structure is substantially the same as that of the first embodiment, the difference is that in this embodiment, the clamp surface 133 faces away from the corresponding middle support surface 131 Inclined to form an open corner with the inclined surface 132, the clip space 136 is narrow at the top, wide at the middle and narrow at the bottom; an auxiliary rib 310 is also provided between each connecting portion 140 and the corresponding edge rib 120, the auxiliary rib 310 The rib 310 is designed symmetrically with the side rib 120 , and has an auxiliary buckle slot facing inward. The corresponding buckle slot 122 and the auxiliary buckle slot work together to facilitate the installation of the clip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com