Tread cleaning device

A tread cleaning and piston technology, which is applied in the direction of brake actuators, slack adjusters, etc., can solve the problems of small total elongation of the piston and cannot meet the use requirements, etc., to reduce the braking response time and achieve stable and reliable working performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

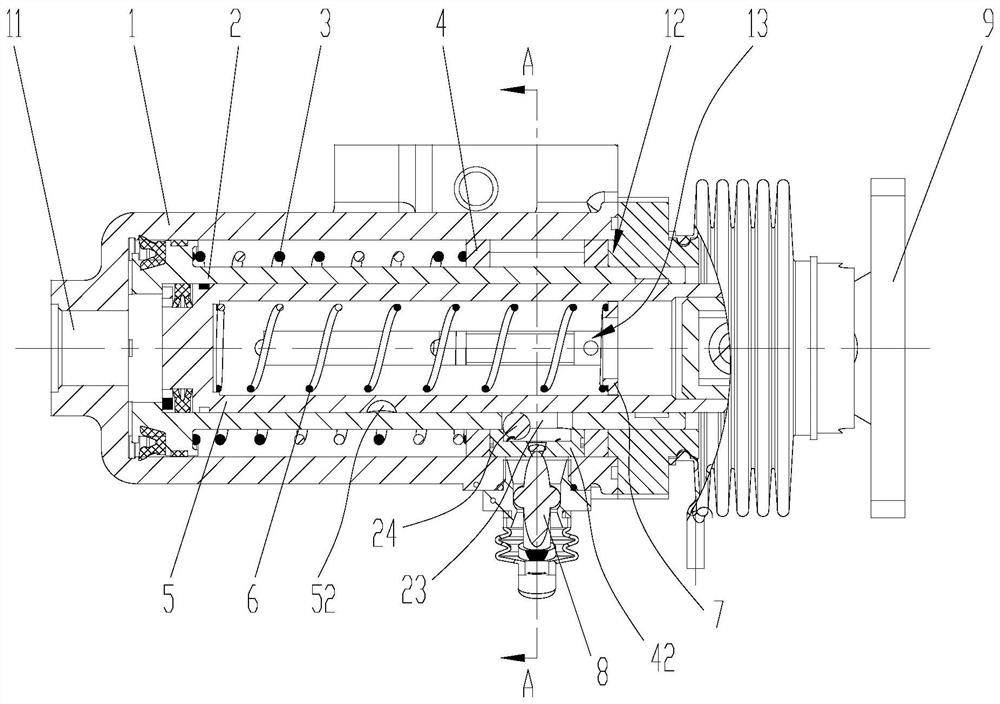

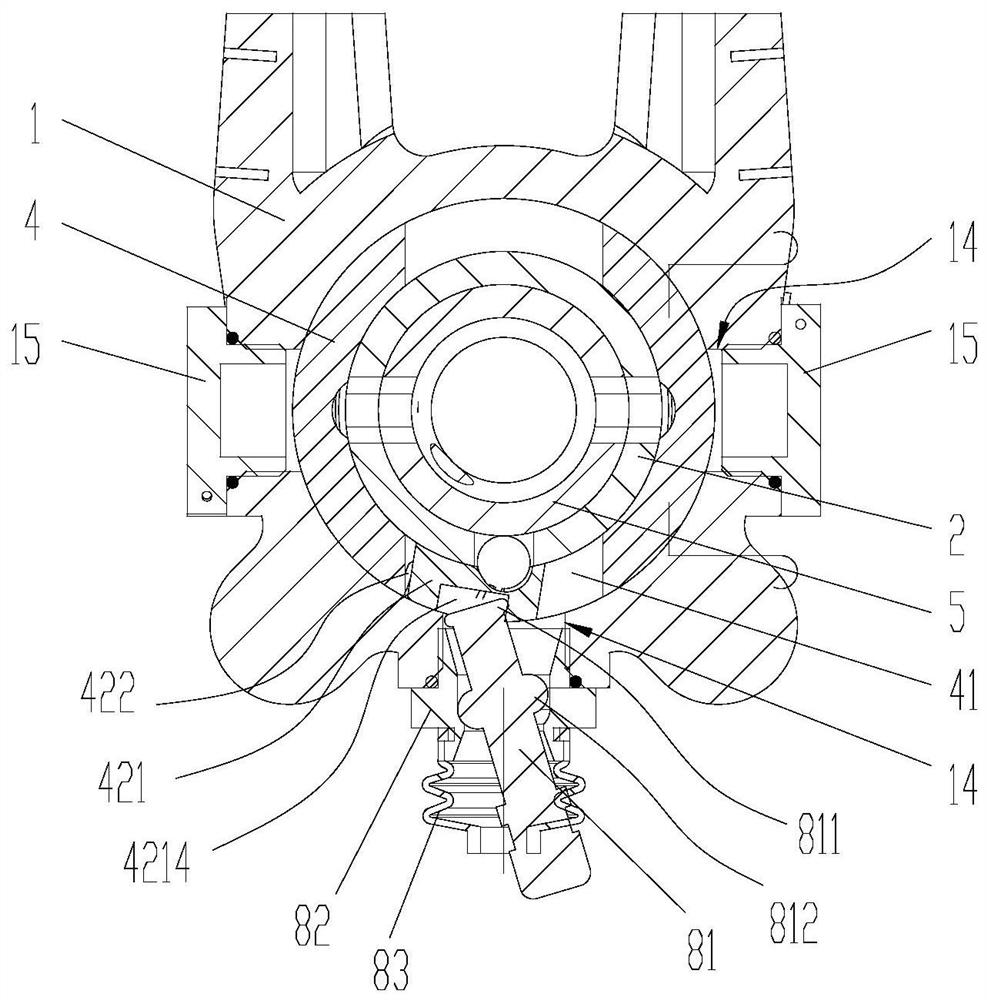

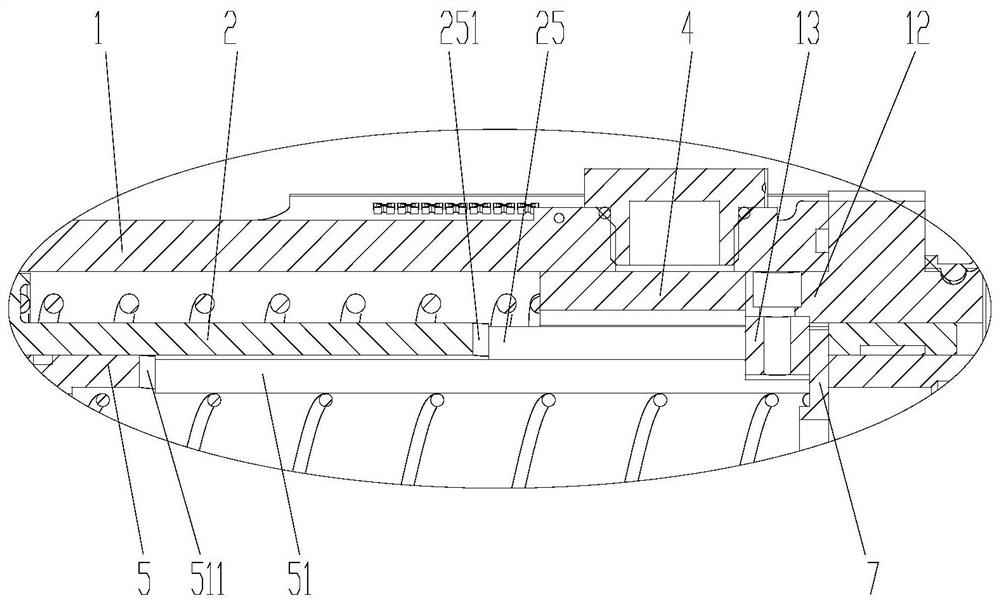

[0051] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0052] Such as Figure 1 to Figure 12 As shown, the present embodiment provides a tread cleaning device, comprising:

[0053] Cylinder 1;

[0054] The first piston 2 with openings at both ends is set in the cylinder body 1, the first end of the first piston 2 is in sealing and sliding connection with the cylinder body 1, and the first piston 2 is sleeved with a first spring 3 and a thrust sleeve 4. The thrust sleeve 4 is axially limited in the cylinder body 1, and the two ends of the first spring 3 are respectively pressed against the first end of the first piston 2 and the thrust sleeve 4; hole 23, and a movable block 24 is embedded in the through hole 23;

[0055] The second piston 5 whose first end closes the opening of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com