Method for analyzing lubrication temperature rise state of high-rotation-speed bearing

A bearing lubrication and state analysis technology, applied in the direction of instruments, electrical digital data processing, geometric CAD, etc., can solve problems such as enhancement, achieve the effects of reducing temperature rise, improving lubrication effect, and optimizing bearing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

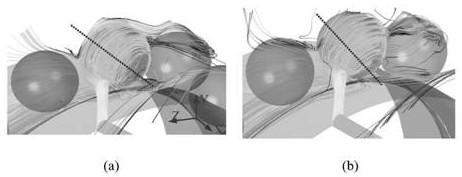

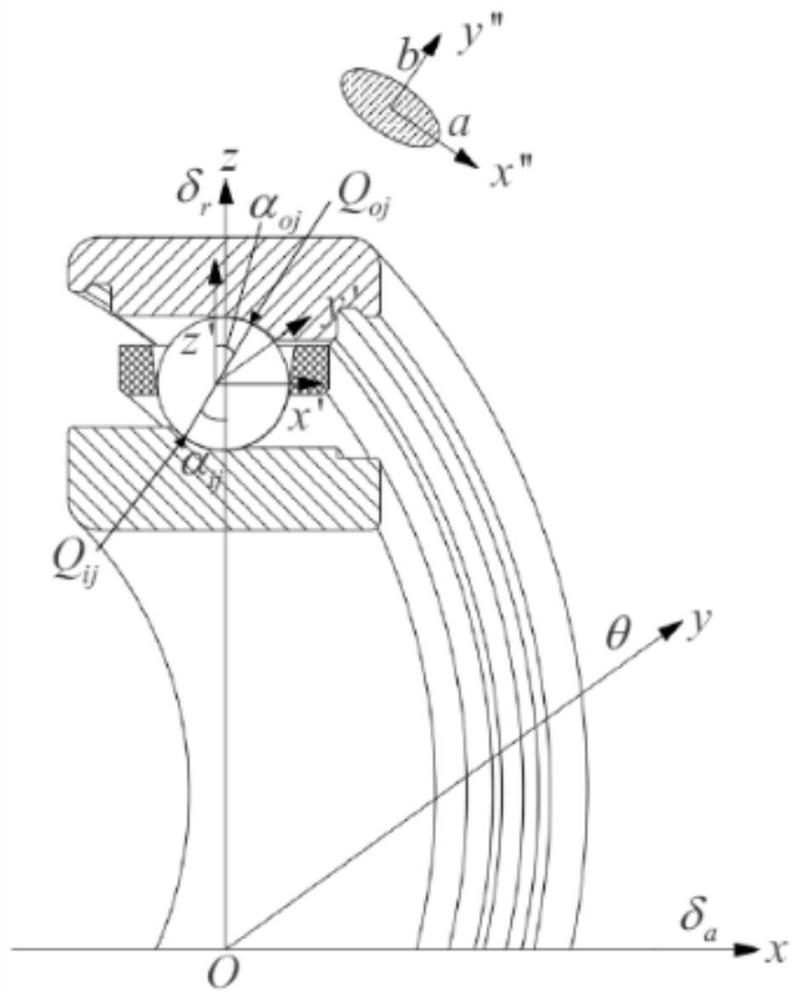

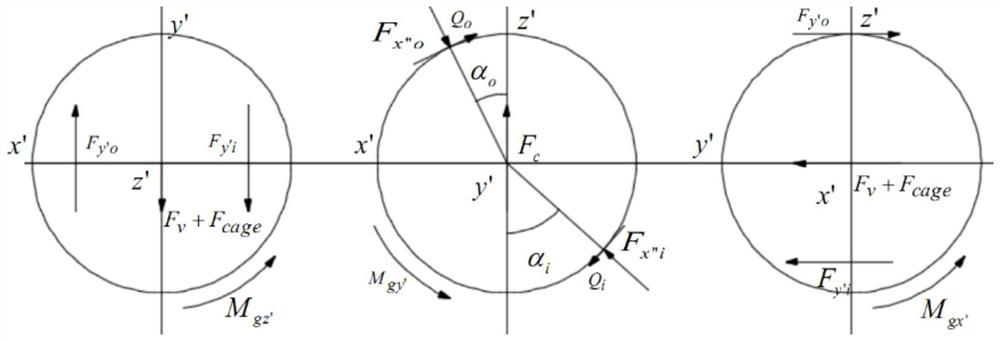

[0094] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0095] refer to image 3 As shown, the present invention provides a high-speed bearing lubrication temperature rise state analysis method, comprising the following steps:

[0096] 1) Obtain bearing structural parameters, working condition parameters, fluid heat transfer parameters and initial value conditions; structural parameters include bearing parameters, material parameters, oil-air lubrication parameters; working condition parameters include rotational speed and radial and axial loads (high and low speeds and light and heavy loads ); the lubrication heat transfer parameters include setting the VOF model, the RNG k-e turbulence model considering the wall adhesion and the MRF model of the region rotation; the initia...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap