Casing round pipe and application and use method thereof

A round tube and casing technology, applied in the application, sausage casing, sausage production and other directions, can solve the problem of accidental eating of the original, affecting production efficiency, weak fixing force, etc., to avoid use and excellent unloading effect of casing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

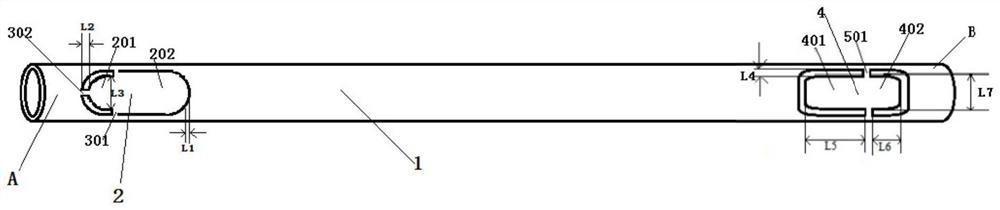

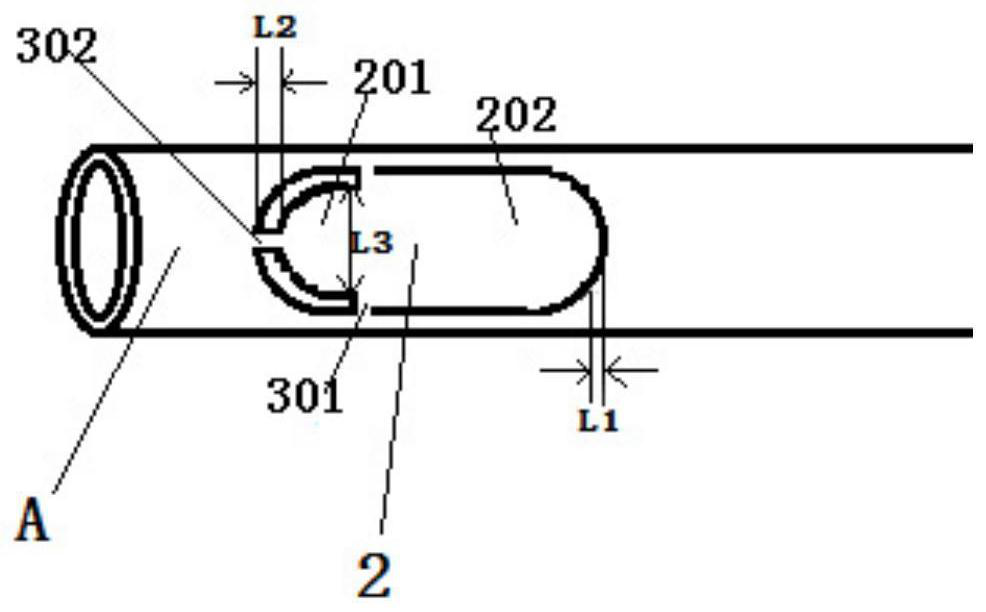

[0042] A round tube of casing, such as figure 1 , figure 2 As shown, it includes a round tube body 1; arc-shaped pressing pieces 2 are respectively arranged on both sides near one end of the round tube body 1, and square pressing pieces 4 are respectively arranged on both sides near the other end of the round tube body 1; The square pressing piece 4 includes a square pressing piece opening and closing end 401 , a square pressing piece finger pressing end 402 , and the square pressing piece opening and closing end 401 and the square pressing piece finger pressing end 402 are integrally connected.

[0043] The arc pressing piece 2 comprises an arc pressing piece fixed end 201 and an arc pressing piece moving end 202, and the arc pressing piece fixed end 201 and the arc pressing piece moving end 202 are integrally connected; The two sides of the connection area between the shaped pressing piece fixed end 201 and the arc-shaped pressing piece movable end 202 are respectively con...

Embodiment 2

[0051] A casing round tube, comprising a round tube body 1; arc-shaped pressing pieces 2 are respectively arranged on both sides close to one end of the round tube body 1, and square pressing pieces are respectively set on both sides close to the other end of the round tube body 1 4. The square pressing tablet 4 includes a square pressing tablet opening and closing end 401 and a square pressing tablet finger pressing end 402, and the square pressing tablet opening and closing end 401 and the square pressing tablet finger pressing end 402 are integrally connected.

[0052] The arc pressing piece 2 comprises an arc pressing piece fixed end 201 and an arc pressing piece moving end 202, and the arc pressing piece fixed end 201 and the arc pressing piece moving end 202 are integrally connected; The two sides of the connection area between the shaped pressing piece fixed end 201 and the arc-shaped pressing piece movable end 202 are respectively connected with the round pipe body 1 th...

Embodiment 3

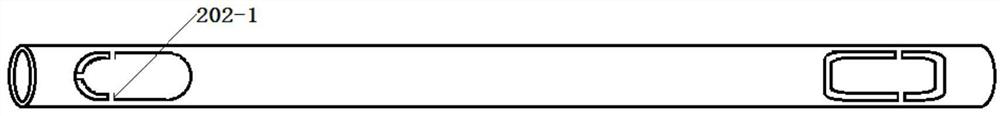

[0060] A round tube of casing, such as image 3 , Figure 4 As shown, it includes a round tube body 1; arc-shaped pressing pieces 2 are respectively arranged on both sides near one end of the round tube body 1, and square pressing pieces 4 are respectively arranged on both sides near the other end of the round tube body 1; The square pressing piece 4 includes a square pressing piece opening and closing end 401 , a square pressing piece finger pressing end 402 , and the square pressing piece opening and closing end 401 and the square pressing piece finger pressing end 402 are integrally connected.

[0061] The arc pressing piece 2 comprises an arc pressing piece fixed end 201 and an arc pressing piece moving end 202, and the arc pressing piece fixed end 201 and the arc pressing piece moving end 202 are integrally connected; The two sides of the connection area between the shaped pressing piece fixed end 201 and the arc-shaped pressing piece movable end 202 are respectively con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com