Patents

Literature

35results about How to "To achieve the purpose of fine-tuning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

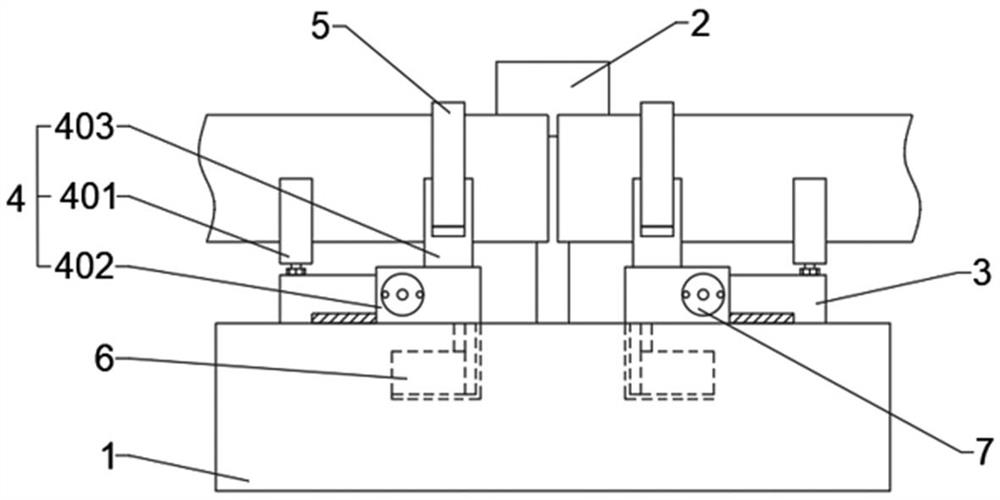

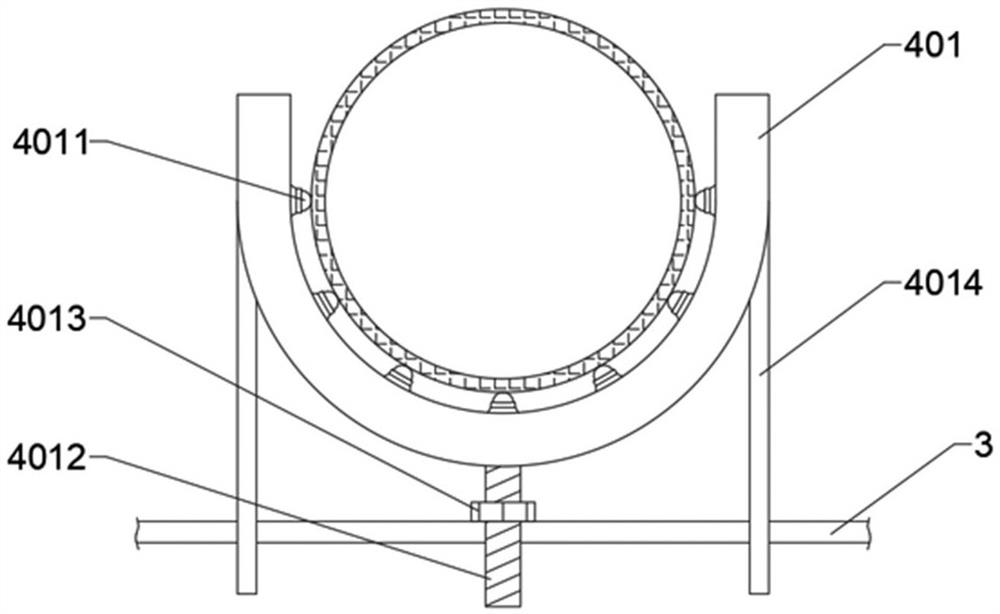

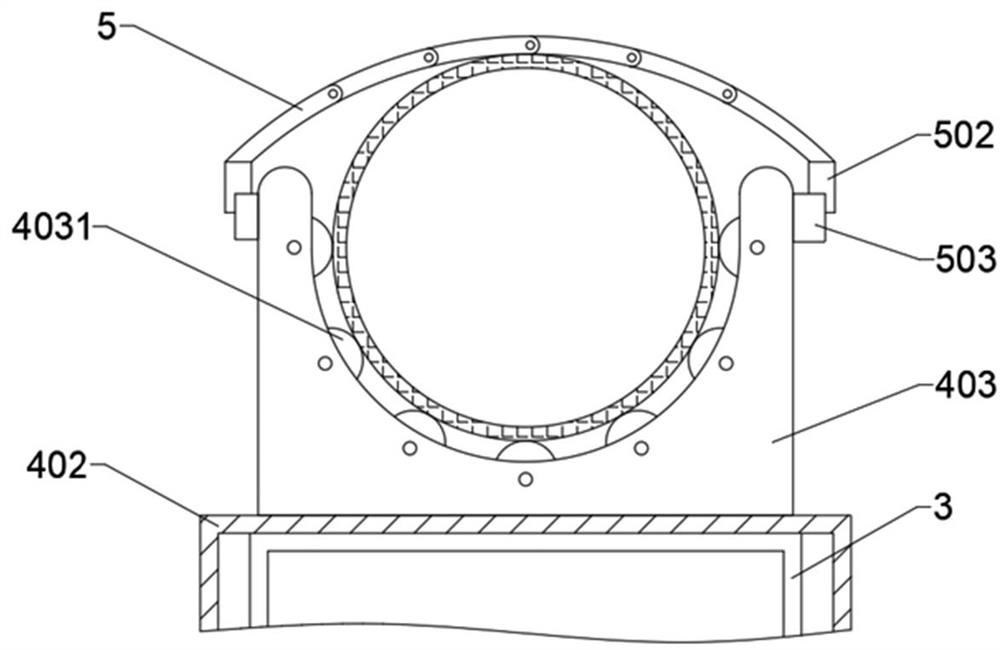

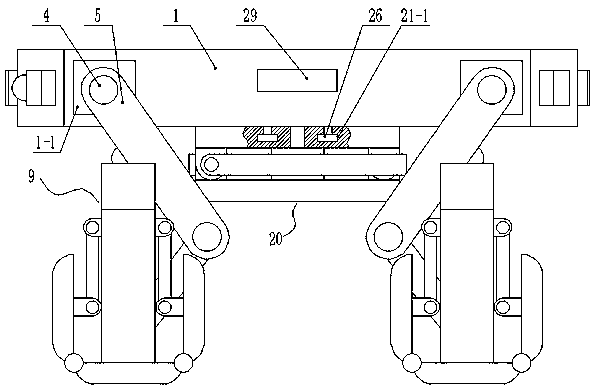

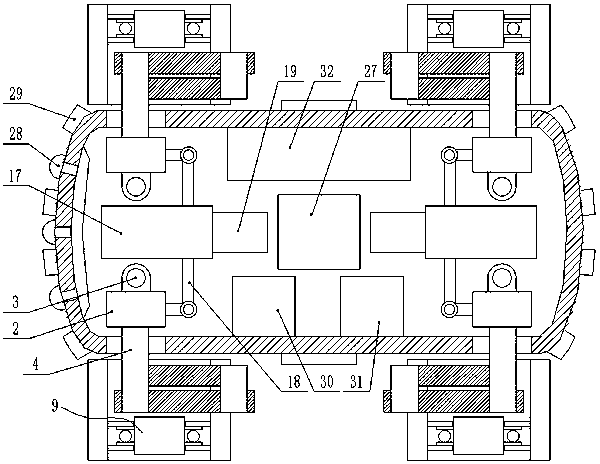

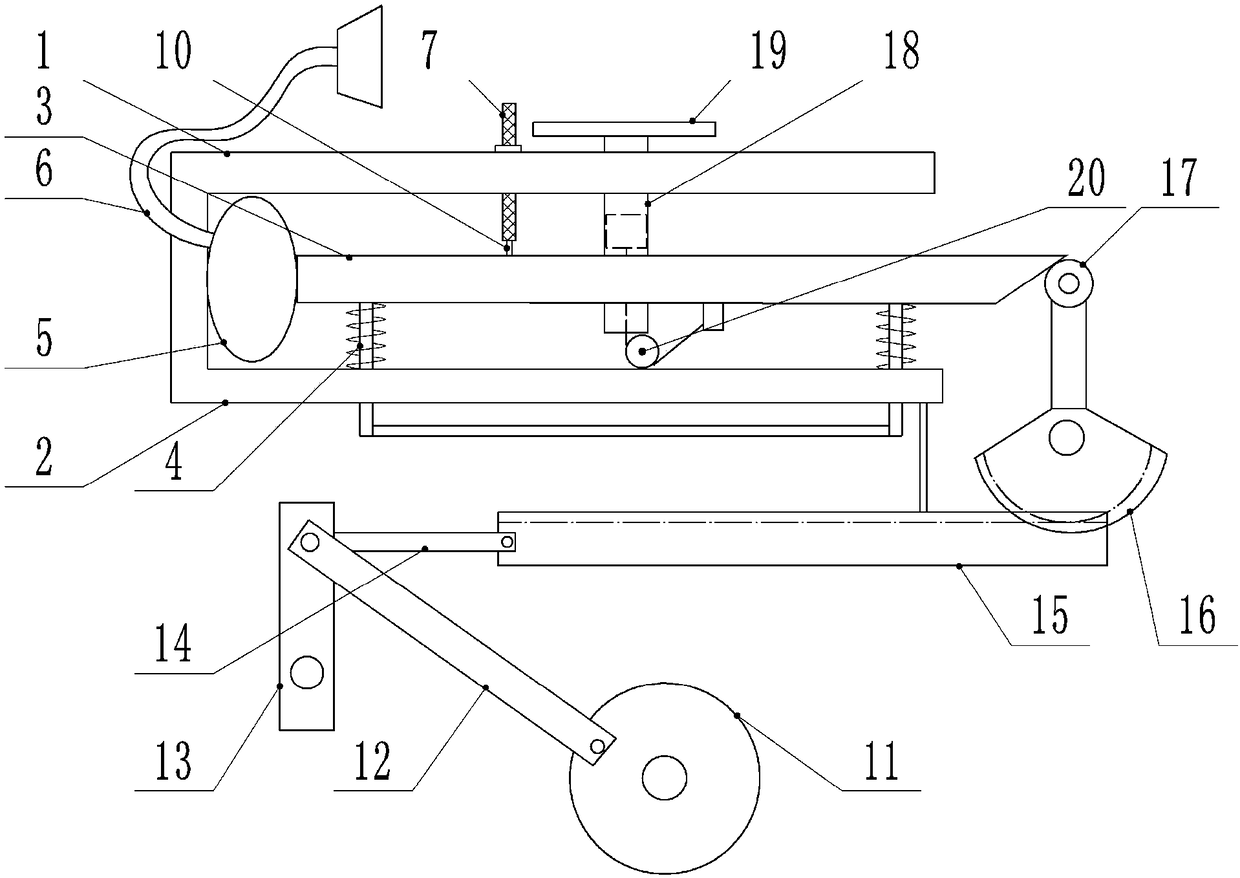

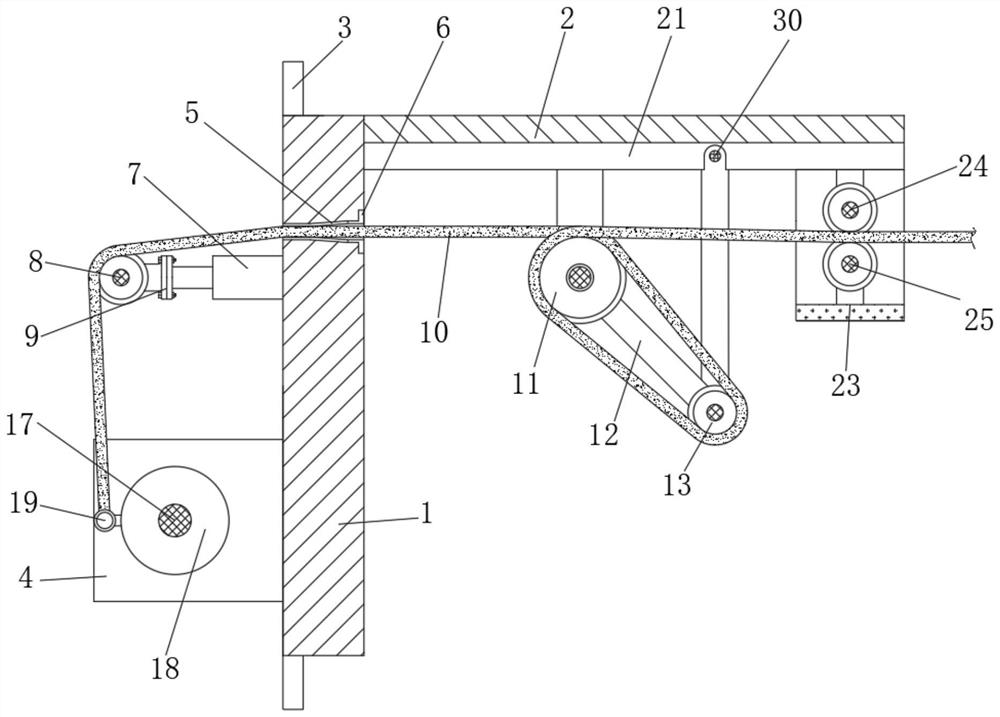

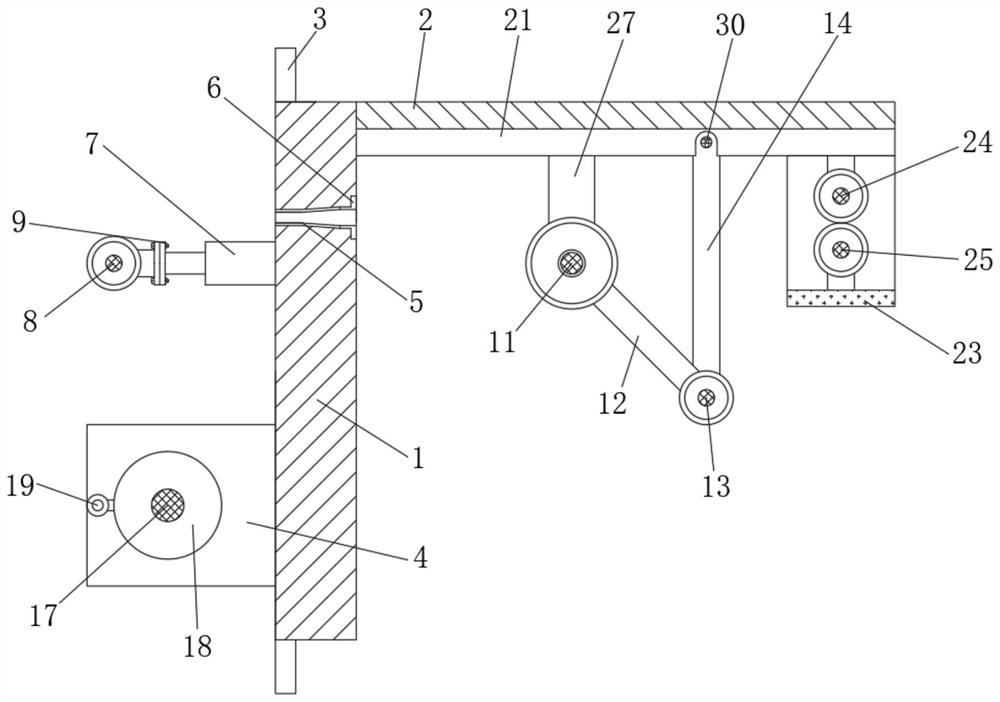

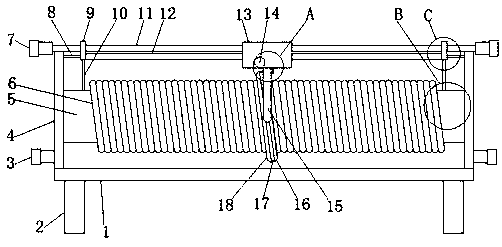

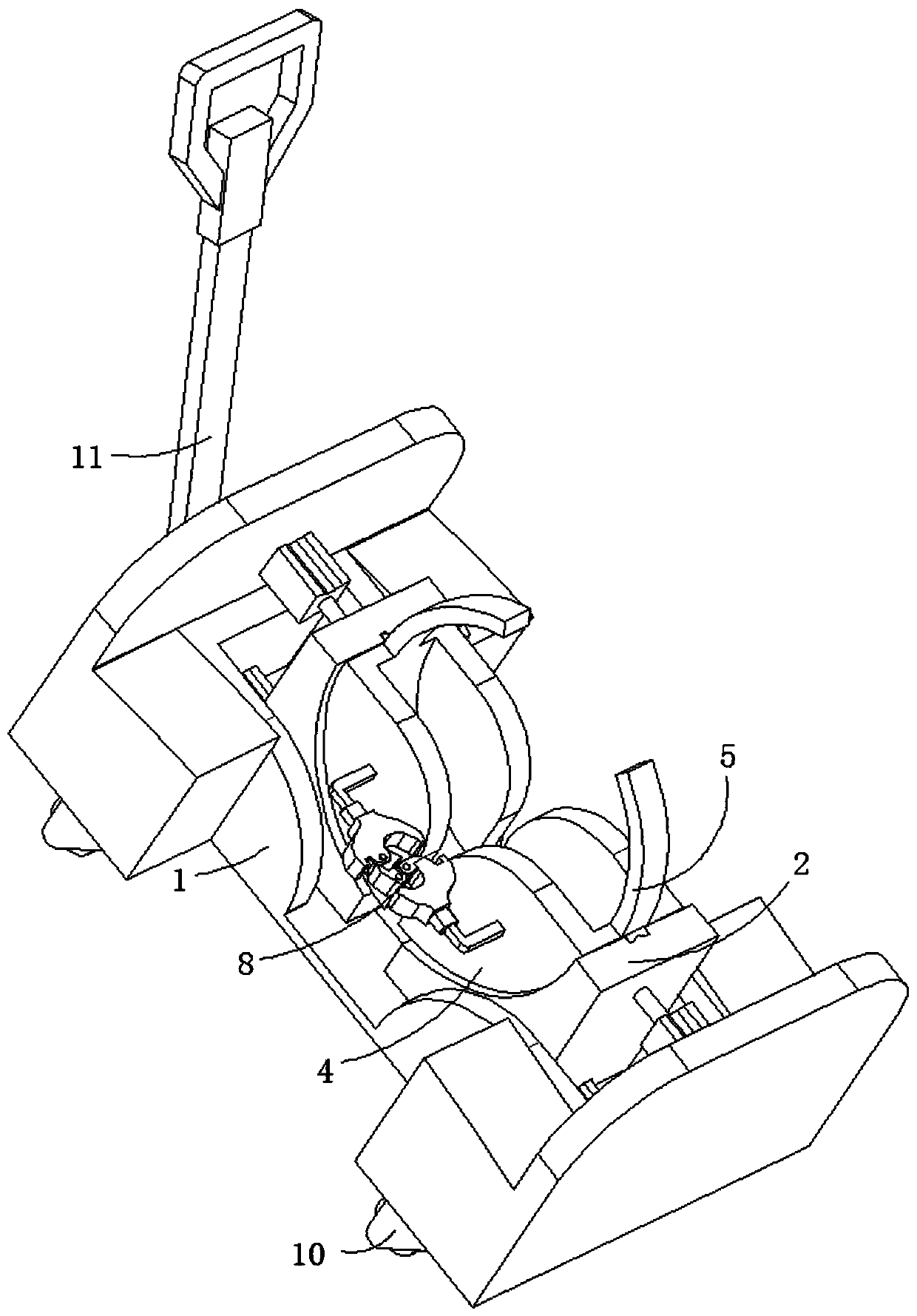

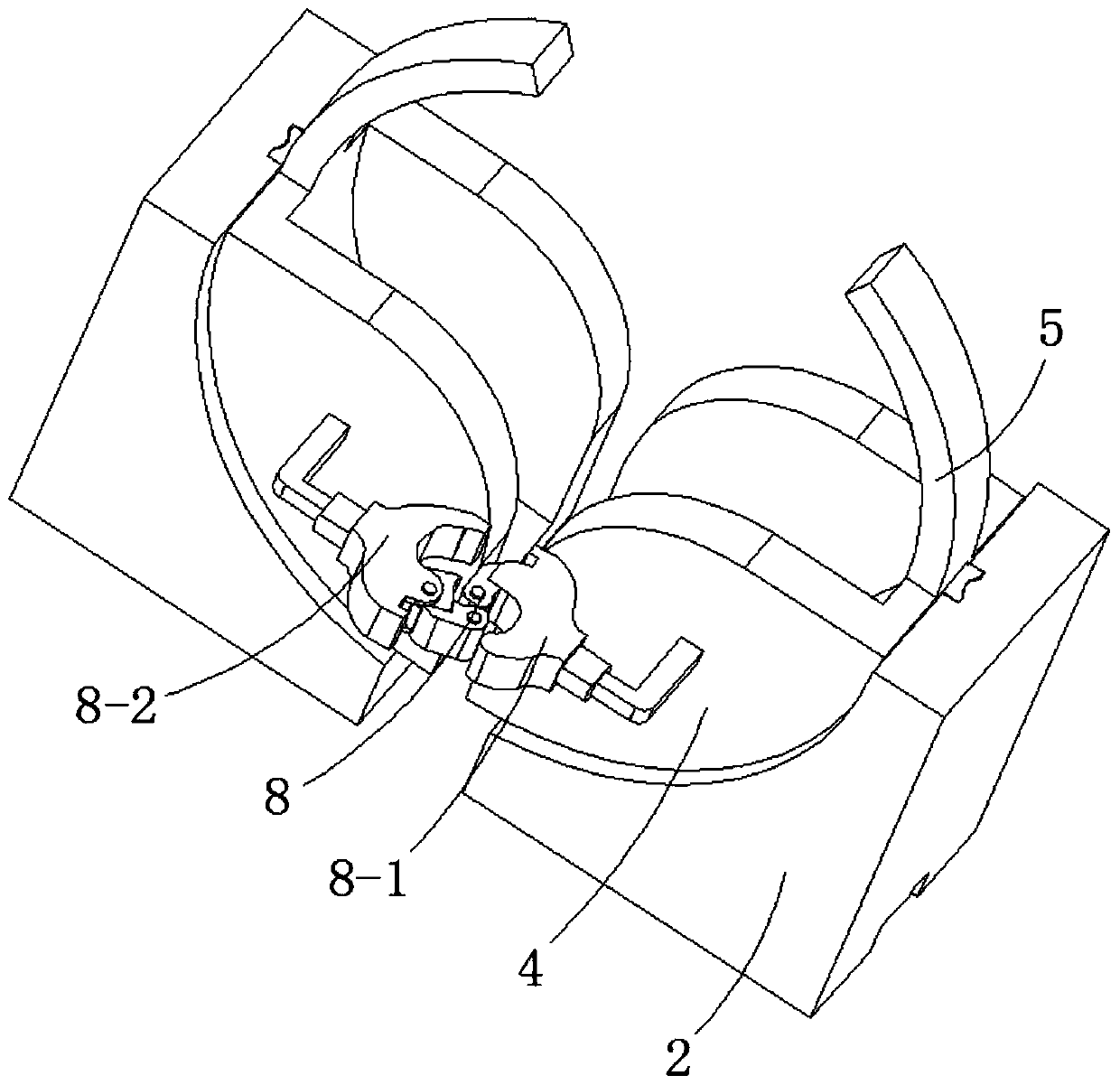

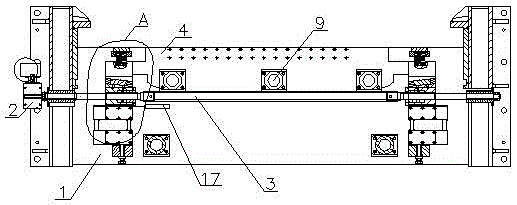

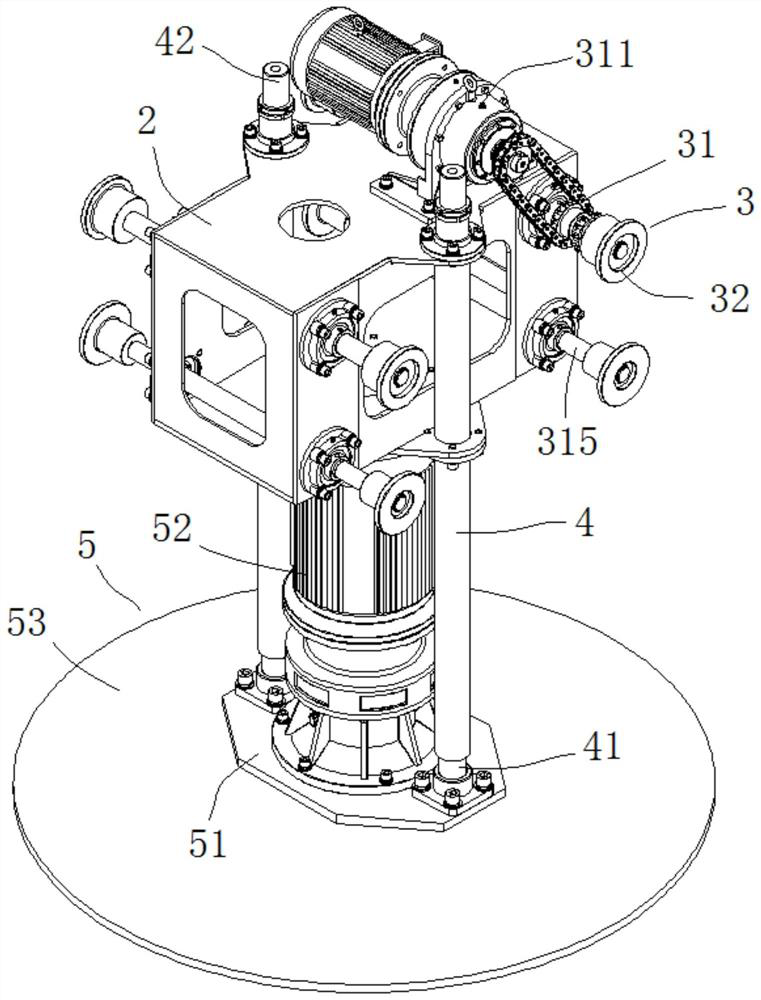

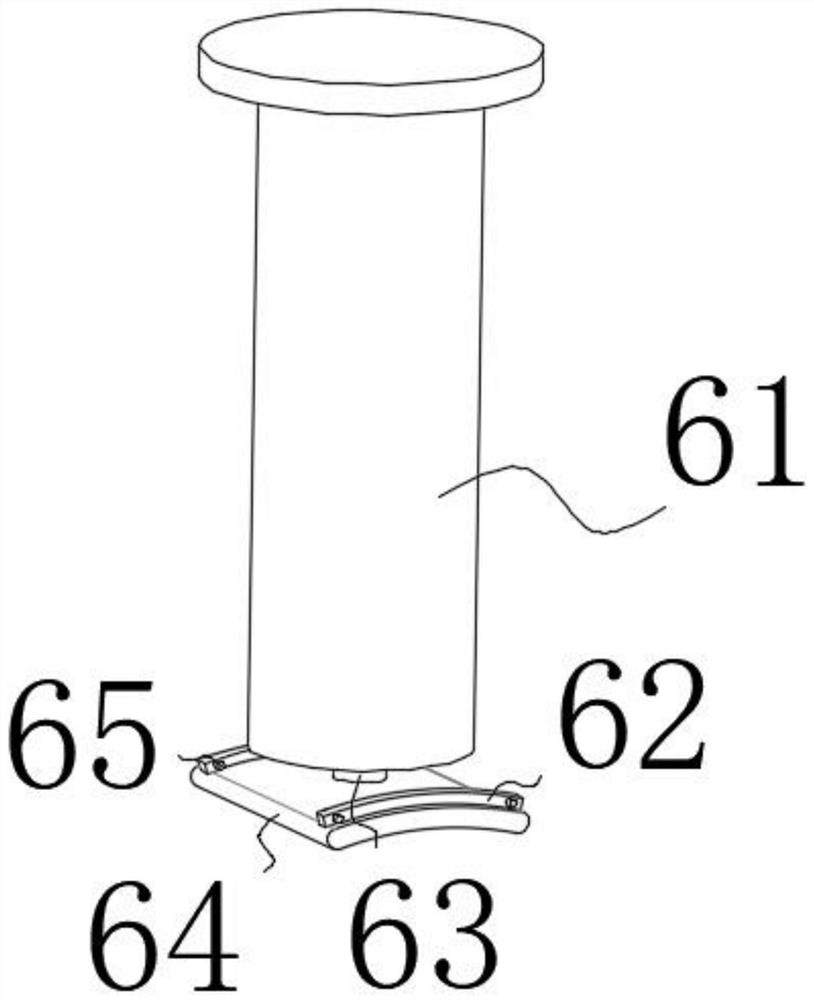

Metal power pipe straight seam welding device

ActiveCN111730282AReduce the chance of slippingEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesSeam weldingEquipment use

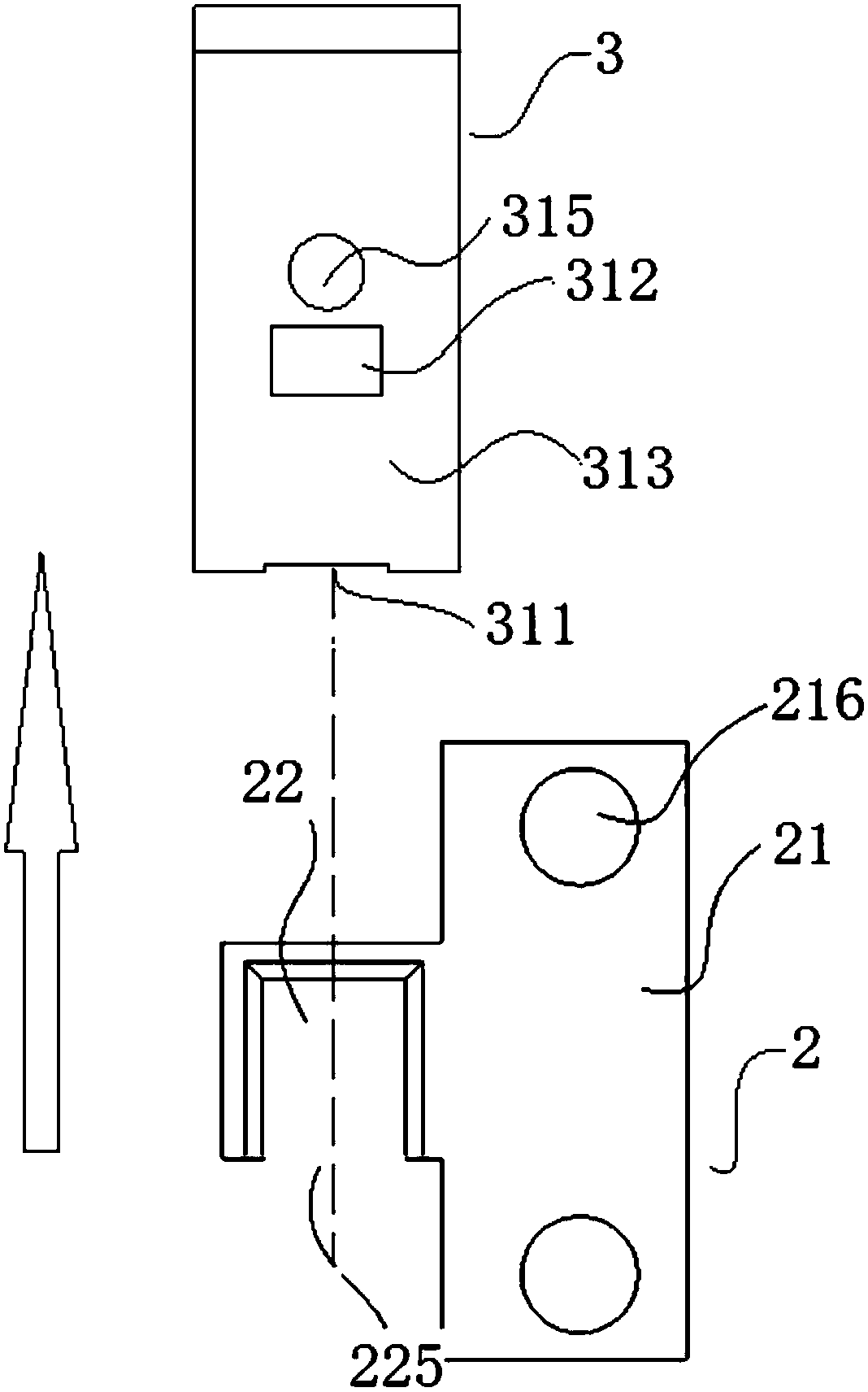

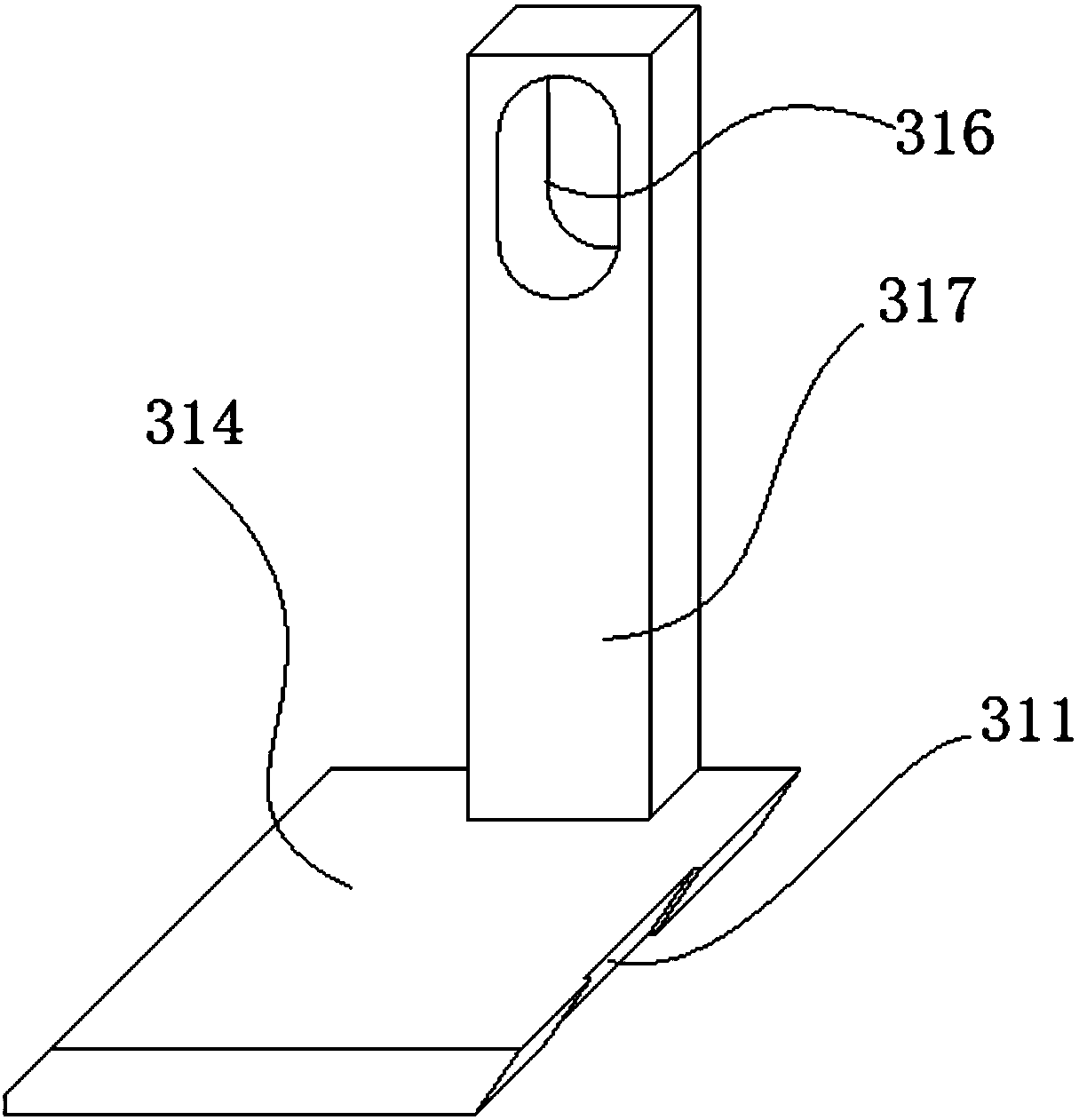

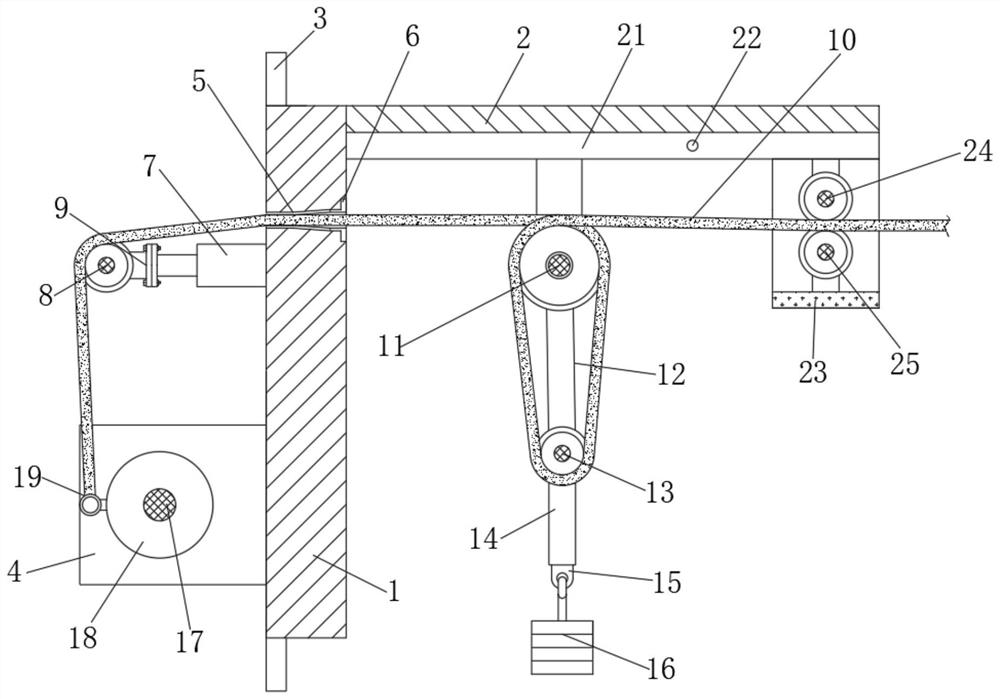

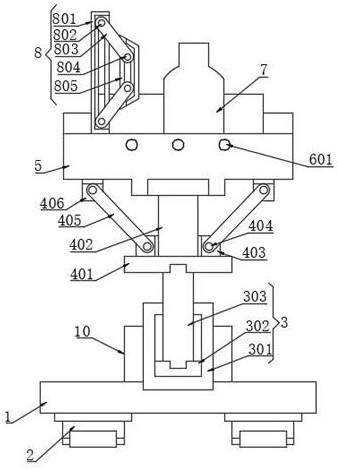

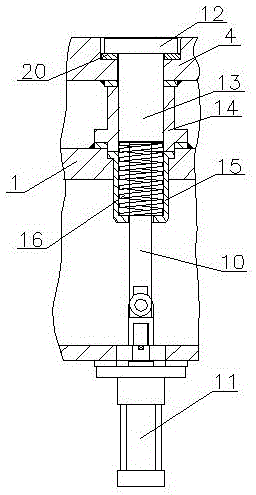

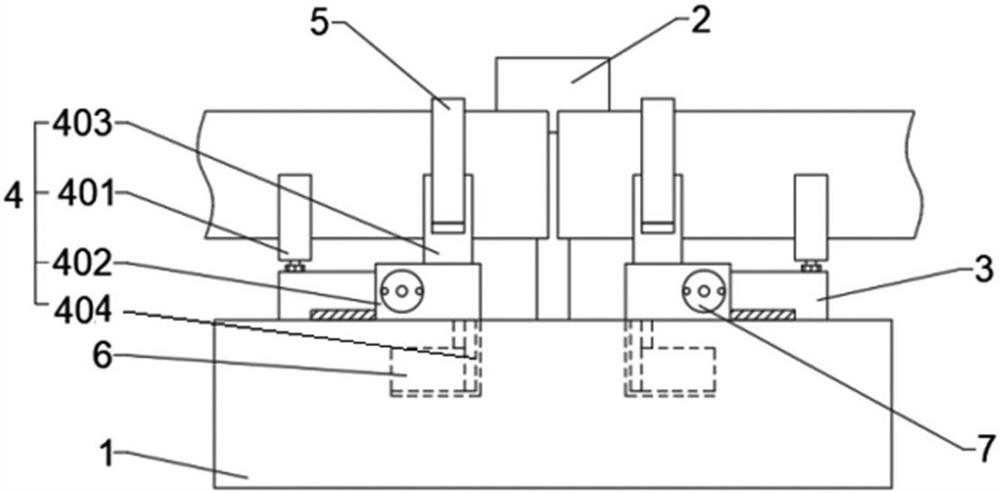

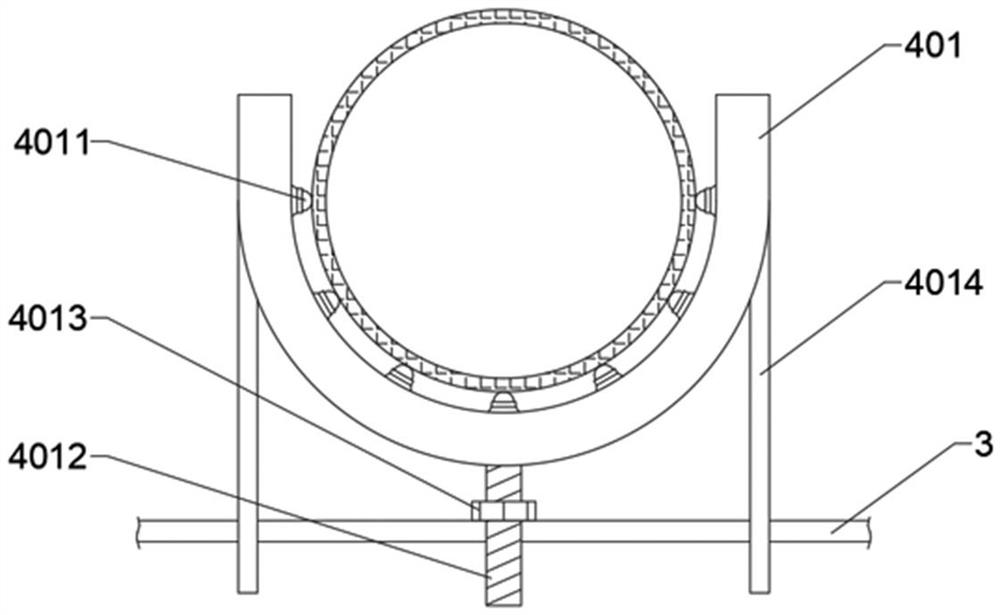

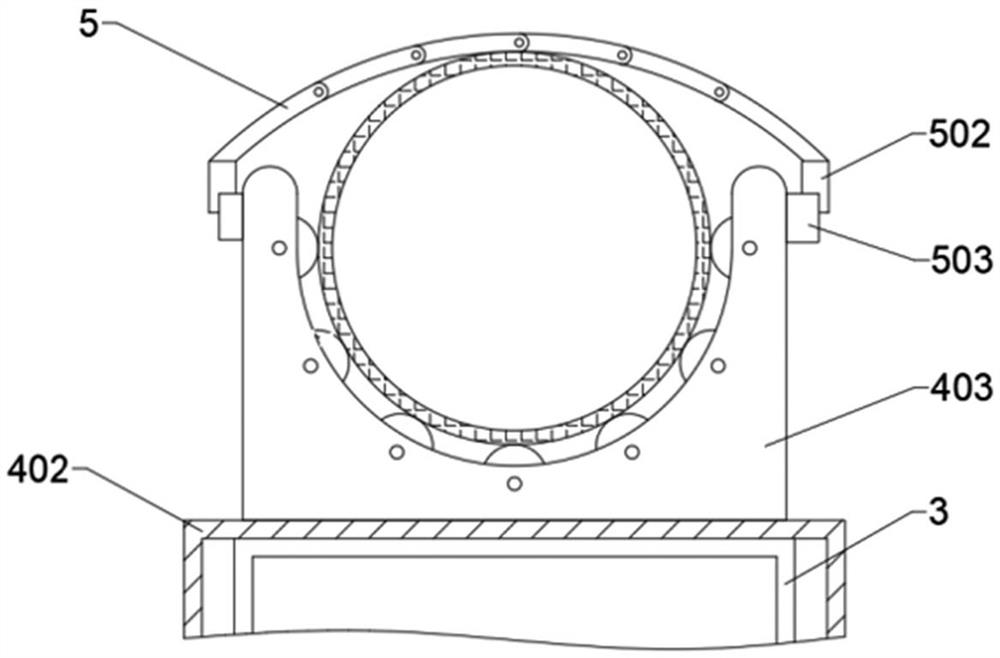

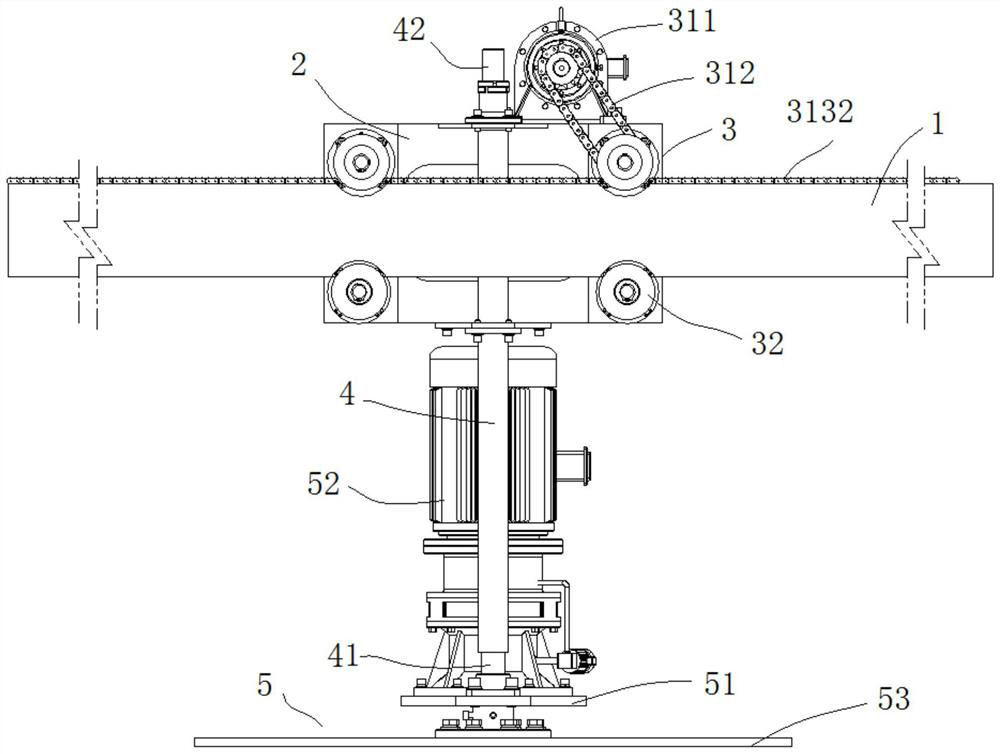

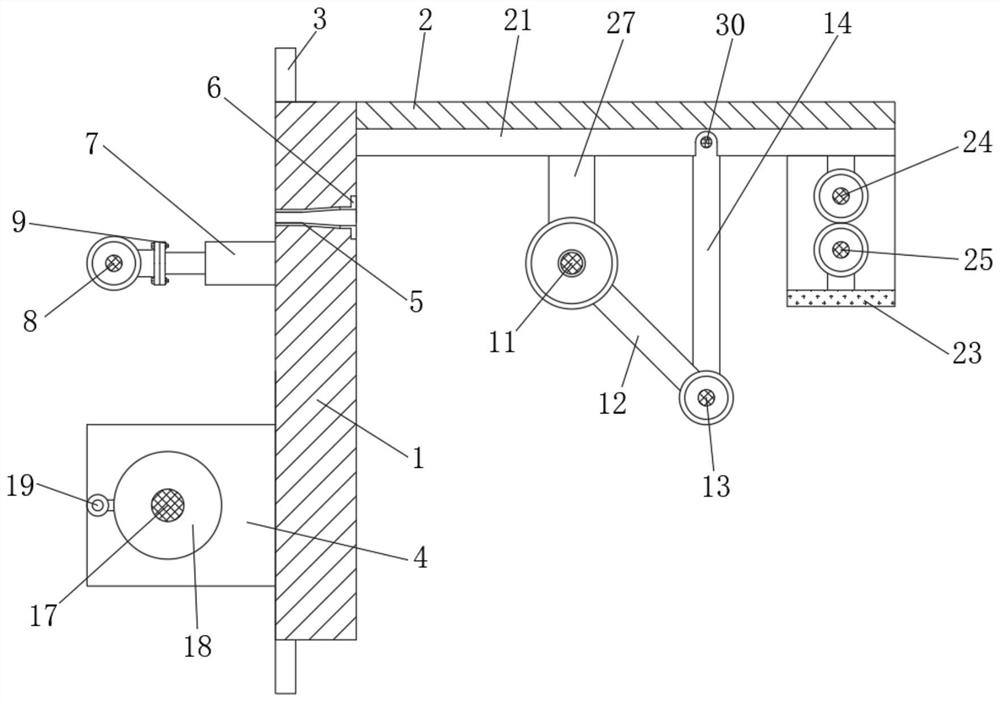

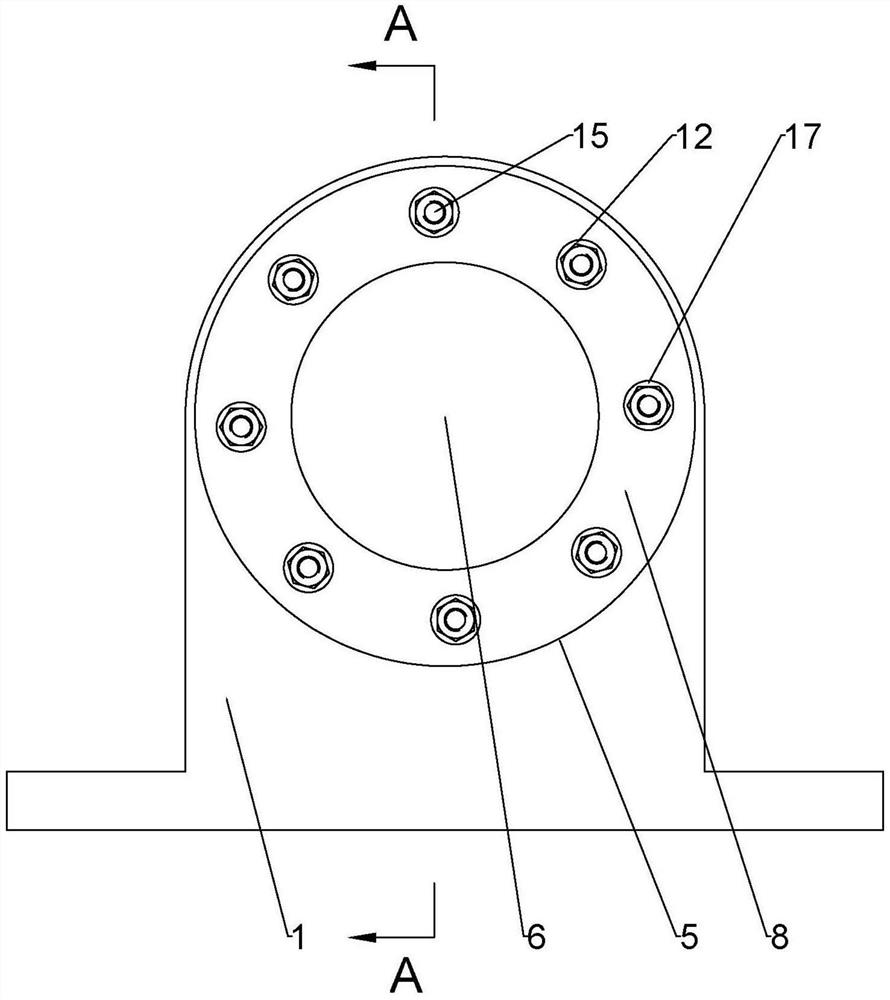

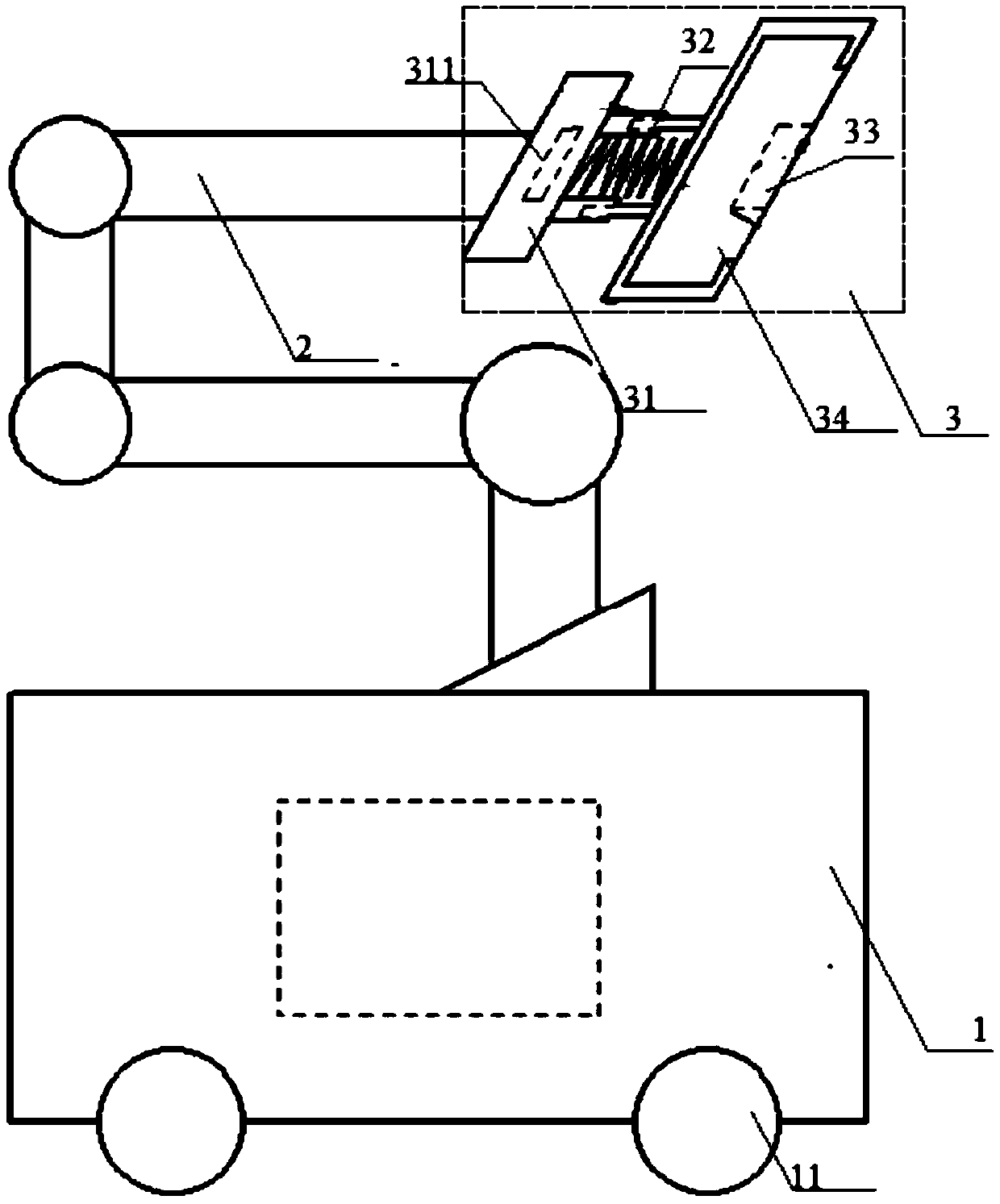

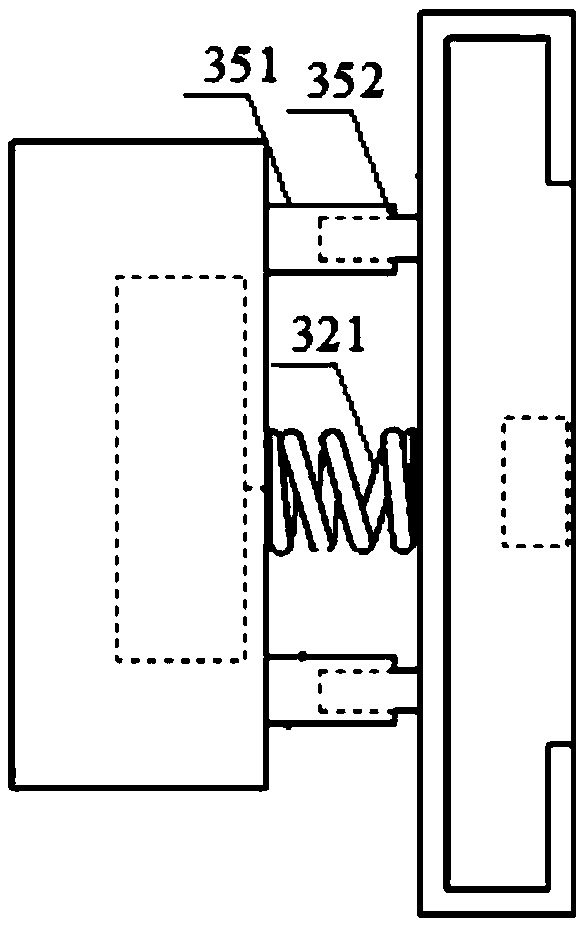

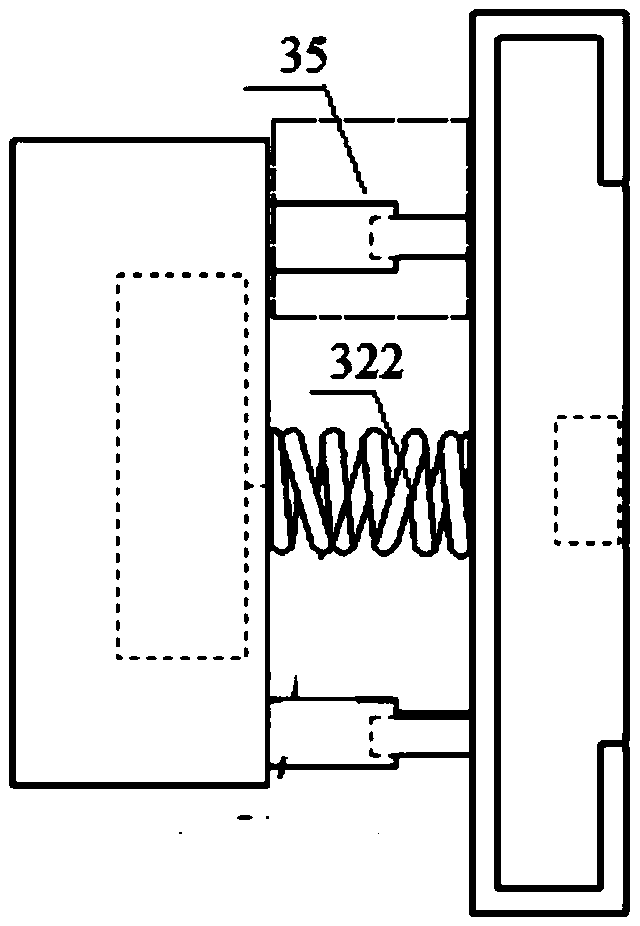

The invention discloses a metal power pipe straight seam welding device. The metal power pipe straight seam welding device comprises a mounting base, welding equipment used for welding power pipelinesis mounted on the mounting base, two sets of bracket mounting seats symmetrically distributed relative to the welding equipment are mounted on the mounting base, pipe bracket mechanisms for supporting the power pipelines is mounted on the bracket mounting seats; and the mounting base supports the two coaxial power pipelines through the two sets of pipe bracket mechanisms, and roller binding beltmechanisms used for binding the power pipelines are mounted on the pipe bracket mechanisms. According to the metal power pipe straight seam welding device, two sets of brackets are arranged to be usedfor horizontally supporting the power pipelines, anti-skid rollers are arranged on the inner sides of one set of brackets to drive electric power pipelines to rotate, and the roller binding belt mechanisms for binding the power pipelines are installed on the brackets and used for increasing the contact area and strength of the power pipelines and the anti-skid rollers, so that the probability that the power pipelines slip on the anti-skid rollers is reduced, and the power pipelines at the two ends can rotate synchronously.

Owner:GUANGDONG POWER GRID CO LTD DONGGUAN POWER SUPPLY BUREAU +1

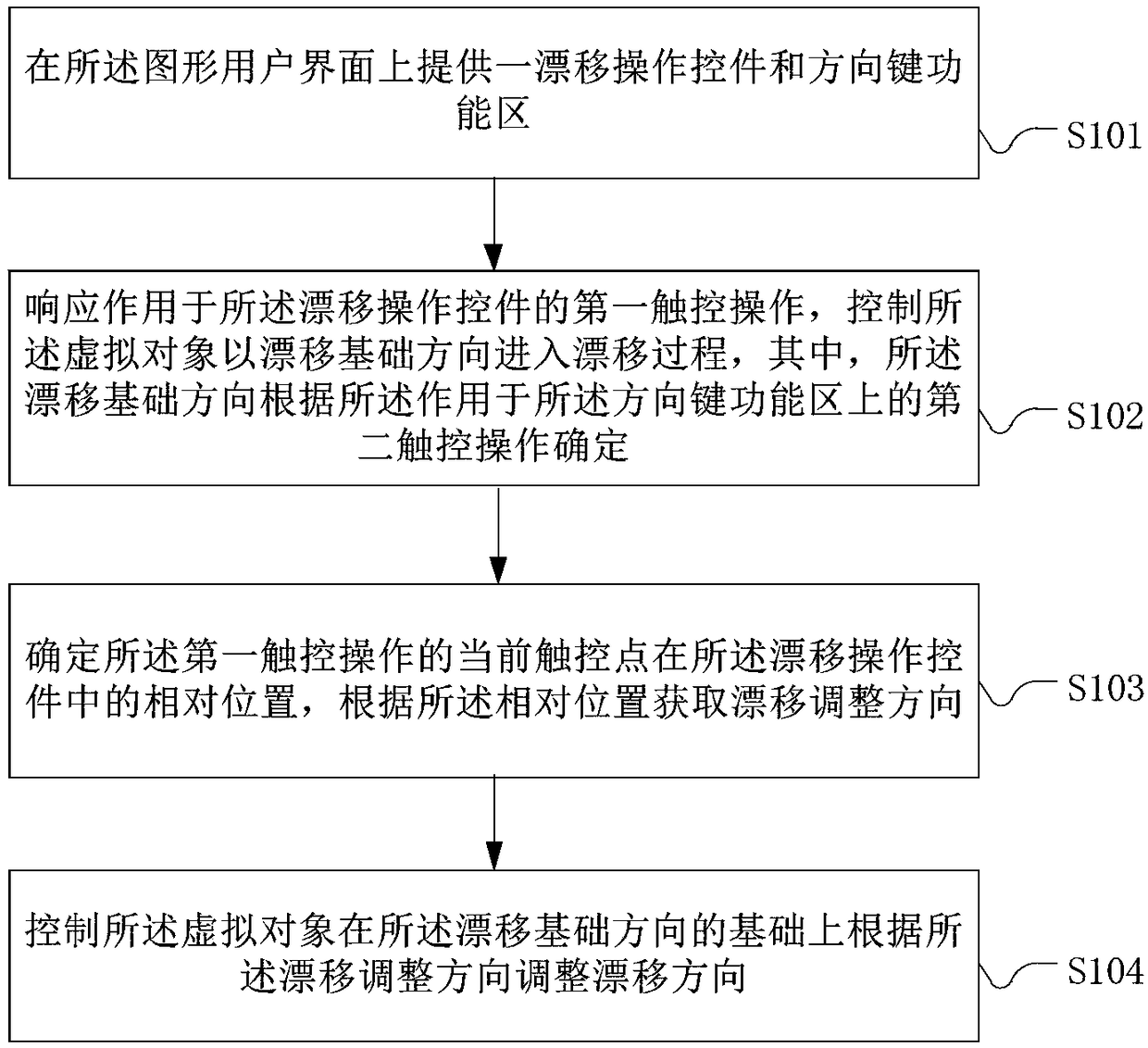

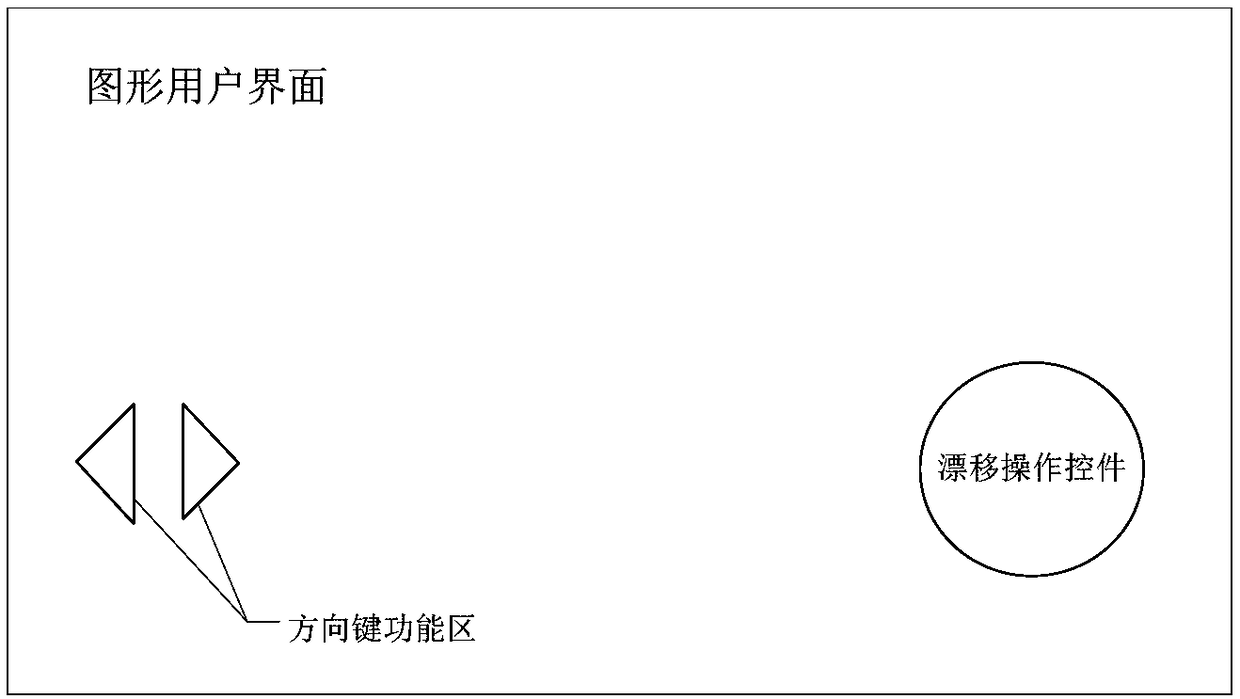

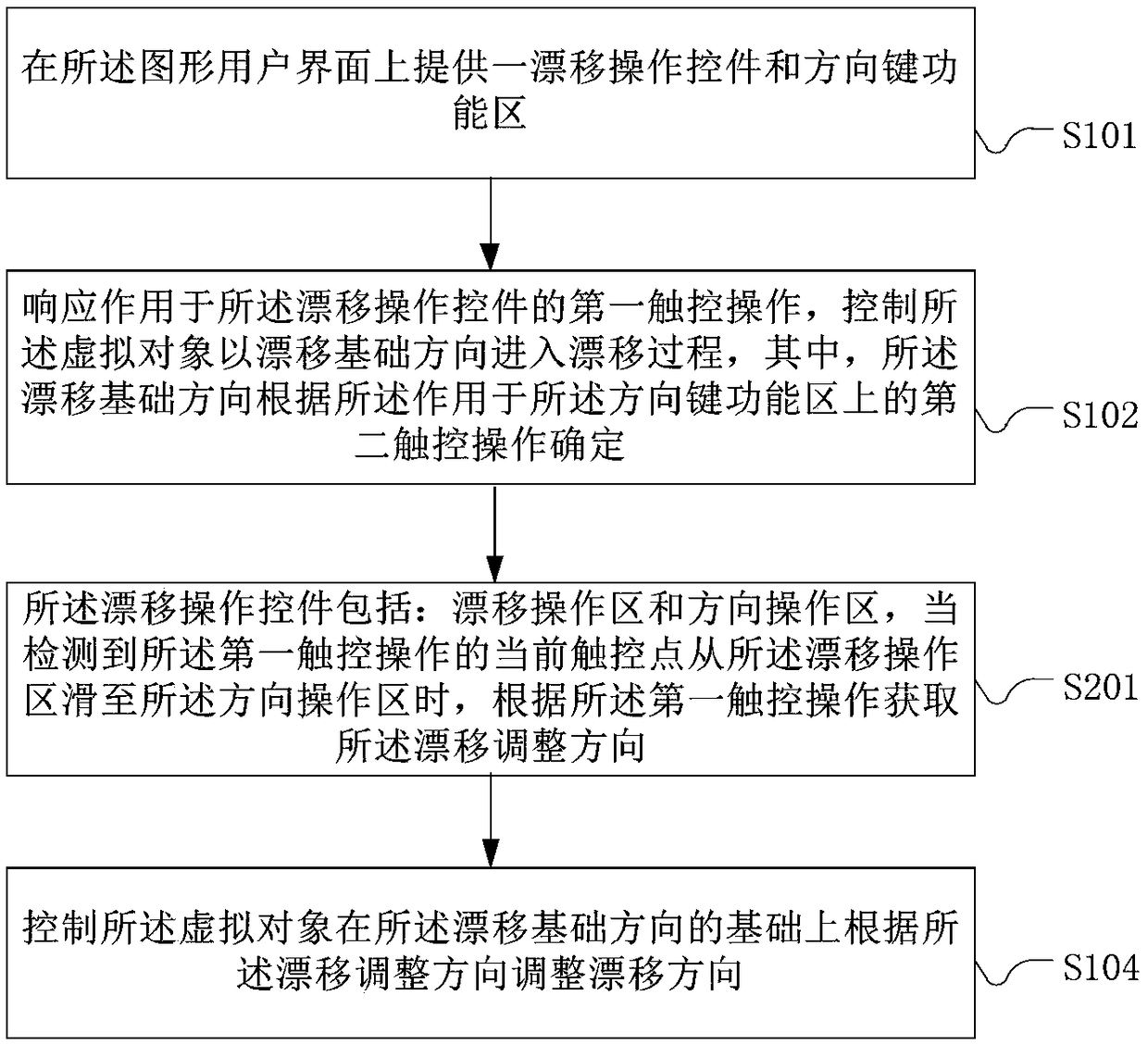

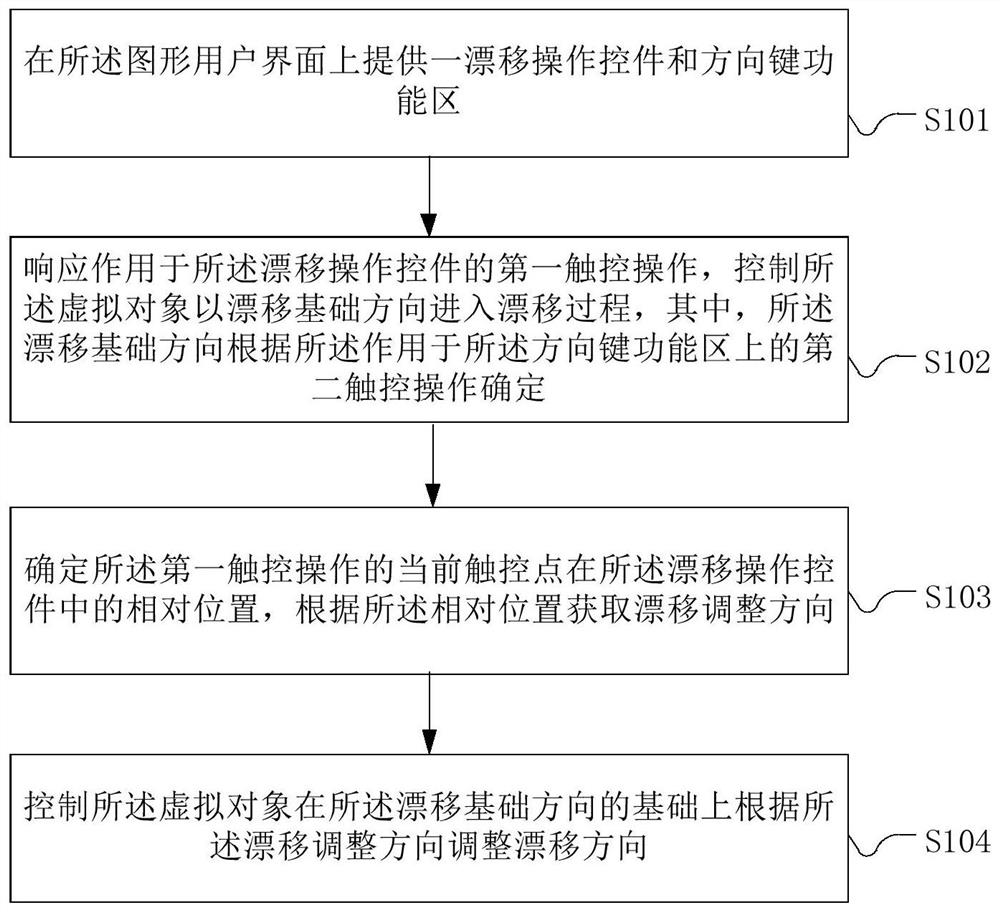

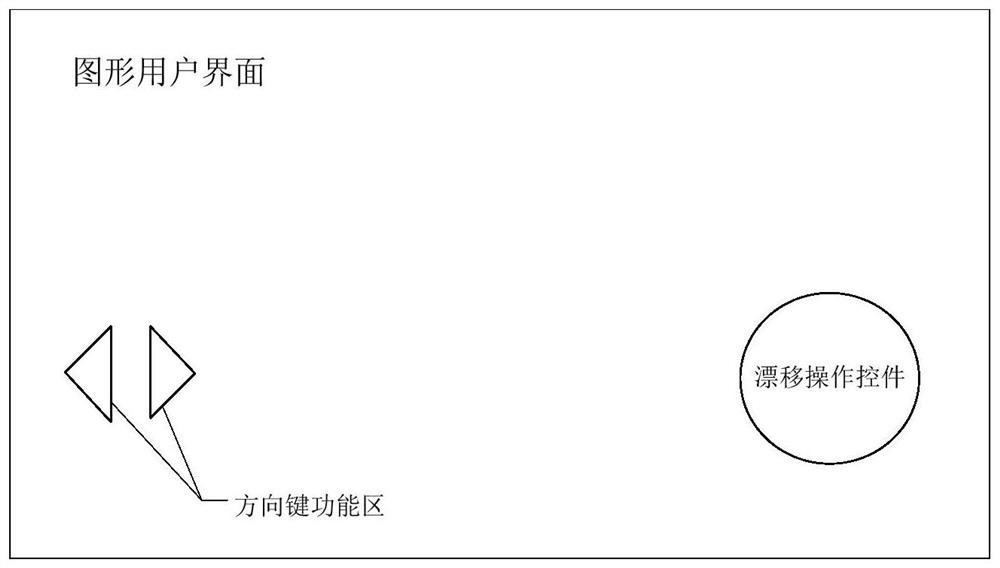

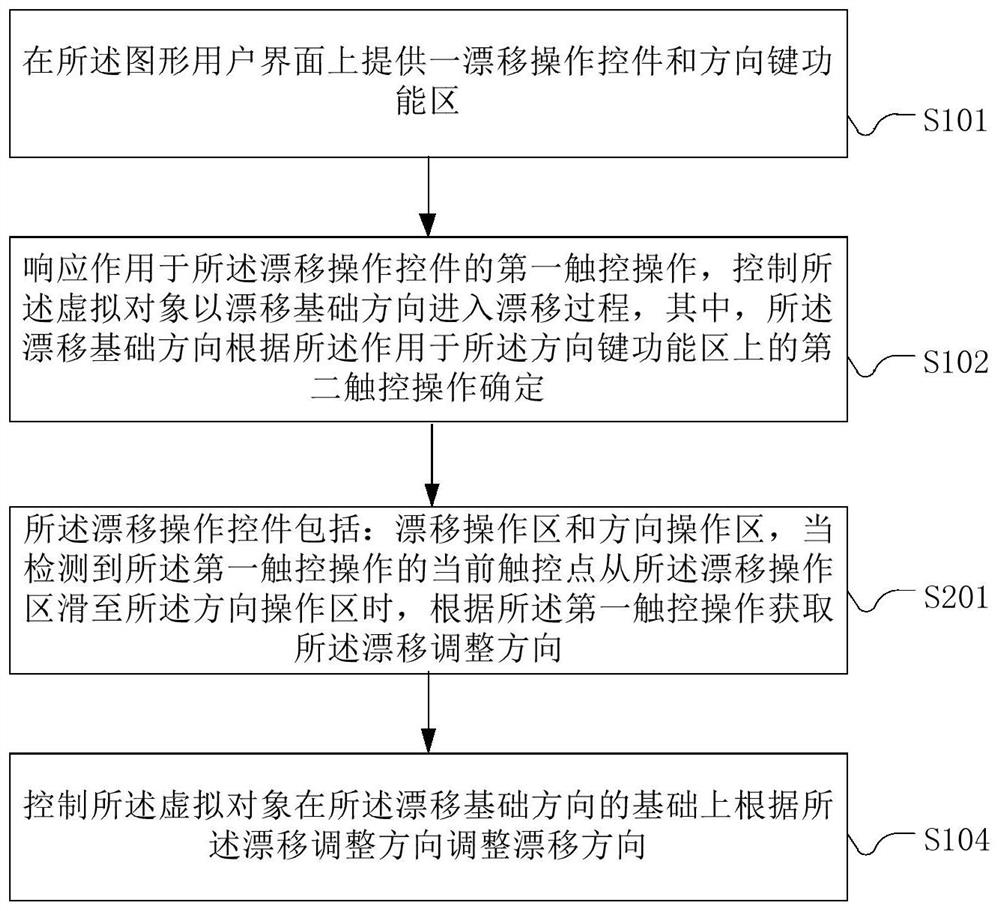

Method and apparatus for controlling virtual object drift

ActiveCN109107152ATo achieve the purpose of fine-tuningImprove gaming experienceVideo gamesGraphicsGraphical user interface

The present invention provides a method and apparatus for controlling virtual object drift. The method comprises the following steps of: providing a drift operation control and a direction key function area on the graphical user interface; controlling the virtual object to enter a drift process in a drift base direction in response to a first touch operation acting on the drift operation control,wherein the drift base direction is determined according to the second touch operation acting on the direction key function area; determining a relative position of a current touch point of the firsttouch operation in the drift operation control, and obtaining a drift adjustment direction according to the relative position; the virtual object is controlled to adjust the drift direction accordingto the drift adjustment direction on the basis of the drift basic direction. Compared with the prior art, the invention realizes the purpose of fine-tuning the drift direction of the virtual object, and improves the game experience of the player.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

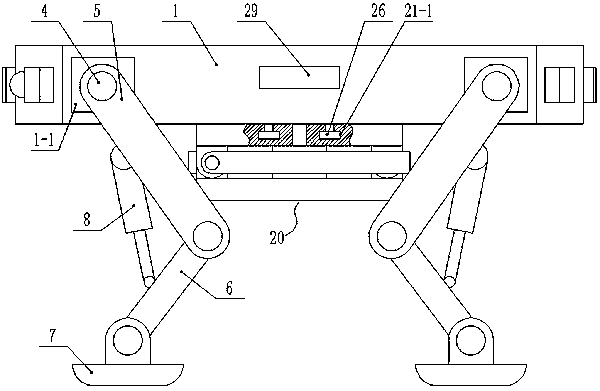

A walking device of a multifunctional all-terrain biomimetic robot

InactiveCN109018060ATo achieve the purpose of fine-tuningAdapt to complex road conditionsElectric propulsion mountingVehiclesTerrainThigh

The invention discloses a walking device of a multifunctional all-terrain biomimetic robot, which includes that box, the front two sides and the back two sides of the box body are symmetrically provided with thigh brackets, A calf bracket is rotatably connecte with that end of the thigh bracket, a foot disk is rotatably connected with that end of the calf support, an electric telescopic rod is arranged between that thigh bracket and the calf bracket, , the electric telescopic rod is rotatably connected with the thigh bracket, A telescopic rod of the electric telescopic rod is rotatably connected with a calf bracket, A foot expand device is fixed on that upper end of the foot plate, a plurality of lights are arranged at one end of that box body, under the driving of a leg rotating motor, Asthat leg drive motor drives the thigh bracket to rotate in a small range, the leg can be fine-tuned, the legs are more flexible, can be more adapt to complex road conditions, and the auxiliary foot plates on both sides of the foot plate are spread, the landing area is increased, and the soft ground such as sand and the like is effectively supported, and the walking is more convenient.

Owner:东莞市史雷帝三维数控科技有限公司

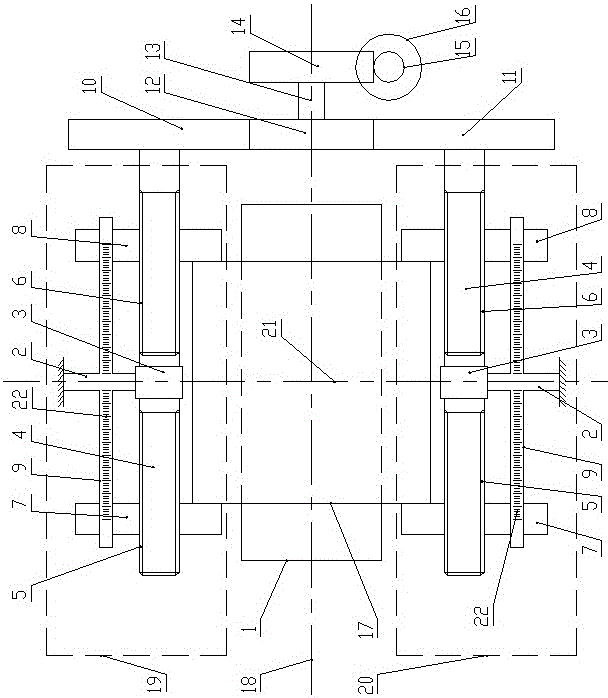

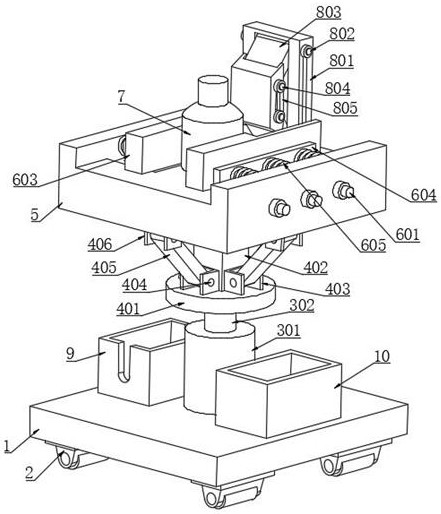

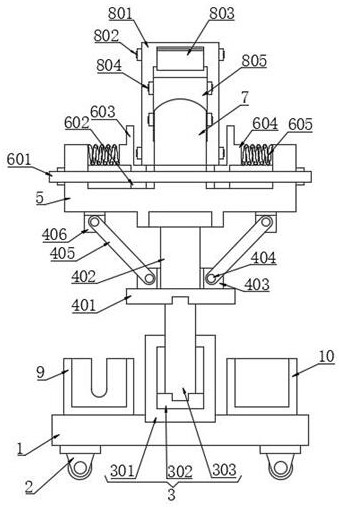

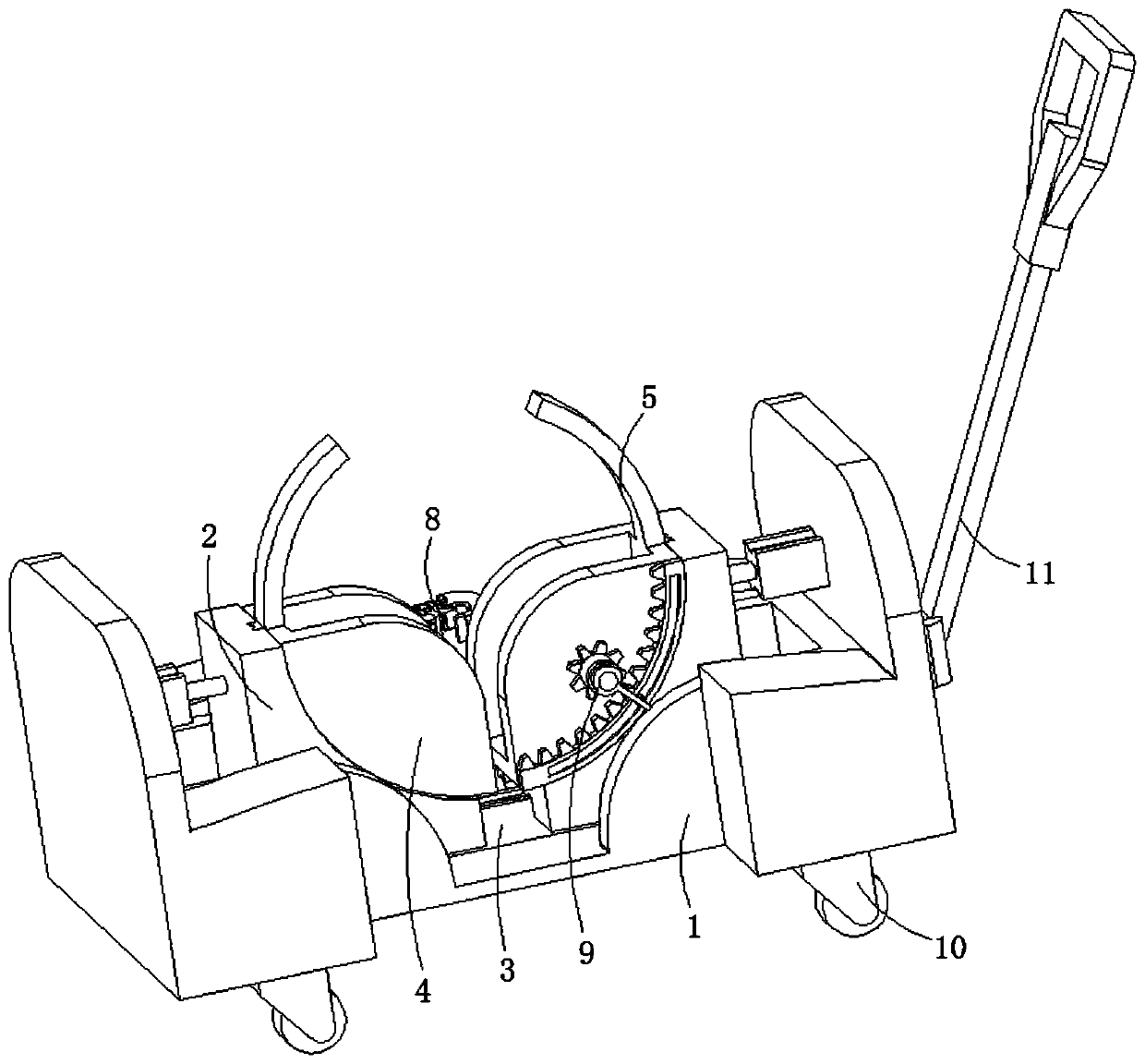

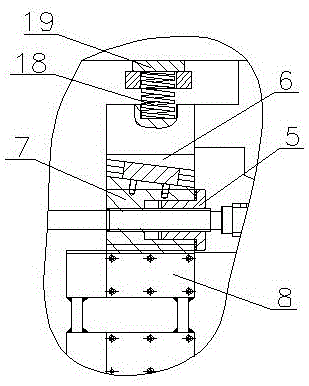

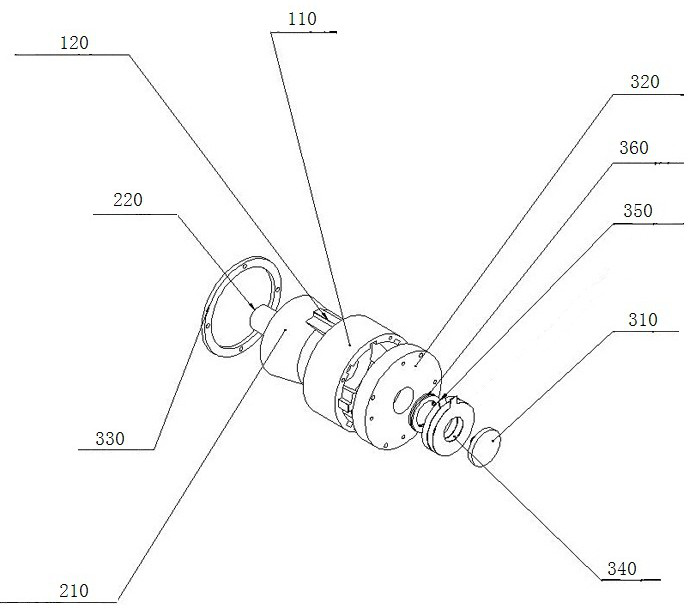

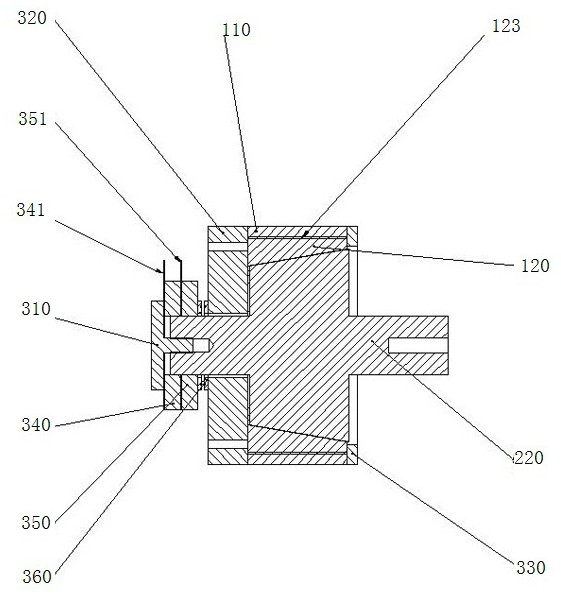

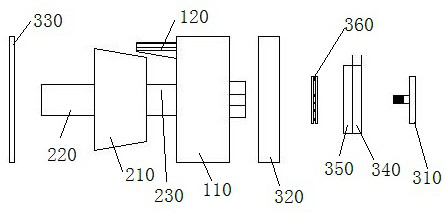

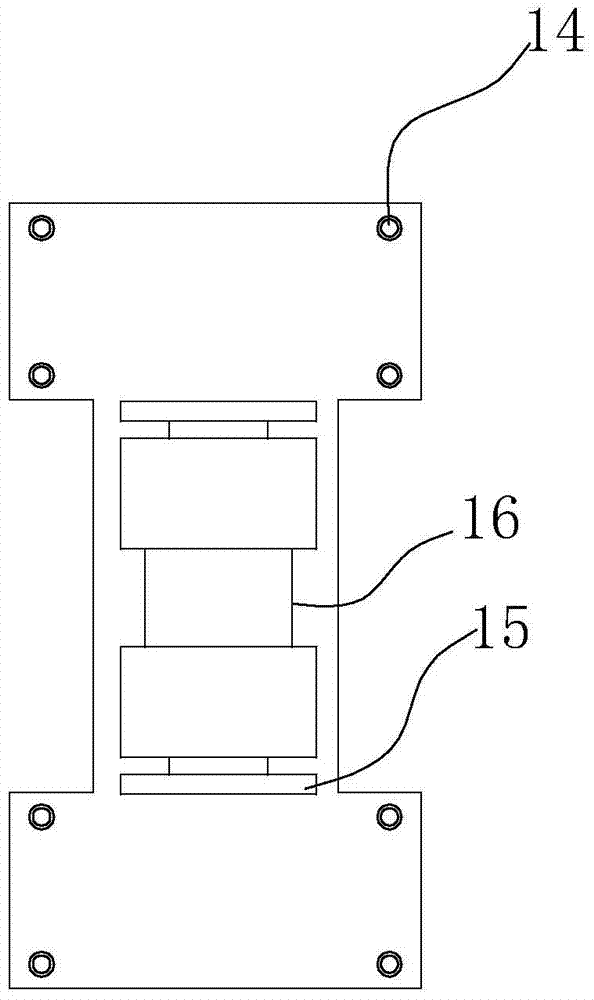

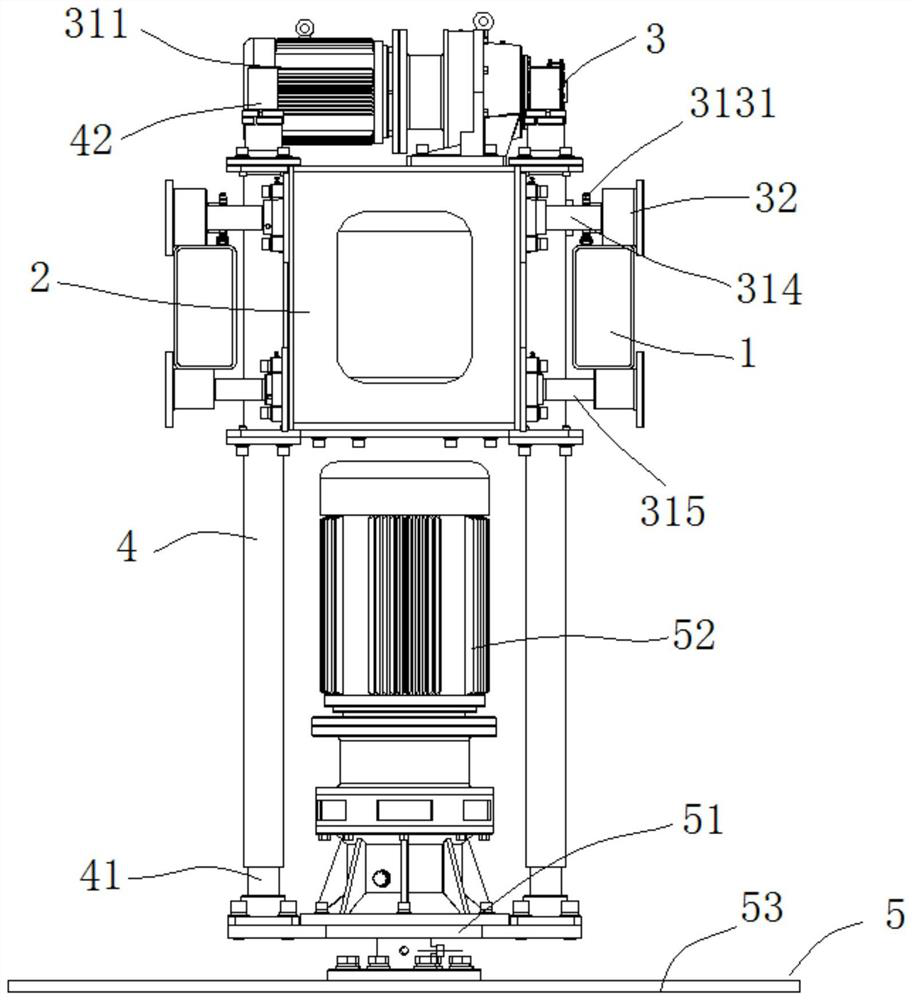

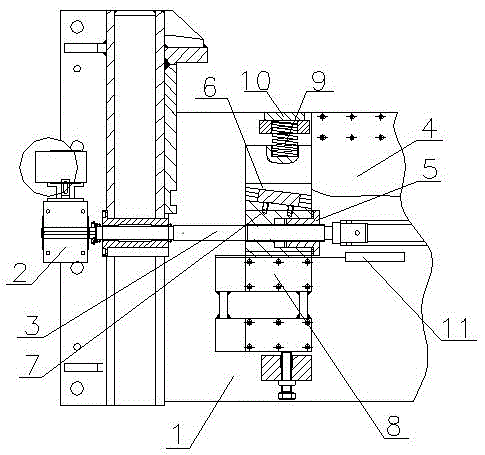

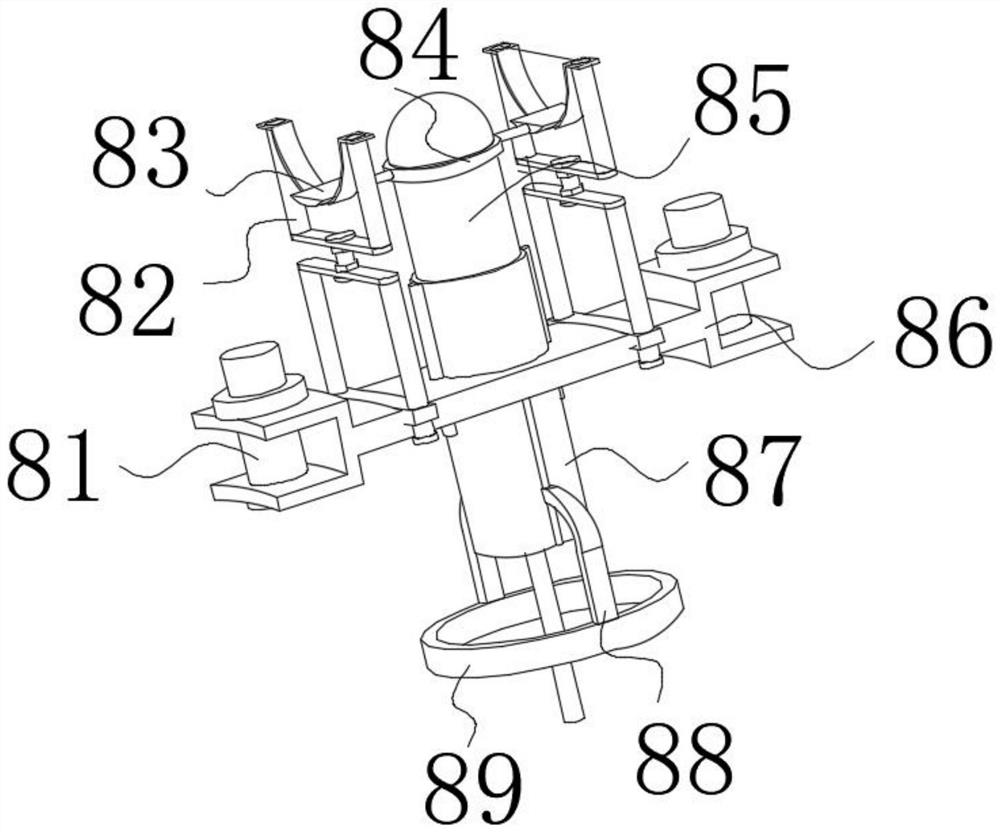

Centring micro-setting device for heavy equipment installation

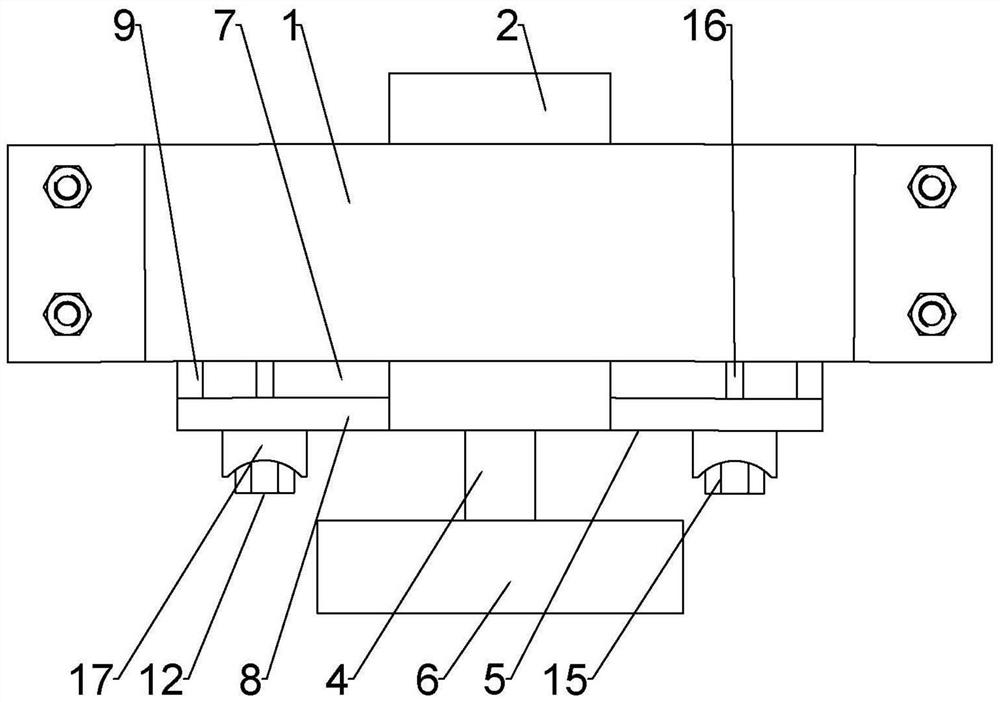

InactiveCN105751175ARestricted degrees of freedomRestricted rotational degrees of freedomWork benchesDrive shaftEngineering

A centring micro-setting device for heavy equipment installation comprises a workbench.Two sets of centring devices are arranged on the front side and back side of the workbench and are a front centring device and a back centring device, and the two sets of centring devices are the same in structure.The front centring device comprises a center support, the back end of the center support is connected with a sleeve, the sleeve is rotationally connected with a transmission rod, the left portion of the transmission rod is in threaded connection with a left positioning plate, the right portion of the transmission rod is in threaded connection with a right positioning plate, the center of the center support is connected with a guide column, and a first gear is vertically arranged at the right end of the transmission rod of the front centring device.A second gear is vertically arranged at the right end of a transmission rod of the back centring device.A third gear is arranged between the back side of the first gear and the front side of the second gear, a transmission shaft is arranged at the right end of the third gear, a worm wheel is arranged at the right end of the transmission shaft, the back side of the worm wheel is in transmission connection with a worm, and a handle is arranged at the top end of the worm.The centring micro-setting device for heavy equipment installation is simple in structure, easy and convenient to operate, reliable in work and high in use precision and working efficiency, and can lower the operation difficulty of operators.

Owner:HUANGHE S & T COLLEGE

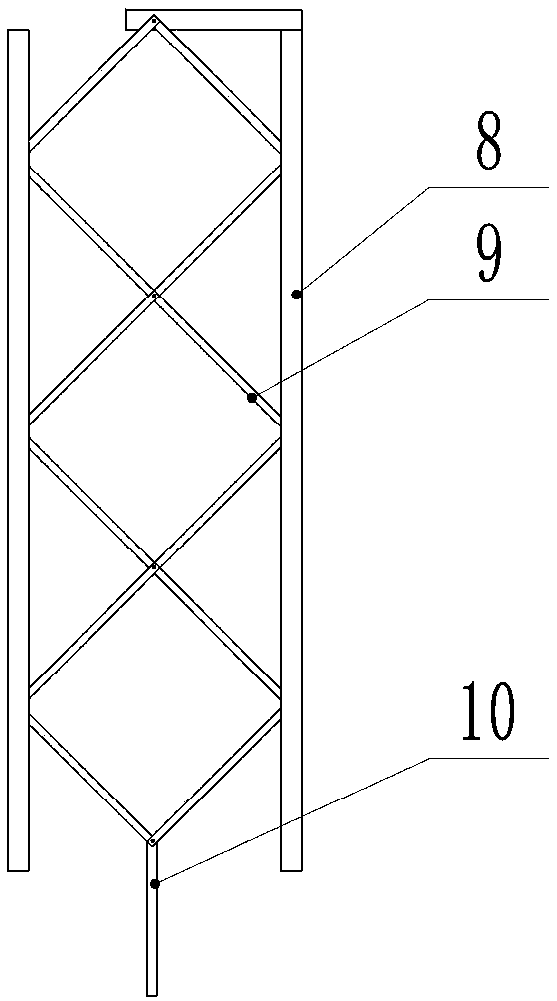

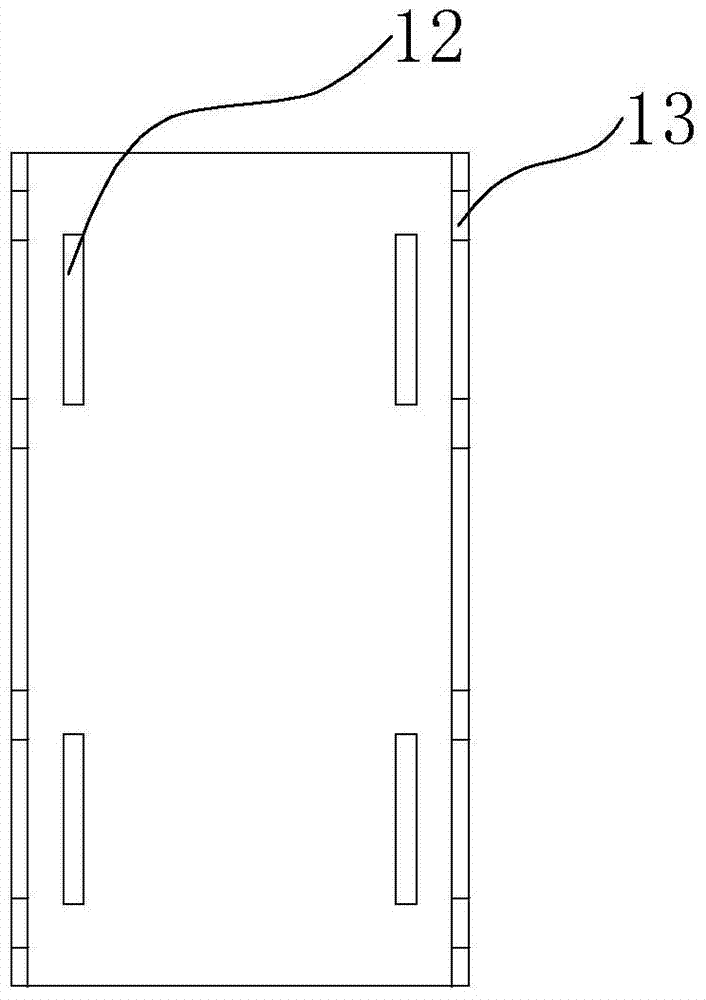

Fixing device for PCB maintenance

The invention relates to the technical field of a PCB fixing device, and discloses a fixing device for PCB maintenance. The fixing device comprises a table board, wherein a fixing shaft is arranged onthe table board, the fixing shaft comprises two parallel vertical rods and a width adjusting mechanism positioned between the two vertical rods, and the width adjusting mechanism comprises a plurality of sets of rhombic frames which are sequentially arranged from top to bottom; each set of rhombic frame comprises four connecting rods which are sequentially hinged to one another in an end-to-end mode, moreover, each rhombic frame comprises two sliding corners which are opposite to each other and two connecting corners which are opposite to each other, the two sliding corners are slidably connected to the two vertical rods respectively, the two proximate connecting corners between the adjacent rhombus frames are hinged to each other, the uppermost connecting corner is hinged to one of the vertical rods, a supporting rod is hinged to the bottommost connecting corner, and the supporting rod is connected with a pulling mechanism. According to the fixing device, a PCB with positioning holeswith different sizes can be positioned and fixed, so that the maintenance of the PCB is facilitated.

Owner:重庆合聚达智能装备有限公司

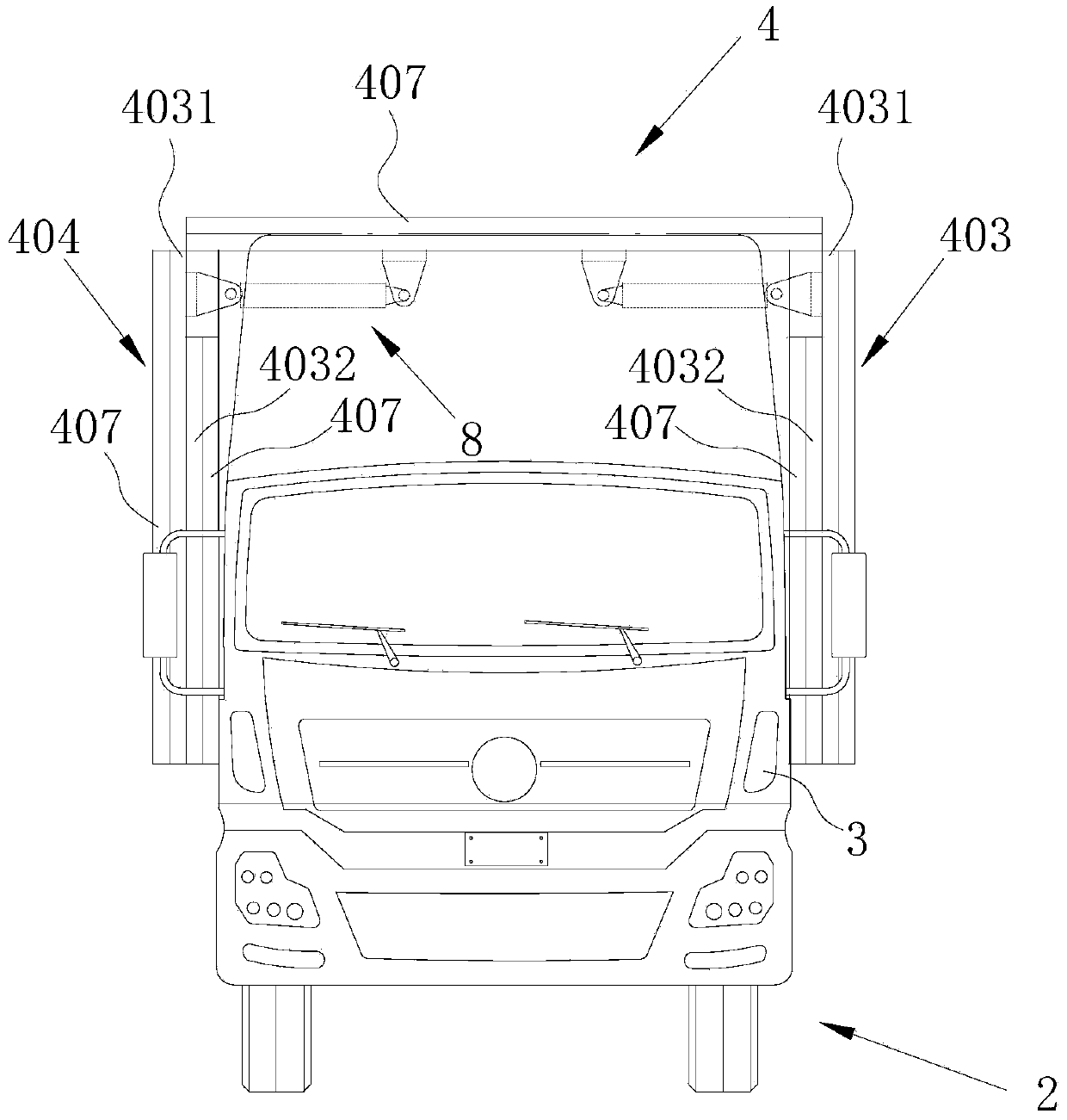

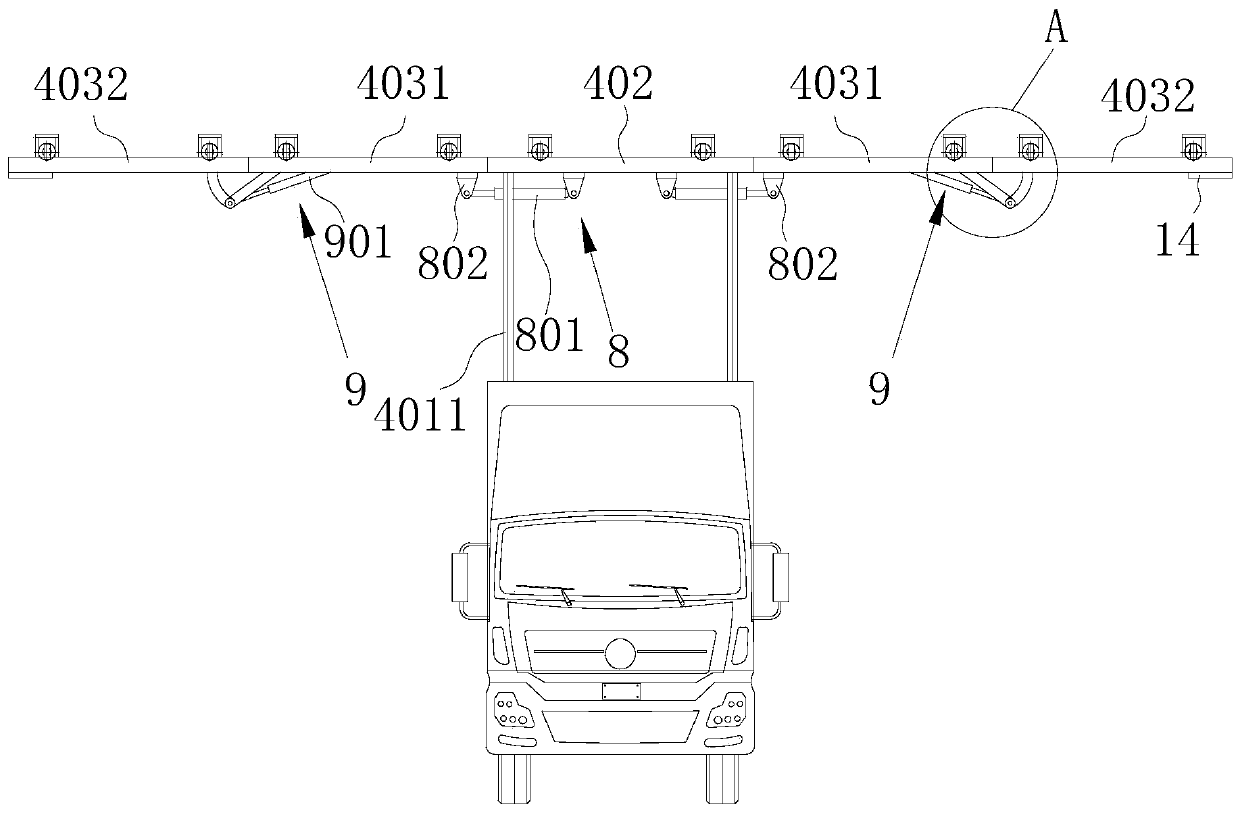

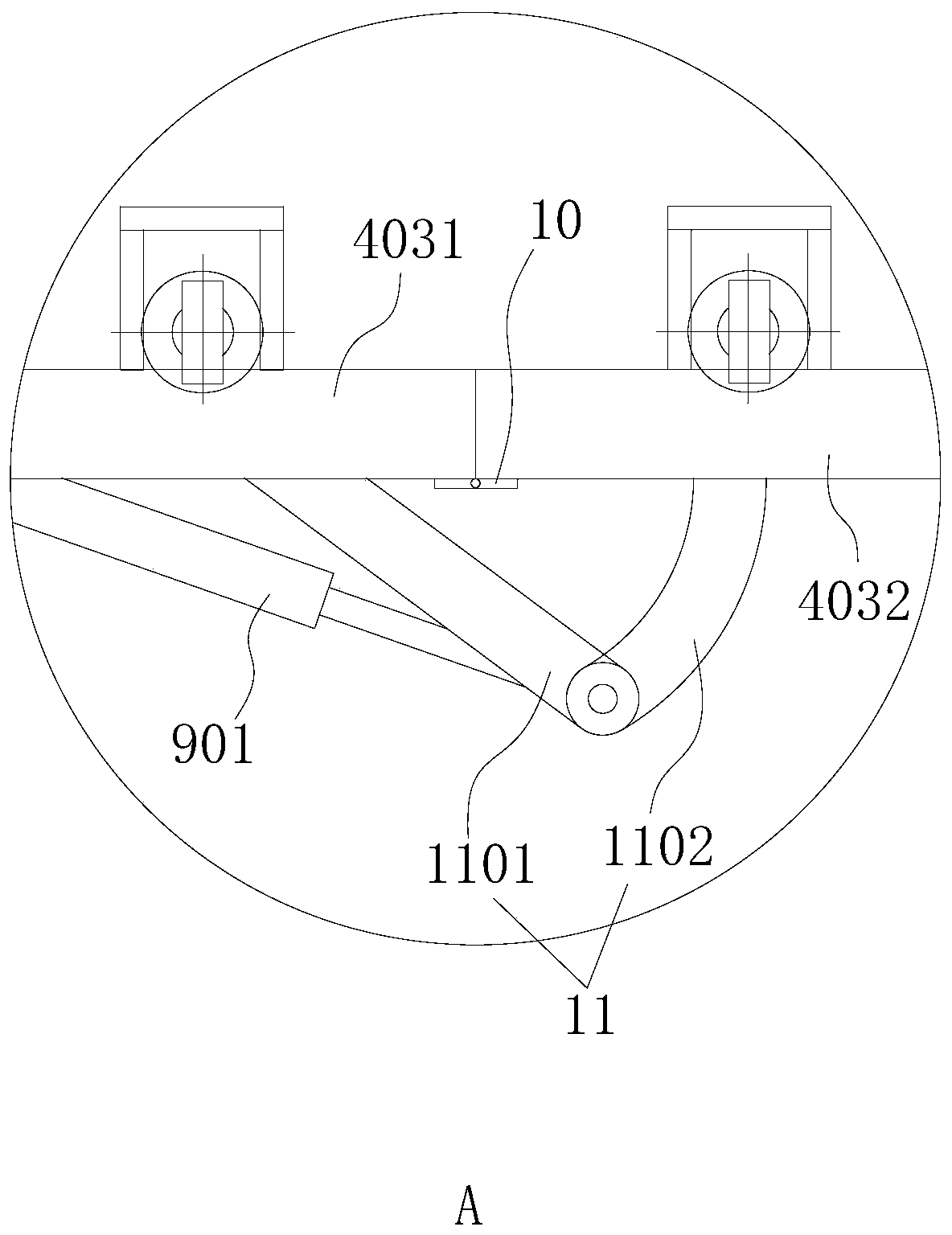

Engineering maintenance vehicle

PendingCN110576787AIncrease the shade areaImprove usabilityItem transportation vehiclesControl systemRolling chassis

The invention discloses an engineering maintenance vehicle, and belongs to the field of special vehicles. The scheme includes a vehicle chassis, a walking system, a ceiling unfolding device, a maintenance work platform, a vehicle-mounted lifting device and a protective curtain assembly. The ceiling unfolding device includes a carriage body, a jacking component, an unfolding component and an unfolding control system; a left carriage panel and a right carriage panel each include a primary unfolding panel and a secondary unfolding panel; the unfolding component includes a primary unfolding driveassembly and a secondary unfolding drive assembly; the carriage body also includes wing plates; and the unfolding assembly also includes an unfolding drive assembly and an unfolding drive assembly. The left carriage panel and the right carriage panel can be divided into two-stage unfolding, and the wing plates are arranged, so that the sheltered area of a ceiling formed after unfolding is increased; and in cooperation with the protective curtain assembly, the space under the ceiling is surrounded and covered, the protection effect is good, and the using applicability of the engineering maintenance vehicle is improved.

Owner:广东精益专用汽车有限公司

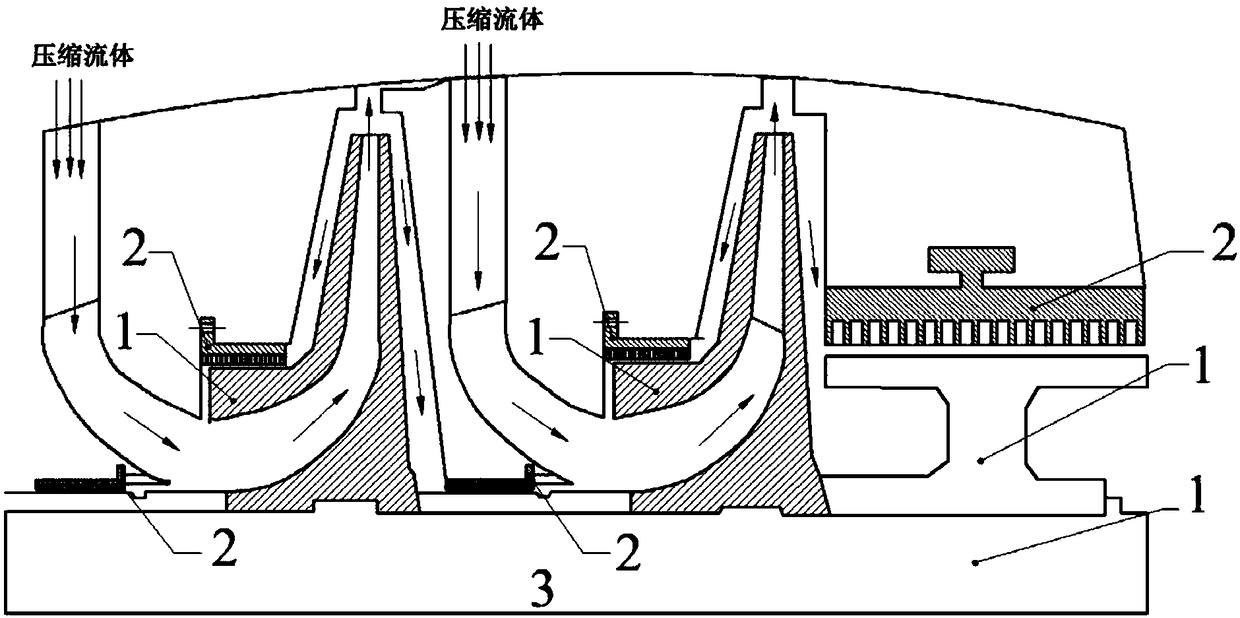

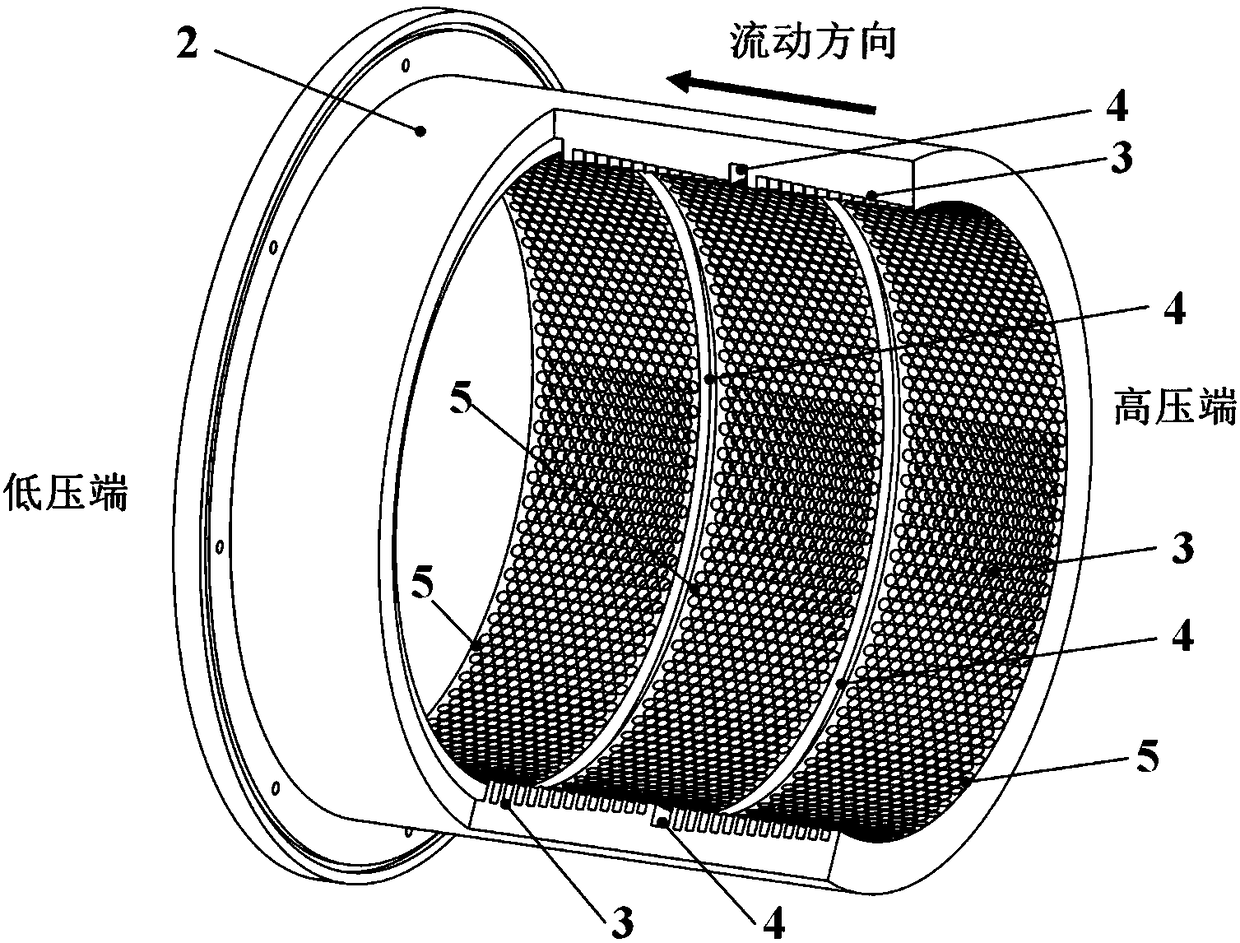

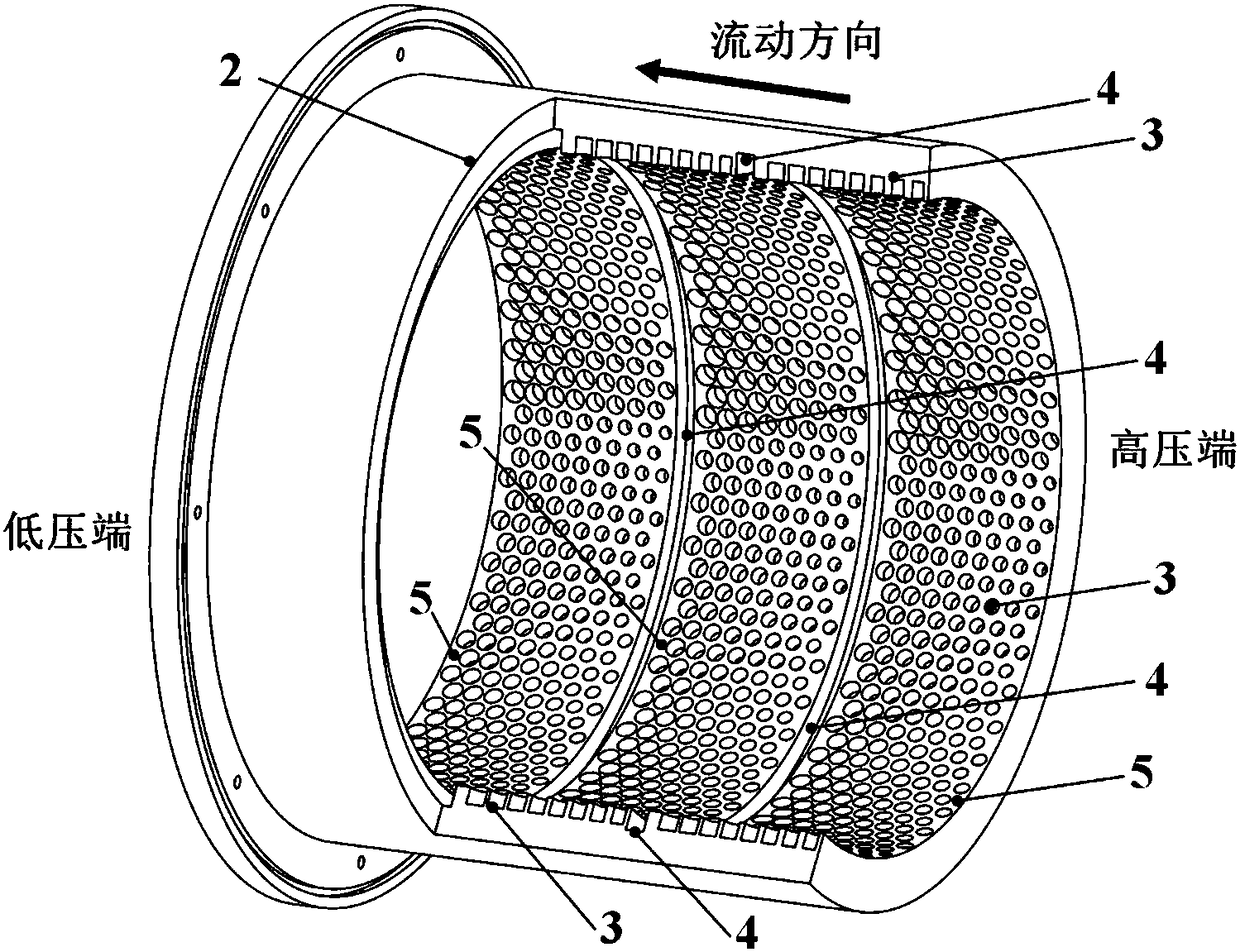

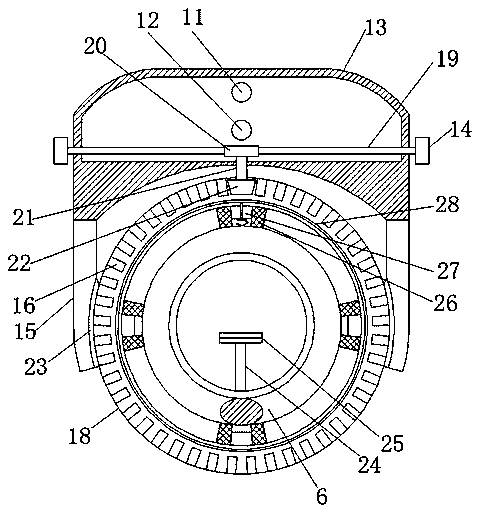

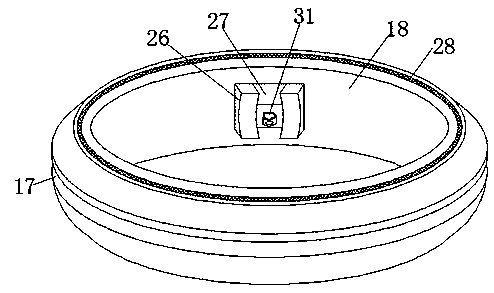

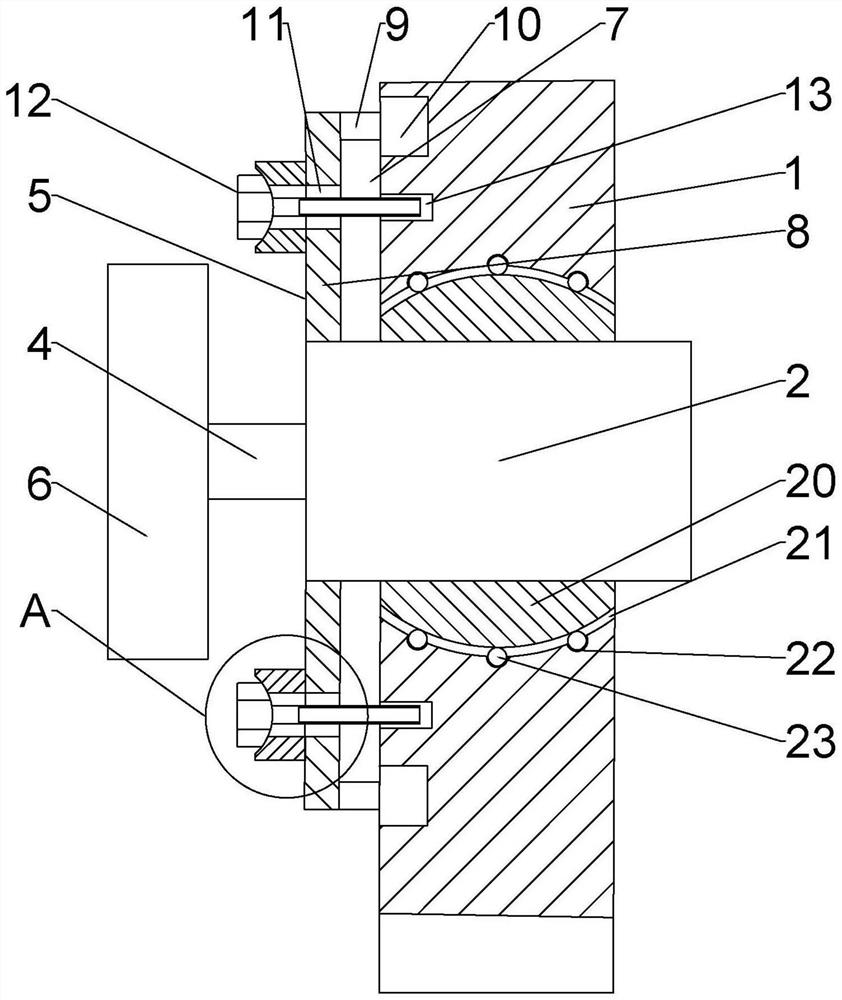

Nonuniform controllable cavity rotary sealing structure

ActiveCN108397416AGood sealing performanceImprove operating efficiency and shafting stabilityPump componentsLeakage preventionImpellerStator

The invention discloses a nonuniform controllable cavity rotary sealing structure. The sealing structure is a sealing stator used for being mounted on a rotating part in a sleeving mode and comprisesa hole-type sealing cavity and an annular pressure stabilizing cavity both formed in the inner surface of the sealing stator. The processing section of the hole-type sealing cavity can be circular, oval or hexagonal, and the annular pressure stabilizing cavity is through in the circumferential direction. The hole diameter and hole depth of the hole-type sealing cavity are changed according to a set rule in the axial direction and the circumferential direction, and the changing rule can be a linear type, a quadratic curve type, a cosine curve type and a B-spline curve type. The inner surface ofthe sealing stator is divided into a plurality of independent sealing sections by the annular pressure stabilizing cavity, and the sealing sections can independently regulate and control the hole diameter and the hole depth of the hole-type sealing cavity. Fine regulation and control over the magnitude and symbols of sealing power characterization factors (rigidity and damping) can be realized, the sealing power characterization is improved, and the impeller mechanical shafting stability is improved.

Owner:XI AN JIAOTONG UNIV

Novel camera lens assembly and projector

The invention discloses a novel camera lens assembly, which belongs to the field of projectors. The novel lens assembly comprises a camera lens sleeve, an adjusting sleeve, a lens sleeve, a locking ring and a lens pressing ring, wherein the lens sleeve and the locking ring are sequentially arranged in the camera lens sleeve from front to back, the outer wall of the lens sleeve is in clearance fitwith the inner wall of the camera lens sleeve, and the outer wall of the locking ring is in threaded connection with the inner wall of the camera lens sleeve; a limiting convex ring is arranged at thefront end of the inner wall of the camera lens sleeve; lens steps are arranged at the front end and / or the rear end of the inner wall of the lens sleeve; the lens pressing ring is pressed between thelens sleeve and the locking ring, and the inner wall of the lens pressing ring protrudes out of the inner wall of the lens step; and the inner wall of the adjusting sleeve is in threaded connection with the outer wall of the camera lens sleeve, the outer wall of the adjusting sleeve is provided with a connecting convex ring, and a connecting hole is formed in the connecting convex ring. The novelcamera lens assembly is simple in structure and reasonable in design, different types of camera lens assemblies can be implemented by rapidly replacing different lenses, and therefore the camera lensassembly is suitable for different occasions and projectors, and the position of the camera lens can be finely adjusted in the using process.

Owner:上海星迅科技有限公司

Device for carrier tape bagging and cover tape offset correction after chip package test and process thereof

ActiveCN107662725AAvoid offsetTo achieve the purpose of forward and backward adjustmentPackaging automatic controlPackaging machinesStructural engineeringMechanical engineering

The invention discloses a device for carrier tape bagging and cover tape offset correction after a chip package test and a process thereof, belonging to the technical field of chip packaging. The device comprises a carrier tape bagging mechanism and a cover tape offset preventing mechanism arranged in a process order. The carrier tape bagging mechanism comprises a square pressing plate and a taping window which is extended outwards from the middle of the square pressing plate to the running direction of the carrier tape, wherein the square pressing plate and the tapingwindow are fixedly connected in to one, and the bottom of the taping window is opened to the outside. The cover tape offset preventing mechanismcomprises apressing plate, a bracket, and a fixing frame; the pressing plate, thebracket, wherein the fixing frame are connected in turn in a soft connection mode, a cover tape groove is formed in the side of the pressing plate for guiding the running direction of the cover tape,the width of the cover tape groove is the same as the cover tape, and the vertical center lines of the taping window and the cover tape groove are in the same plane. The device is provided with the anti-warping leg taping window for the nozzle to accurately insert a chip into a carrier tape bag, improves the original hard connection into soft connection, and is capable of fine adjustment to achieve the purpose of effectively preventing the offset of the cover tape.

Owner:CHANGJIANG ELECTRONICS TECH CHUZHOU

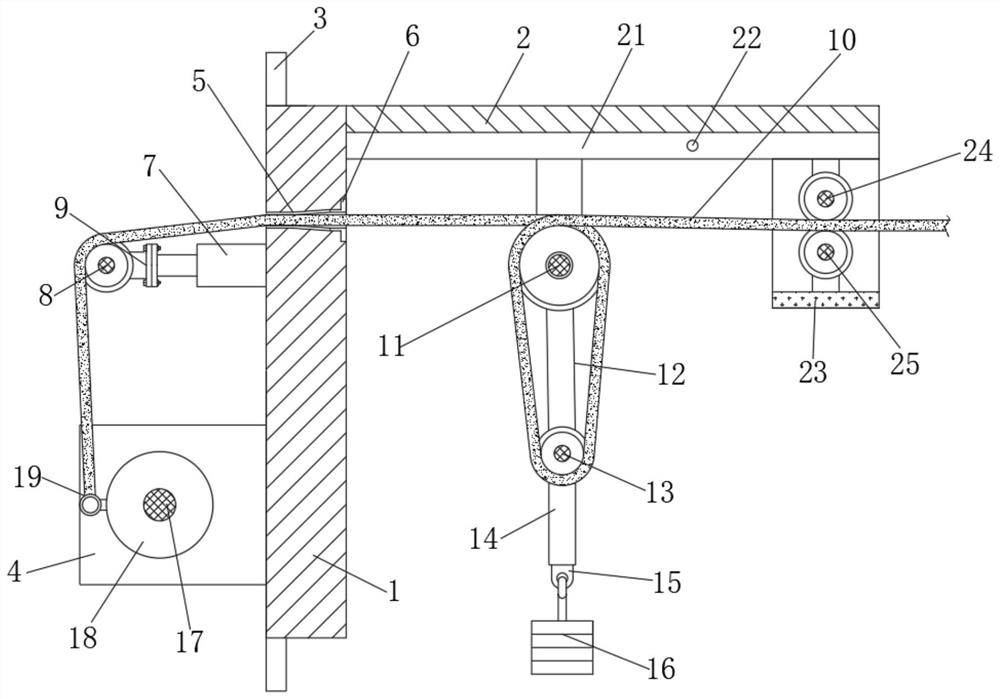

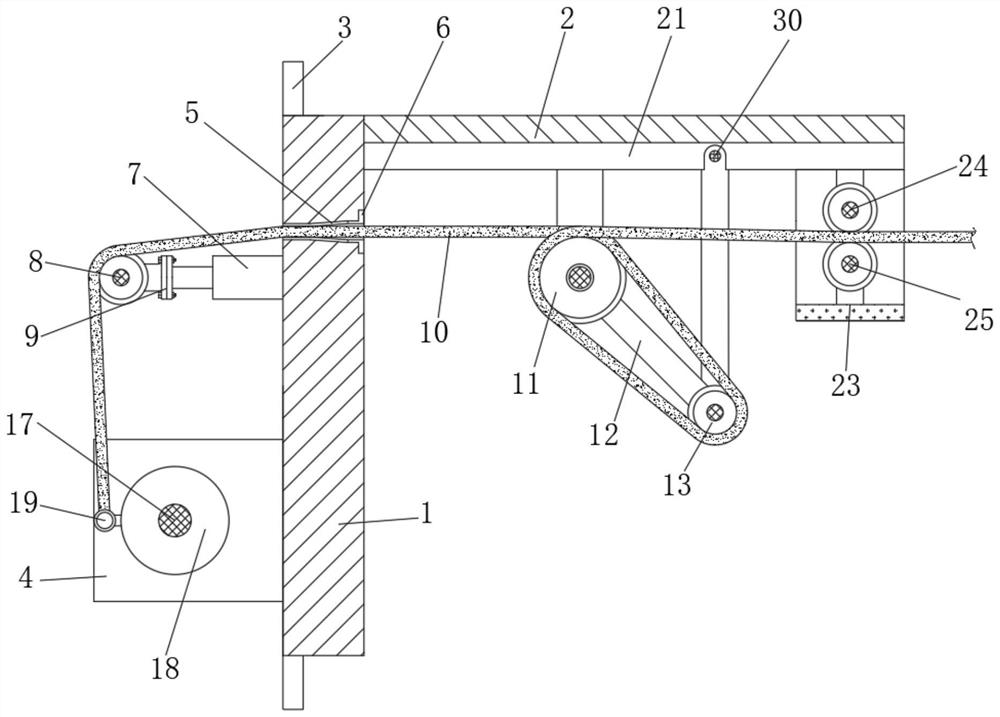

Electric power iron tower high-voltage line pre-tightening device

ActiveCN111697492AAchieve winding fixationImprove securityApparatus for overhead lines/cablesElectric machineDrive motor

The invention relates to the technical field of a high-voltage line laying device and particularly relates to an electric power iron tower high-voltage line pre-tightening device. The high-voltage line pre-tightening device of an electric power iron tower comprises a vertical plate, wherein a cross beam plate is transversely welded at an upper end of the right side of the vertical plate, a throughhole penetrating left and right is formed in an upper end of the vertical plate, and an electric telescopic rod and a side support are vertically welded at upper and lower ends of the left side of the vertical plate. The high-voltage line laying device is advantaged in that winding and fixing of a high-voltage cable are achieved through cooperation of a driving motor and a pulley, so stretching and laying of the high-voltage cable are achieved through rotation of a motor, manual pulling is avoided, operation safety and convenience are greatly improved, and high-altitude operation is more convenient, three-stage pre-tightening is realized through motor driving, extension of a telescopic rod and stretching of a balancing weight, so adjustment of pre-tightening force is refined, the magnitude of the pre-tightening force on the high-voltage cable is convenient to control, excessive stretching is avoided, and a purpose of fine adjustment is realized.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

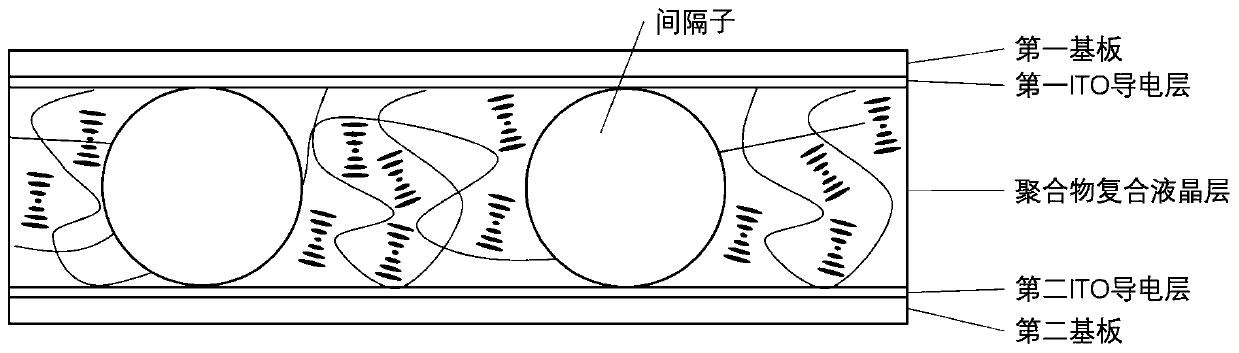

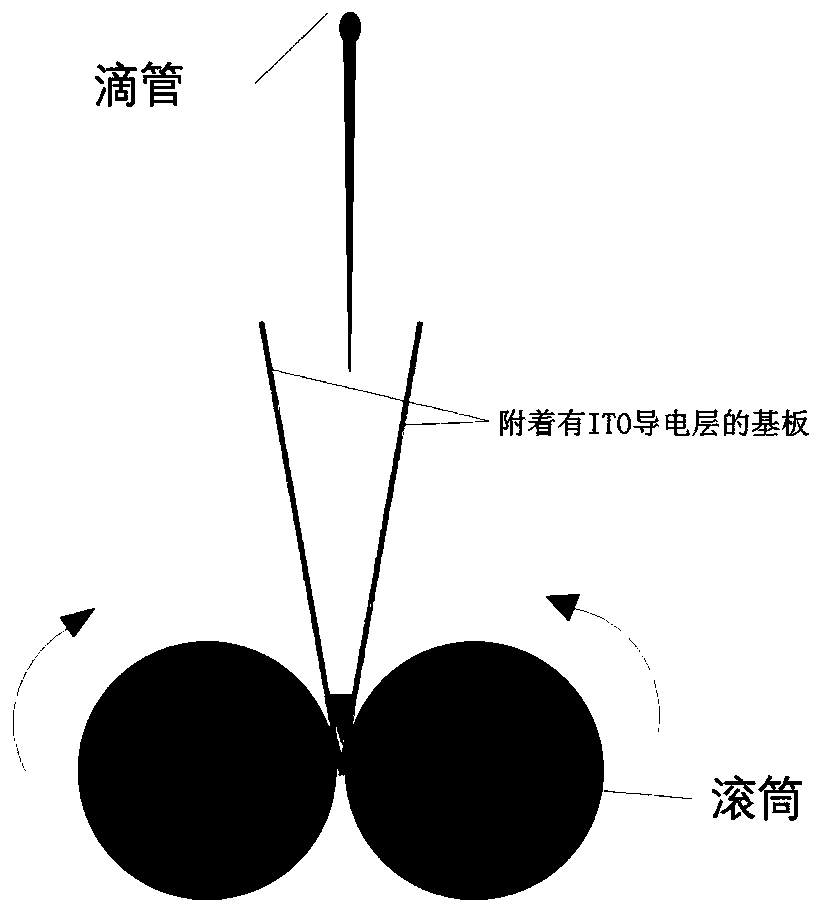

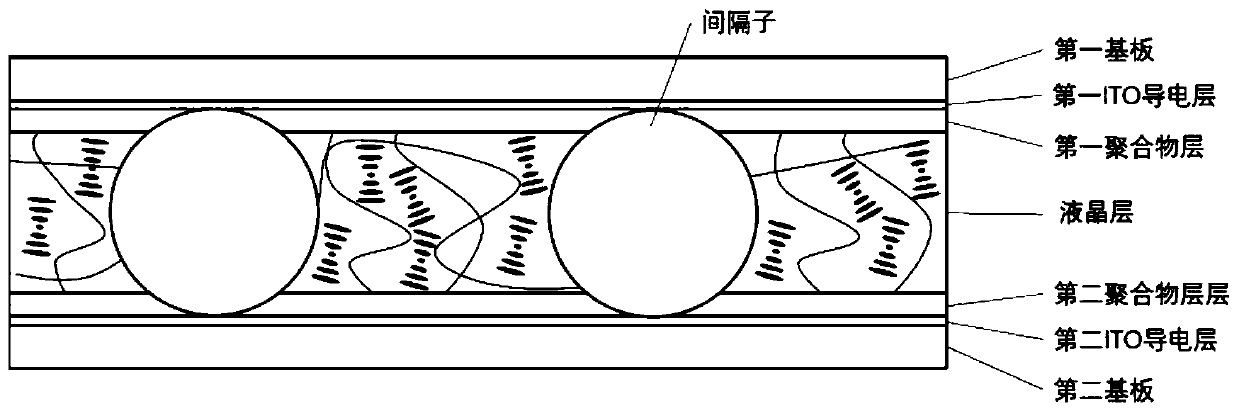

Cholesteric liquid crystal handwriting board and preparation method thereof

InactiveCN111488065AExtended service lifeReduce thicknessNon-linear opticsInput/output processes for data processingPhysicsChemistry

The invention provides a cholesteric liquid crystal handwriting board and a preparation method thereof, and belongs to the technical field of liquid crystal materials. The invention provides a cholesteric liquid crystal handwriting board. The cholesteric liquid crystal handwriting board comprises a first substrate, a first ITO conducting layer, a first polymer layer, a liquid crystal layer, a second polymer layer, a second ITO conducting layer and a second substrate which are sequentially arranged in a stacked mode. According to the handwriting board, the polymer layer is attached to the conducting layer, the thickness of the liquid crystal layer can be finely adjusted due to the existence of the polymer layer, and the thickness of the liquid crystal layer can be reduced as much as possible while handwriting brightness is not affected, so that driving voltage is reduced, and the service life of the handwriting board is prolonged. Meanwhile, due to the existence of the polymer layer, the adhesion between the substrate and the liquid crystal layer is improved, and the integrity of the handwriting board is improved.

Owner:SHENZHEN POLICRAL TECH CO LTD

Anti-overcurrent fine adjustment slide rheostat

InactiveCN111048272ATo achieve the purpose of fine-tuningReduce the temperatureResisitors with sliding contactResistor detailsElectrical resistance and conductanceElectrical conductor

The invention belongs to the technical field of rheostats, and particularly relates to an anti-overcurrent fine adjustment slide rheostat. In view of the problems that an existing slide rheostat is easy to generate heat during working to result in damage of the rheostat, and that the resistance cannot be finely adjusted at the same time, the invention puts forward the following scheme: the slide rheostat comprises a bottom plate, fixing plates are welded to the two sides of the top end of the bottom plate, a fixing pipe is welded between the fixing plates, a fixing column is welded into the fixing pipe, a bimetallic strip is welded to the top end of the fixing column, the fixing pipe is externally sleeved with a resistance wire, and a second conductor and a third conductor are arranged between the two fixing plates. According to the invention, a worm gear drives a transmission shaft to rotate, a bevel gear is enabled to rotate and drive a rotating ring to rotate through a tooth groove,the rotating ring drives an elastic piece to rotate, the elastic piece slides on the resistance wire so as to achieve the purpose of the fine adjustment, the resistance wire generates heat to enablethe bimetallic strip to deform, a moving column rises and enables a first conductor to rotate through a push rod, the first conductor is separated from the second conductor, and the device is disconnected.

Owner:HUBEI UNIV OF TECH

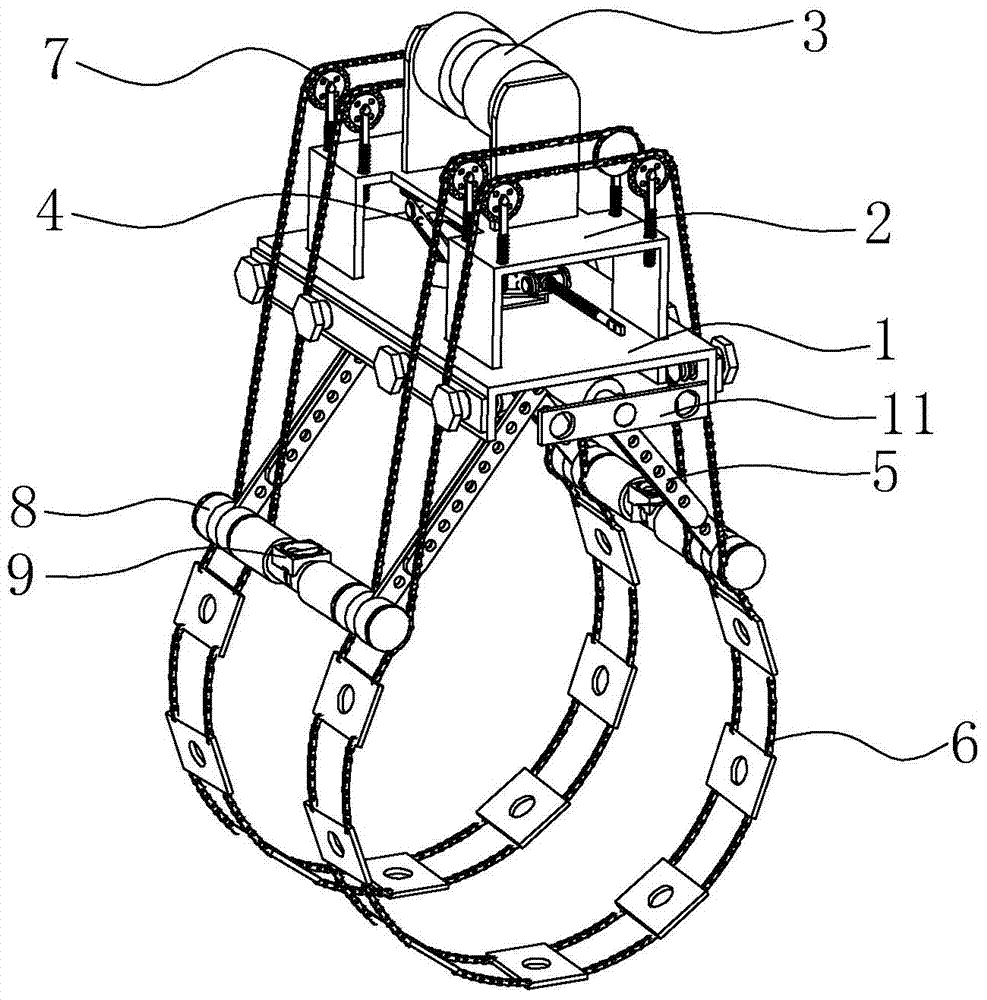

Aircraft tire mounting device

InactiveCN111231576AAchieve regulationHigh precisionWheel mounting apparatusGround installationsButt jointAirplane

The invention provides an aircraft tire mounting device. The aircraft tire mounting device comprises a base; an arc-shaped seat; a sliding guide rail is arranged in an inner cavity of the base, the arc-shaped base is arranged on the sliding guide rail in a sliding mode, an arc-shaped protective plate is connected to the inner side of the arc-shaped base in a sliding mode, and an arc-shaped clamping plate is fixedly arranged at the top of the arc-shaped protective plate. An arc-shaped sliding groove is formed in the inner side wall of the arc-shaped base, and a sliding strip block matched withthe sliding groove is fixedly arranged on the outer side wall of the arc-shaped protective plate. A telescopic mechanism is further fixedly arranged on the inner wall of the base, and the output end of the telescopic mechanism is fixedly connected with the outer side wall of the arc-shaped seat; a butt joint mechanism is arranged on the side wall of one side of the arc-shaped protective plate andcomprises first driving blocks symmetrically arranged on the side wall of the arc-shaped protective plate. According to the technical scheme, the problem that in the prior art, when the axial positionof the tire needs to be finely adjusted in the installation process, the function of finely adjusting the axial position of the aircraft tire cannot be achieved is effectively solved.

Owner:荆门怡盛源环保科技有限公司

Blade gap adjusting and locking mechanism for plate shearing machine

InactiveCN105149681ATo achieve the purpose of fine-tuningPrevent looseningShearing toolsPush and pullMotor drive

The invention relates to a blade gap adjusting and locking mechanism for a plate shearing machine. The blade gap adjusting and locking mechanism comprises a speed reducing motor installed at one side of a rack of the plate shearing machine, a lead screw connected with the output end of the speed reducing motor, and a lower blade base installed on the rack. The two ends of the lead screw are sleeved with nuts. Two fixed inclining blocks are fixedly installed on the lower blade base. Each nut is sleeved with one inclining block. The inclining blocks make close contact with the fixed inclining blocks. The horizontal side faces of the inclining blocks are matched with supporting blocks installed on the rack. The lower blade base and the rack are connected through the locking mechanism. The blade gap adjusting and locking mechanism is simple in structure; the speed reducing motor drives the lead screw, the lead screw pushes and pulls the nuts, the nuts drive the inclining blocks to move left and right, and therefore the inclining blocks push the fixed inclining blocks to enable the lower blade base and a lower blade to move slightly; meanwhile, by means of the thrust effect of a compressing spring, it is ensured that the fixed inclining blocks and the inclining blocks keep a close contact state constantly, and the purpose of fine adjustment of a gap between upper blade and lower blade cutting edges is achieved.

Owner:JIANGSU YAWEI MACHINE TOOL

A metal power tube straight seam welding device

ActiveCN111730282BReduced chance of slippingEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringSeam welding

Owner:GUANGDONG POWER GRID CO LTD DONGGUAN POWER SUPPLY BUREAU +1

Variable stiffness device controlled by piezoelectric ceramics and its control method

ActiveCN110509264BChange frictionWide range of stiffness adjustmentProgramme-controlled manipulatorBall bearingEngineering

The present invention proposes a variable stiffness device controlled by piezoelectric ceramics and its control method, including: a torque speed input part and a torque speed output part; the torque speed input part includes a cylindrical ring with multiple spline grooves on the inner wall and a plurality of fine adjustment block; the top of the flat key of the fine-tuning block is pasted with a piezoelectric ceramic sheet, and has an arc surface with a slope; the torque and speed output part includes a circular frustum and a screw hole on the side of the small bottom of the circular frustum. Connect the shaft and the output shaft on the side of the large bottom of the conical frustum; the inclination of the inclination of the conical frustum is the same as that of the bottom surface of the contact part; the fine-tuning block and the conical frustum pass through the positioning bolts and the mounting plate on the side of the connecting shaft, and the input shaft The cover plate on one side maintains limited contact; the first stacked piezoelectric ceramic group, the second stacked piezoelectric ceramic group and thrust ball bearings are arranged sequentially between the positioning bolts and the mounting plate. Compared with conventional methods, it has a larger stiffness adjustment range, and the stiffness is precisely controllable.

Owner:FUJIAN UNIV OF TECH

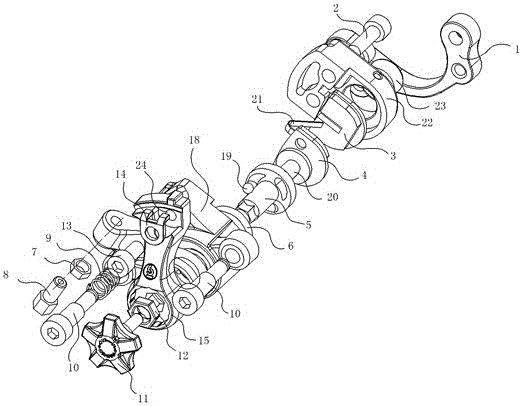

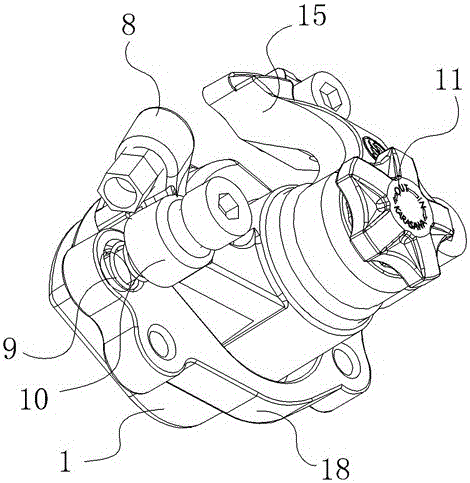

A fine-tuning disc brake caliper

ActiveCN103754312BExtended service lifeAvoid inconvenienceCycle brakesSlack adjustersEngineeringCalipers

The invention relates to a fine-tuning disc brake caliper. The caliper main body (18) has a rope-tightening adjustment part and a support part. The two ends of the caliper main body (18) are provided with fine-tuning devices and protective covers, and the support part is a rocker arm (15). , the fine-tuning device is composed of an external adjustment device connected to the tight rope adjustment part and an internal adjustment device connected to the cover plate (22). One end of the main body of the caliper (18) is also provided with a brake drive assembly. The first lever (4 ) is in contact with the driving push rod (20); the second locking piece (3) is in contact with the cover plate (22), and the first locking piece and the second locking piece are adjusted with the disc brake on the bicycle through the fine-tuning device. The distance between the pads can be adjusted on three sides of the disc brake, so as to solve the inconvenience caused by the loading, more fast and stable loading and debugging, fine-tuning on both sides can minimize the gap between the pad and the disc brake pad in the future, and can achieve The problem of moving the best state prolongs the service life of the pad.

Owner:KUNSHAN KARASAWA CLEAN ENERGY TECH CO LTD

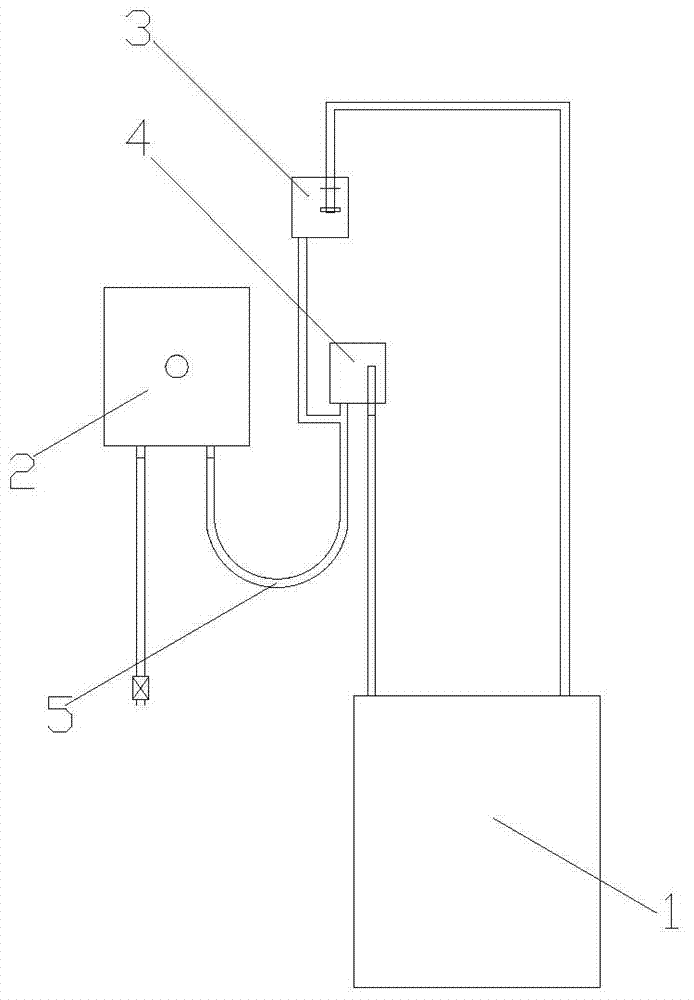

Humidity balance device

InactiveCN104503500AAchieve balance adjustmentControl adjustmentHumidity controlWater flowEngineering

The invention discloses a humidity balance device which comprises a main water tank, a moisturizing water tank, a water flow control box and a water level control box, wherein the water level control box is positioned above the main water tank; the water flow control box is positioned above the water level control box; the water flow control box, the water level control box and the main water tank are connected in series in sequence through pipelines to form water path circulation; the pipeline between the water flow control box and the water level control box is also communicated with a U-shaped pipeline; the other end of the U-shaped pipeline is connected with the moisturizing water tank; the height of the moisturizing water tank is equal to the water level control box. Due to the mode, the moisture balance device which is simple in structure and convenient to use is provided, so that moisture balance adjustment can be quickly realized; furthermore, the humidity adjustment value can be precisely controlled, and the aim of fine adjustment is fulfilled.

Owner:SUZHOU DONGHUA TESTING INSTR

Method and device for controlling virtual object drift

ActiveCN109107152BTo achieve the purpose of fine-tuningImprove gaming experienceVideo gamesGraphical user interfaceSimulation

The invention provides a method and device for controlling the drift of a virtual object. The method includes: providing a drift operation control and an arrow key function area on the graphical user interface; in response to a first touch operation acting on the drift operation control, controlling the virtual object to enter a drifting process in a drifting basic direction, Wherein, the basic drift direction is determined according to the second touch operation acting on the function area of the direction key; the relative position of the current touch point of the first touch operation in the drift operation control is determined , acquiring a drift adjustment direction according to the relative position; controlling the virtual object to adjust the drift direction according to the drift adjustment direction on the basis of the drift basic direction. Compared with the prior art, the purpose of fine-tuning the drifting direction of the virtual object is realized, and the game experience of the player is improved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

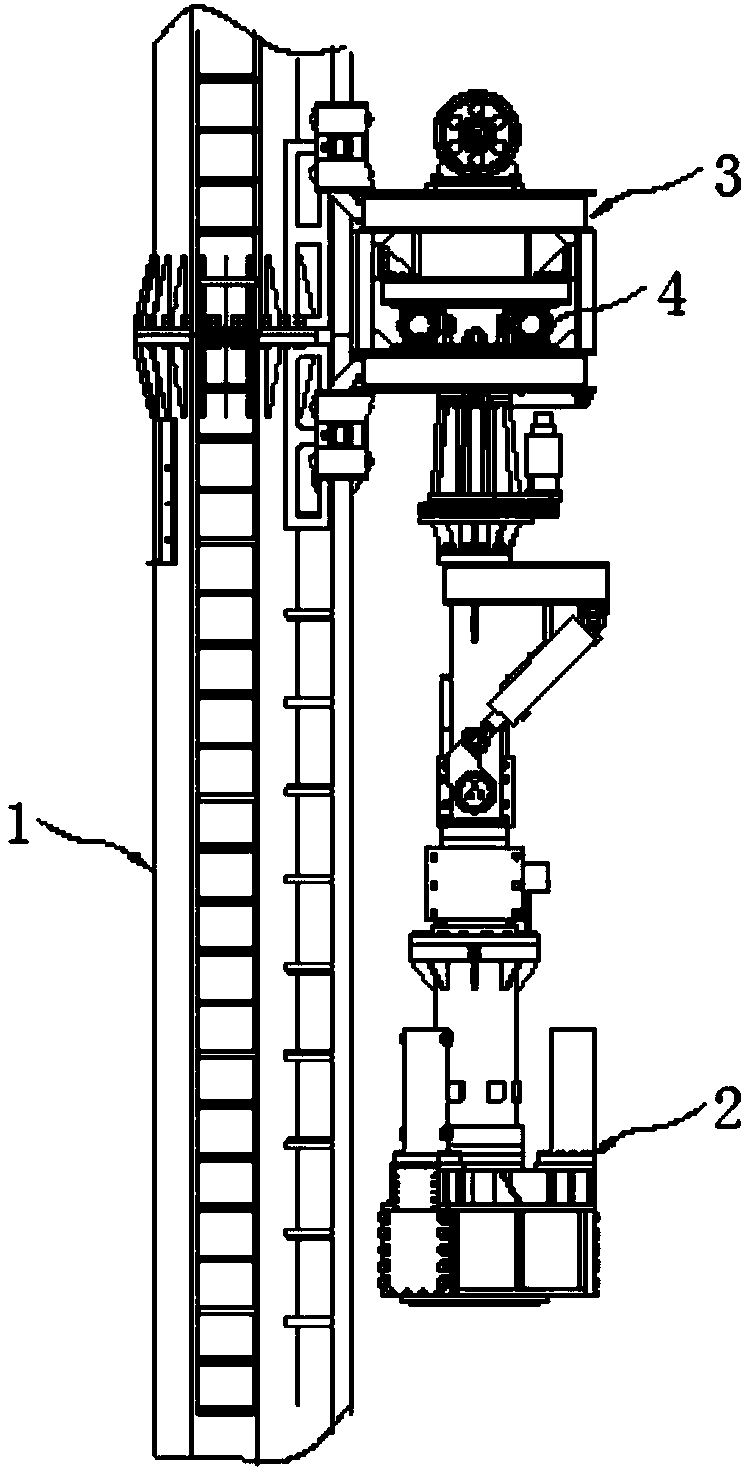

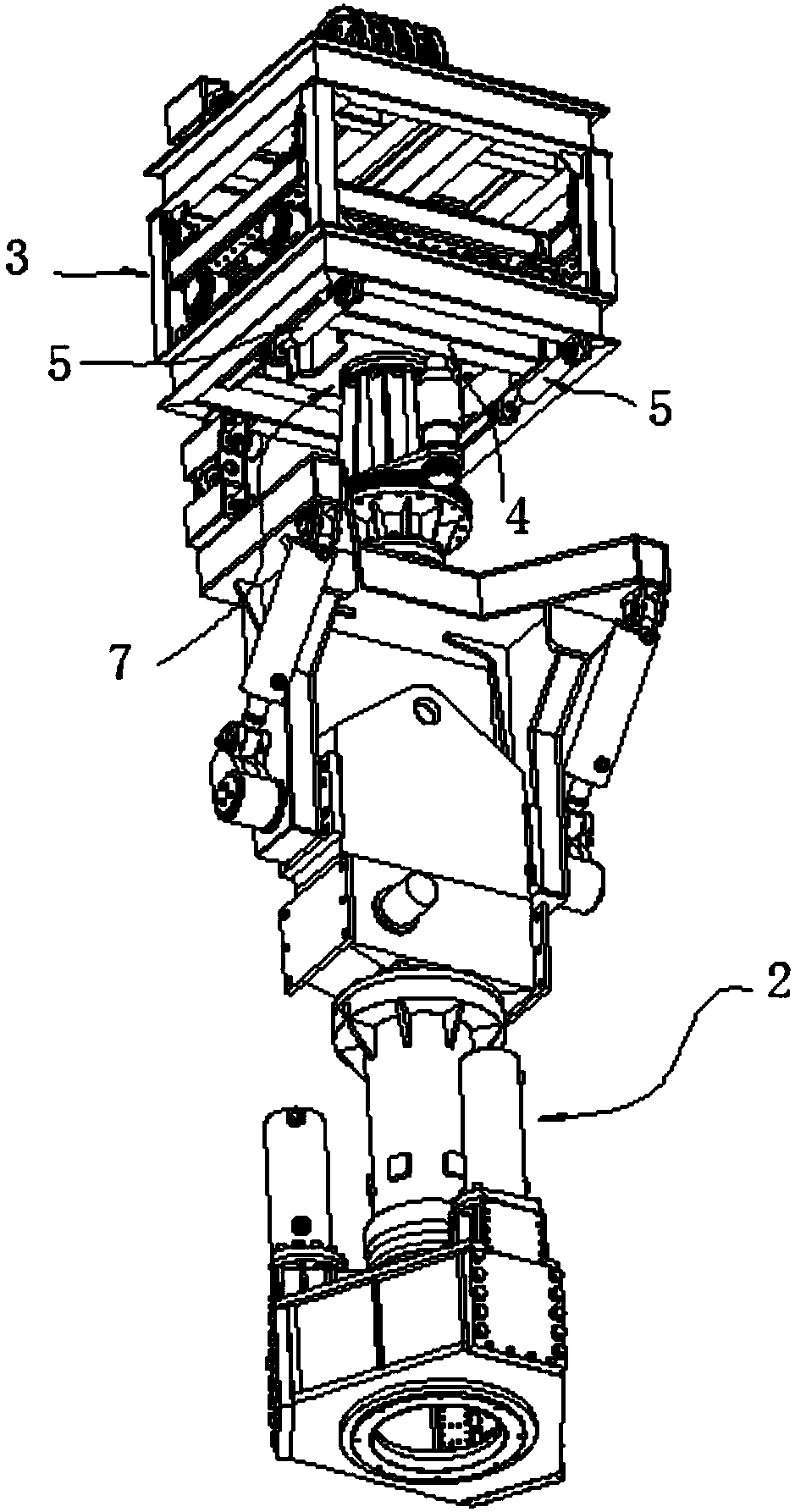

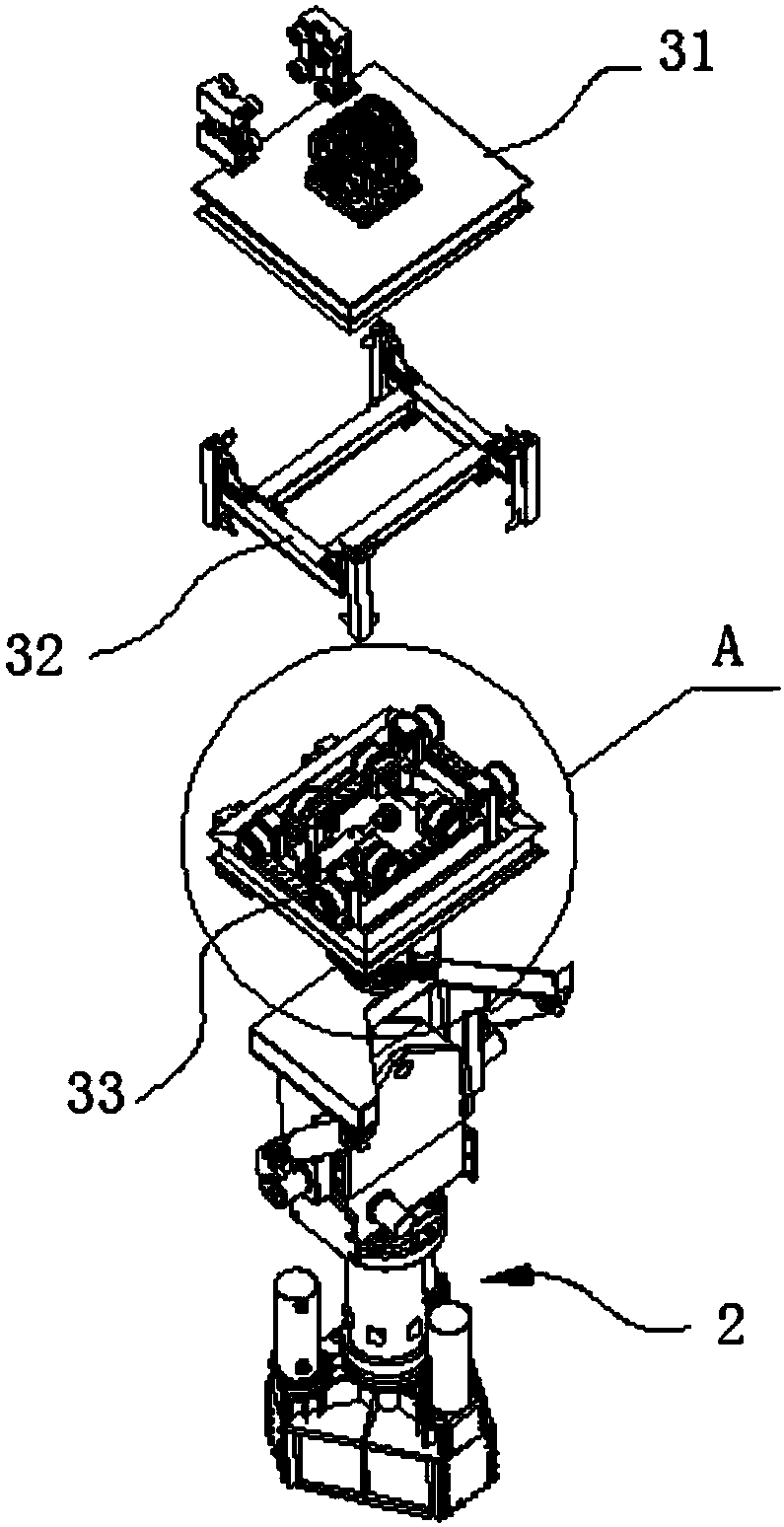

Piling machine horizontal position adjustment device and piling machine

InactiveCN108301412ATo achieve the purpose of fine-tuningRealize the purpose of prefabricated pilesBulkheads/pilesEngineeringControl theory

The invention relates to the technical field of piling machine equipment, in particular to a piling machine horizontal position adjustment device and a piling machine. The piling machine horizontal position adjustment device comprises a liftable sliding platform (3), a first trolley (4) capable of moving horizontally on the sliding platform (3) and a second trolley (7) capable of moving horizontally on the first trolley (4), moving directions of the first trolley (4) and the second trolley (7) are arranged in an interlaced manner, a pile sinking device (2) is connected to the lower portion ofthe second trolley (7) and moves synchronously along with the second trolley (7), and the piling machine comprises the piling machine horizontal position adjustment device. By means of the piling machine horizontal position adjustment device and the piling machine, when the pile sinking device deviates from a predetermined position, fine adjustment can be performed on the position of the pile sinking device in the horizontal plane, the piling machine horizontal position adjustment device and the piling machine are quite convenient, and the accuracy is increased.

Owner:周兆弟

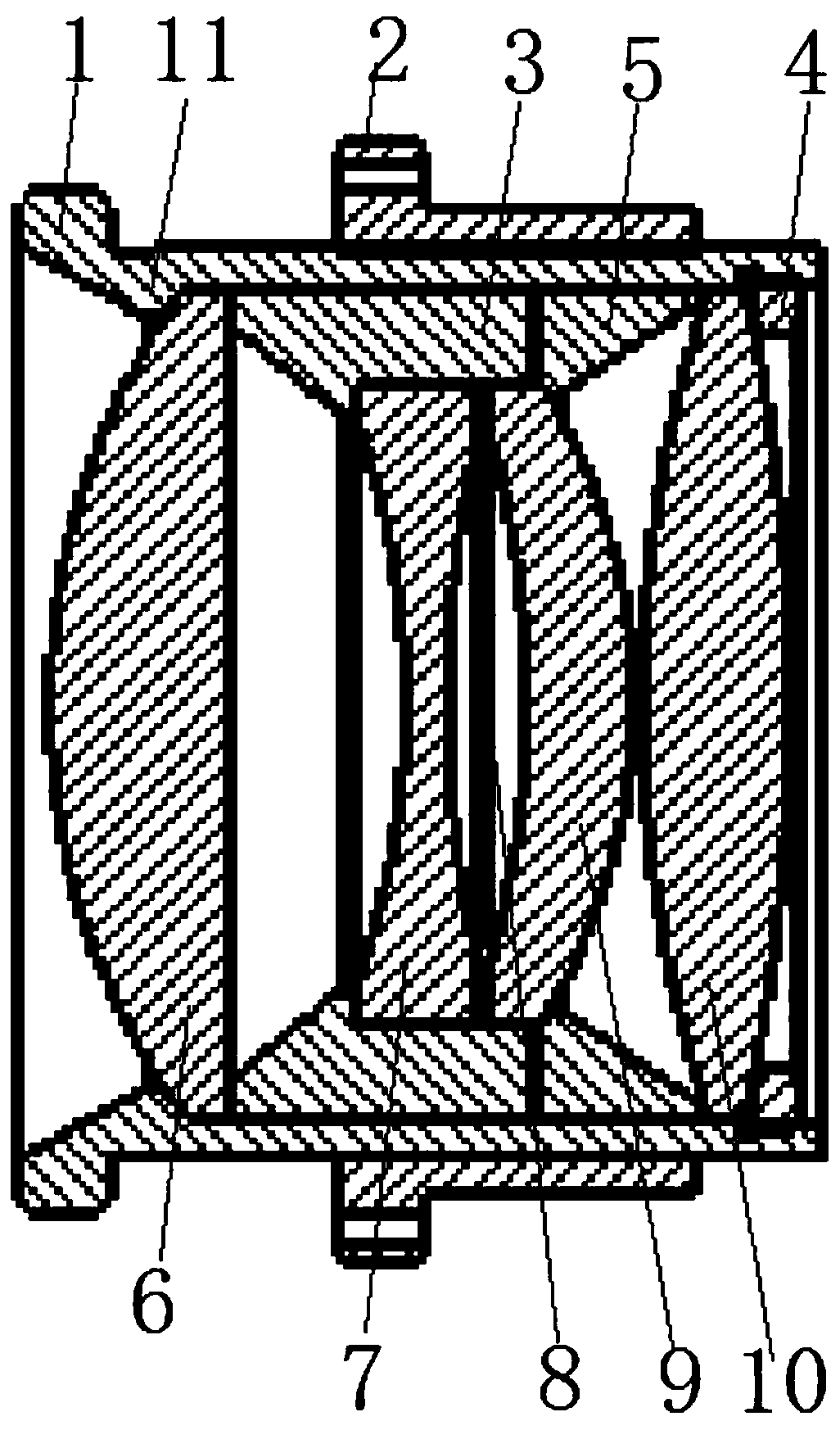

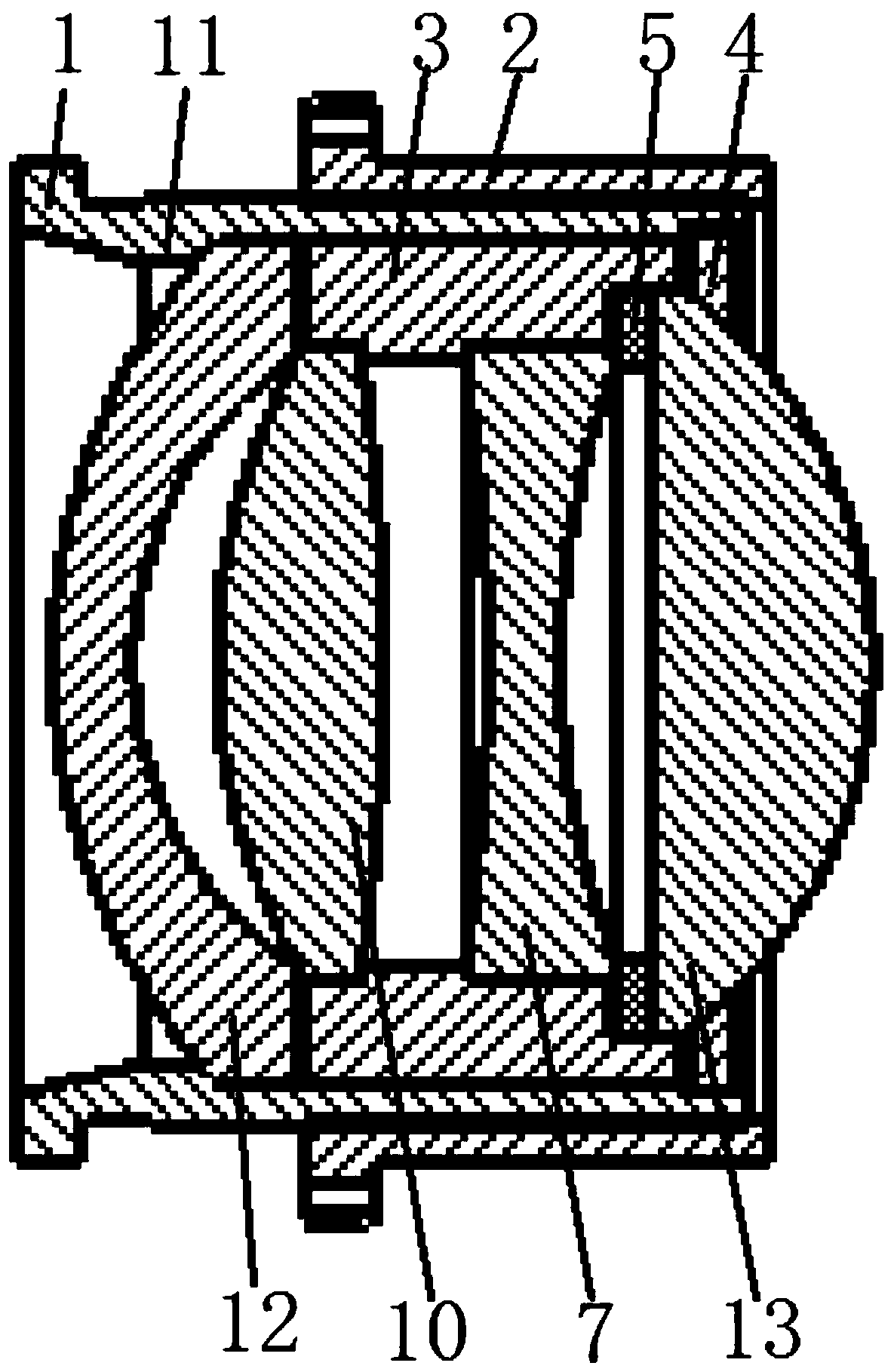

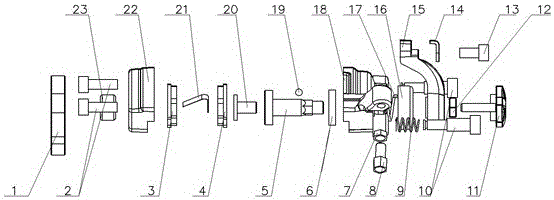

Pipeline jointing device

ActiveCN103386580BGuaranteed accuracyHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

Owner:SINOPEC NINGBO ENG +2

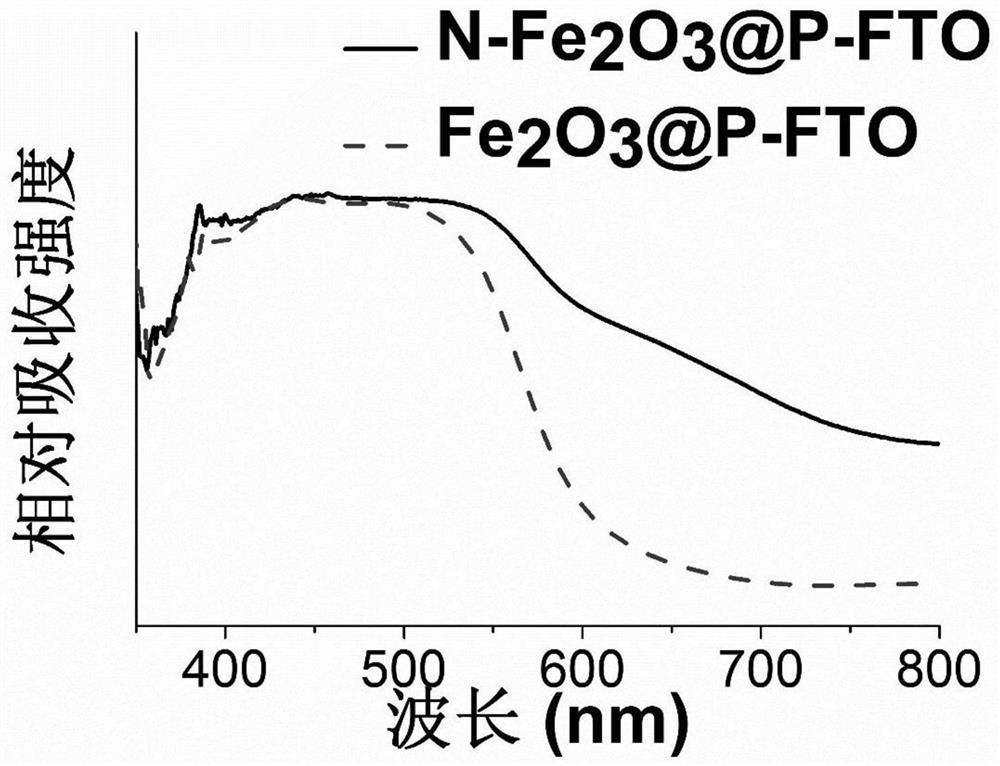

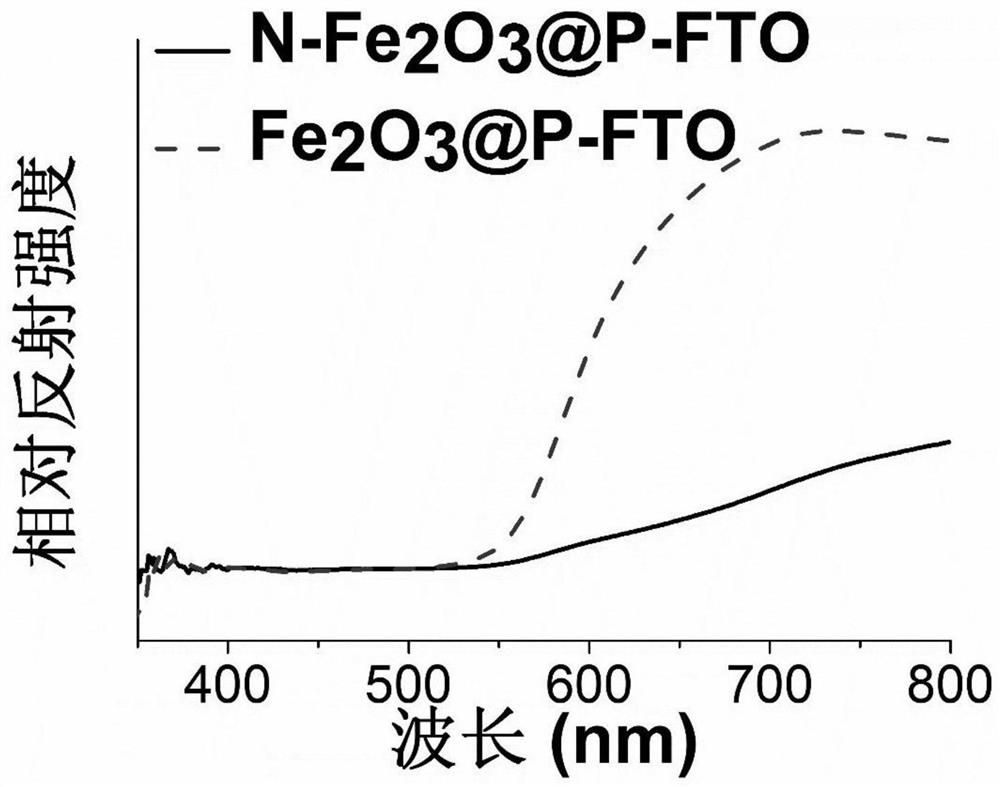

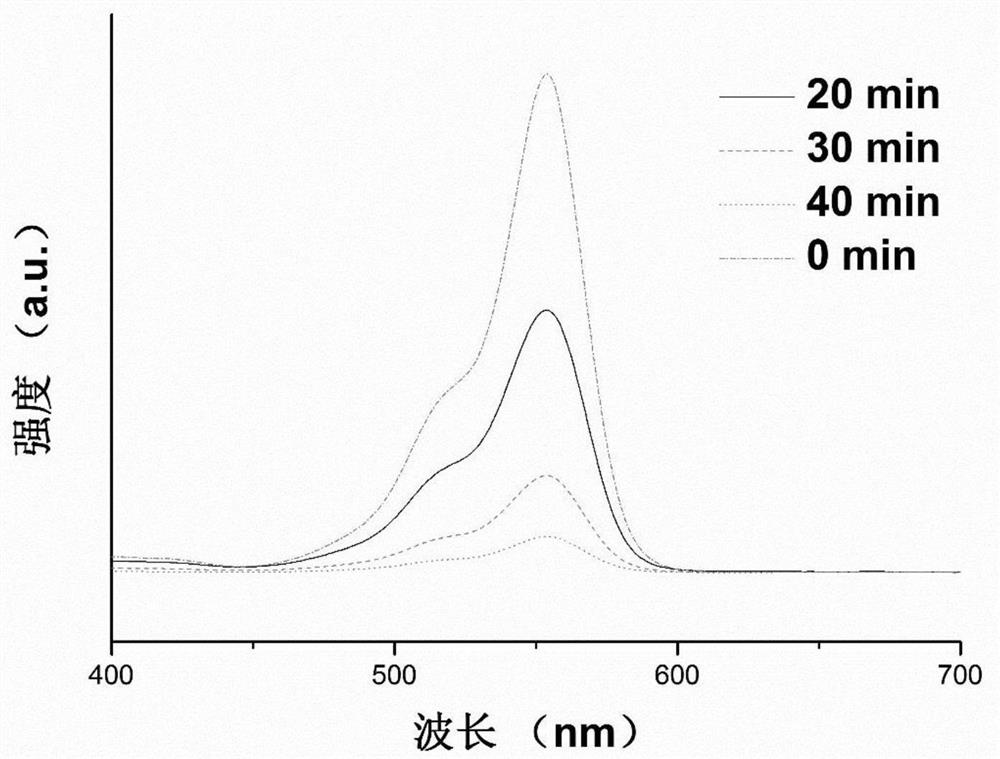

A kind of ferric oxide photocatalyst heat-treated under nitrogen atmosphere, preparation method and application thereof

ActiveCN110465292BTo achieve the purpose of fine-tuningEnhanced light absorptionWater/sewage treatment by irradiationWater treatment compoundsPhysical chemistryNitrogen atmosphere

Owner:GUANGDONG UNIV OF TECH

Self-weight downward-pressing and trowelling device

PendingCN112497428APrevent overloadPrevent looseningAuxillary shaping apparatusIdler-wheelScrew thread

Owner:GUANGXI HONGFA HEAVY IND MACHINE

A pretensioning device for high-voltage wires of electric power towers

ActiveCN111697492BAchieve winding fixationImprove securityApparatus for overhead lines/cablesElectric machineDrive motor

The invention relates to the technical field of a high-voltage line laying device and particularly relates to an electric power iron tower high-voltage line pre-tightening device. The high-voltage line pre-tightening device of an electric power iron tower comprises a vertical plate, wherein a cross beam plate is transversely welded at an upper end of the right side of the vertical plate, a throughhole penetrating left and right is formed in an upper end of the vertical plate, and an electric telescopic rod and a side support are vertically welded at upper and lower ends of the left side of the vertical plate. The high-voltage line laying device is advantaged in that winding and fixing of a high-voltage cable are achieved through cooperation of a driving motor and a pulley, so stretching and laying of the high-voltage cable are achieved through rotation of a motor, manual pulling is avoided, operation safety and convenience are greatly improved, and high-altitude operation is more convenient, three-stage pre-tightening is realized through motor driving, extension of a telescopic rod and stretching of a balancing weight, so adjustment of pre-tightening force is refined, the magnitude of the pre-tightening force on the high-voltage cable is convenient to control, excessive stretching is avoided, and a purpose of fine adjustment is realized.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

A kind of processing equipment and processing technology of micron-scale hexahedron of mold

ActiveCN112847045BTo achieve the purpose of fine-tuningStable structureGrinding machine componentsGrinding machinesMicron scaleProcess engineering

The invention discloses a processing equipment and a processing technology of a micron-level hexahedron of a mold, and aims to provide a processing equipment and a processing technology of a micron-level hexahedron of a mold capable of fine adjustment. It includes a machine base, an electric spindle and gaskets. The electric spindle is installed on the machine base and connected with the machine base. The output end of the electric spindle is provided with an output shaft and a flange assembly. Grinding wheel, the flange assembly is fixedly installed on the side wall of the electric spindle and is located between the fine grinding wheel and the machine base. A socket is formed between the flange assembly and the machine base, and the gasket is detachably installed in the socket . The beneficial effects of the present invention are: the fine-tuning of any angle can be carried out on the fine-grinding grinding wheel to adapt to different working conditions, and the purpose of fine-tuning can be achieved; the structure is stable, and the machining accuracy is guaranteed and improved; the machining data is closer to the theoretical data, After the product is injection molded, it will be more in line with the quality target.

Owner:宁波舜邦模具科技有限公司

A robot with fine-tuning mechanical arm, control method and device

ActiveCN106514604BTo achieve the purpose of fine-tuningAvoid collisionProgramme-controlled manipulatorEngineeringRobot control

The invention provides a robot with a fine adjustment mechanical arm and a control method and device. The robot comprises the mechanical arm, a control platform, wheels and a fine adjustment device. The fine adjustment device comprises a fine adjustment controller, a memory spring, a displacement sensor and a support. A heating device is arranged on the fine adjustment device. According to the robot, when it is detected by the displacement sensor that the distance between an imaging plate on the support and target equipment reaches the preset distance, the control platform of the robot controls the mechanical arm to stop moving, the electric heating device in the fine adjustment controller is controlled by the control platform to heat the memory spring, the memory spring slowly moves forwards so that the imaging plate can be made to advance slowly by the preset distance, the imaging plate can be closer to the target object and prevented from colliding with the target, and the fine adjustment purpose is achieved.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

Blade gap adjustment mechanism for plate shearing machine

InactiveCN105149680ATo achieve the purpose of fine-tuningSimple structureShearing machinesShearing machine accessoriesPush and pullMotor drive

The invention relates to a blade gap adjustment mechanism for a plate shearing machine. The blade gap adjustment mechanism comprises a speed reducing motor installed at one side of a rack, a lead screw connected with the output end of the speed reducing motor, and a lower blade base installed on the rack. The two ends of the lead screw are sleeved with nuts. Two fixed inclining blocks are fixedly installed at the lower end of the lower blade base. Each nut is sleeved with one inclining block. The inclining blocks make close contact with the fixed inclining blocks. The horizontal side faces of the inclining blocks are matched with supporting blocks installed on the rack. The blade gap adjustment mechanism is simple in structure; the speed reducing motor drives the lead screw, the lead screw pushes and pulls the nuts, the nuts drive the inclining blocks to move left and right, and the inclining blocks push the fixed inclining blocks to enable the lower blade base and a lower blade to move slightly; meanwhile, by means of the thrust effect of a compressing spring, it is ensured that the fixed inclining blocks and the inclining blocks keep a close contact state constantly, the purpose of fine adjustment of a gap between upper blade and lower blade cutting edges is achieved, adjustment is convenient, and the service life is long.

Owner:JIANGSU YAWEI MACHINE TOOL

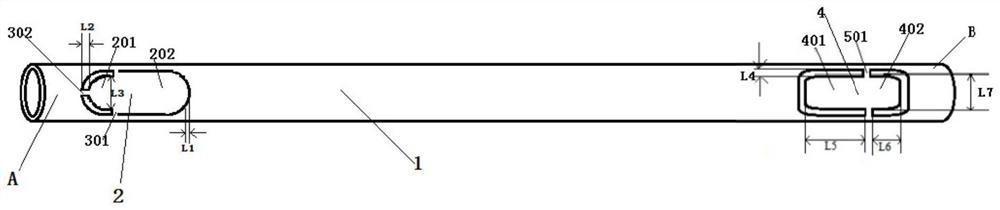

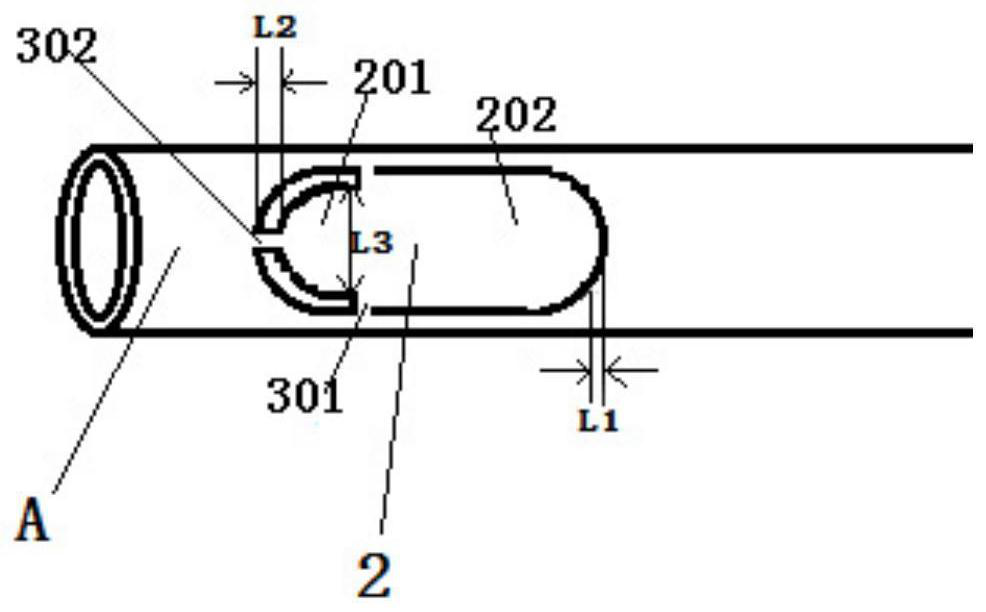

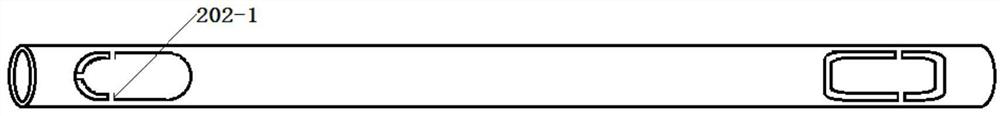

Casing round pipe and application and use method thereof

ActiveCN113662027AEasy to fixStable removalSausage casingsSausage filling/stuffing machinesStructural engineeringPipe

The invention relates to the field of casing processing, and provides a casing round pipe which comprises a round pipe body; arc-shaped pressing pieces are arranged on the two sides close to one end of the round pipe body respectively, and square pressing pieces are arranged on the two sides close to the other end of the round pipe body respectively; Each square pressing piece comprises a square pressing piece opening and closing end and a square pressing piece finger-pressing end, and the square pressing piece opening and closing end and the square pressing piece finger-pressing end are integrally connected; and the casing round pipe is mainly applied to casing supporting components. The casing round pipe has the design characteristics that the casing unloading function is focused, and the casing round pipe also has the characteristic that casing loading is smoother.

Owner:SHANGHAI LINZHI RUBBER & PLASTIC PRODS

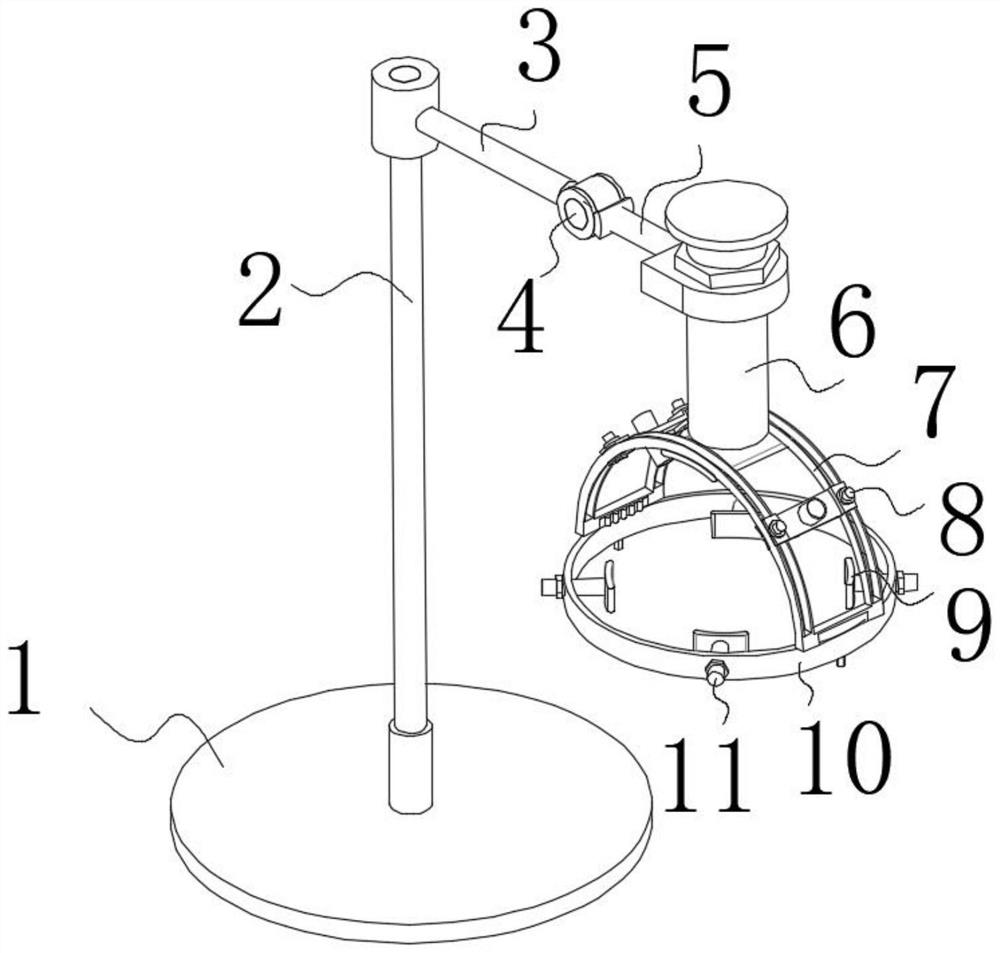

Improved cranium drilling device for neurosurgery operation

InactiveCN114795377AGuaranteed adjustabilityHeight adjustableDiagnosticsInstruments for stereotaxic surgeryEngineeringMechanical engineering

The invention relates to the field of neurosurgical operations, in particular to an improved cranium drilling device for neurosurgical operations, which comprises a chassis, a supporting rod is movably connected to the top of the chassis, a steering rod is arranged at the top of the supporting rod, the top of the supporting rod is movably connected with the left end of the steering rod, and a rotating column is arranged at the right end of the steering rod. The right end of the steering rod is movably connected with the outer surface of the rotating column, a positioning rod is arranged on the outer surface of the rotating column, the outer surface of the rotating column is movably connected with the left end of the positioning rod, a clamping device is arranged in the positioning rod, and the inner wall of the positioning rod is movably connected with the top of the clamping device; according to the improved cranium drilling device for the neurosurgery operation, the problems that in the punching process, bone scraps and the like generated on the head of a patient need to be treated in real time, the bone scraps and the like need to be limited, the cleaning area of the bone scraps and the like needs to be reduced, and the workload and the working difficulty of later cleaning work are reduced are solved.

Owner:PEOPLES HOSPITAL OF HENAN PROV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com