Novel camera lens assembly and projector

A lens assembly and a new type of technology, applied in the field of projectors, can solve the problems that the lens is difficult to replace quickly and cannot be well applied to new projectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

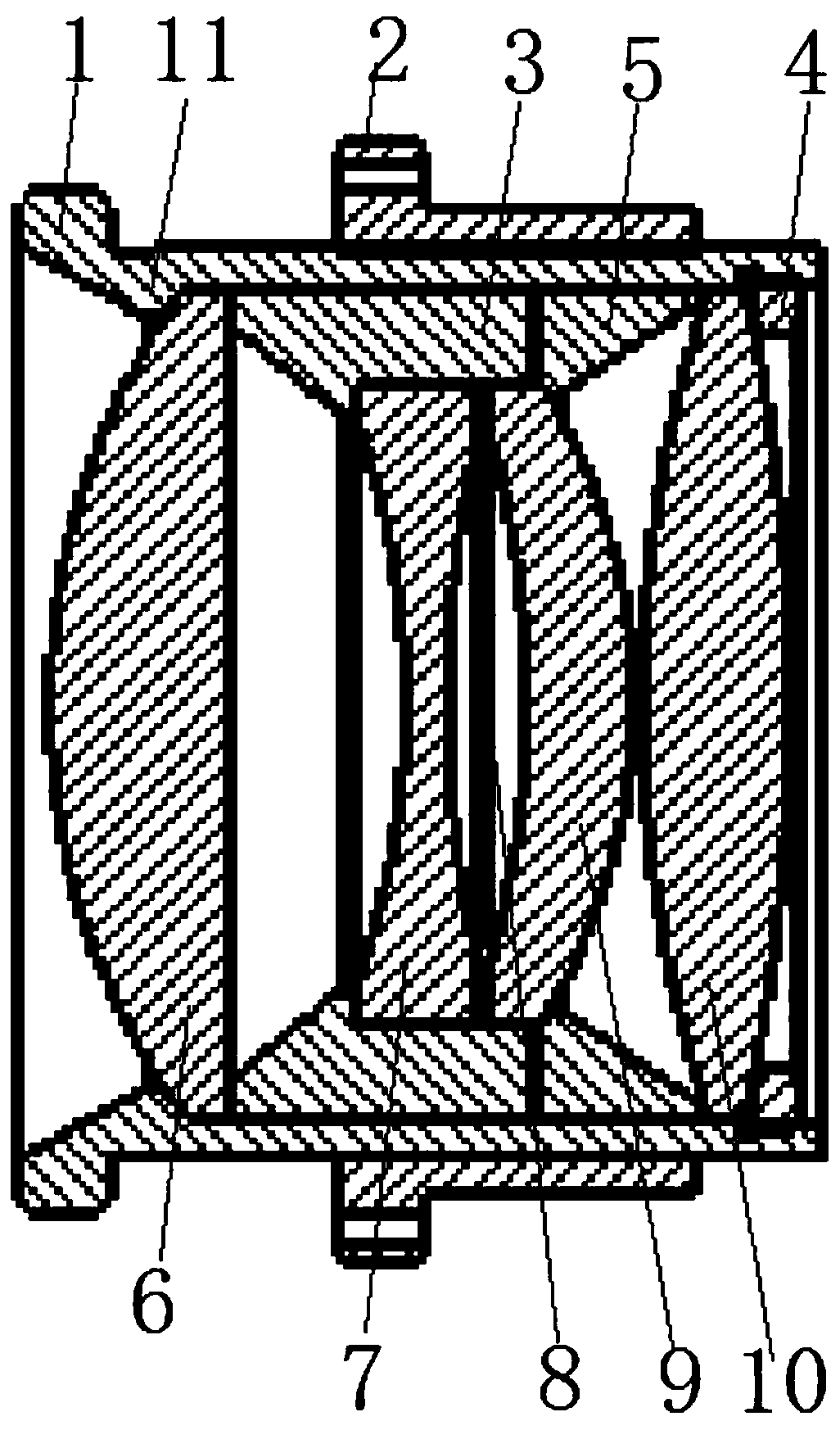

[0025] like figure 1 As shown, the present invention firstly provides a new type of lens assembly, including a lens cover 1 , an adjustment cover 2 , a lens cover 3 and a locking ring 4 . Wherein, the above-mentioned lens case 1 is in the shape of a cylinder, the lens case 3 and the locking ring 4 are sequentially arranged in the lens case 1 from front to back, and the outer wall of the lens case 3 is matched with the inner wall of the lens case 1 so that the lens case 3 It can move smoothly, and the outer wall of the locking ring 4 is threadedly connected with the inner wall of the lens case 1 .

[0026] The front end of the inner wall of the lens case 1 is provided with a limiting convex ring 11, which is integrally formed on the inner wall of the lens case 1, and the limiting convex ring 11 is used to prevent the lens from falling off from the front end of the lens case 1. The front end and / or the rear end of the inner wall of the lens case 3 are provided with lens steps f...

Embodiment 2

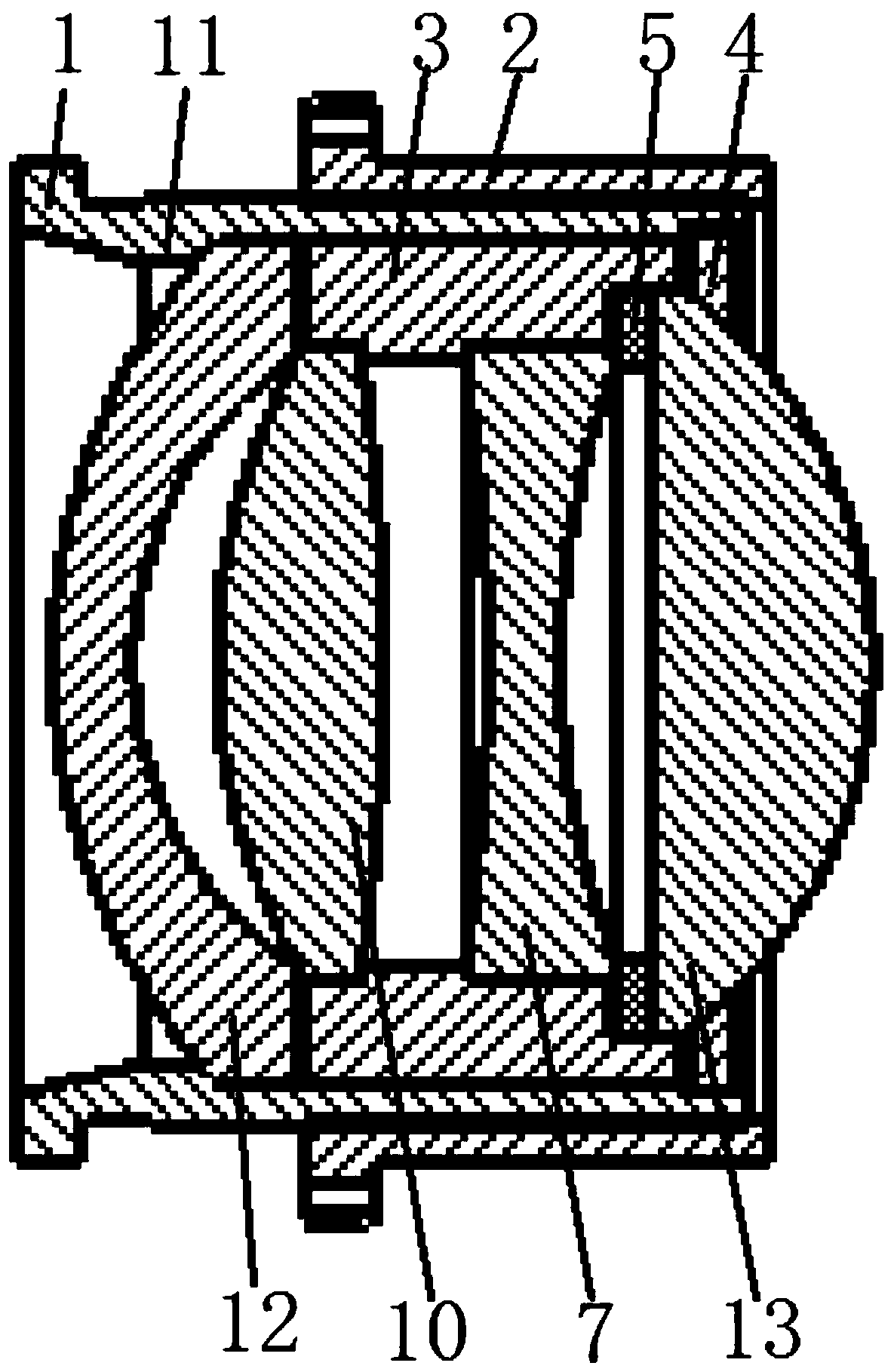

[0032] It differs from Embodiment 1 in that: as figure 2 As shown, in this embodiment, a convex-concave mirror 12 is pressed between the limiting convex ring 11 and the lens cover 3 , and the convex-concave mirror 12 refers to a lens with a convex front end and a concave rear end. And in the present embodiment, the front end and the rear end of the inner wall of the lens cover 3 all have the above-mentioned lens steps, and what is arranged on the lens steps at the front end of the inner wall of the lens cover 3 is a biconvex mirror 10, which is arranged behind the inner wall of the lens cover 3 It is double concave mirror 7 that is installed on the eyeglass step at the end. And what press-fit between the lens pressure ring 3 and the locking ring 4 is a plano-convex mirror 13 . Specifically in this embodiment, the rear end of the inner wall of the lens cover 3 is also provided with a lens pressure ring installation step, the diameter of the lens pressure ring installation ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com