Blade gap adjustment mechanism for plate shearing machine

The technology of a gap adjustment mechanism and a shearing machine is applied in the direction of shearing equipment, shearing devices, and attachments of shearing machines. It can solve the problems of inaccuracy and low safety, and achieve long service life, convenient adjustment, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

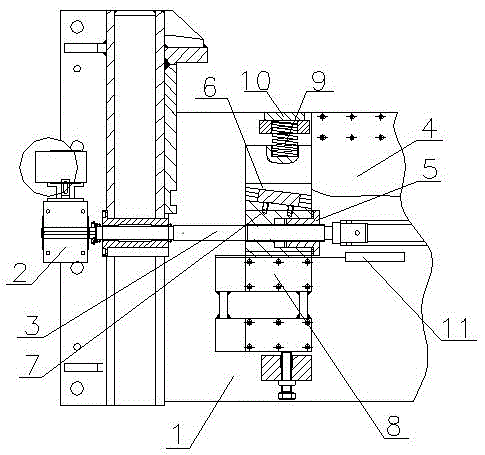

[0013] A shearing machine blade gap adjustment mechanism, comprising a reduction motor 2 installed on one side of a frame 1, a screw rod 3 connected to the output end of the reduction motor 2, and a lower knife seat 4 installed on the frame 1, the Two ends of the screw rod 3 are covered with nuts 5, and the lower end of the lower tool holder 4 is fixedly equipped with two fixed slanting blocks 6, and each of the nuts 5 is respectively covered with a slanting block 7, and the slanting block 7 is connected with the fixed slanting block. 6 in close contact, the horizontal side of the inclined block 7 is matched with the support block 8 installed on the frame 1; the horizontal side of the fixed inclined block 6 is equipped with a compression spring 9, and the other side of the compression spring 9 One end is against the baffle plate 10 fixedly installed on the frame 1 ; a linear displacement sensor 11 is installed on the frame 1 , and the contact of the linear displacement sensor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com