Pipeline jointing device

A counterpart and pipeline technology, applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of affecting the accuracy of pipeline alignment, cumbersome use, and deformation of the winding structure, so as to be easy to carry and assemble, and improve The effect of improving work efficiency and improving the matching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

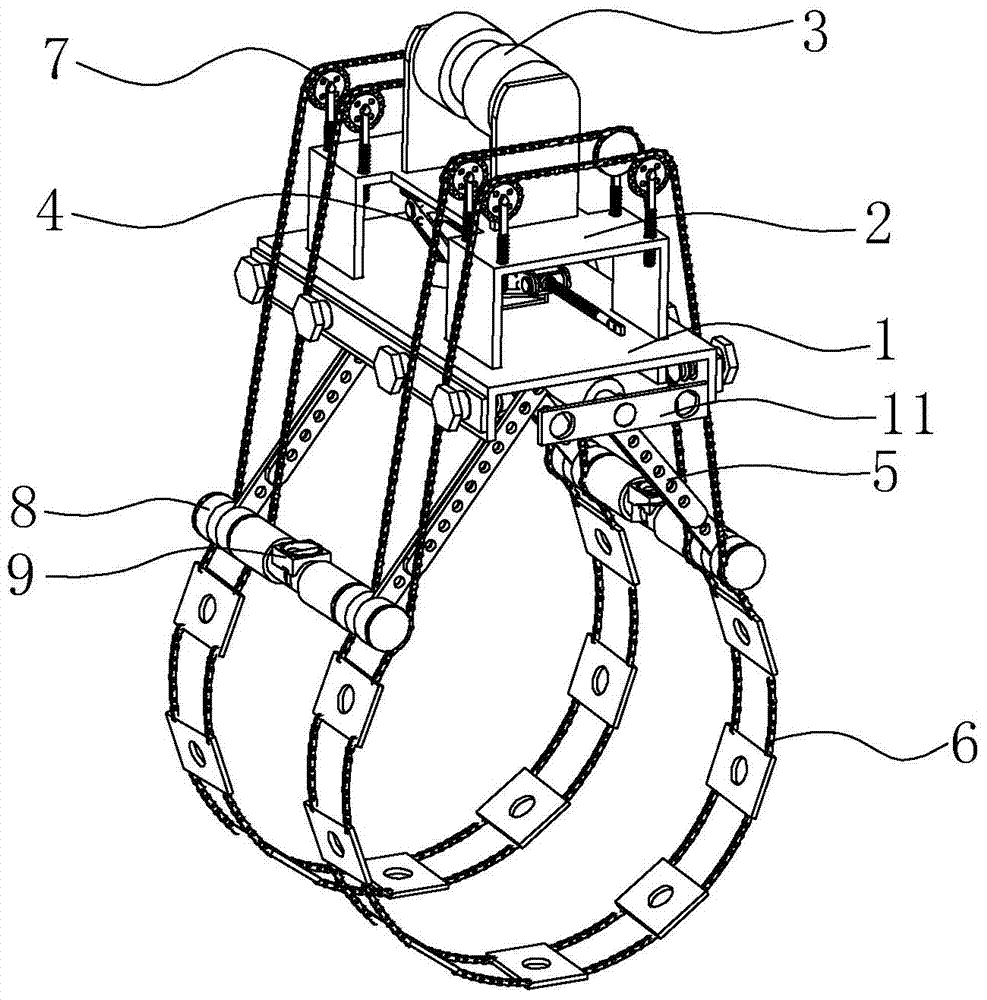

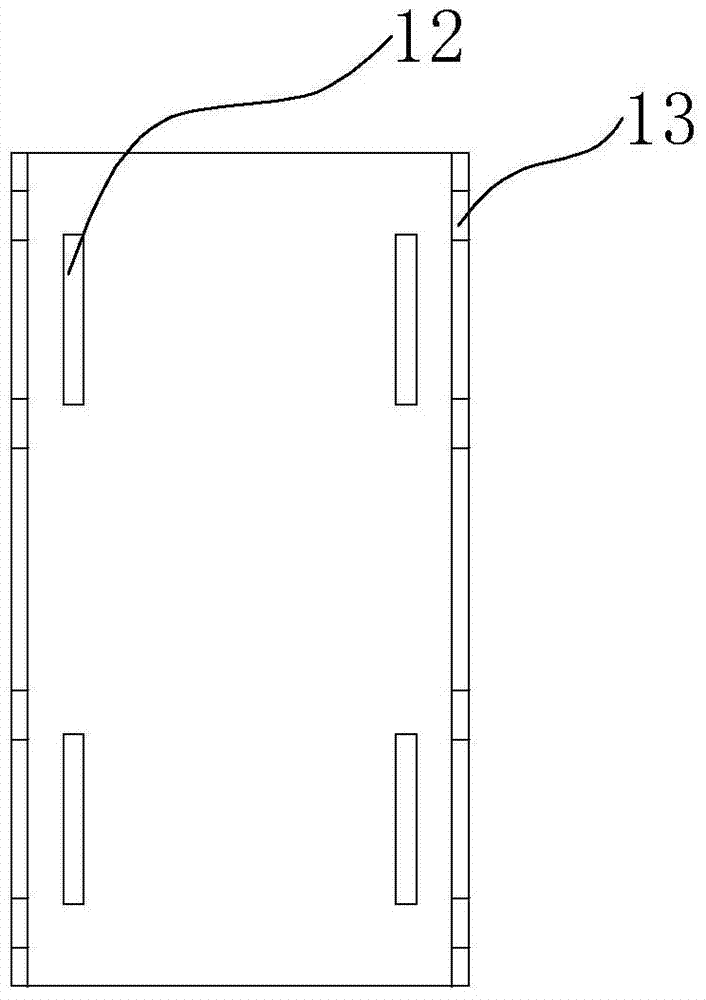

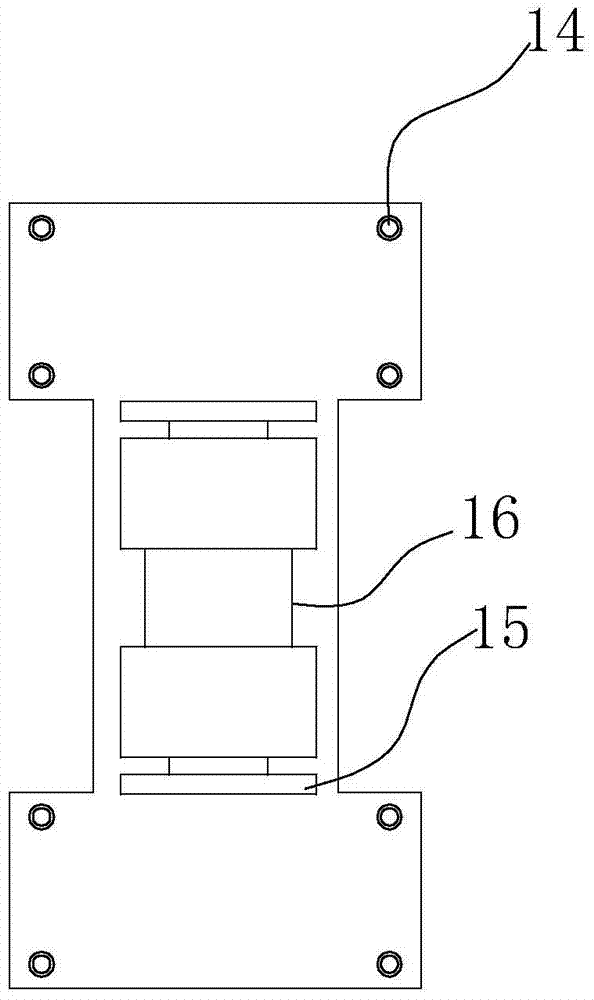

[0025] Embodiment 1: a kind of pipe counterpart, such as figure 1 As shown, it includes a main frame, an upper parallel roller 3, a lifting mechanism 4, a leg 5, a lower parallel roller 8, a chain plate structure 6 and a chain plate adjustment mechanism 7, wherein the main frame includes a main board 1 and a The top plate 2 above the main board 1 and connected to the main board 1, the main board 1 is as figure 2 As shown, the top board 2 is inserted into the main board 1 through the connecting hole 12 between the main board and the top board to realize the connection between the top board 2 and the main board 1; the top board 2 is connected with an upper parallel roller 3, as image 3 As shown, the upper parallel roller 3 includes an upper parallel roller support plate 15 and an upper parallel roller groove 16; the lifting mechanism 4 is located between the top plate 2 and the main board 1, as Figure 4 As shown, the above-mentioned lifting mechanism 4 includes a pivot 17 an...

Embodiment 2

[0026] Embodiment 2: as Figure 1-10 As shown, the present invention adjusts the supporting leg 5 to a suitable angle during the use of the external mouthpiece, and sets the chain plate structure 6 on the pipeline to be matched; the chain 30 is placed on the second guide on the lower side of the supporting leg 5 In the chain groove 53 and the first chain guide groove 20 of the chain plate adjustment mechanism 7, the weld seam distance adjustment pin 35 is inserted into the butt welding seam; the nut 32 is turned to make the chain plate adjustment mechanism 7 move up and down, changing the direction of the chain 30 To the proper position, turn the operating lever 18 so that the pivot 17 rotates accordingly and drives the top plate 2 and the chain plate adjustment mechanism 7 to move up and down, tighten the chain plate structure 6, and complete the preliminary alignment of the pipeline; after completing the above operations, check the weld seam For the reserved amount, adjust t...

Embodiment 3

[0027] Embodiment 3: as Figure 1-10 Shown, the present invention can be combined the various forms of welding mouth group that the external mouthpiece can't finish in the process of using as the inner mouthpiece. Adjust the length and angle of the legs 5, put the counterpart into the pipe; turn the operating lever 18 to make the pivot 17 rotate accordingly and drive the top plate 2 and the upper parallel roller 3 to move, so that the upper parallel roller 3 and the lower parallel roller The shaft 8 fits closely with the inner wall of the pipe to realize fast alignment.

[0028] Due to the relatively high requirements for the levelness of the flange surface, the levelness of the flange surface is related to the effect of the flange connection. In order to make the combination effect better, the present invention provides a flange surface inspection and adjustment structure 11 . When checking and adjusting the flange surface, extract the telescopic joint 42 and the detection a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com