Nonuniform controllable cavity rotary sealing structure

A rotary-sealed, non-uniform technology used in non-variable-capacity pumps, leakage prevention, components of pumping devices for elastic fluids, etc., can solve the problem of fine control, neglect of effective stiffness, overall effective damping of shafting and The effective stiffness deviates from the stable operating range, etc., to achieve good sealing performance, improve operating efficiency and shaft stability, and enhance stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and technical principles.

[0042] Concrete structure of the present invention is referring to accompanying drawing, and design train of thought is as follows:

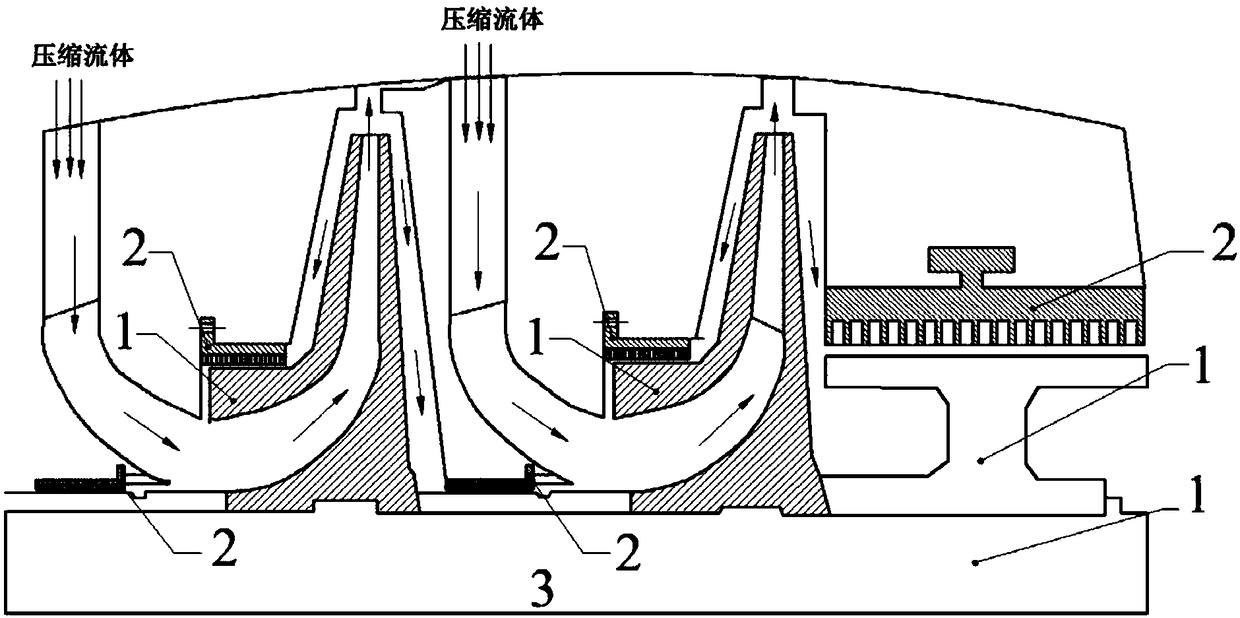

[0043] see figure 1 , the present invention provides a non-uniform controllable cavity rotary seal structure, the rotary seal stator 2 can replace the traditional seal structure installed in the shaft end, blade top, diaphragm and interstage, etc., to enhance the stability of the shaft system. For the convenience of processing and installation, the sealing stator parts can be processed into 2-6 pieces of equal arc. The sealed stator part 2 and the rotating part 1 form a leakage channel of the working fluid.

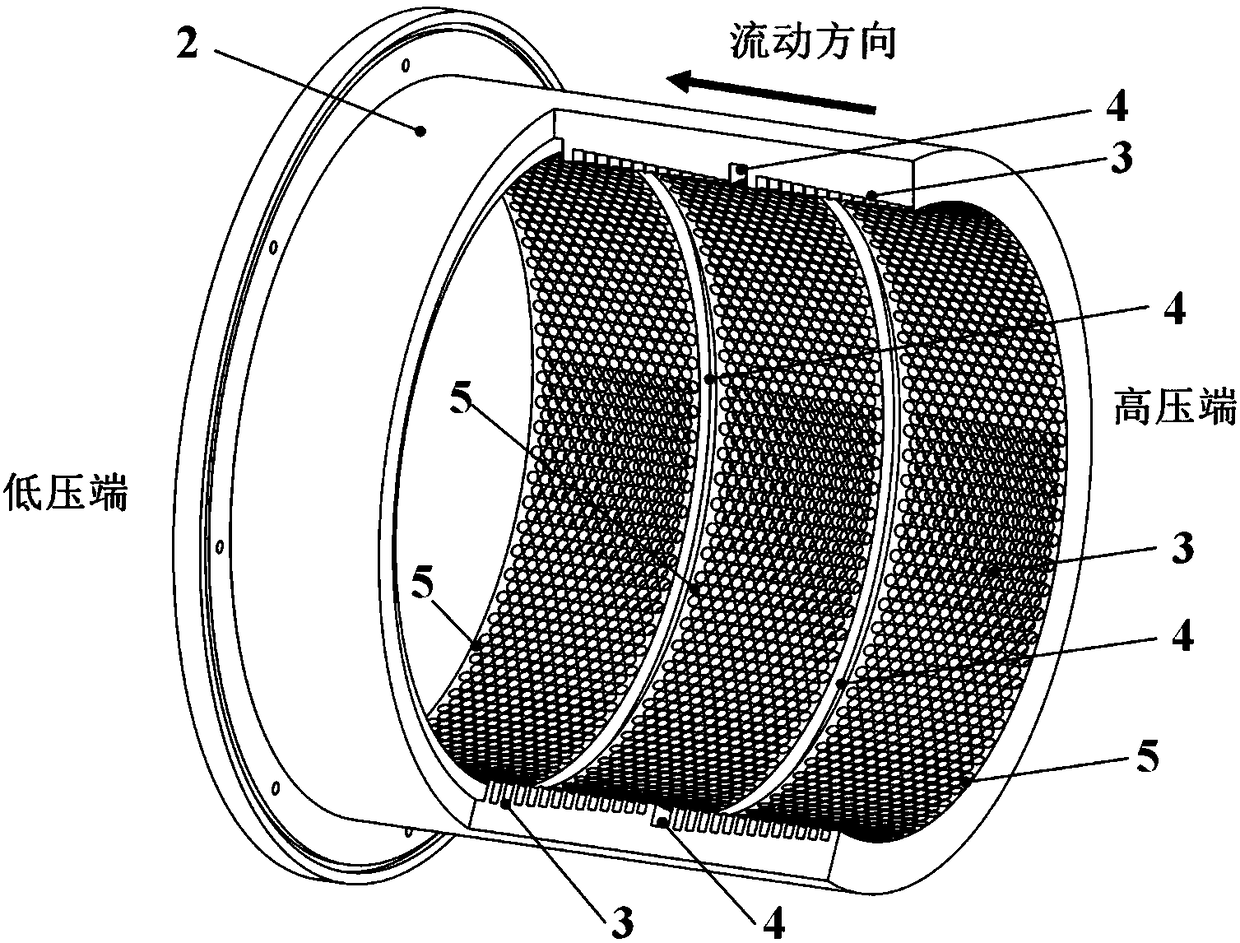

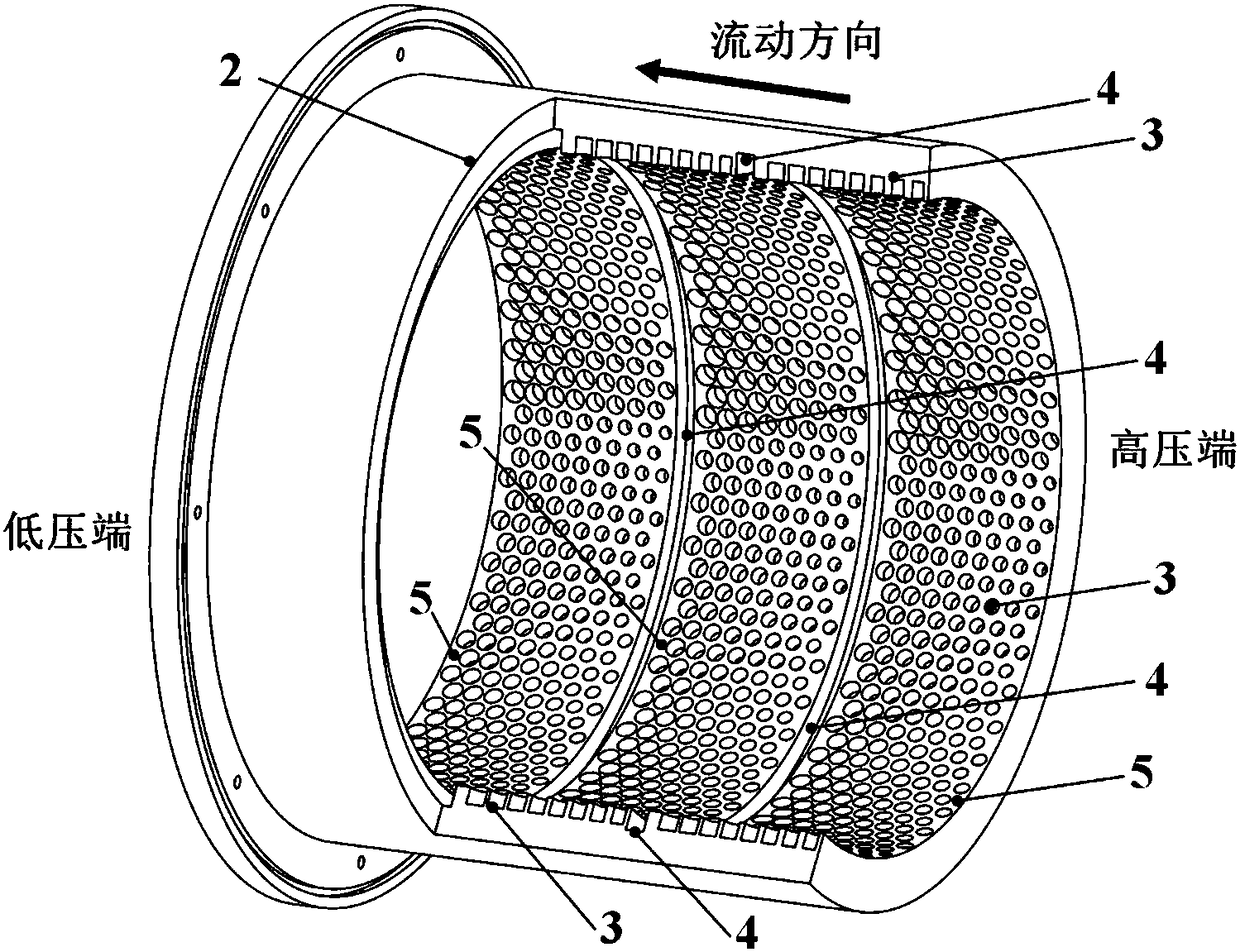

[0044] see Figure 2a to Figure 2d , On the inner surface 5 of the sealing stator part of the rotary sealing structure of the present invention, a hole-type sealing cavity structure 3 and an ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com