Centring micro-setting device for heavy equipment installation

A technology of heavy equipment and centering device, applied in the direction of workbench, manufacturing tools, etc., can solve the problems of time-consuming and laborious, increasing the difficulty of centering operation, and high technical requirements of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

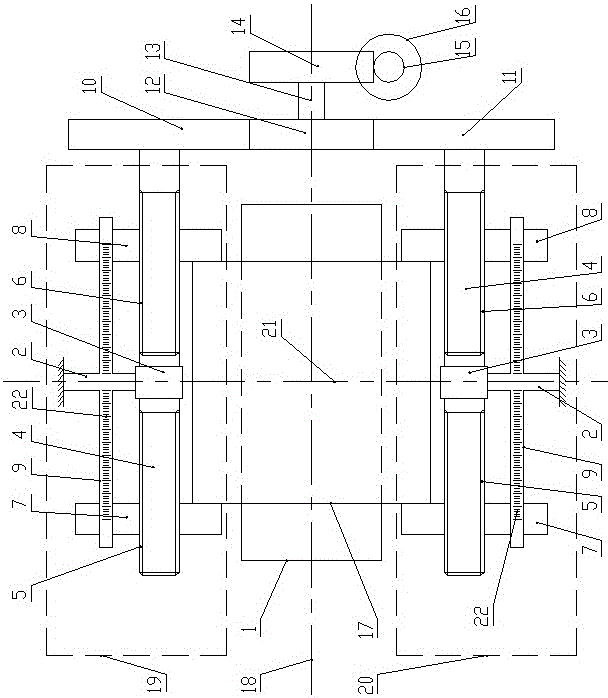

[0014] In the present invention, the figure 1 The direction to the left in the center is the left direction, with figure 1 The upward direction is the forward direction.

[0015] Such as figure 1 As shown, the heavy equipment installation centering fine-tuning device of the present invention includes a workbench 1, and two sets of centering devices are arranged symmetrically on the front and rear sides of the workbench 1 with respect to the central axis 18 of the workbench 1 along the left and right horizontal directions, respectively Before the centering device 19 and the rear centering device 20, the front centering device 19 and the rear centering device 20 have the same structure, and the front centering device 19 includes a central support 2 arranged in the front and rear horizontal directions, and the rear end of the central support 2 is fixedly connected with Sleeve 3, the axis of sleeve 3 is arranged horizontally and extends along the left and right direction, sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com