Mopping machine base station for preventing mopping cloth of mopping robot from mildewing and using method thereof

A mopping robot and machine base station technology, applied in machine parts, manual floor scrubbing machinery, applications, etc., can solve problems such as poor effect, manual intervention in adding chemical agents, affecting the home environment and air, etc., to avoid mildew change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

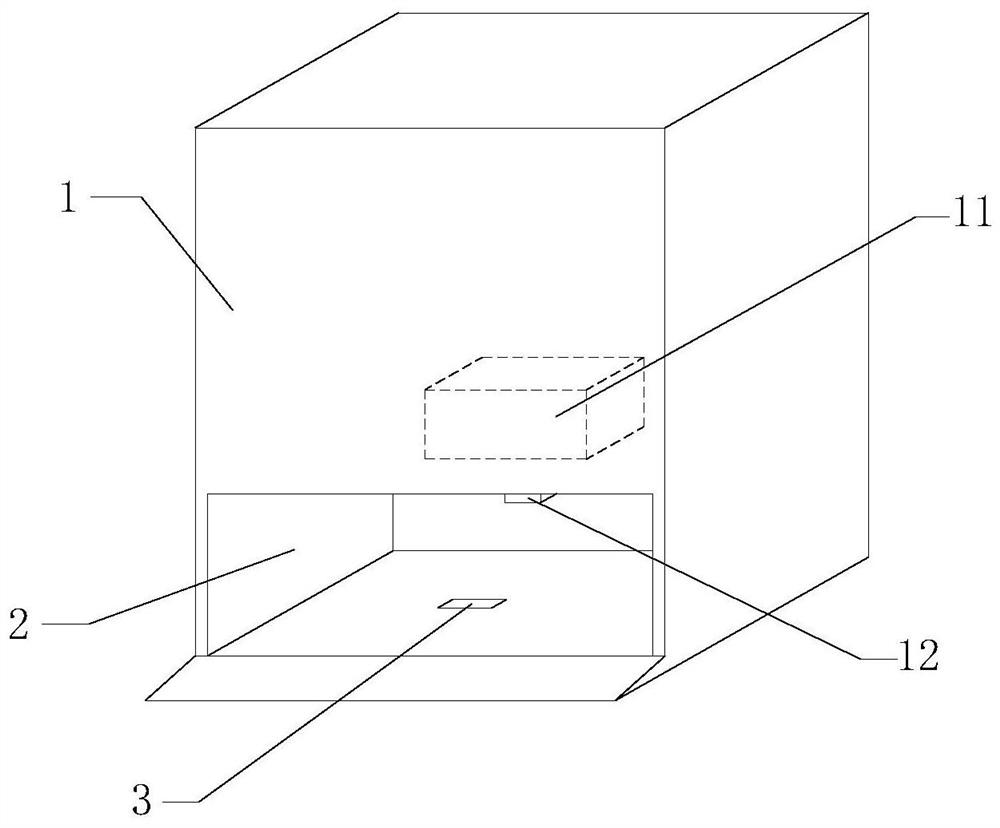

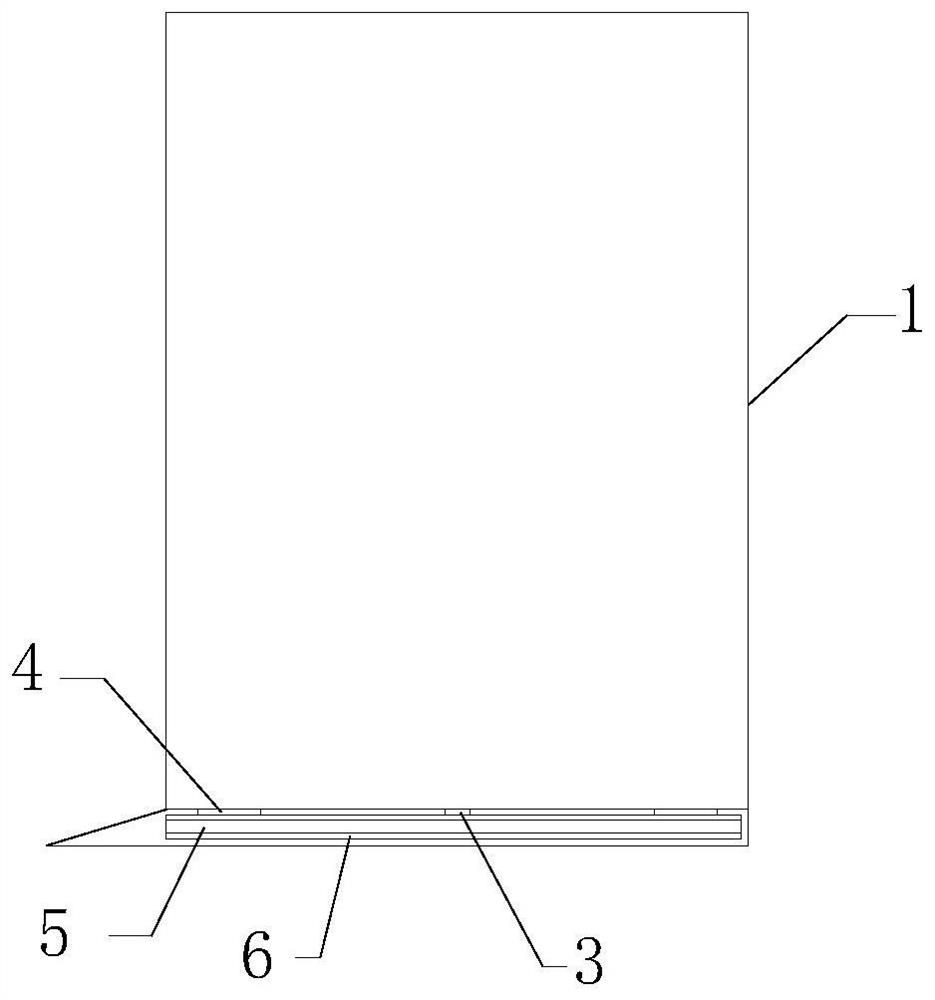

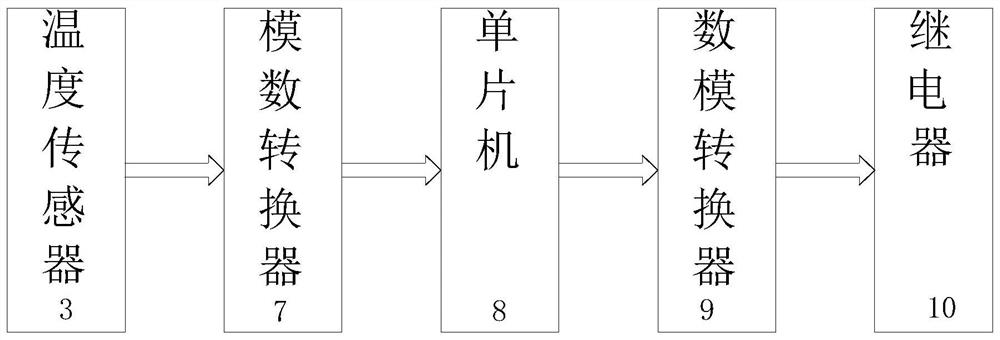

[0028] see Figure 1-Figure 3 , a mopping machine base station for preventing the mopping robot mopping cloth from becoming moldy, comprising a mopping machine base body 1, a heating plate 5 and a temperature sensor 3, and a mopping machine cleaning machine is provided near the bottom of the mopping machine base body 1 Cavity 2, a cavity is provided at the bottom of the mopping machine base body 1, the heating plate 5 is arranged inside the cavity, and the temperature sensor 3 is embedded in the bottom of the mopping machine cleaning chamber 2 of the mopping machine base body 1.

[0029] As an improved solution to the above solution, a heat conduction sheet 4 is also included, and the contact surface between the cavity 6 and the cleaning chamber 2 of the mopping machine is provided with a heat conduction sheet 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com