A stacking device for a plate production line

A production line and plate technology, which is applied in the direction of object stacking, transportation and packaging, roller tables, etc., can solve the problems of low stacking efficiency, inability to fix and limit, and plate damage, etc., to achieve enhanced stacking efficiency, simple stacking, and guaranteed The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

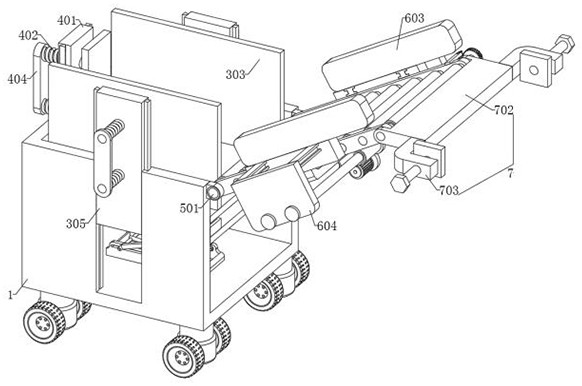

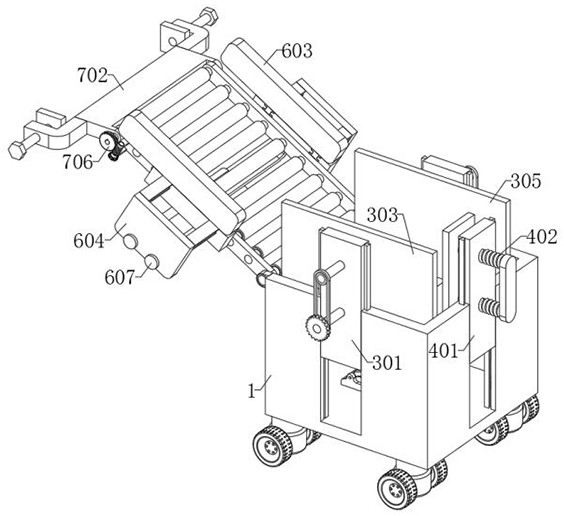

[0033] Embodiment one: as attached figure 1To attach Figure 8 As shown: the present invention provides a stacking device for a plate production line, including a device main body 1; the device main body 1 includes: a fixed plate 101, a lifting rod A102, a lifting rod B103, a connecting plate 104 and a connecting rod 105, and the fixing plate 101 is fixedly arranged At the bottom of the inner side of the device main body 1; the lifting rod A102 is rotatably set on the top of the fixed plate 101; the bottom of the lifting rod B103 is rotatably set with a shaft, and the shaft is slidably set on the top of the fixed plate 101; the lifting rod B103 and the lifting rod A102 are rotatably connected , and a hydraulic rod is set between the shaft at the bottom of the lifting rod B103 and the fixed plate 101; the connecting plate 104 is rotatably set on the top of the lifting rod B103; the connecting rod 105 is rotatably set on the top of the lifting rod A102, and the connecting rod 10...

Embodiment 2

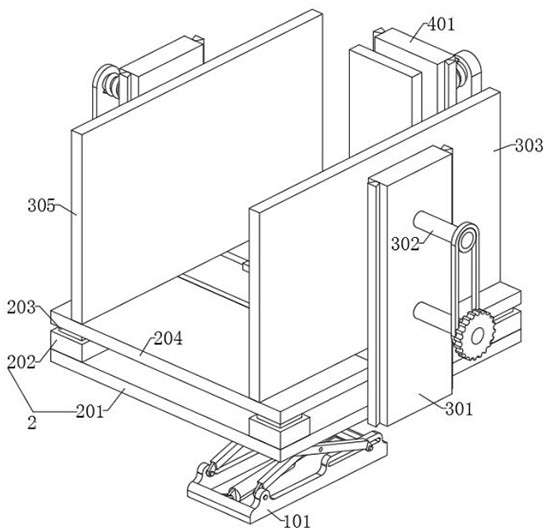

[0038] Embodiment two: as attached figure 2 As shown, on the basis of Embodiment 1, other structures remain unchanged. In this embodiment, the load-bearing mechanism 2 includes: a load-bearing plate 201, a load-bearing column 202, a connecting column 203 and a bottom plate 204, and the load-bearing plate 201 is fixedly arranged on the top of the connecting plate 104. The load-bearing column 202 is fixedly arranged on the top of the load-bearing plate 201, and the interior of the load-bearing column 202 is set as a hollow structure; the number of the load-bearing column 202 is set to four groups; Spring parts are arranged inside; the bottom plate 204 is fixedly arranged on the top of the connecting column 203; by setting the load-bearing column 202, the connecting column 203 and the spring parts, the effect of buffering the board is realized, and the damage to the board is prevented when the board is lowered role.

Embodiment 3

[0039] Embodiment three: as attached Figure 11 As shown, on the basis of Embodiment 1, other structures remain unchanged. In this embodiment, the fixing frame 301 is fixedly arranged on both sides of the bottom of the bearing plate 201, and the fixing frame 301 is slidably arranged inside the device main body 1 through the dovetail groove; the fixing frame The number of 301 is set to two groups; the threaded rod 302 is arranged inside the fixed frame 301 through threaded connection, and the rear end of the threaded rod 302 is fixedly provided with a strut, and the strut is in an L-shaped structure; the outer side of the strut is equipped with a bearing, and the bearing A thin plate is installed on the outside; a bearing is installed inside the side plate A303, and the inner side of the bearing is installed on the front end of the threaded rod 302; by being provided with a thin plate and a pole, the effect of making the two sets of threaded rods 302 rotate at the same time is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com