Three-layer cantilever steel structure fast to build and capable of saving land and construction method thereof

A steel structure and overhanging technology, which is applied in the direction of building components, structural elements, building structures, etc., can solve the problems that the suspension cable structure is not suitable for hanging loads, rust, and easy to accumulate dust, so as to expand the usable building area and simplify Simple effect of transmission path and internal force analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

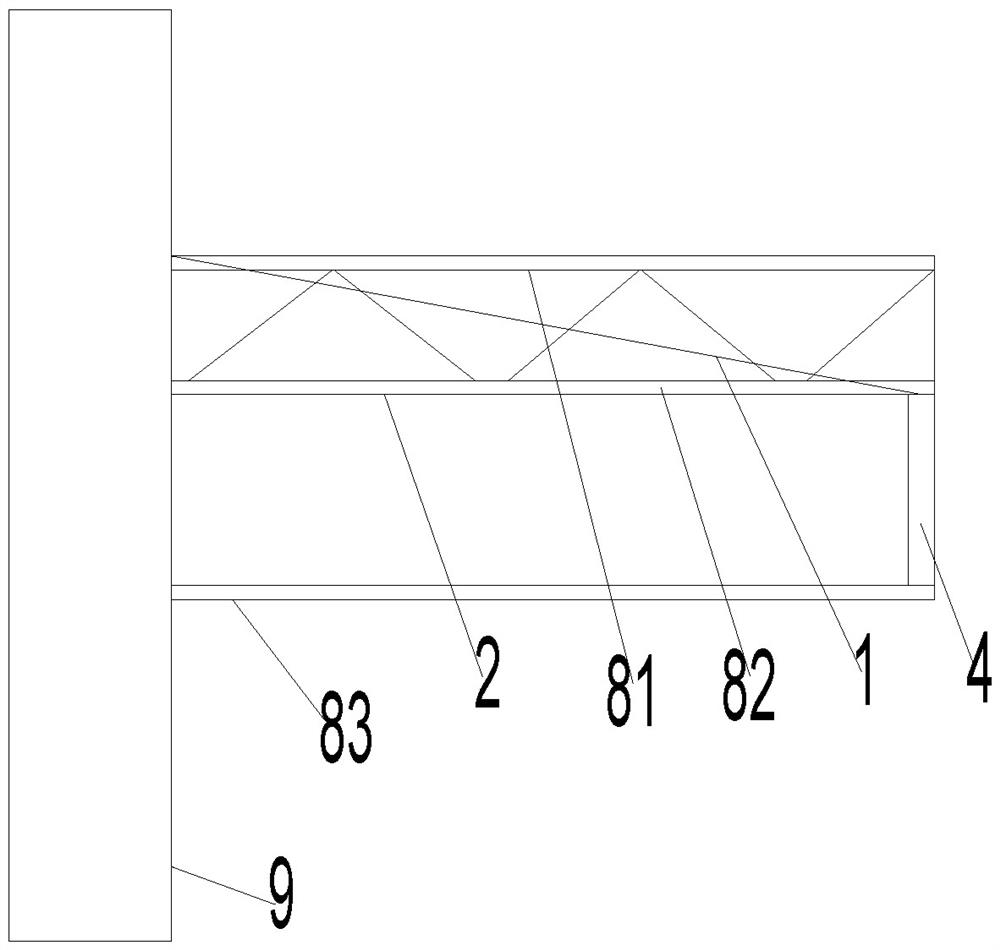

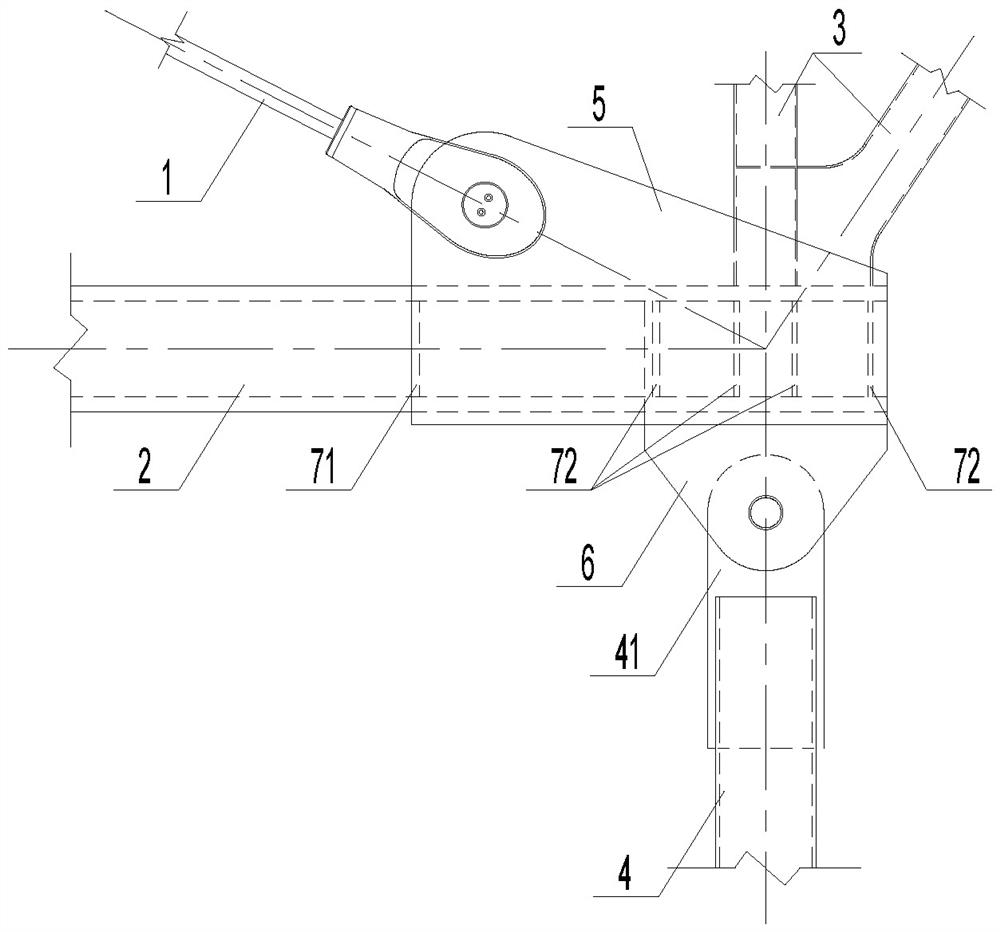

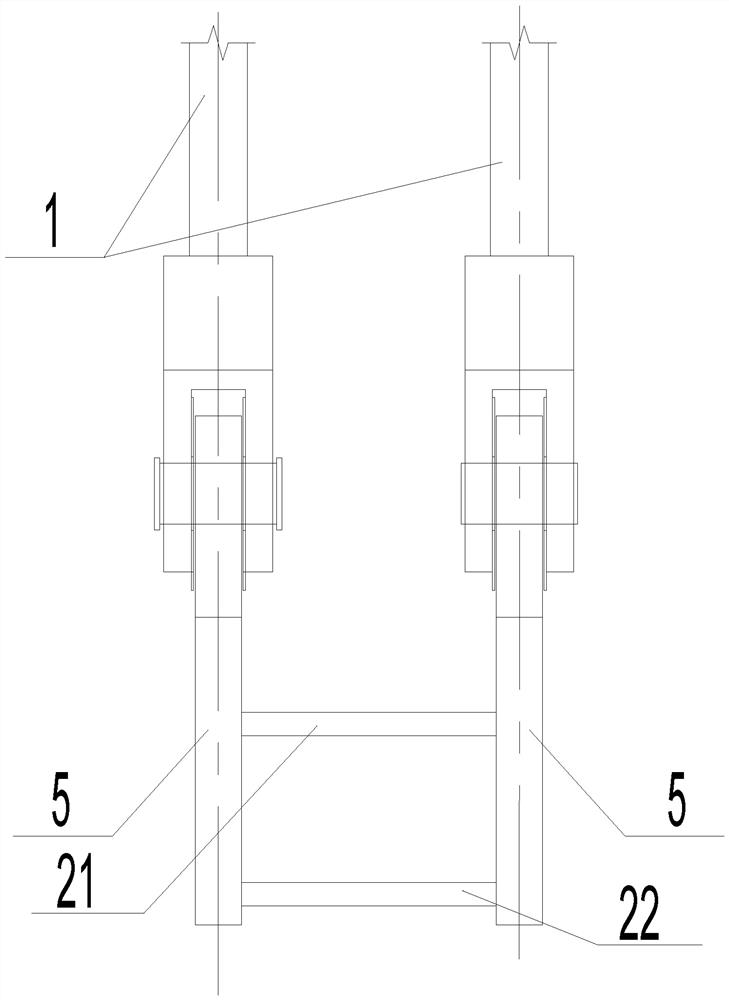

[0046] like Figure 1-2 As shown, a three-story cantilevered steel structure that is built quickly and saves land includes a plurality of cross-story trusses that are anchored on the vertical installation foundation 9 at one end and cantilevered outward at the other end; The top bearing floor 81 on the upper chord, the bottom floor 82 laid on the lower chord of the cross-story truss, the hanging floor 83 suspended under the cross-story truss through the suspender 4, and the lower end connected to the cross-story truss and the upper end is inclined Upwards is connected to the stay cable 1 on the vertical installation foundation 9. In this embodiment, the vertical installation base 9 is a column, and the upper end of the cable 1 is connected to the position where the upper chord of the cross-story truss is connected to the column.

[0047] The vertical installation foundation 9 here can be a column or a wall, but it should be noted that the vertical installation foundation 9 he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com