Original bamboo column assembly, original bamboo truss beam-original bamboo column connection node and construction method

A technology for connecting nodes and truss beams, which is applied in the direction of truss beams, truss structures, columns, etc., can solve the problems that cannot meet the requirements of modern structures, are prone to damage, and the reliability of connection methods is weak.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

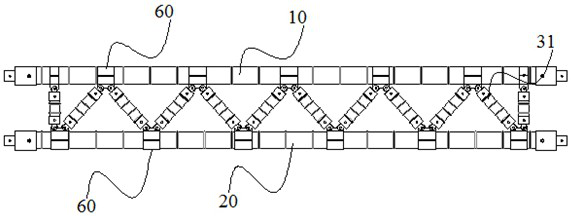

[0068] An assembled original bamboo truss beam 700 includes: a first chord 10 and a second chord 20 arranged in parallel, the first chord 10 and the second chord 20 are made of original bamboo and both are Extending in one direction; the web bar 30 used to connect the first chord 10 and the second chord 20, the web bar 30 is made of raw bamboo and located on the first chord 10 and the second chord 20 between.

[0069] in:

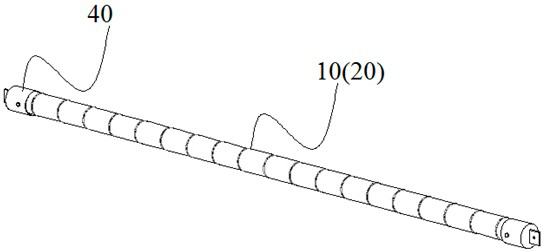

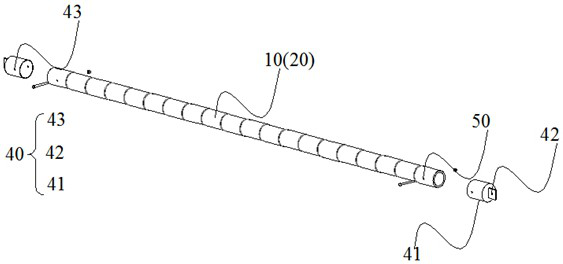

[0070] like figure 1 As shown, the first chord 10 extends along the first direction, the material of the first chord 10 is original bamboo, preferably, the material of the first chord 10 is 3-4 years old, with an average diameter of 105 Moso bamboo poles between -135mm and treated with anti-mildew, insect-proof and crack-proof. The first direction is the horizontal direction, wherein the anti-mildew, insect-proof, and crack-proof treatment methods can use the existing treatment technology, which will not be repeated here.

[0071] Specifically, as fig...

Embodiment 2

[0092] An original bamboo column assembly, comprising:

[0093] The node column 100, the node column 100 extends along the first direction, the side wall of the node column 100 is provided with first fixing members 101 evenly distributed along the circumferential direction, and the first fixing member 101 is away from the node column 100. A first gap 102 extending along the first direction is formed at one end of the ;

[0094] a connecting sleeve 200, one end of the connecting sleeve 200 is connected with both ends of the node column 100, and one end of the connecting sleeve 200 away from the node column 100 has an opening;

[0095] The original bamboo column 300 includes: at least one original bamboo pole, the original bamboo pole extends along the first direction, one end of the original bamboo pole enters the opening, and is fixedly connected with the connecting sleeve 200 .

[0096] Wherein: the node column 100 is a steel structure, preferably, it can be a square steel p...

Embodiment 3

[0101] Please refer to Figure 14 , a connection node of a prefabricated original bamboo truss beam and an original bamboo column, comprising: the original bamboo column assembly as described in the second embodiment; and the original bamboo truss beam as described in the first embodiment, on the original bamboo truss A third connecting piece located at one end of the first chord and the second chord can enter the first gap and be fixedly connected with the first fixing piece. Optionally, the third connecting member and the first fixing member are fixedly connected by bolts.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap