Insulation installation method for top rolling stopping support of B-type independent liquid cargo tank

An installation method and technology for liquid cargo tanks, which are applied in the directions of bulk cargo, transportation and packaging, load handling devices, etc., can solve problems such as hidden safety hazards, damage, and difficulty in installing insulating blocks, and achieve the effect of avoiding heat leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention is further described below in conjunction with specific embodiments:

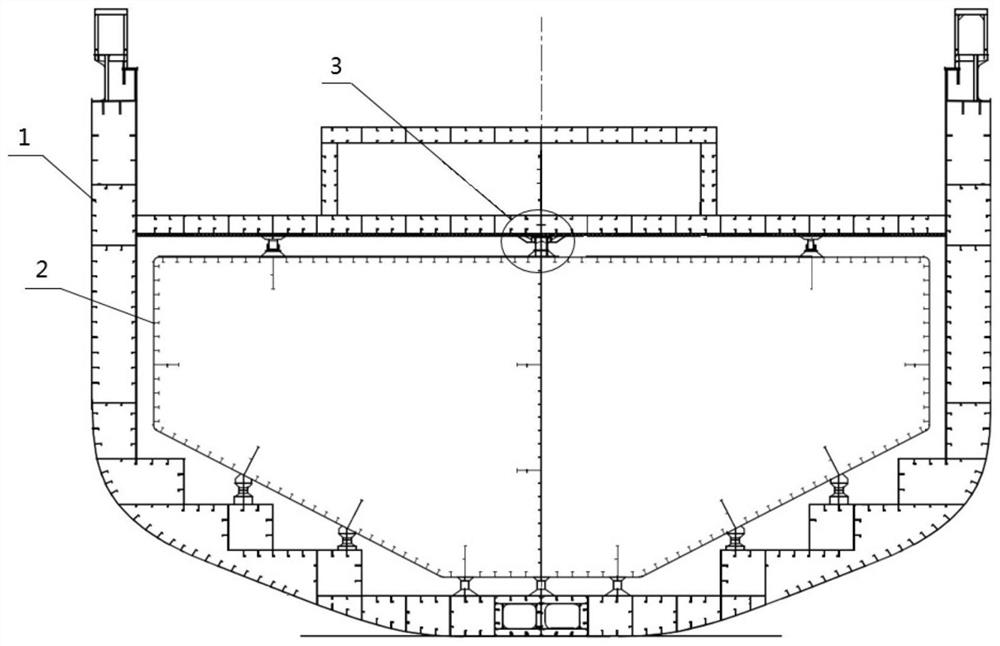

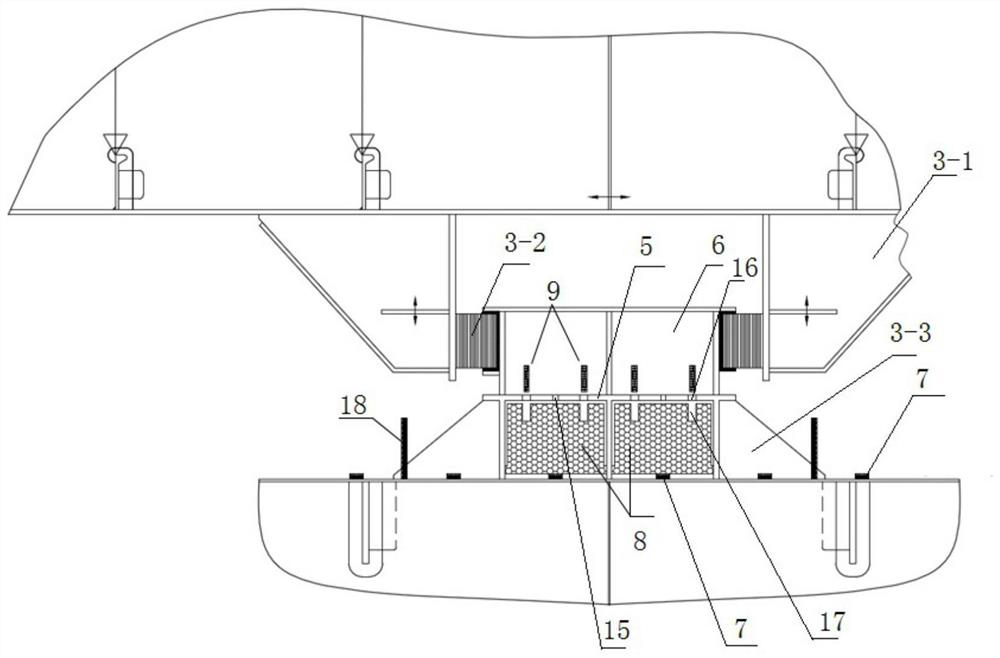

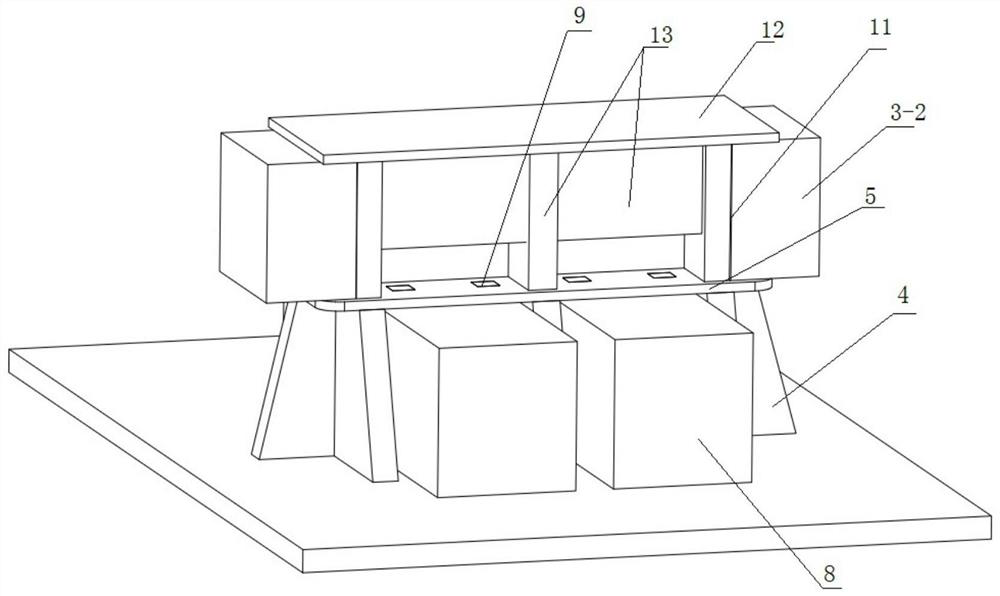

[0033] An insulating installation method for the top anti-sway support of the B-type independent liquid cargo tank, which is used for the insulation installation of the top anti-sway support of the B-type independent liquid cargo tank. The seat 3 is installed at the middle position of the top of the Type B independent liquid cargo tank 2, and plays the role of limiting the lateral displacement of the Type B independent liquid cargo tank 2. The anti-rolling support 3 on the top of the B-type tank includes the upper hull anti-rolling support 3-1, laminated wood 3-2, the lower liquid cargo tank anti-rolling support 3-3, and the lower liquid cargo tank anti-rolling support 3 -3 is installed on the top of Type B independent liquid cargo tank 2, laminated wood 3-2 is fixed on both sides of the anti-rolling support 3-3 of the lower liquid cargo tank near the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com