Guide mechanism for ensuring linearity of steel wire entering die

A guiding mechanism and linear technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of lower pass rate, uneven deformation of steel wire, scraping and copper removal, etc., to ensure concentricity , Eliminate scratching and copper removal, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

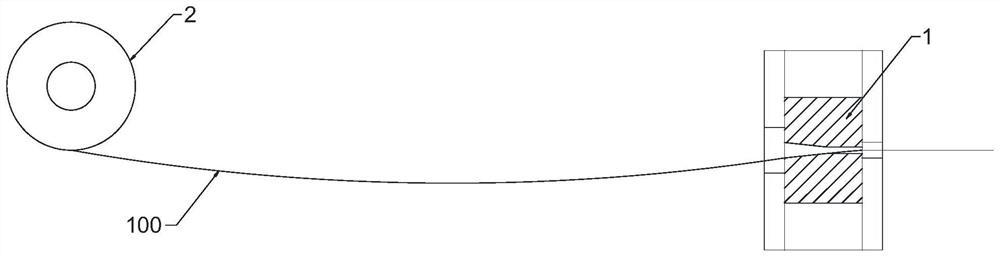

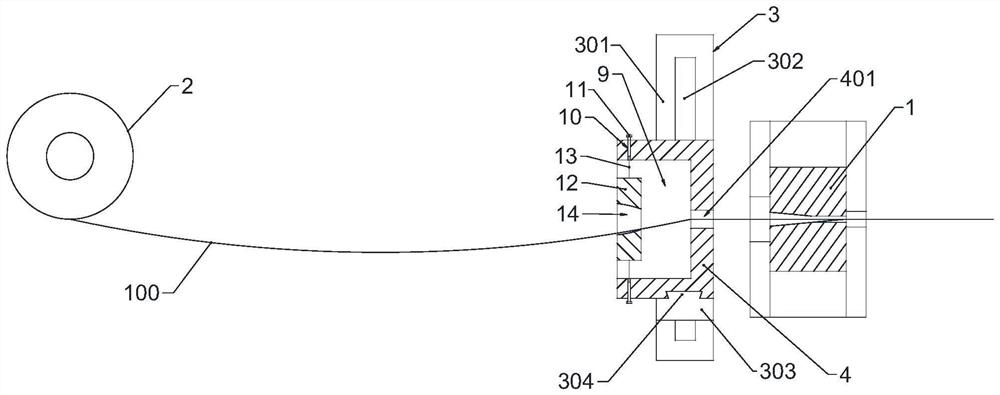

[0020] Such as figure 2 and image 3 As shown, a guide mechanism to ensure the linearity of steel wire feeding, including a bracket 3 fixedly arranged between the drawing die 1 and the guide wheel 2 and a guide die 4 connected to the bracket 3, the guide die 4 and the steel wire The drawing die 1 is arranged concentrically, and the diameter of the guide die 4 is not smaller than the diameter of the front end of the drawing die 1. In this embodiment, the diameter of the guide hole 401 of the guide die 4 is 0.2-0.4 mm larger than the diameter of the front end of the drawing die 1.

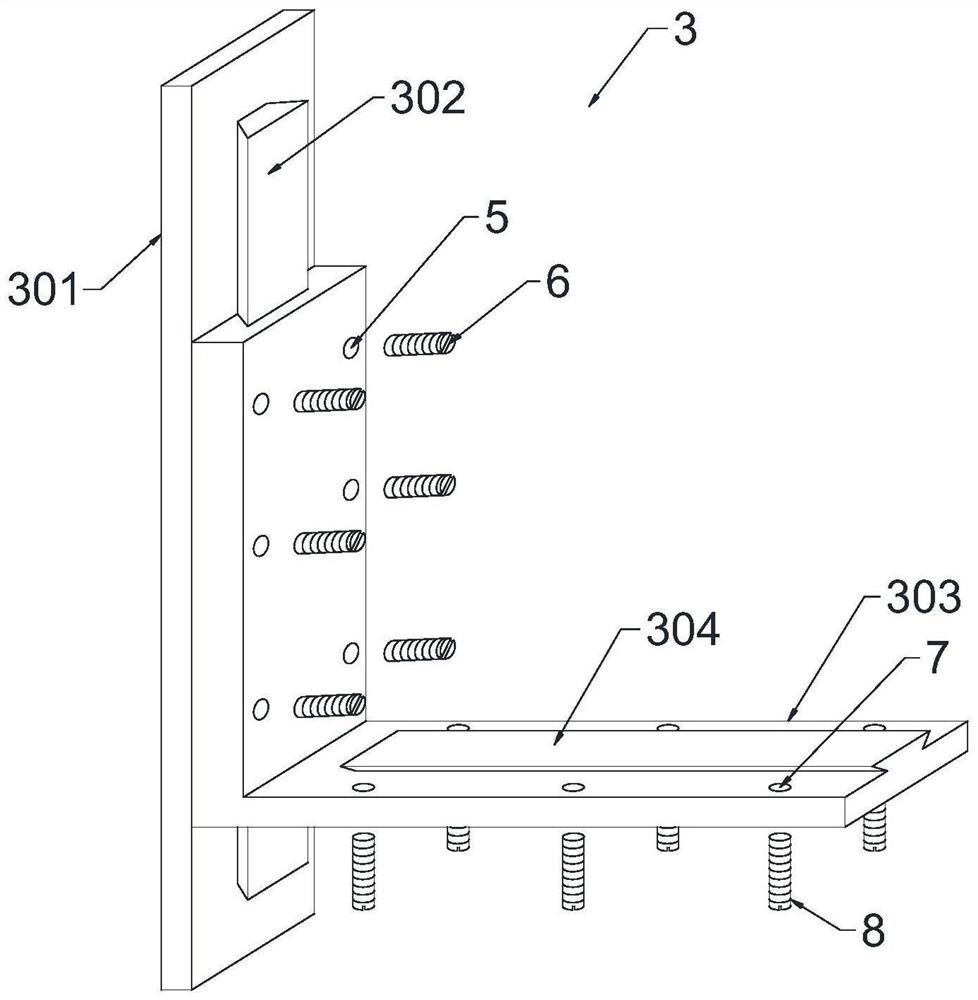

[0021] Such as image 3 As shown, the bracket 3 includes a vertically arranged vertical plate 301, and at least one vertical rail 302 is vertically arranged on the vertical plate 301, and each vertical rail 302 is parallel to each other, and an L-shaped slider 303...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com