Simple shaft platform

A shaft and platform technology, applied in the field of simple shaft platforms, can solve the problems of high purchase and transportation costs, consuming installation man-hours, and large overall weight, and achieve the effects of convenient installation and transportation, efficient use process, and simple use process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

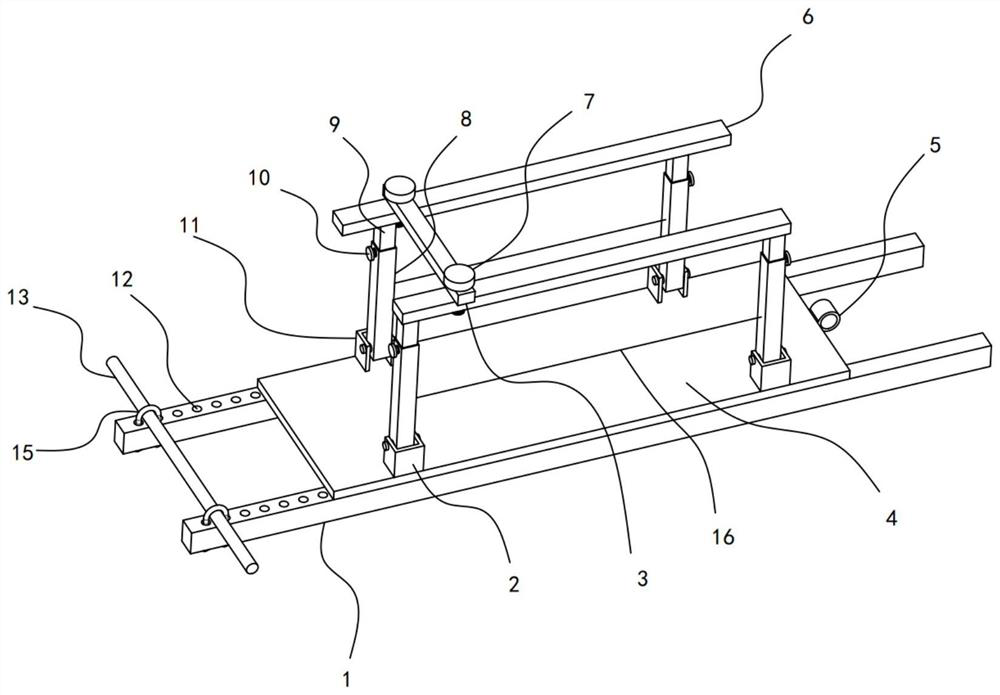

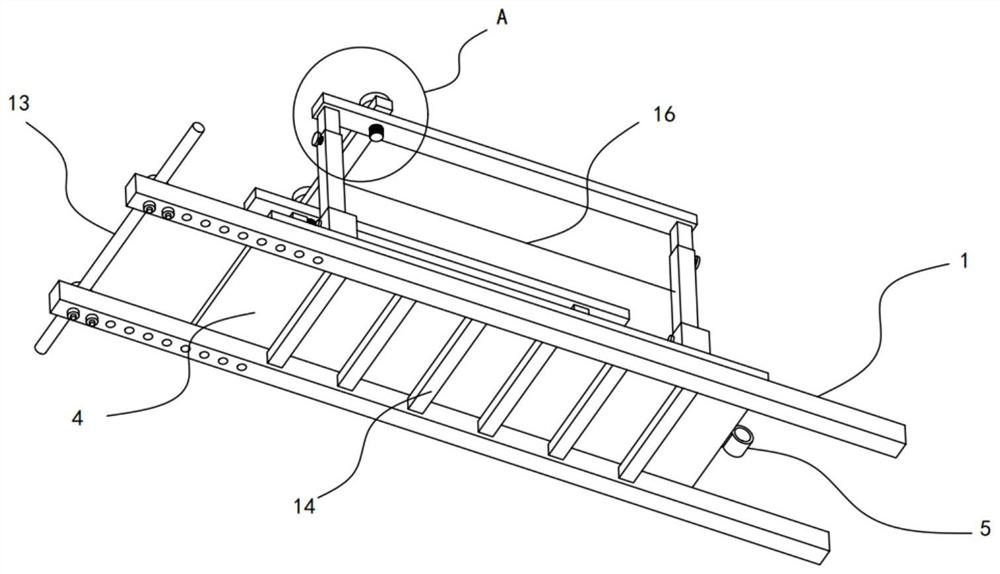

[0024] see Figure 1-3 , a simple hoistway platform, including a bearing plate 4, two parallel supporting strips 1 are installed on the bottom of the supporting plate 4, a pair of rotating seats I2 and a pair of rotating seats II11 are fixedly installed on the supporting plate 4, The distance between the two rotating seats I2 is less than the distance between the two rotating seats II11, each of the rotating seats I2 and each of the rotating seats II11 is hinged with a sleeve 8, and each of the sleeves 8 Lifting columns 9 are slidably installed on the top, and gear rods 6 are fixed on the lifting columns 9, and connecting strips 3 are fixed on the gear rods 6 .

[0025] When the platform is in use, one end of the support slat 1 is clamped on the side wall of the hoistway, the other end of the support slat 1 is set on the floor to which the hoistway belongs, and the set bearing plate 4 is used as a working platform for the staff to stand on. The provided sleeve pipe 8, lifting...

Embodiment 2

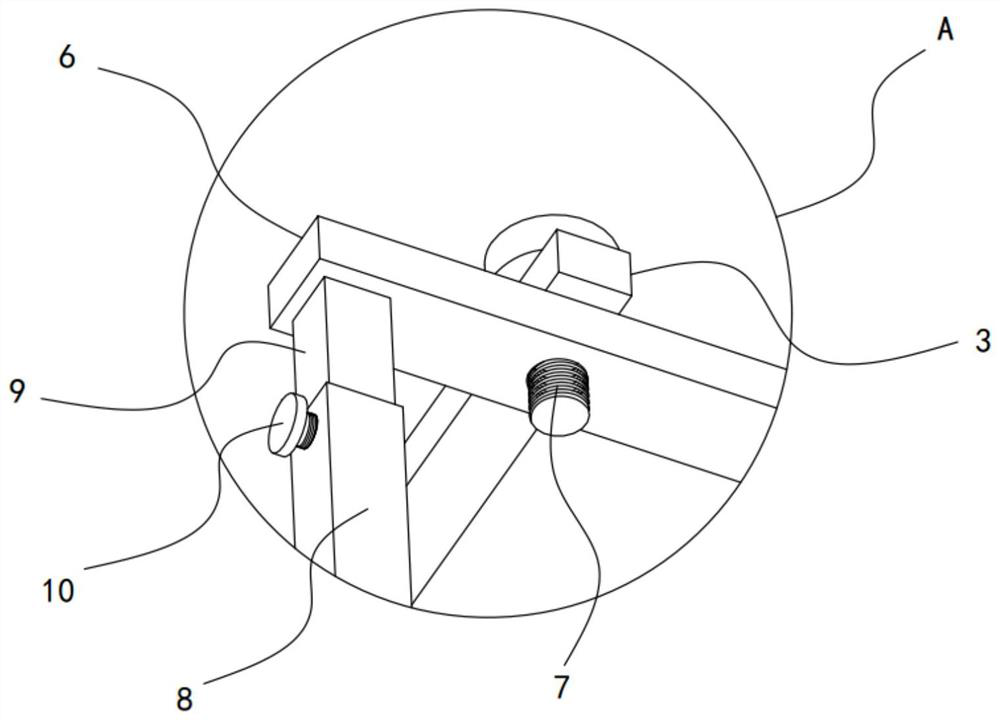

[0028] On the basis of Embodiment 1, in addition, the side wall of the casing 8 is threadedly connected with a locking stud II10, and the locking stud II10 abuts against the side wall of the lifting column 9, and slides relative to the casing 8 through the lifting column 9. The tightening stud II10 realizes the locking effect after the lifting height of the lifting column 9 is adjusted, realizes the flexible adjustment of the protection height range on both sides of the carrying plate 4, and is safer to use.

[0029] In addition, a locking stud I7 is pierced on the connecting strip 3, and the locking stud I7 extends into the gear rod 6 through a threaded connection. The stud I7 is locked to ensure the stability of the connection between the sleeve pipe 8, the lifting column 9, the gear lever 6 and the connecting strip 3.

[0030] Further, several mounting holes 12 are opened at equal intervals on each of the support strips 1 , each of the support strips 1 is equipped with buck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com