Working device position parameter data acquisition method and loader

A working device and data acquisition technology, which can be applied in the fields of earth movers/shovels, mechanically driven excavators/dredgers, construction, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation will be described below in conjunction with the accompanying drawings.

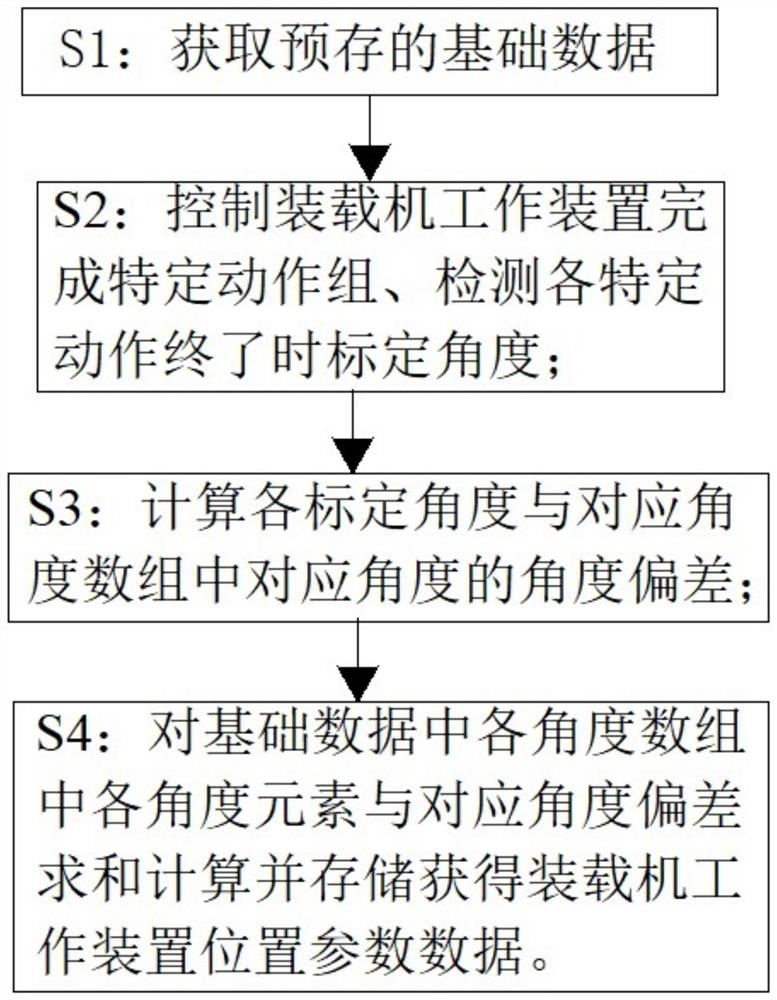

[0029] Such as figure 1 figure 2 As shown, this embodiment provides a method for acquiring position parameter data of a working device, and the method is used to acquire position parameter data of a working device of a loader. The position parameter data of the working device is used for the automatic control of the loader.

[0030] The steps of the location parameter data acquisition method are as follows:

[0031] S1: Obtain pre-stored basic data;

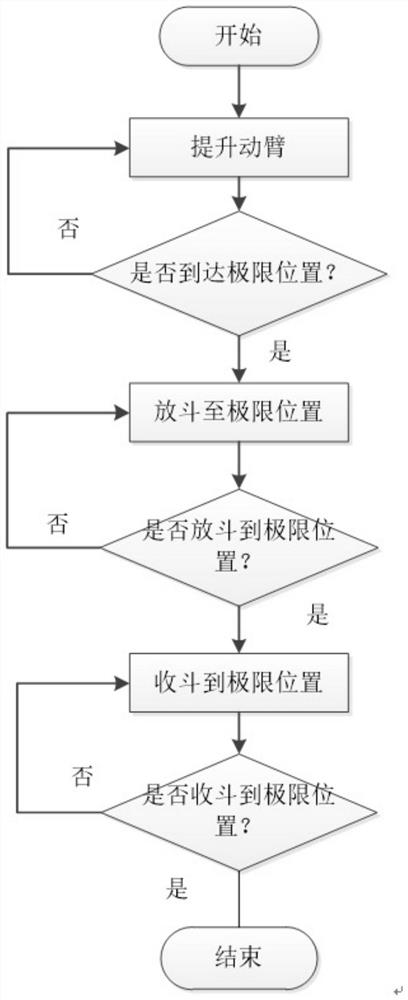

[0032] S2: Automatically control the working device of the loader through the control program to complete a specific action group and detect the calibration angle at the end of each specific action;

[0033] S3: Calculate the angle deviation between each calibration angle and the angle corresponding to the boom lifting limit position in the corresponding angle array;

[0034] S4: Calculate and store the sum of each an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com