Anti-vibration turbulent flow device of wind turbine generator blade

A technology of wind turbines and spoilers, which is applied in the control of wind turbines, wind power generation, wind turbines, etc., can solve the problems of blade damage, time-consuming maintenance, and failure to prevent blade vortex-induced vibration, so as to suppress vibration and reduce Instability, the effect of avoiding economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

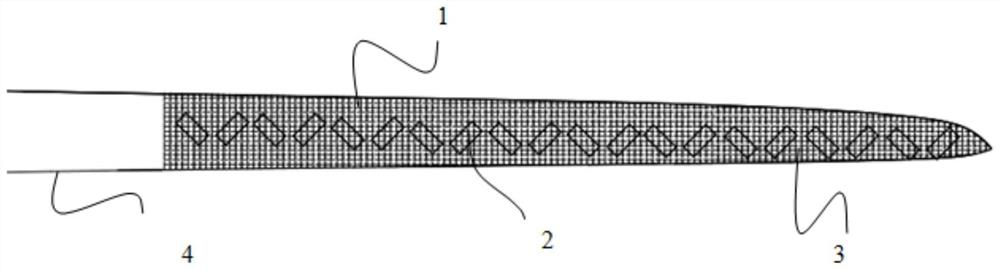

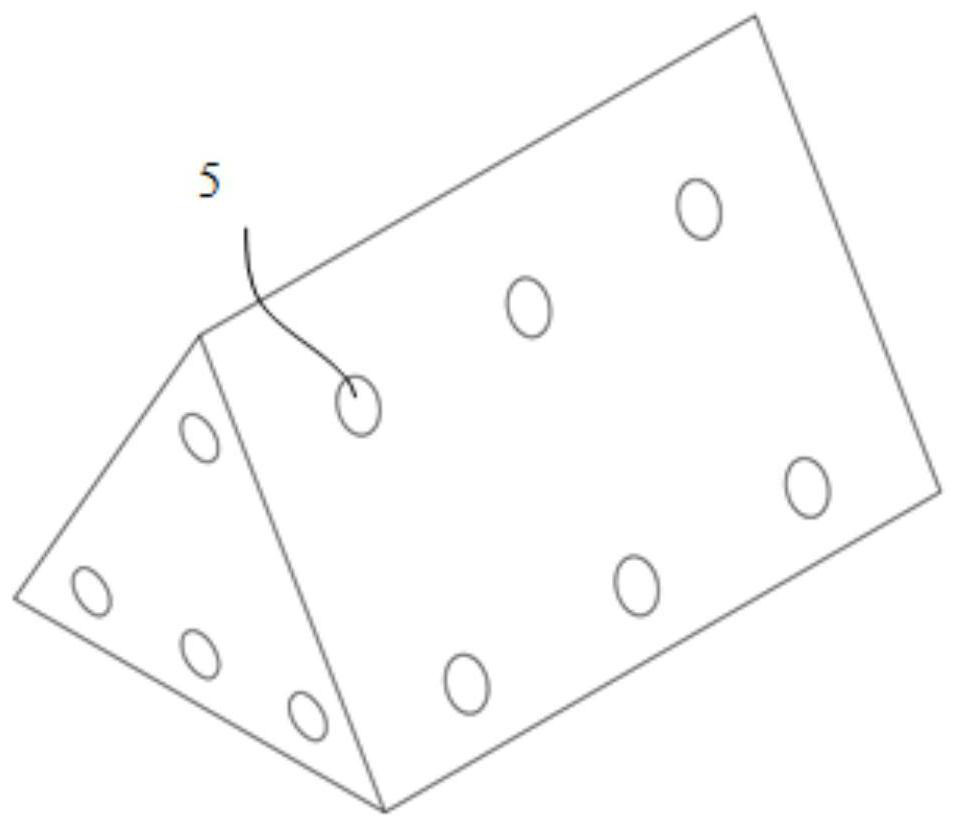

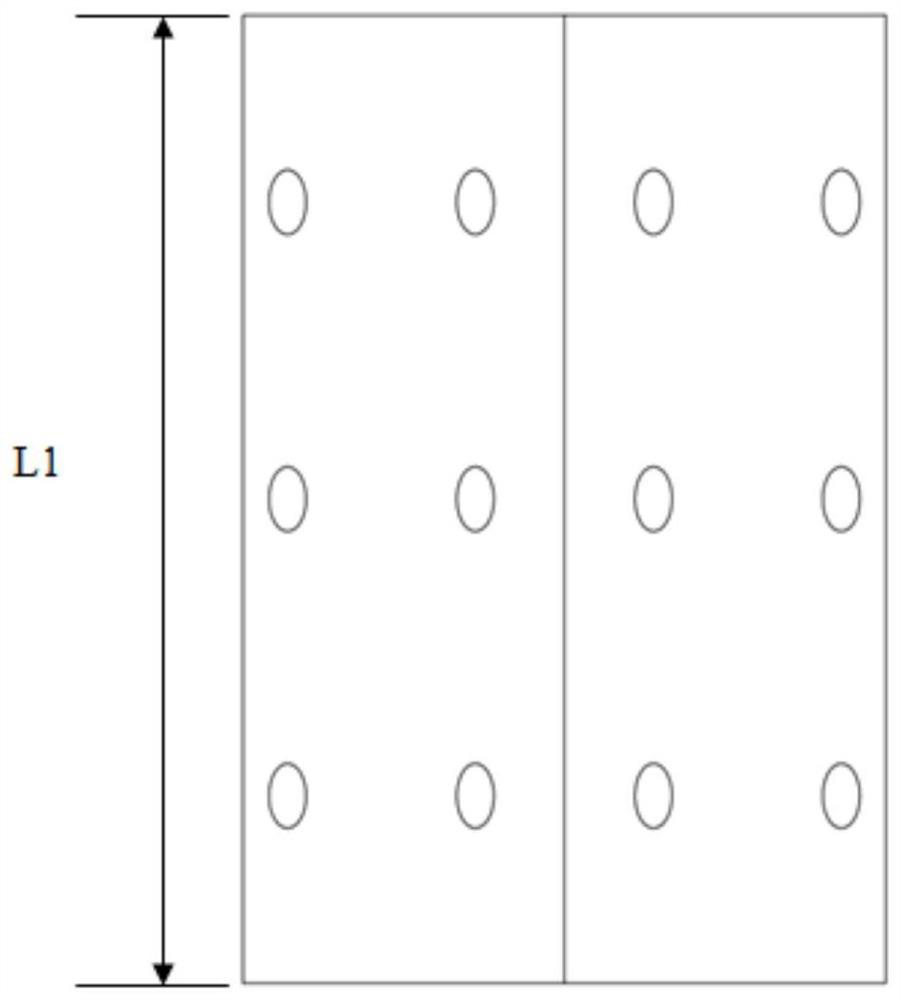

[0020] see Figure 1 to Figure 4 As shown, the anti-vibration and spoiler device for wind turbine blades provided in this embodiment includes net sleeves, spoiler strips 2, traction ropes 4 and locking ropes 6, 7, 8, 9, 10, 11, and the net The sleeve includes a first net sleeve 1 and a second net sleeve 3, the first net sleeve 1 is set from the maximum chord length position on the blade surface to the blade tip position, and is tied to the handrail outside the hub of the wind turbine through a traction rope 4, The spoiler strips 2 are fixed on the first net cover 1 through locking ropes 6, 7, 8, 9, and are distributed along the length direction of the first net cover 1, and each two adjacent spoiler strips 2 are in the shape of The splayed symmetrical structure, the spo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com