Concrete-filled steel tube bridge tower and construction method thereof

A technology of steel pipe concrete and construction methods, which is applied in the direction of bridges, suspension bridges, bridge parts, etc., can solve problems such as the lack of transportation conditions for large steel components, vortex-induced vibration of steel box tower columns, and small self-weight of steel towers, so as to achieve low construction difficulty , high adaptability, and the effect of saving steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

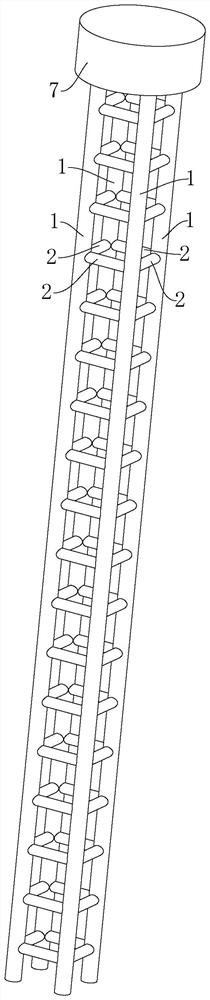

[0048] A steel pipe concrete bridge tower, such as Figure 1-10 , including several splicing segments, the splicing segment includes several steel pipes-1 and at least one consolidation unit located on the steel pipe-1, the steel pipe-1 is filled with concrete, and the consolidation unit is used to connect all the steel pipes-1 as a whole, ensuring The overall stability of the steel tube concrete bridge tower structure, the consolidation unit includes a number of steel pipes 2, the steel pipe 2 2 is connected to two adjacent steel pipes 1 along the circumferential direction of the bridge tower, and the steel pipe 2 2 is used as a web member, which can resist bending by itself The ability to transmit the unbalanced axial force of two adjacent steel pipes-1; two adjacent consolidation units are arranged at intervals along the longitudinal direction of the bridge tower, and all spliced segments are connected through the butt joint of steel pipe-1.

[0049] In this embodiment, t...

Embodiment 2

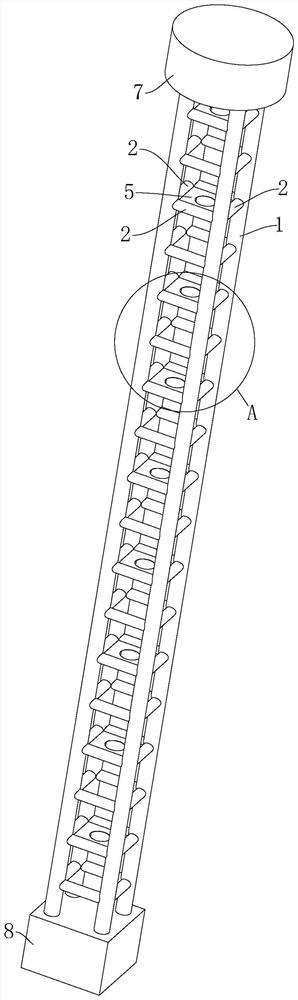

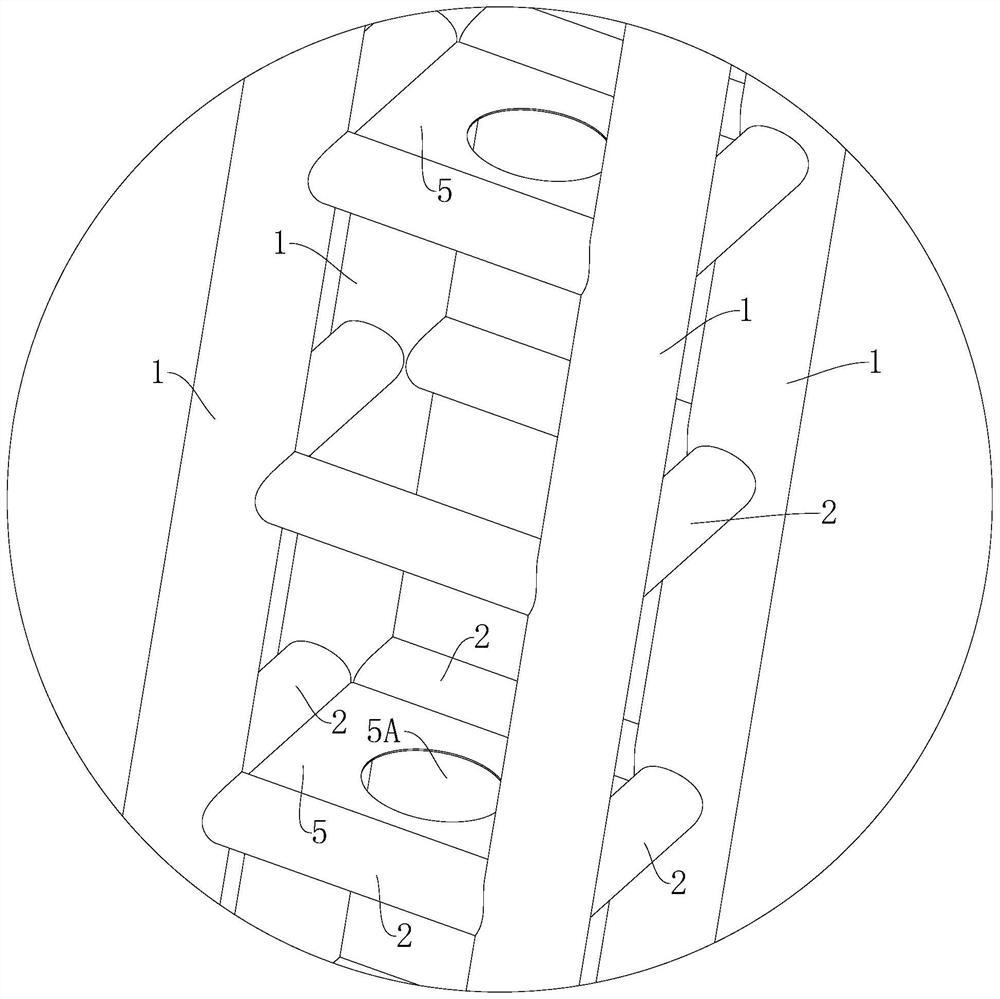

[0052] Based on Example 1, as a specific implementation, such as figure 2 , image 3 , the pylon also includes a transverse diaphragm 5 adjoining all steel pipes 2 in a single consolidation unit. The arrangement of the diaphragm 5 is mainly used to improve the torsion resistance and other performances of the bridge tower structure, further strengthening the structural stability. In this embodiment, among all the consolidation units, it is preferable that the transverse diaphragm 5 is arranged longitudinally by one consolidation unit along the bridge tower, so as to ensure that the bridge tower structure has sufficient bending resistance, torsional strength and compressive bearing capacity, saving The amount of steel is used, and the structure is beautiful.

[0053] Further, a manhole 5A is provided in the center of the transverse partition 5, which is convenient for maintenance personnel to pass through.

Embodiment 3

[0055] Based on Example 1, as a specific implementation, such as Figure 4-Figure 7 , the bridge tower also includes a steel pipe 3 3, and the steel pipe 3 3 connects two adjacent steel pipes 2 2 in a single consolidation unit. The arrangement of the steel pipe three 3 can also be used to improve the torsional performance of the bridge tower structure, and further strengthen the structural stability.

[0056] In this embodiment, among all the consolidation units, the steel pipes 33 are arranged at intervals of one consolidation unit along the longitudinal direction of the bridge tower, so as to save steel consumption under the premise of ensuring that the bridge tower structure has sufficient bending resistance, torsional strength and compressive bearing capacity , beautiful structure. Furthermore, the steel pipe 3 3 is a hollow member, and is light in weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com