Auxiliary temperature measurement junction box for YBX4 high-efficiency explosion-proof three-phase asynchronous motor

A three-phase asynchronous, junction box technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of difficult replacement of wiring terminals, and achieve the effects of excellent sealing performance, simple structure and convenient use of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

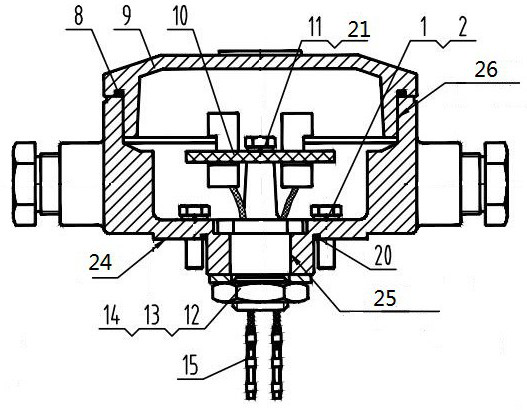

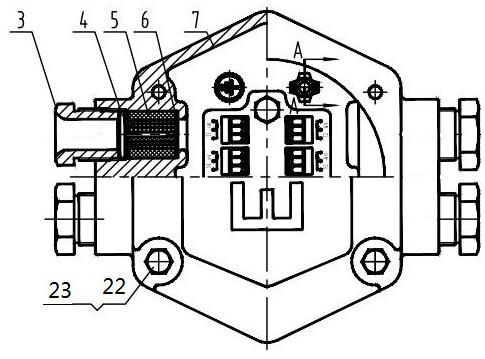

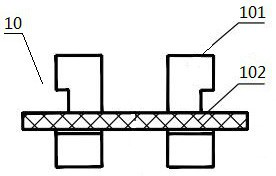

[0032] Such as Figure 1-7 As mentioned above, this embodiment provides a YBX4 high-efficiency flameproof three-phase asynchronous motor auxiliary temperature measurement junction box, including a junction box seat 7, a terminal board 10 arranged inside the junction box seat 7, and fixed on the junction box seat 7. The wire passing device 12 at the bottom of the junction box seat 7, four junction box buckets respectively provided on both sides of the junction box seat 7, the junction box cover 9 connected to the top of the junction box seat 7, the junction box seat 7 and the junction box cover 9 are hexagonal structures. The bottom of the wire passing device 12 is connected with a terminal 15, and the junction box bucket is provided with a compression nut 3, a metal plugging rod 4, a sealing ring 5 and a metal washer 6 sequentially from the outside to the inside.

[0033] The junction box seat 7 and the junction box cover 9 are connected by a first O-ring 8, and the top of th...

Embodiment 2

[0043] Such as Figure 1-7 As mentioned above, this embodiment provides a YBX4 high-efficiency flameproof three-phase asynchronous motor auxiliary temperature measurement junction box, which is an improvement on the basis of Embodiment 1:

[0044] The outer surface of the bottom of the junction box seat 7 is provided with a flameproof surface 24, and the flameproof joint surface 25 at the contact surface between the junction box seat 7 and the junction box cover 9: L≥14, ic≤0.15; The flameproof joint surface 26 at the contact surface between the junction box seat 7 and the wire passing device 12: L≥14, ic≤0.15.

[0045] The net volume of the temperature measurement junction box is: V≤2000cm³.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com