Three-axis clamping device for conveniently allowing rubber sleeve to be replaced

A gripper and rubber sleeve technology, used in workpiece clamping devices, manufacturing tools, etc., can solve the problems of wear and fission of rubber sleeves, unusable rubber sleeves, and reduce the efficiency of equipment maintenance, so as to increase sealing performance, replace handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific examples.

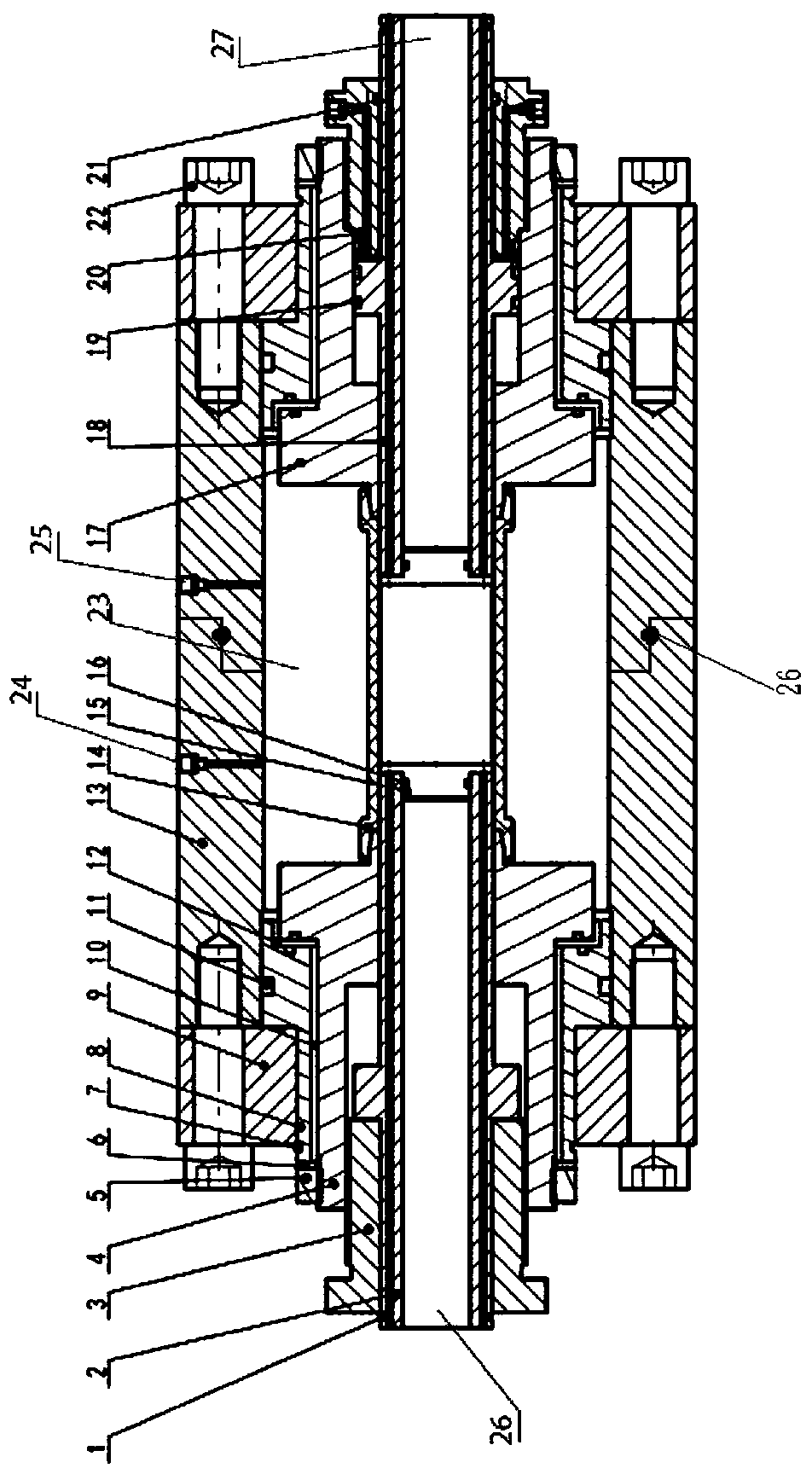

[0010] figure 1 Middle: retaining ring 1 for the first shaft, left core chamber 2, left pressure cap 3, left taper sleeve 4, well cap 5, first insulating sheet 6, retaining ring 7 for the second shaft, sleeve 8, flange 9, The second insulating sheet 10, the first sealing ring 11, the second insulating sheet 12, the cylinder body 13, the rubber sleeve 14, the second sealing ring 16, the right taper sleeve 17, the third sealing ring 19, the right pressure cap 20, the fourth Seal ring 21, screw 22, pressure cavity 23, water inlet 24, water outlet 25, left axial pressure port 26, right axial pressure port 27.

[0011] A three-axis holder for easy replacement of rubber sleeves. The three-axis holder is provided with a PS wave probe 15 for detecting echo changes of samples inside the device, which is equivalent to a B-ultrasound probe. The three-axis holder Including the left core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com