Splicing structure of linear motor carrying device

A technology for conveying devices and linear motors, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of inability to ensure the consistency of a single conveying device, unfavorable disassembly and replacement of multi-section modules, unfavorable use, etc., to achieve simple assembly , Guarantee the effect of processing error and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

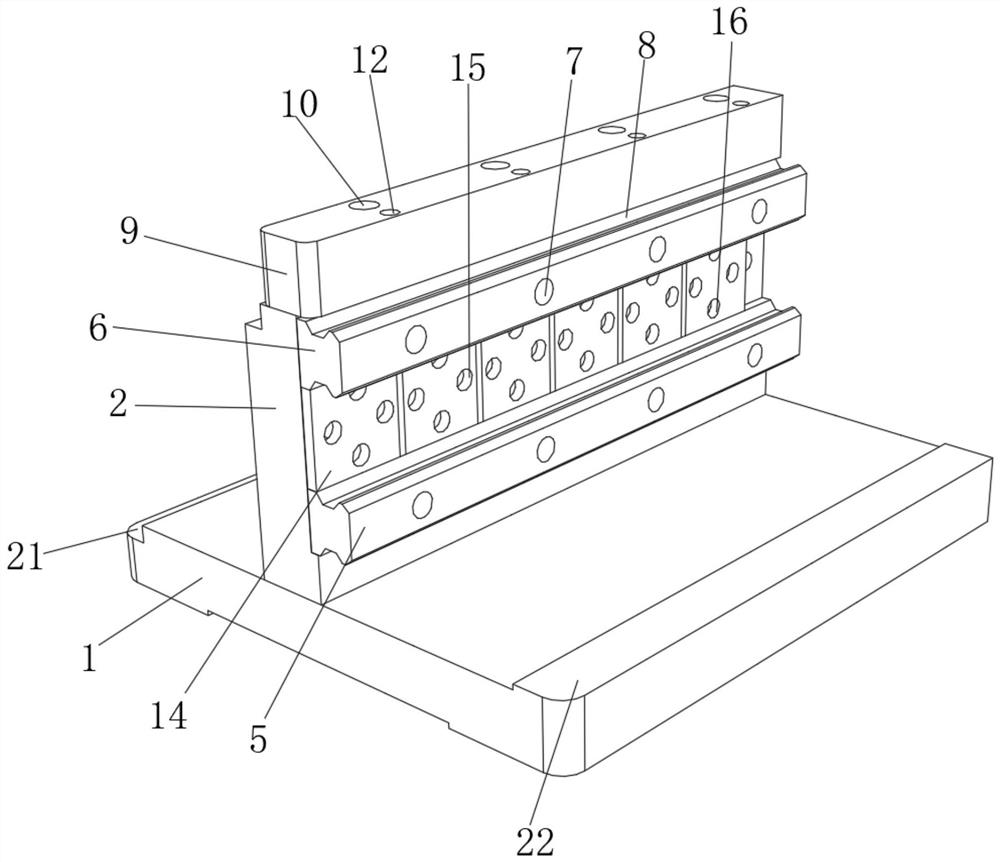

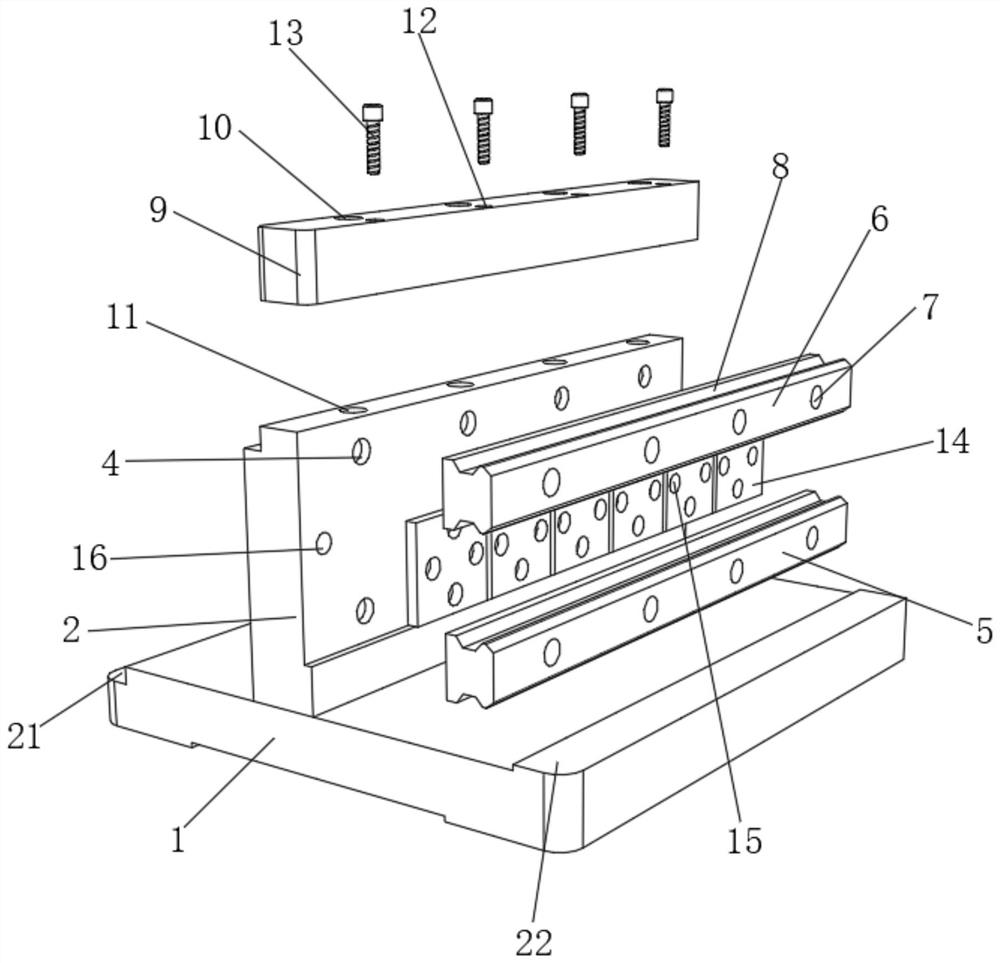

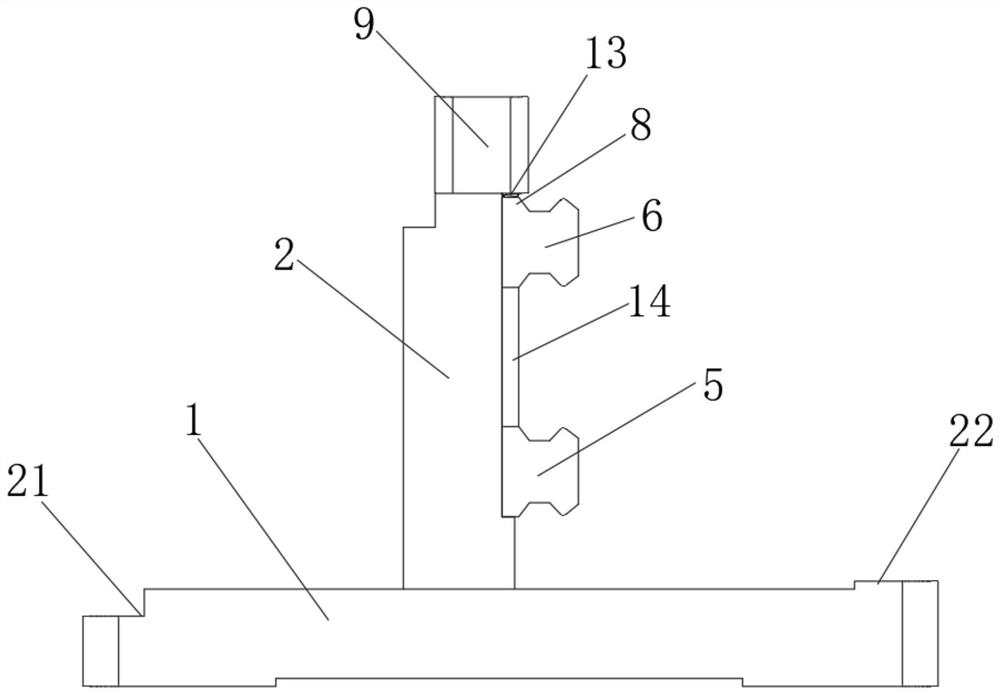

[0026] Refer Figure 1 - Figure 4 A splicing structure of a linear motor conveying device, including the base 1, the top portion of the base 1 is integrated with mounting plate 2, and one side of the mounting plate 2 is provided with a first slide rail 5, a second sliding rail 6, and the adjustment support block 14. The adjustment support block 14 is located in the middle of the first sliding rail 5 and the second sliding rail 6, and the first bump 8 is formed in both sides of the first sliding rail 5 and the second sliding rail 6, and the first slide 6 Fixed with the mounting plate 2, place the adjustment support block 14 at the top of the first slide 5, and then placed the first sliding rail 5 on the top of the second slide rail 6, so that the first sliding rail 5, adjust the support block. 14 and the second sliding rail 6 are tightly arranged along the surface of the mounting plate 2, and one side of the first slide rail 5 and the second slide rail 6 is provided with a plurality...

Embodiment 2

[0030] Refer Figure 5 , A splicing structure of a linear motor conveying device, the top of the second bump 22 and the top of the base 1 are provided with a plurality of threaded perforations 23, and the second wire 24 is provided in the threaded perforation 23, and the second wire 24 is provided. The threaded perforation 23 is placed and tightened. At this time, the second top wire 24 supports the entire module.

[0031] In this example, the working principle is used, and when one of the two modules there is a high difference, the second top wire 24 is placed in the threaded perforation 23 and tighten, at this time, the second wire 24 pair the entire module Support.

[0032] The electrical components that appear in this article are connected to the outside of the main controller and 220V market electrical and electrical electrical electrical, and the master can be controlled for a computer or the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com