Patents

Literature

32results about How to "Easy to ensure consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

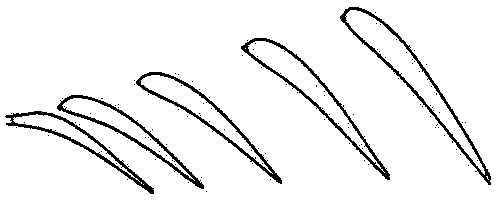

Aero-engine compressor blade and machining method thereof

The invention belongs to the technical field of aero-engines, and discloses a compressor blade machining method. The compressor blade machining method includes the steps that step 1, three-dimensionalmeasurement is carried out, specifically, a crest curve and a trough curve are built by extracting actual curve crest points and trough points of cross sections according to a three-dimensional diagram of a compressor blade; virtual curves of a blade body and a jog are built; step 2, point cloud is extracted, specifically, curvatures of the actual curve, the crest curve and the trough curve of the step 1 are analyzed, and the curves of the crest curve and the trough curve are regulated according to actual curve curvatures; a center line is built according to the crest curve and the trough curve; step 3, a hook face is rebuilt, specifically, a mesh hook face is built with center lines of the cross sections to generate a three-dimensional digital model; step 4, procedures are regulated, specifically, the blade three-dimensional digital model is imported to a three-dimensional software and corrected compared with blade master body data scanned by the three-dimensional software; and step5, numerical control machining is carried out, specifically, numerical control programming is carried out according to the blade three-dimensional digital model of the step 4, and a blade is subjectedto numerical control milling with a ball end milling. According to the compressor blade machining method, the blade precision and the surface roughness of a compressor can be effectively ensured.

Owner:株洲丰发精工实业有限公司

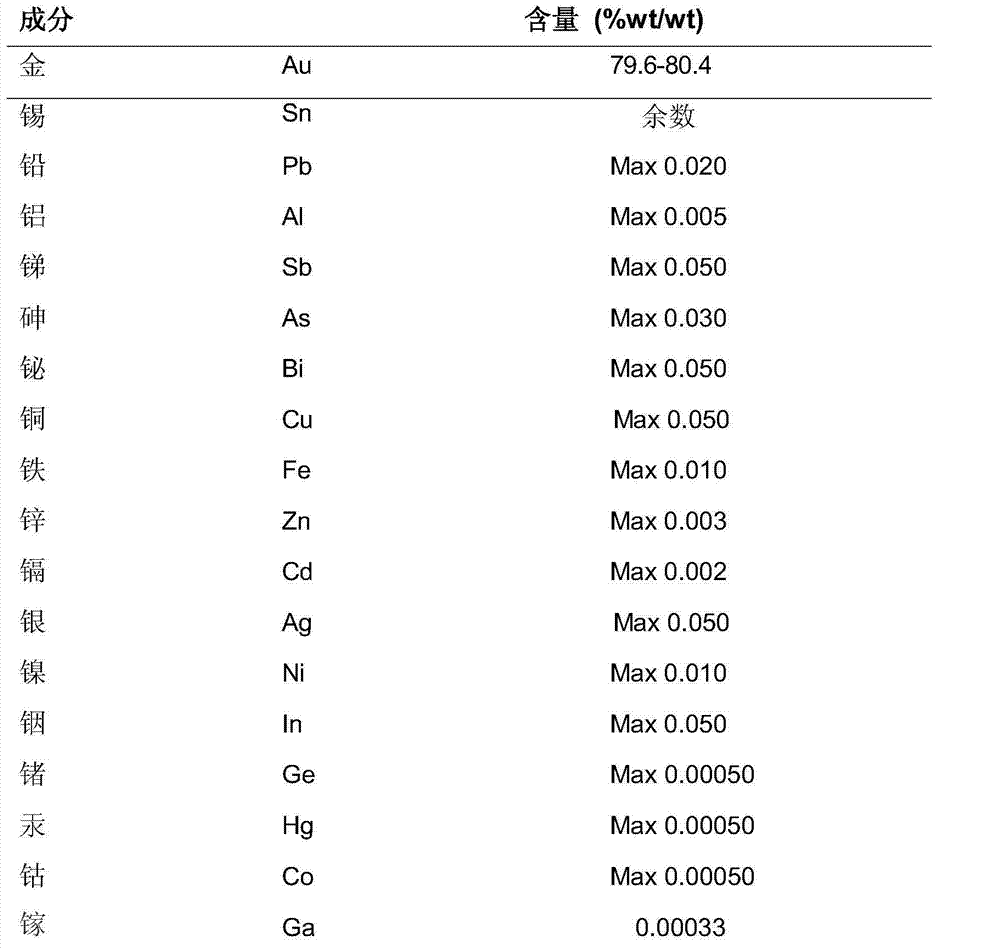

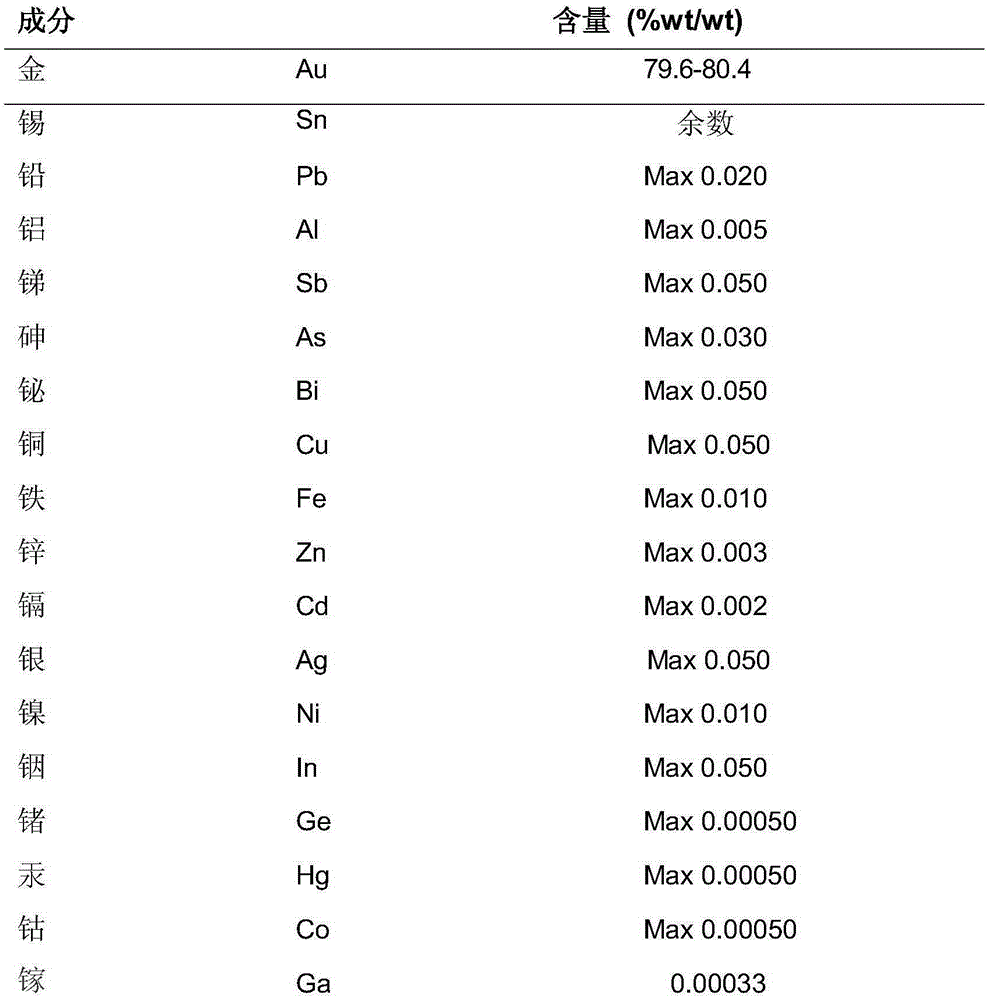

Production method of gold-tin wire, foil belt and preforming welding piece

ActiveCN103753057AMake sure the surface is shinyEnsure that the oxide layer is reducedWelding/cutting media/materialsSoldering mediaMaterials scienceExtrusion

The invention provides a production method of a gold-tin wire, a foil belt and a preforming welding piece and belongs to the welding technical field. The production method comprises step 1, smelting gold and tin into alloy and casting the gold and the tin into an alloy rod; step 2, performing annealing; step 3, performing extrusion forming which comprises arranging a tin wire die with a circular hole at the position of the outlet of an extruding machine first when the ally rod needs to be extruded into a tin wire and arranging a foil belt die with a square hole at the position of the outlet of the extruding machine first when the ally rod needs to be extruded into the foil belt, then placing the product in the step 2 into the extruding machine, adjusting the intensity of pressure of the extruding machine to 250 to 350 Mpa and adjusting the temperature to 150 to 230 DEG C; step 4, cutting the foil belt which is obtained through extrusion in the step 3 into the preforming welding piece. According to the production method of the gold-tin wire, the foil belt and the preforming welding piece, the problem that the machining forming is difficult due to the high brittleness of the gold-tin alloy in the prior art is solved, the technological process is simple and convenient, the mass production can be performed, the product accuracy is good, and the product consistency is good.

Owner:SHENZHEN FUMOSUO METAL PROD

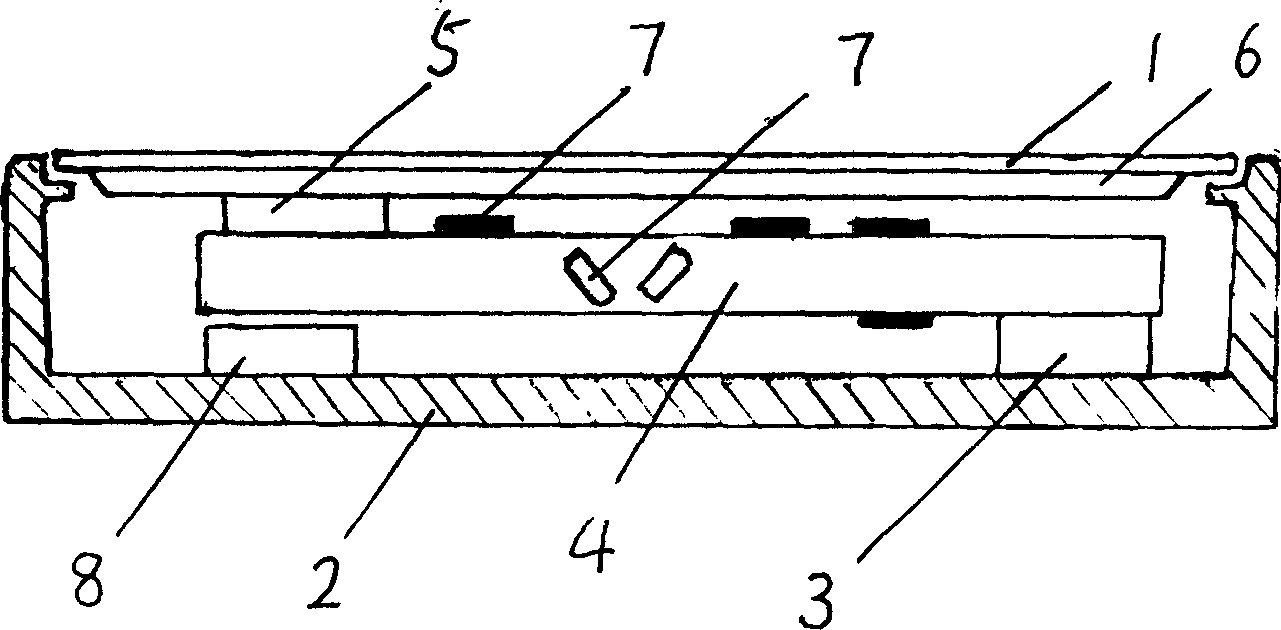

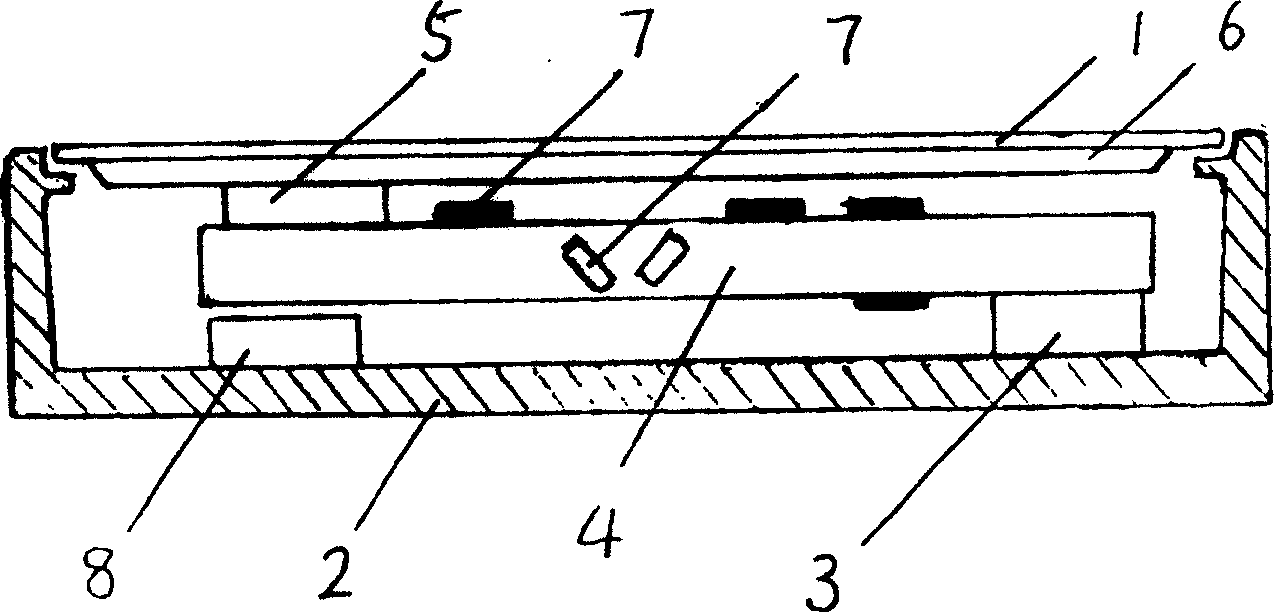

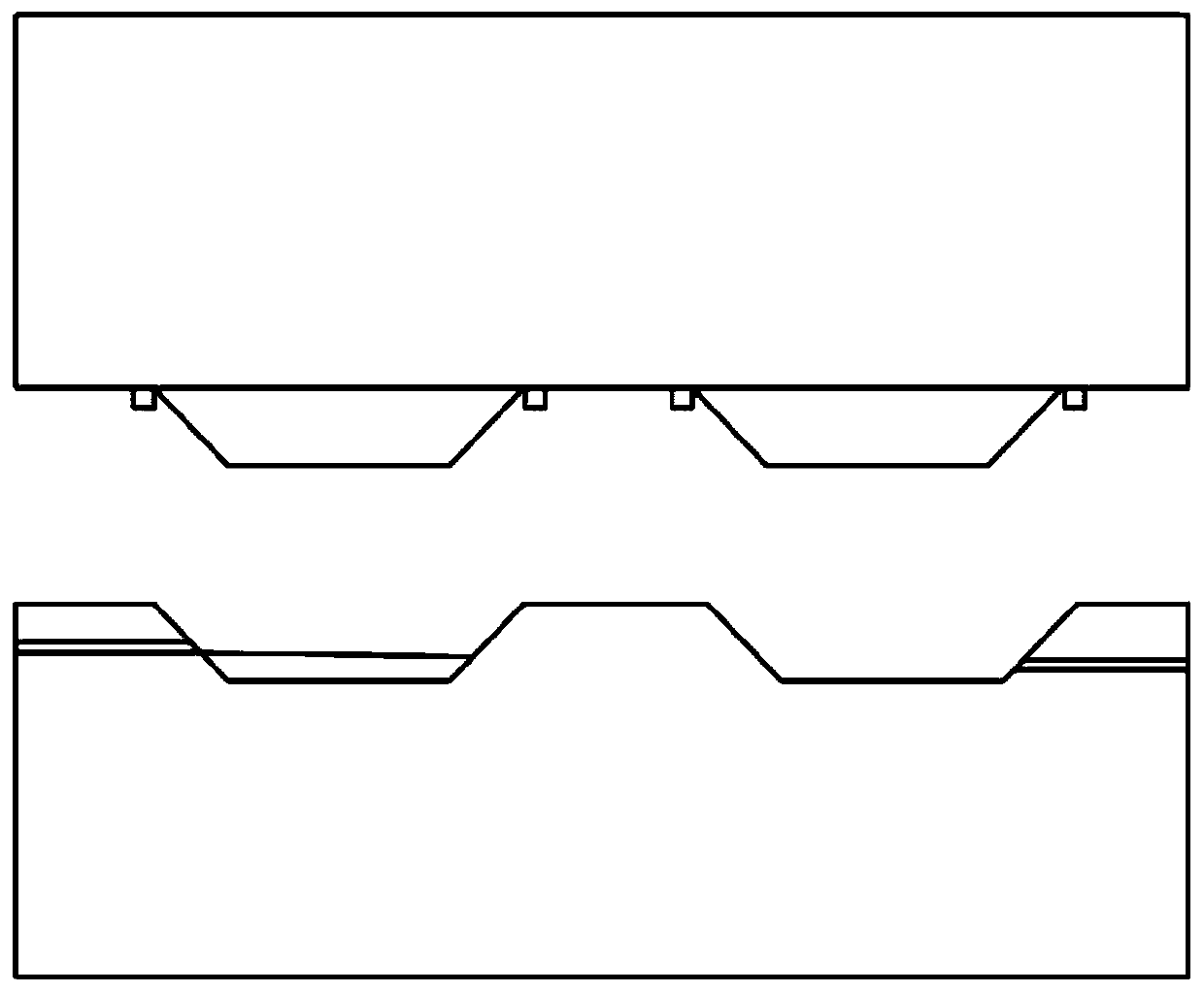

Information input apparatus with pressing plate and method thereof

InactiveCN1825257AHigh densityHigh precisionGraph readingMechanical pattern convertionStrain gaugeMechanical engineering

The invention relates to an information input device and method with pressing board that includes pressing board, force sensitive sensor, and casing. The whole support the pressing board gained would pass through a sensor elastic body. On the elastic body or the elastic body group and carrying the strain gauge, the pressed location would be calculated and judged according to the moment and torsion moment. The device and method simplifies the structure of the device and obviously improves the working accuracy, stability and reliability.

Owner:刘二中

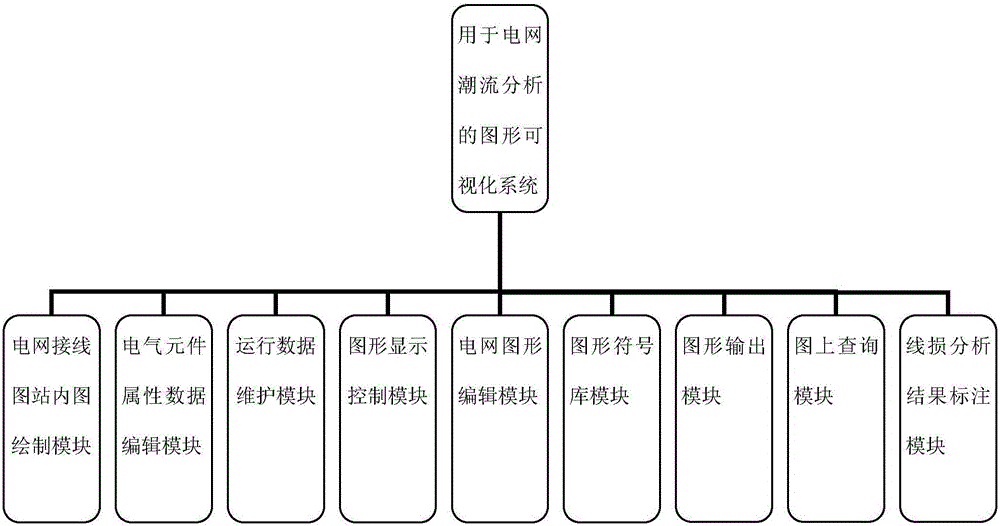

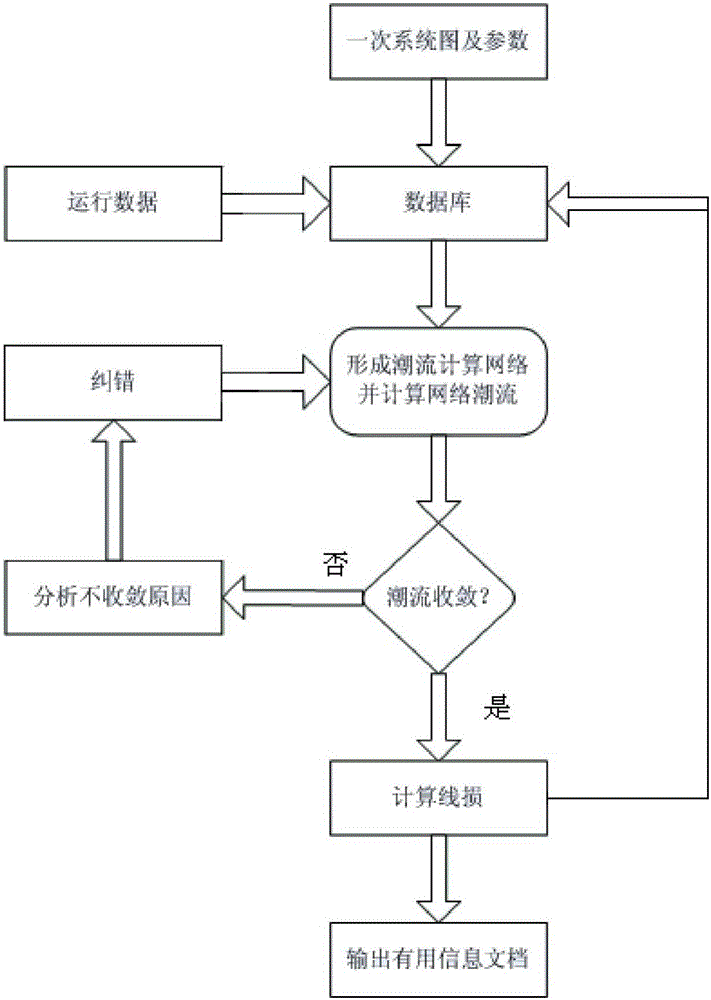

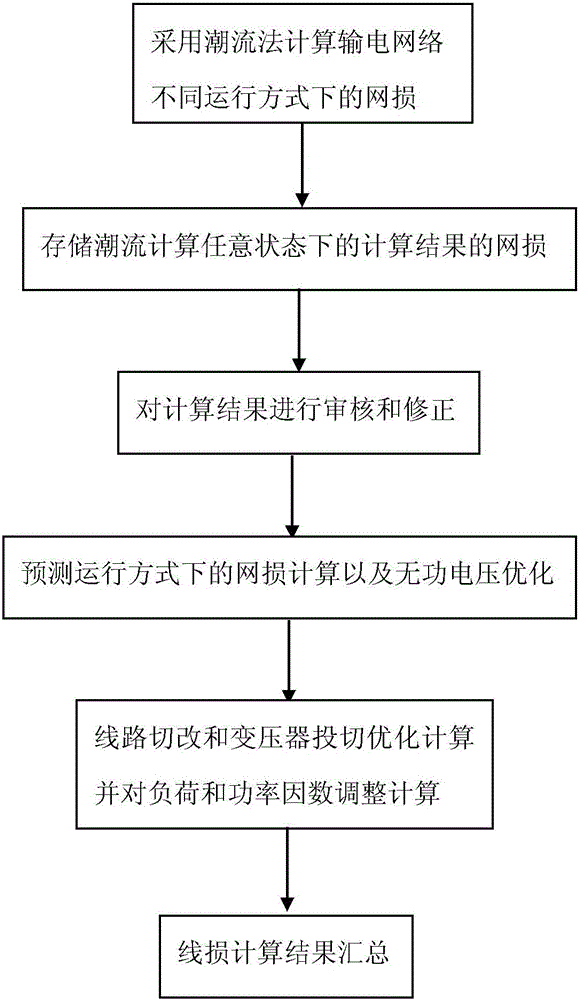

Graph visualization system for power grid power flow analysis

InactiveCN105938506AEasy to ensure consistencyEasy to Guarantee CorrectnessCAD circuit designSpecial data processing applicationsGraphicsPower flow

The present invention relates to a graphical visualization system for power grid power flow analysis, comprising the following modules: a power grid wiring diagram instation diagram drawing module, an electrical element attribute data editing module, an operating data maintenance module, a graph display control module, a power grid graph editing module, a graph symbol library module, a graph output module, an on-graph query module and a line loss analysis result tagging module. According to the graph visualization system, topological information and element parameter information which are conveyed to a computer by a user through a graph editor can be converted into forms convenient for power system module computing program processing, graphical modeling of a power grid is achieved, visualization management can be performed on element parameters, foundation can be further provided for line loss analysis, and visualization of line loss information can be achieved.

Owner:ELECTRIC POWER RES INST STATE GRID JIBEI ELECTRIC POWER COMPANY +2

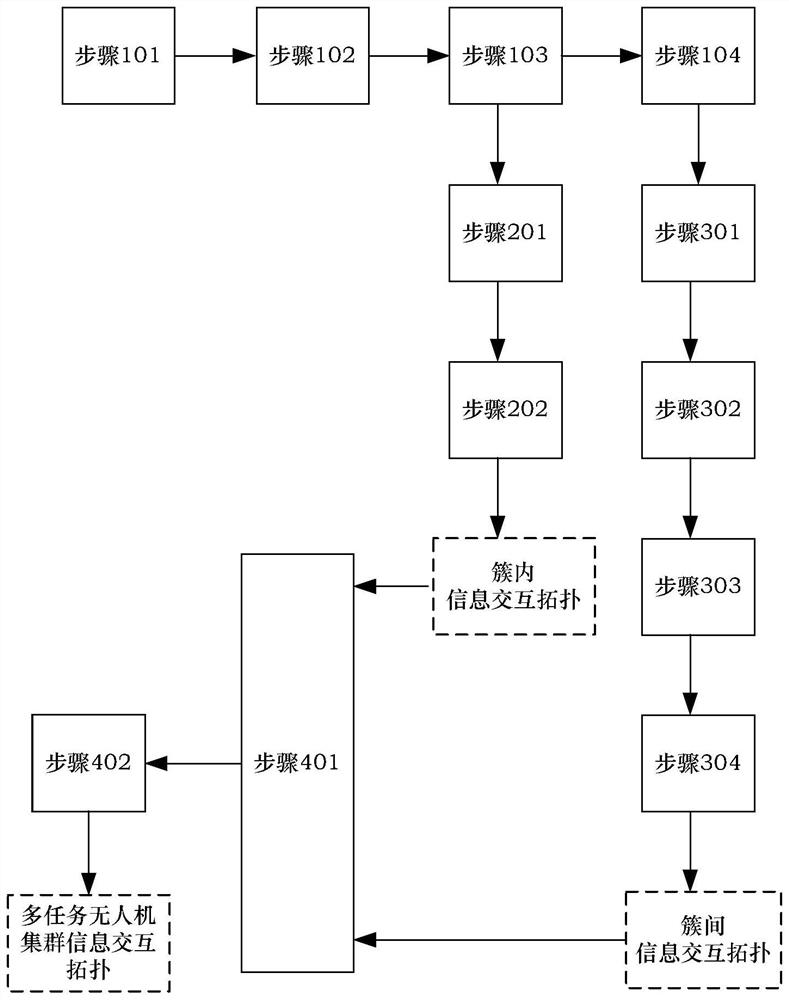

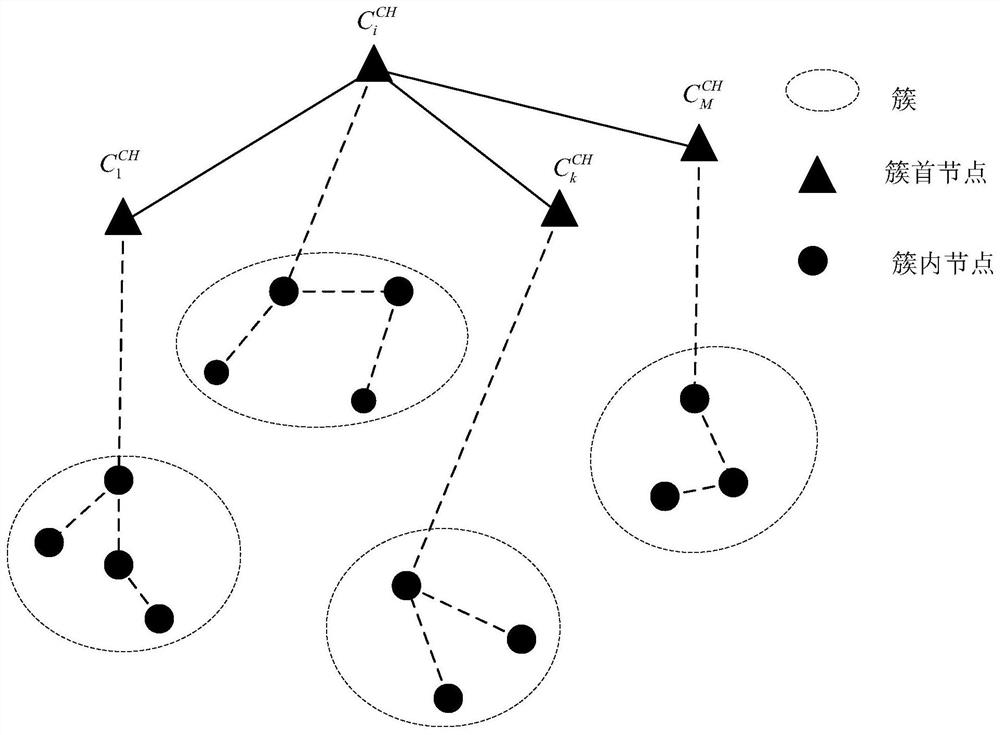

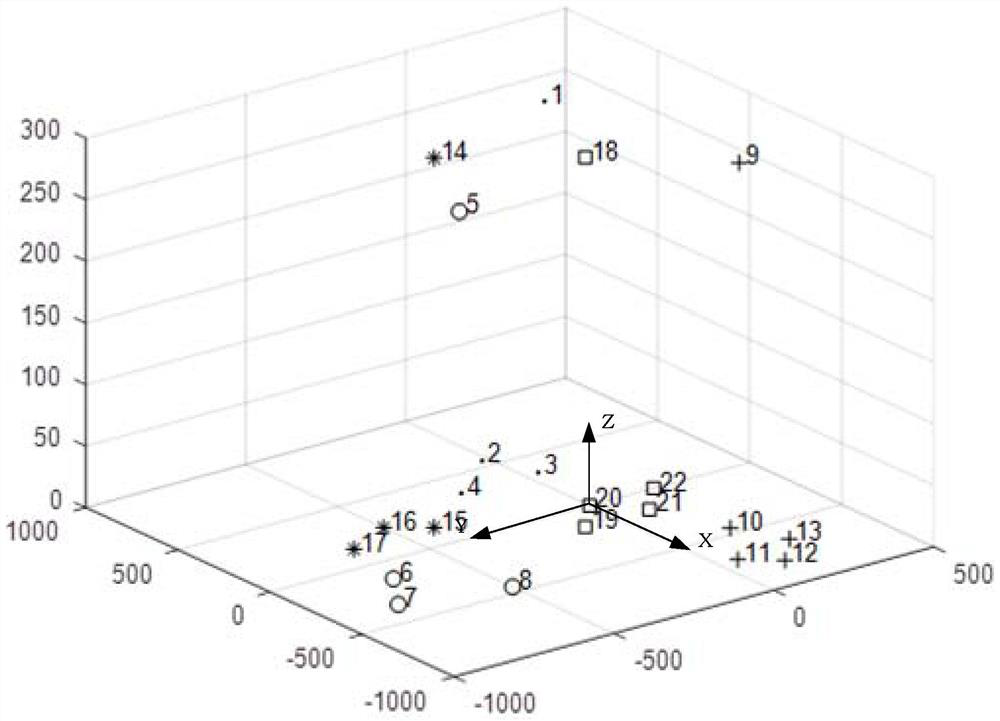

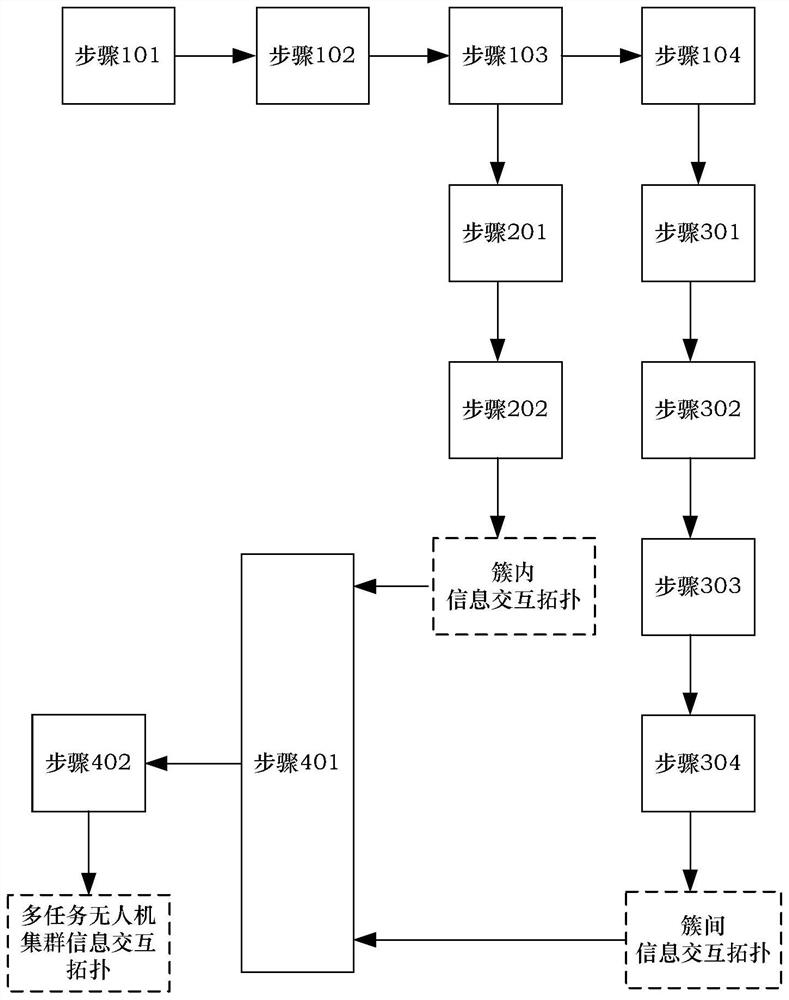

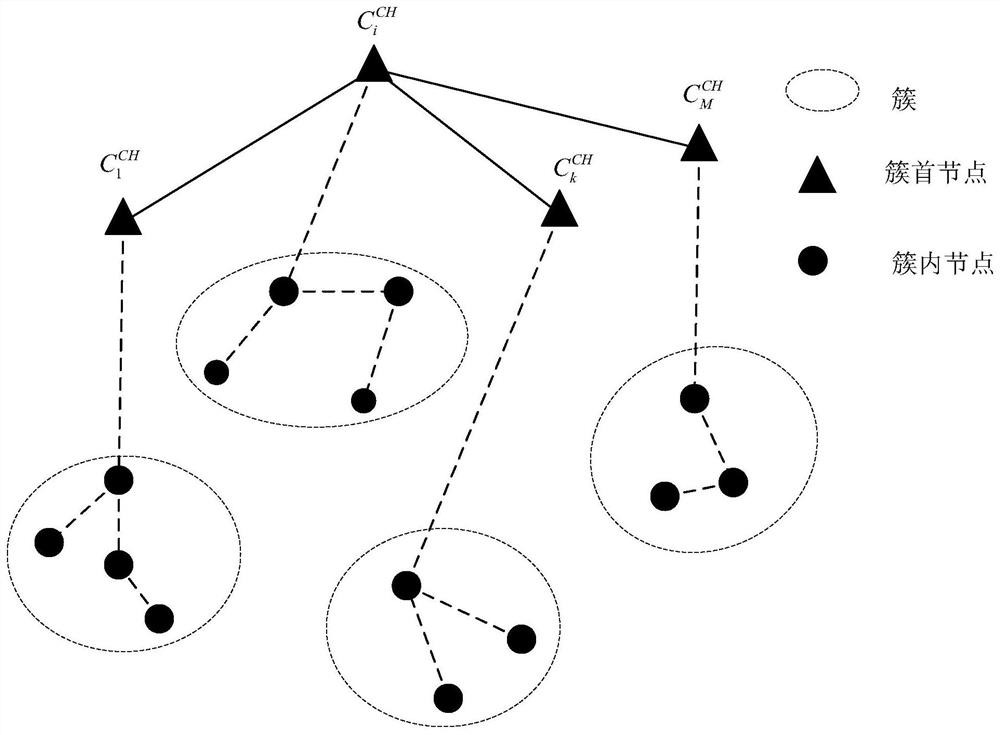

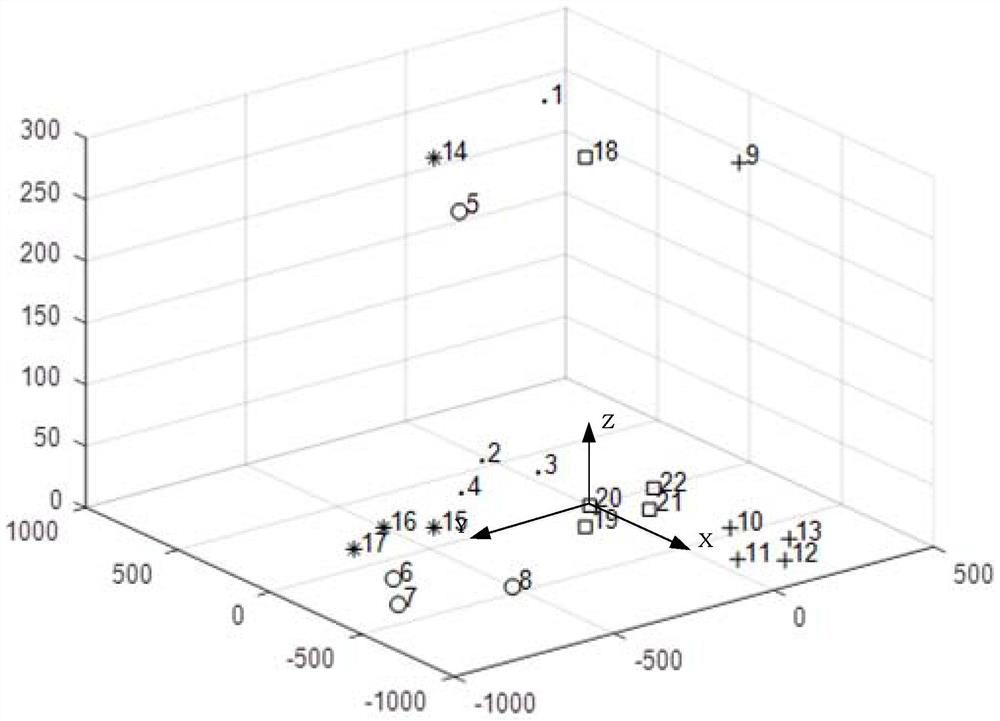

Hierarchical clustering network topology structure generation method based on multi-task unmanned aerial vehicle cluster information interaction

ActiveCN112437502AImprove adaptabilityEasy to ensure consistencyNetwork topologiesPosition/course control in three dimensionsUncrewed vehicleEngineering

The invention discloses a hierarchical clustering network topology structure generation method based on multi-task unmanned aerial vehicle cluster information interaction. The method comprises the following steps: a step of determining an unmanned aerial vehicle cluster set and a position matrix of each cluster; a step of constructing a network topology structure of intra-cluster information interaction of each cluster; and a step of constructing a network topology structure of inter-cluster information interaction. According to the method, the unmanned aerial vehicle cluster is self-organizedby using the hierarchical clustering structure, and the mode of executing different tasks in different clusters is adopted, so that the problems that the scale of the unmanned aerial vehicle clusteris limited and information interaction only faces a single task are solved. Centralized control is adopted in a cluster in SCH topology of multi-task unmanned aerial vehicle cluster information interaction, a minimum spanning tree is calculated with a cluster head as a root to construct a network topology structure of any independent cluster, and therefore information interaction in all the independent clusters is completed. A spatial interaction gravitation model is introduced between the clusters to construct an inter-cluster network topology structure so as to complete information interaction between the unmanned aerial vehicle clusters.

Owner:BEIHANG UNIV

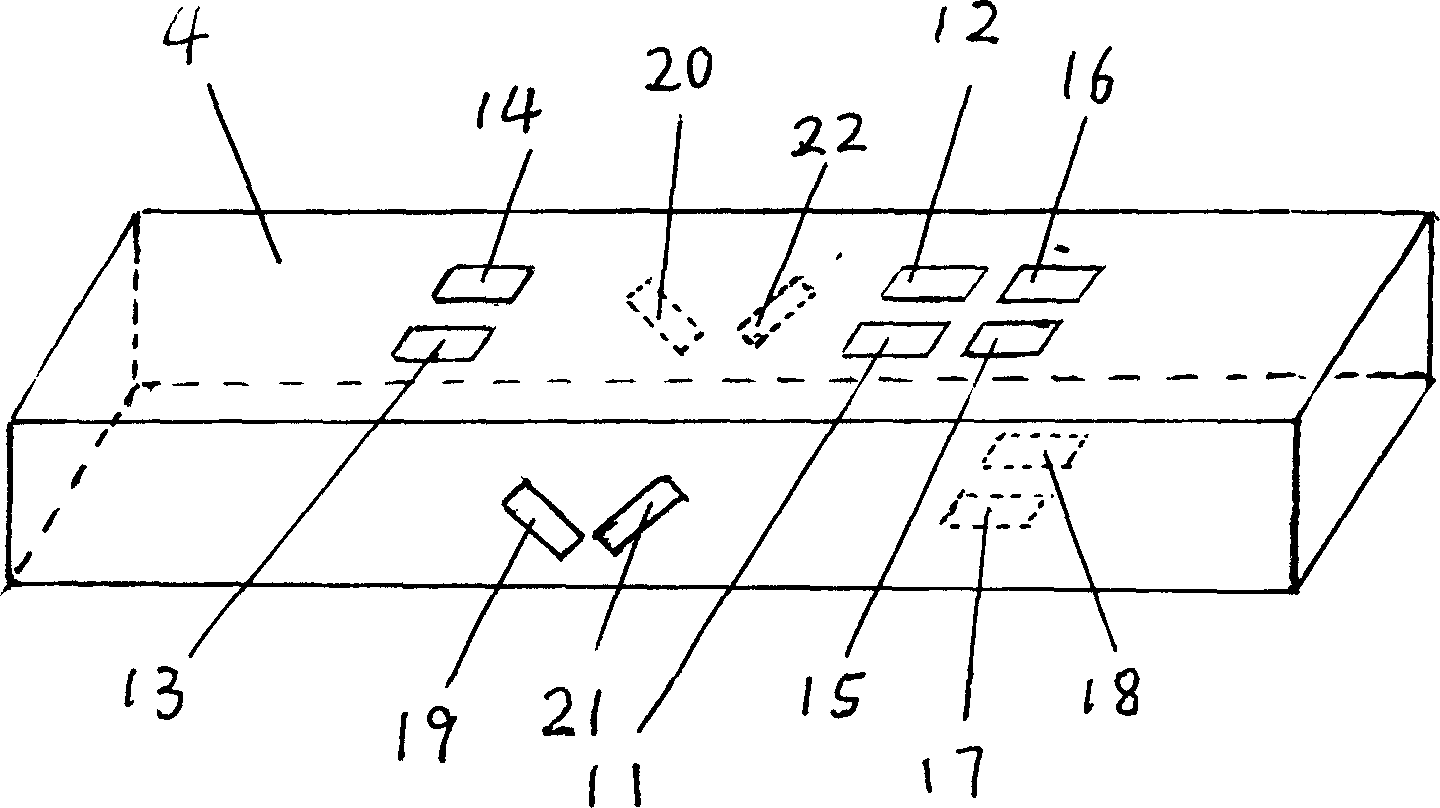

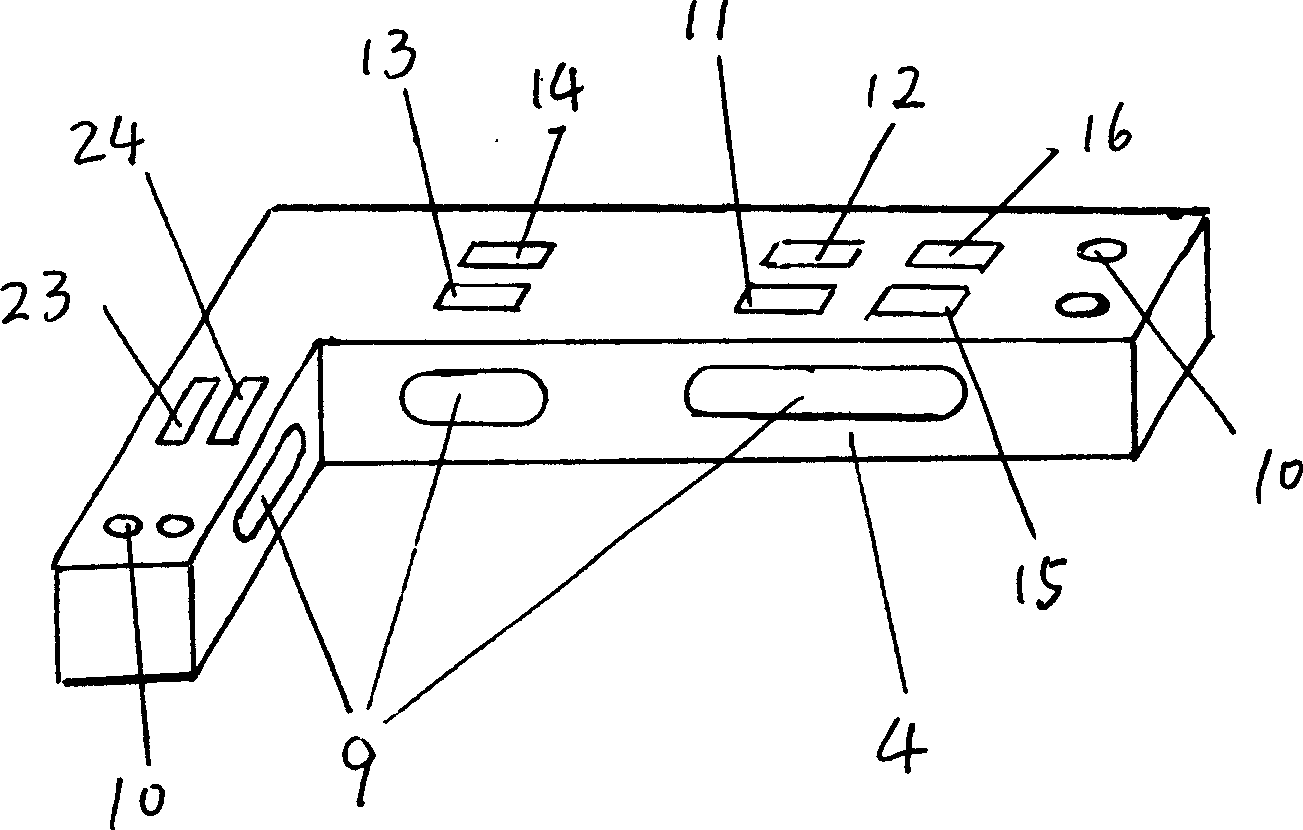

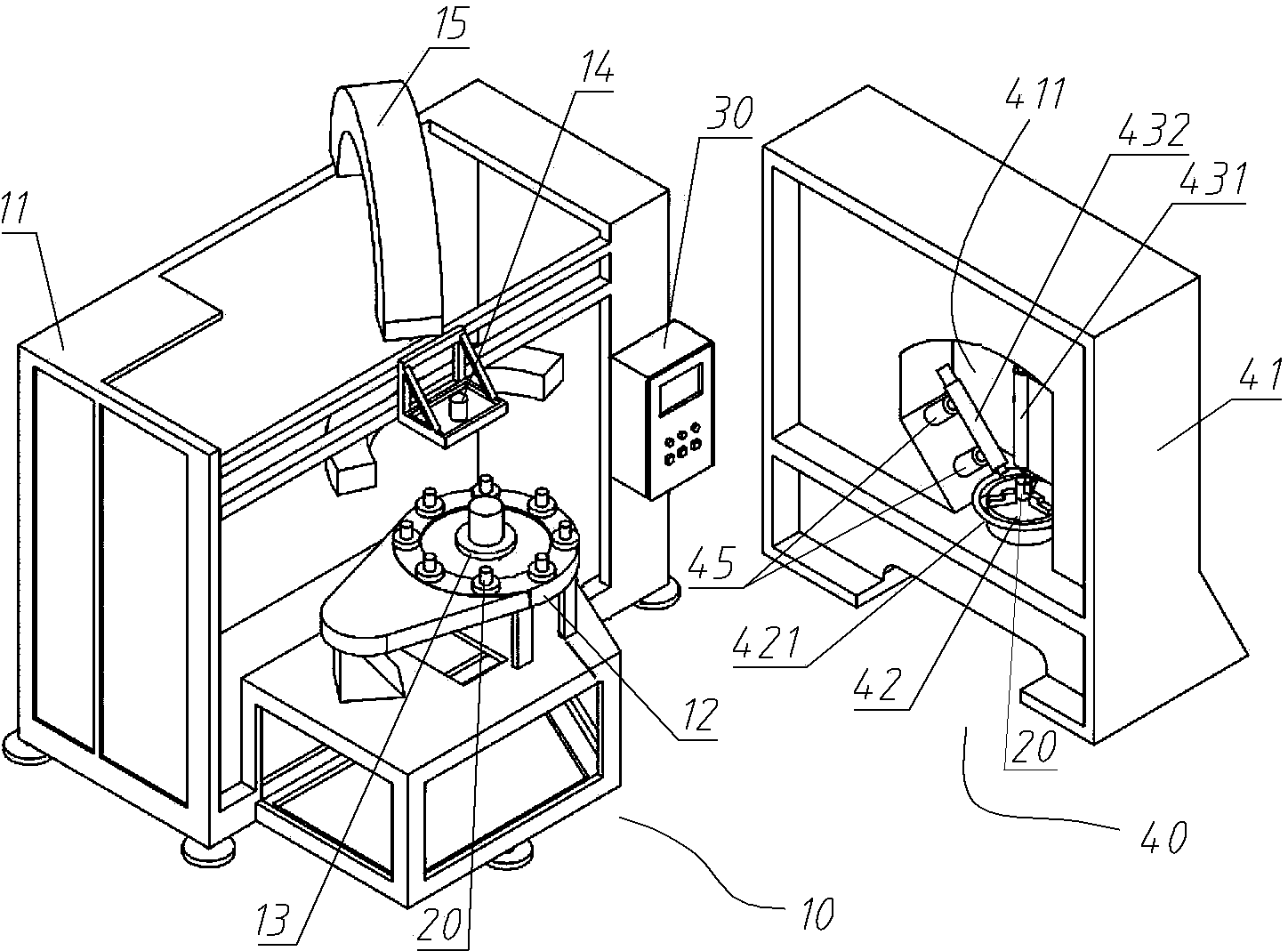

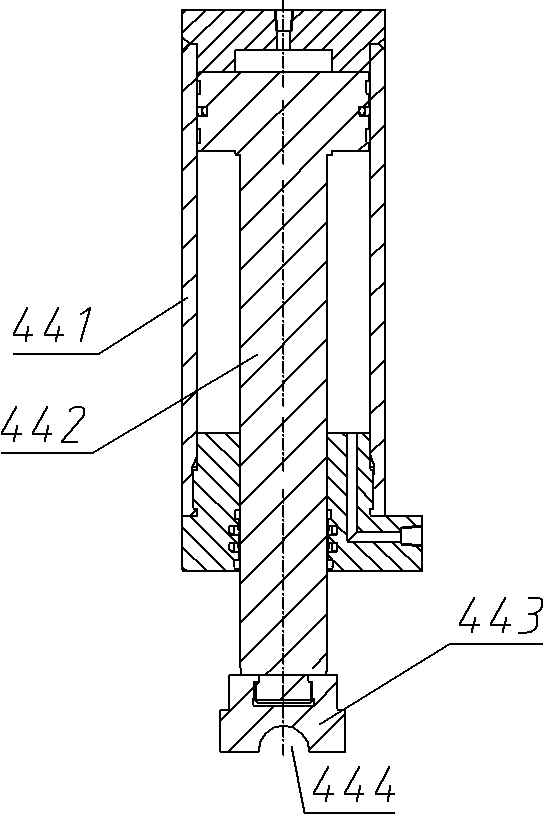

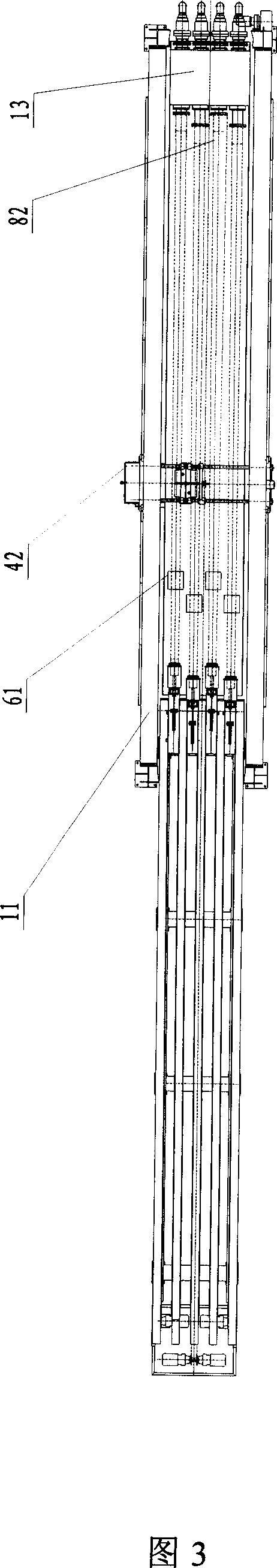

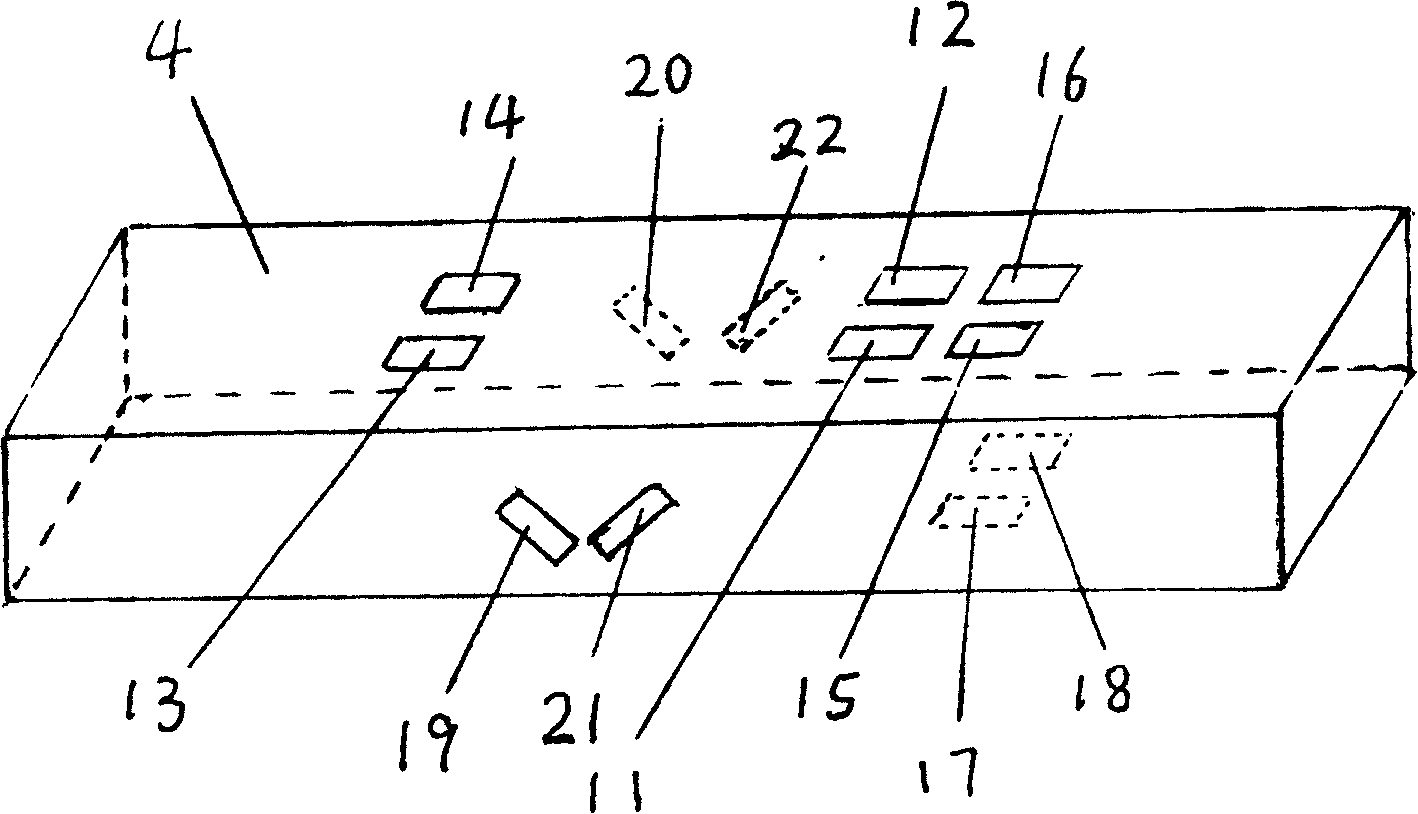

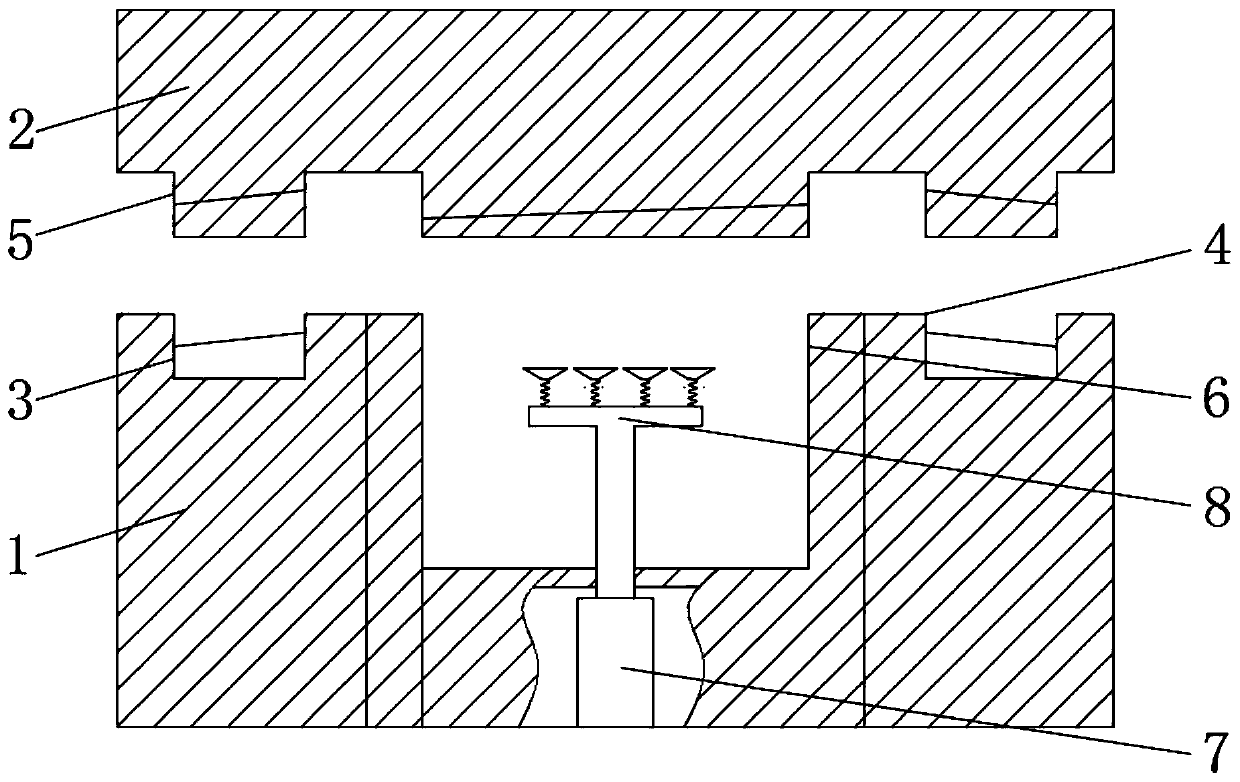

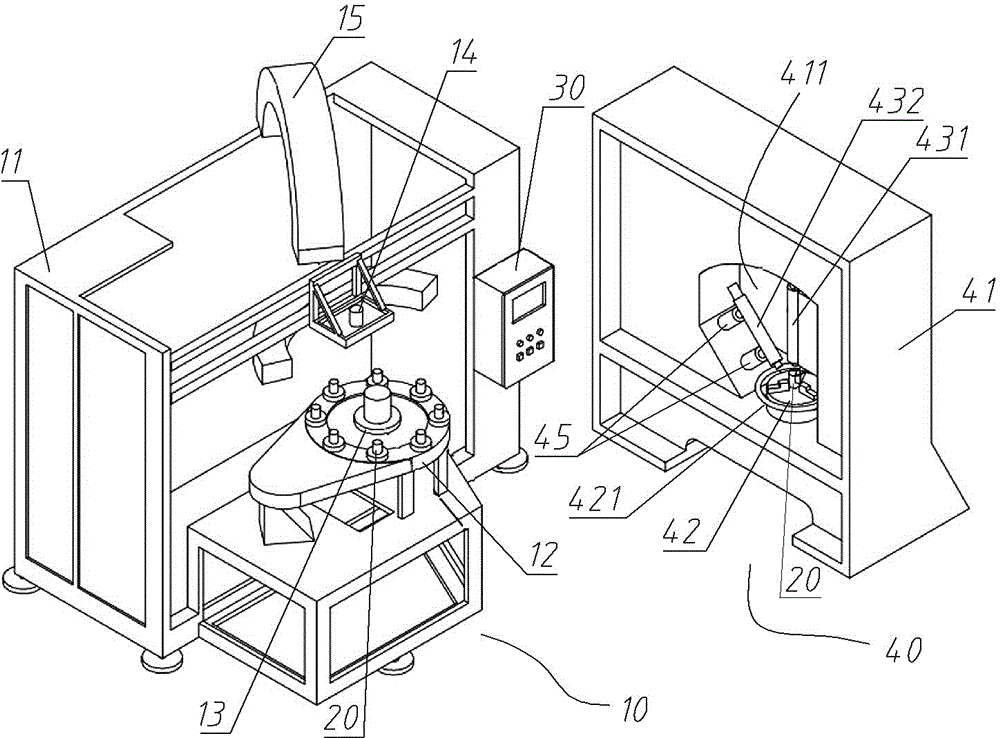

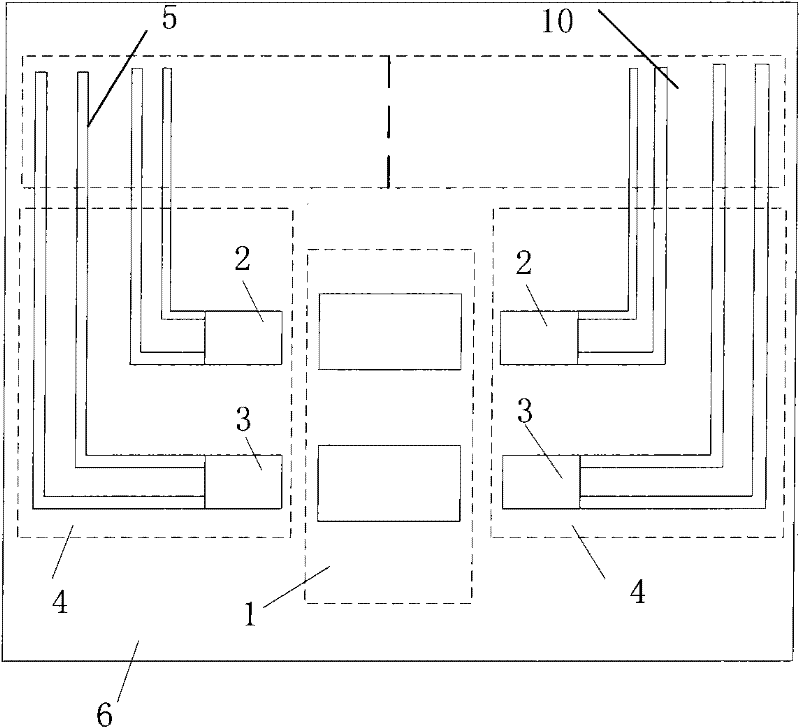

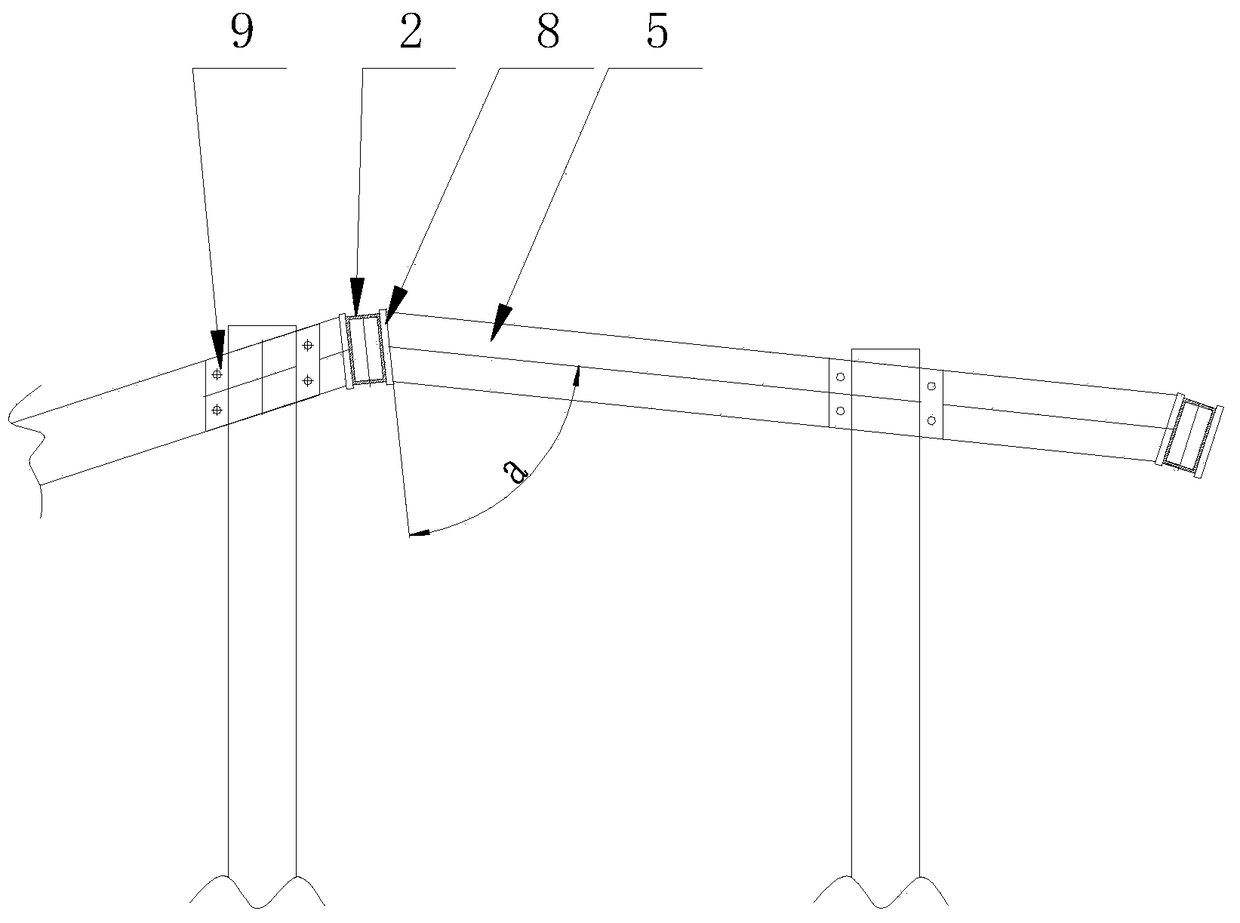

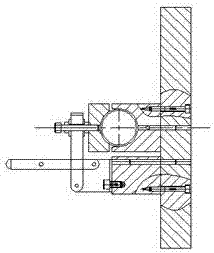

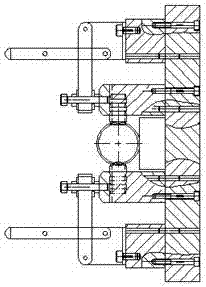

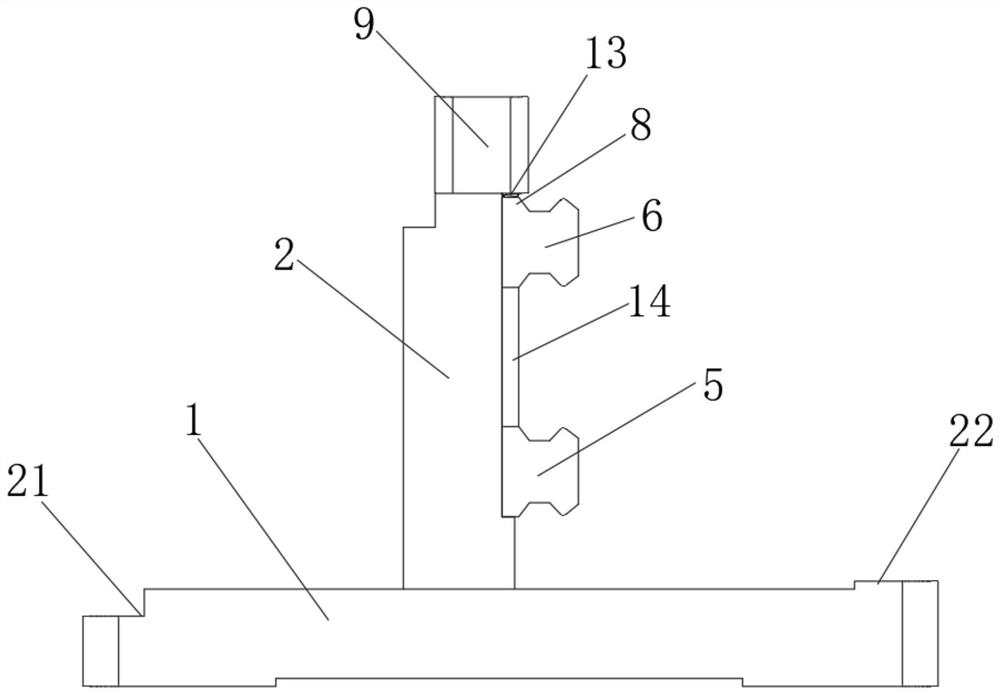

Drill bit tooth pressing device and thermal tooth inserting equipment with drill bit tooth pressing device

InactiveCN104014982ASo as not to damageEasy to ensure consistencyMetal working apparatusEngineeringWell control

The invention relates to a drill bit tooth pressing device and thermal tooth inserting equipment with the drill bit tooth pressing device. The drill bit tooth pressing device comprises a rack. A base body positioning base used for fixing a drill bit base body and a telescopic tooth pressing device corresponding to tooth holes in the drill bit base body are arranged on the rack. The telescopic tooth pressing device is provided with pressing heads extending forwards in the axial direction of the corresponding tooth holes and pressing tooth heads into the corresponding tooth holes in the drill bit base body. A base body positioning base has the axis extending in the axial direction of the drill bit base body fixed to the base body positioning base. The telescopic tooth pressing device is rotationally assembled on the rack around the axis of the base body positioning base or the base body positioning base is rotationally assembled on the rack around the axis of the base body positioning base. After the drill bit base body is fixed, the base body positioning base or the telescopic tooth pressing device is rotated so that the tooth holes in the drill bit base body can correspond to the pressing heads of the telescopic tooth pressing device respectively, and then the tooth heads are pressed through power of the telescopic tooth pressing device. According to the drill bit tooth pressing device and the thermal tooth inserting equipment with the drill bit tooth pressing device, alignment is easy, operation is convenient, production efficiency is high, and product quality can be well controlled.

Owner:HUANGHE S & T COLLEGE

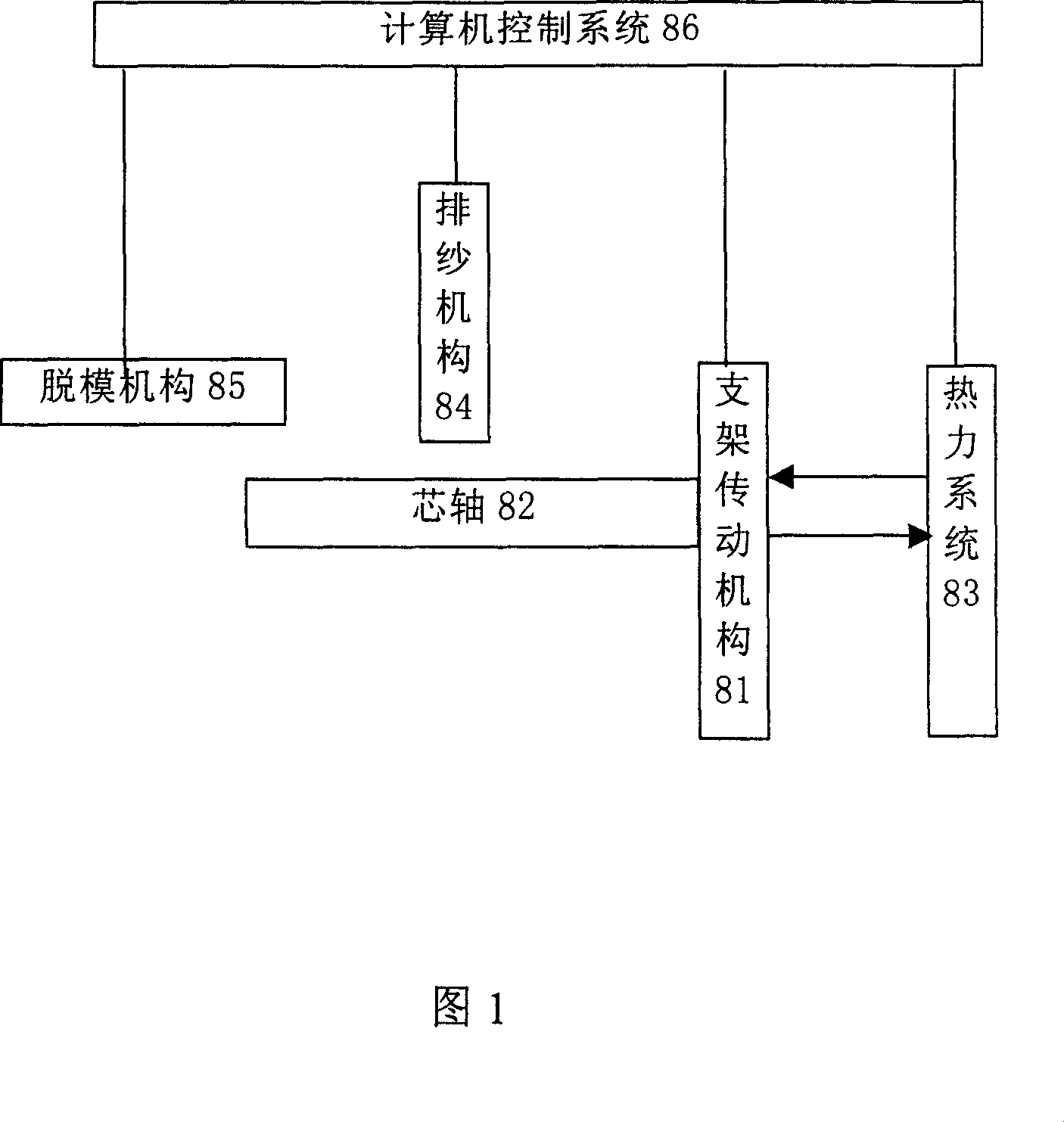

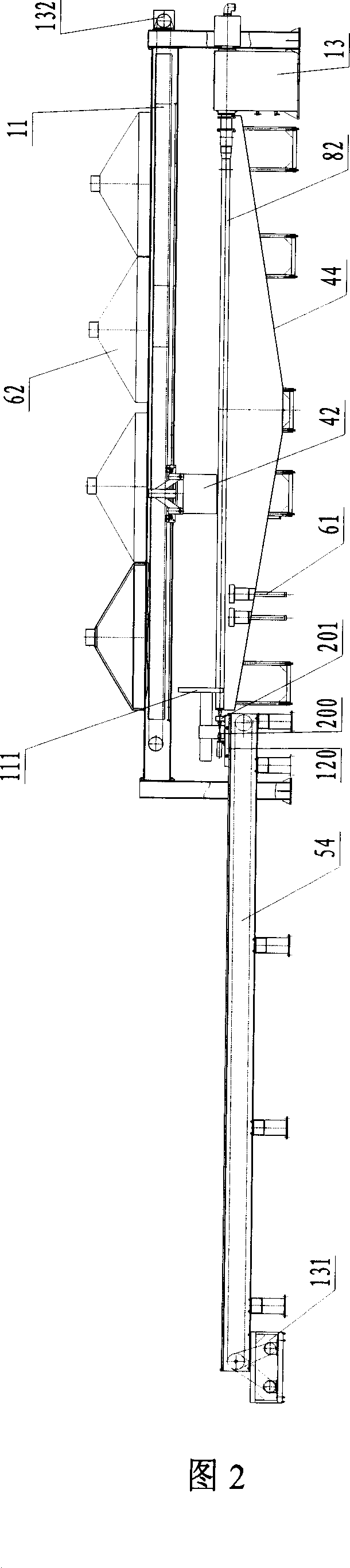

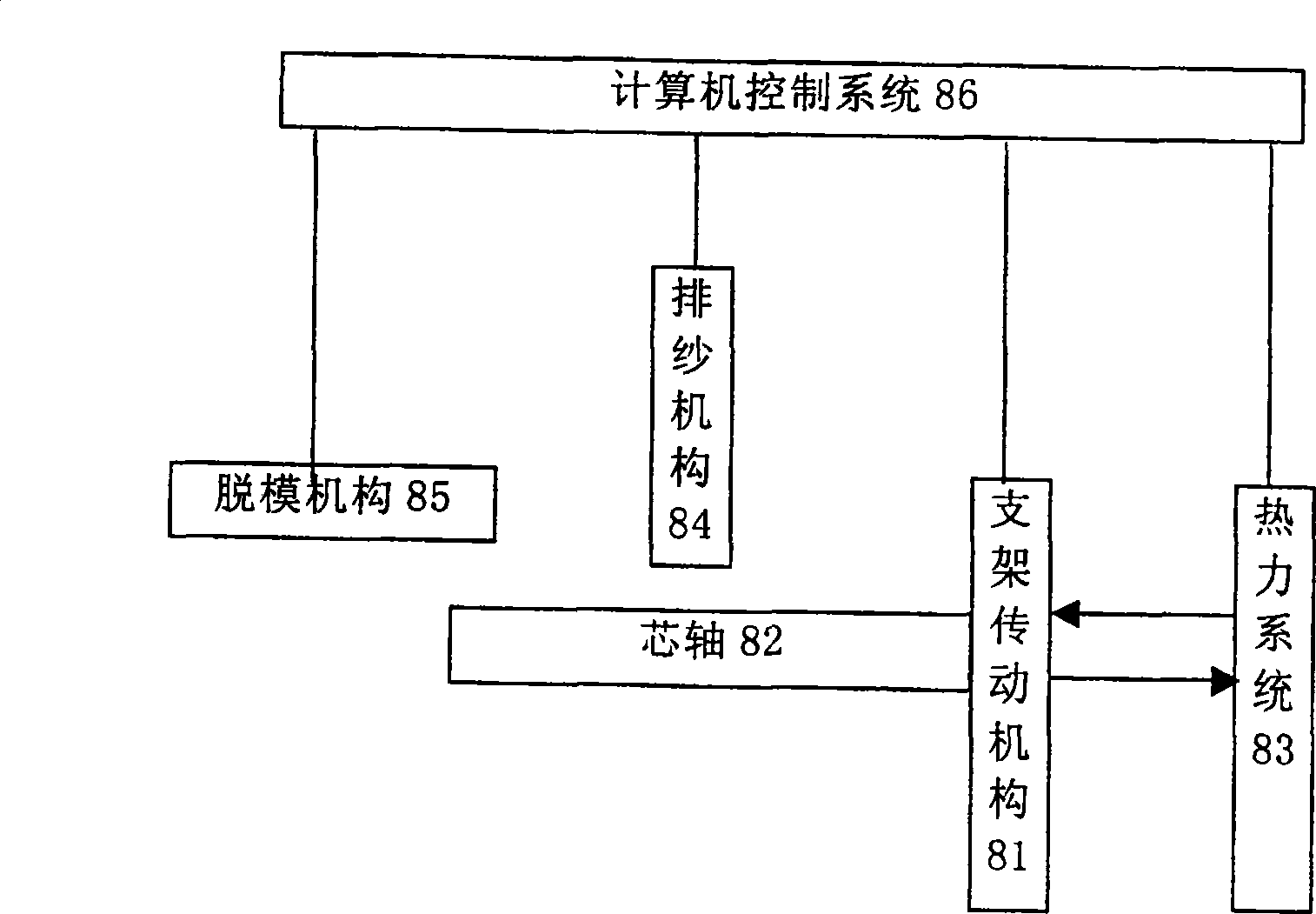

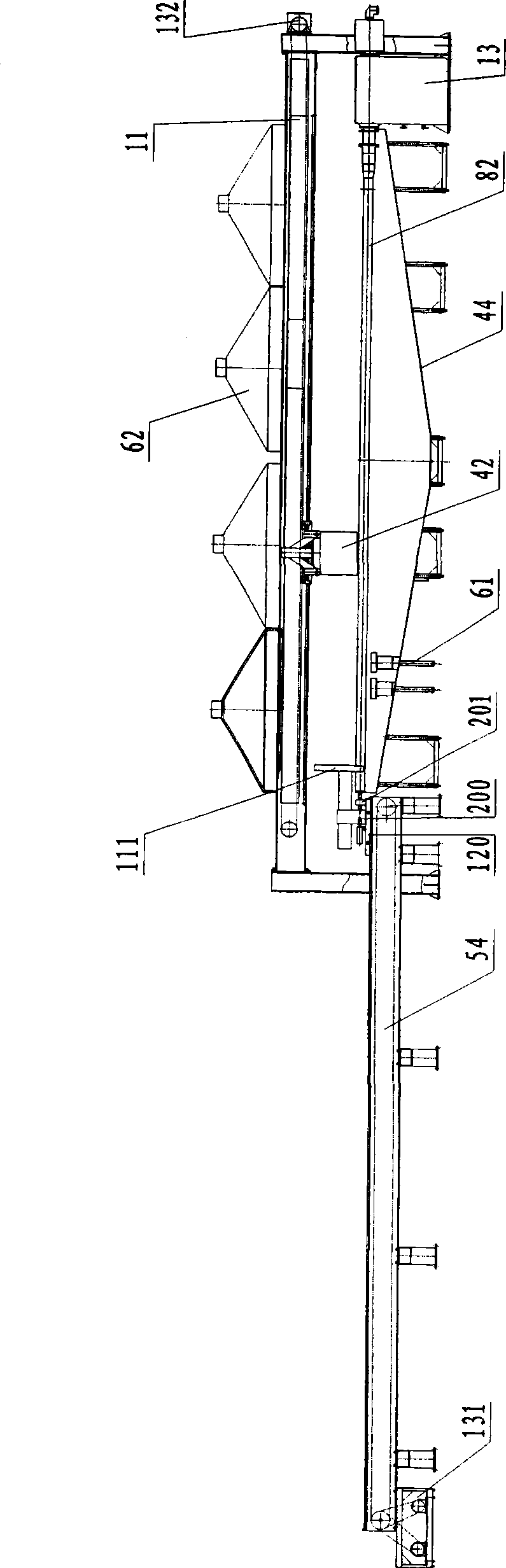

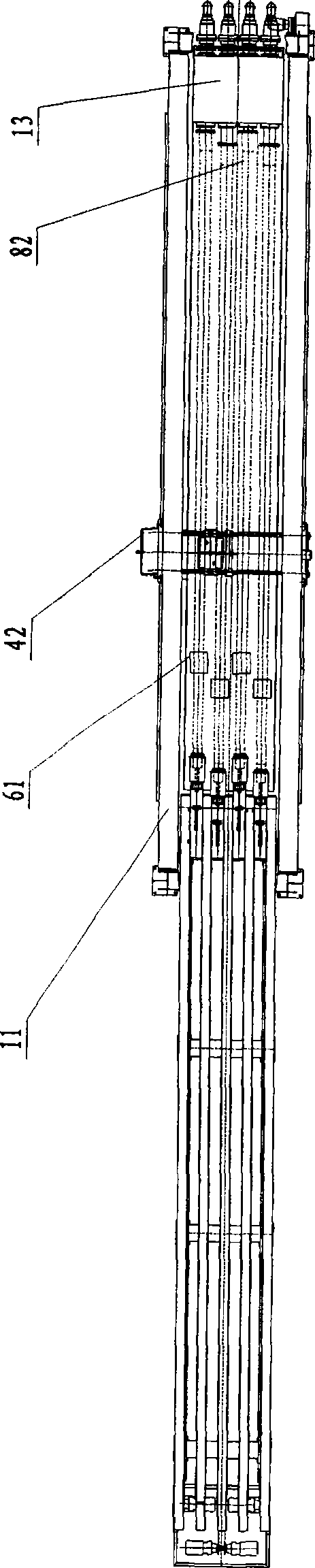

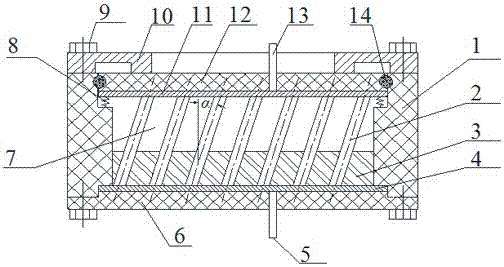

Producing system of internally-heating curing glass fibre reinforced plastic controlled by programm

InactiveCN1982037AImprove product qualityIncrease productivityProgramme controlComputer controlYarnGlass fiber

A program controlled system with internal heating and solidifying for preparing the glass fiber reinforced plastic pipe is composed of a supporting frame-drive mechanism, a dual-layer metallic mandrel for delivering high-temp steam, a steam system, a yarn arranging system, a demoulding unit and computer control system.

Owner:北京朗瑞达管道技术有限公司

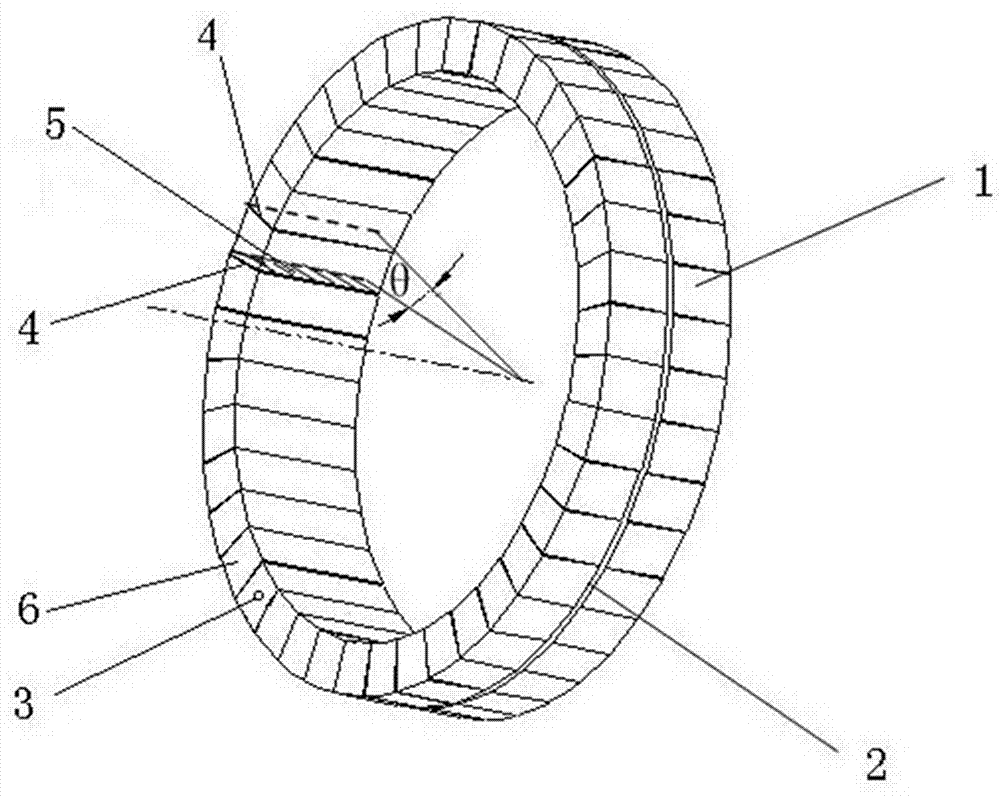

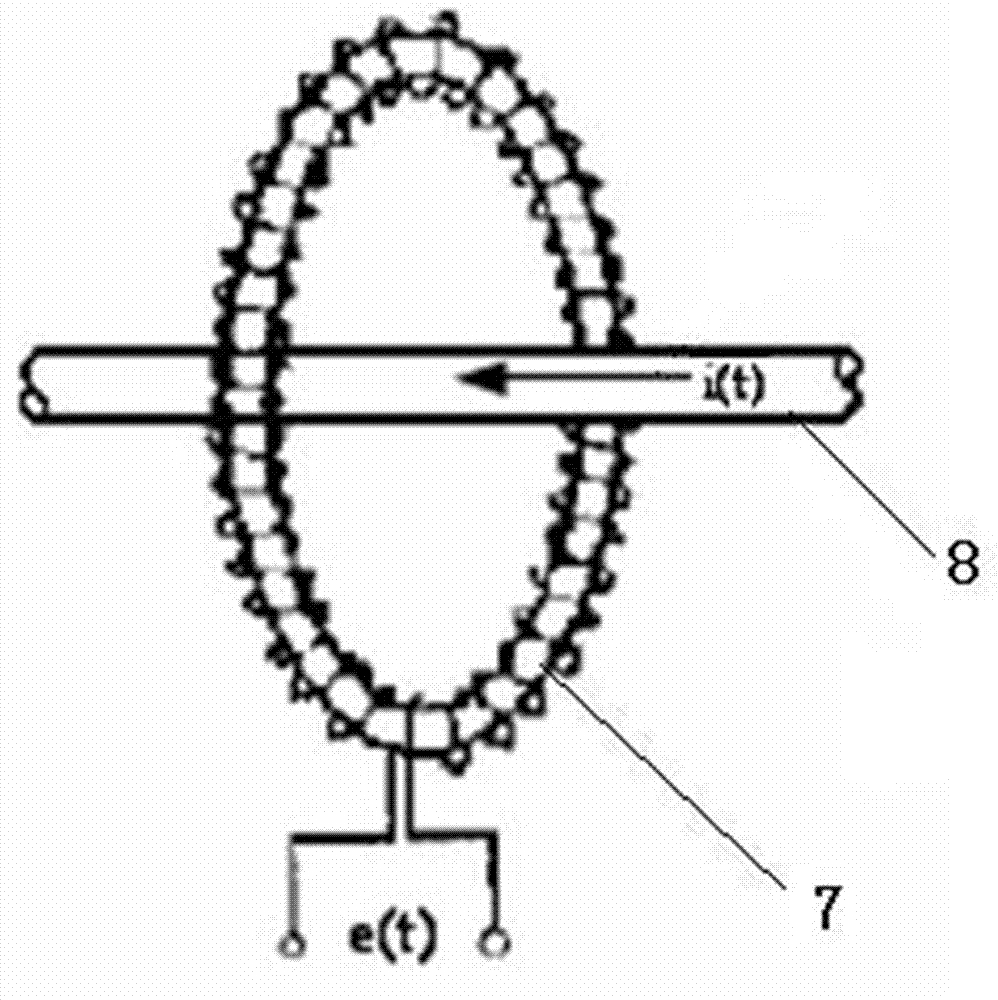

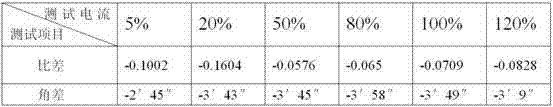

Winding process of electronic current mutual inductor based on Rogowski coil

InactiveCN102969143ALow costImprove electromagnetic parametersCoils manufactureInductorBatch production

The invention provides a winding process of an electronic current mutual inductor based on a Rogowski coil, which comprises the steps of: (1) depicting an identifying break line uniformly on the outer surface of a circular coil framework, wherein the break line is vertical to the circumference of the circular coil framework, and distances between adjacent break lines are equal; and (2) winding a loop first along a loop groove of the coil framework; and then, maintaining a constant hand power with the break line as reference, winding a coil uniformly on the coil framework so that the turns of the coils between adjacent break lines is equal in number. According to the winding process of the electronic current mutual inductor based on the Rogowski coil provided by the invention, the coil is winded with the break line as reference, and the verticality of the wire turn section relative to the coil framework is ensured in low cost, and the wire turn is distributed compactly and uniformly, so that the electromagnetic parameters of the coil are optimized, and the consistency of the wire turn of the coil is ensured, and uniformity of the output voltage of the coil is ensured. The winding process of the electronic current mutual inductor based on the Rogowski coil provided by the invention facilitates batch production.

Owner:CHINA TIANSHUI CHANGCHENG SWITCHGEAR CO LTD

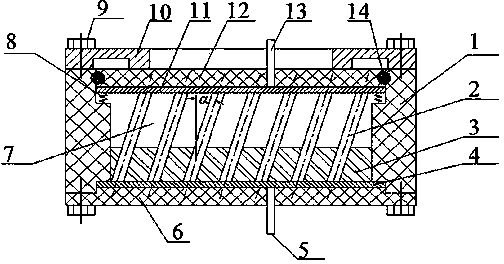

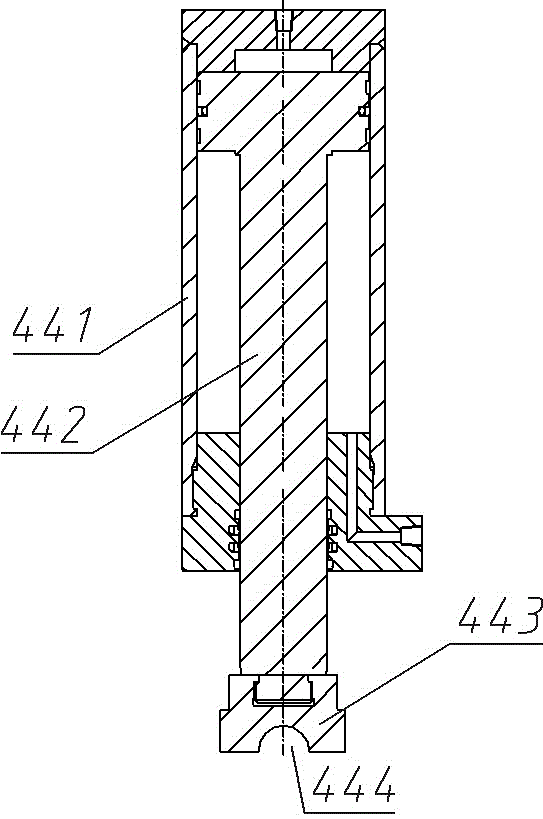

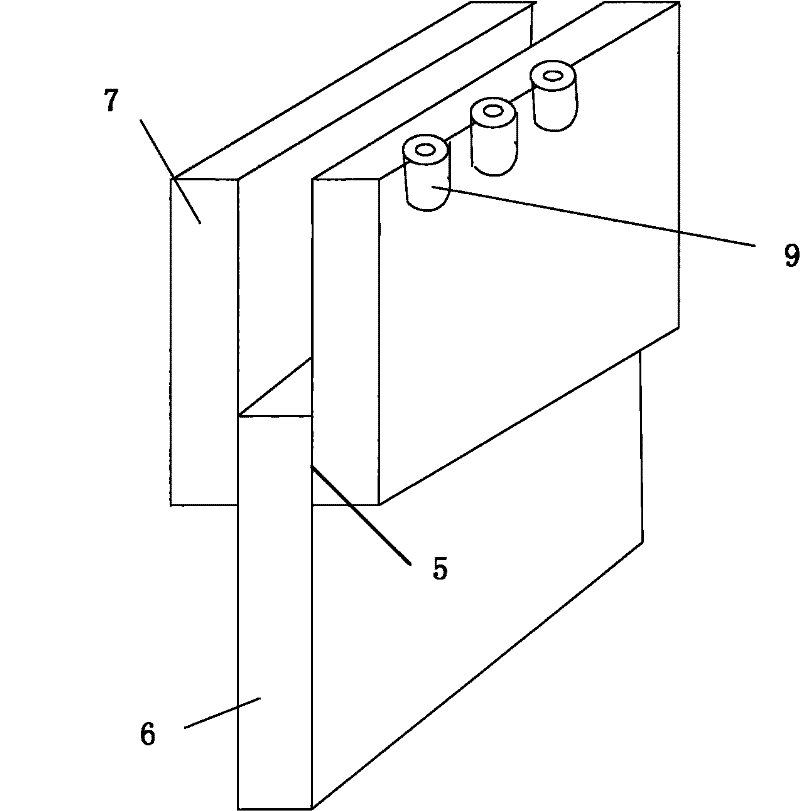

Piezoelectric ceramic sensor oscillator

InactiveCN104538547AHigh sensitivityOvercoming the characteristics of difficult to make large-scale structuresPiezoelectric/electrostrictive device detailsElectricityMetallurgy

The invention discloses a piezoelectric ceramic sensor oscillator. The sensor oscillator comprises a shell, a plurality of piezoelectric ceramic columns, a support, an upper pole plate, a lower pole plate, an upper covering plate, a lower covering plate, an upper binding post, a lower binding post and a pressing plate. The piezoelectric ceramic columns are fixed in the shell through the support, the upper pole plate, the upper covering plate and the pressing plate are arranged above the piezoelectric ceramic columns in sequence, the lower pole plate and the lower covering plate are arranged below the piezoelectric ceramic columns in sequence, the upper pole plate is connected with the upper binding post, and the lower pole plate is connected with the lower binding post. The piezoelectric ceramic columns are adopted, the advantages that sensitivity is high, and the defect that piezoelectric ceramic pieces cannot be manufactured to be of a large-size structure easily in the aspect of mounting and manufacturing and low frequency is overcome are achieved, consistency of parameters of the piezoelectric ceramic columns is guaranteed easily, the sensitivity of low-frequency signals is improved, and the large frequency response range is achieved.

Owner:XIAN TECH UNIV

A kind of preparation method of gold-tin-tin wire, foil tape and solder preform

ActiveCN103753057BKeep it brightAvoid formingWelding/cutting media/materialsSoldering mediaAlloyMachining

The invention provides a production method of a gold-tin wire, a foil belt and a preforming welding piece and belongs to the welding technical field. The production method comprises step 1, smelting gold and tin into alloy and casting the gold and the tin into an alloy rod; step 2, performing annealing; step 3, performing extrusion forming which comprises arranging a tin wire die with a circular hole at the position of the outlet of an extruding machine first when the ally rod needs to be extruded into a tin wire and arranging a foil belt die with a square hole at the position of the outlet of the extruding machine first when the ally rod needs to be extruded into the foil belt, then placing the product in the step 2 into the extruding machine, adjusting the intensity of pressure of the extruding machine to 250 to 350 Mpa and adjusting the temperature to 150 to 230 DEG C; step 4, cutting the foil belt which is obtained through extrusion in the step 3 into the preforming welding piece. According to the production method of the gold-tin wire, the foil belt and the preforming welding piece, the problem that the machining forming is difficult due to the high brittleness of the gold-tin alloy in the prior art is solved, the technological process is simple and convenient, the mass production can be performed, the product accuracy is good, and the product consistency is good.

Owner:SHENZHEN FUMOSUO METAL PROD

Information input apparatus with pressing plate and method thereof

InactiveCN100381993CHigh densityHigh precisionGraph readingMechanical pattern convertionElastomerEngineering

The invention relates to an information input device and method with pressing board that includes pressing board, force sensitive sensor, and casing. The whole support the pressing board gained would pass through a sensor elastic body. On the elastic body or the elastic body group and carrying the strain gauge, the pressed location would be calculated and judged according to the moment and torsion moment. The device and method simplifies the structure of the device and obviously improves the working accuracy, stability and reliability.

Owner:刘二中

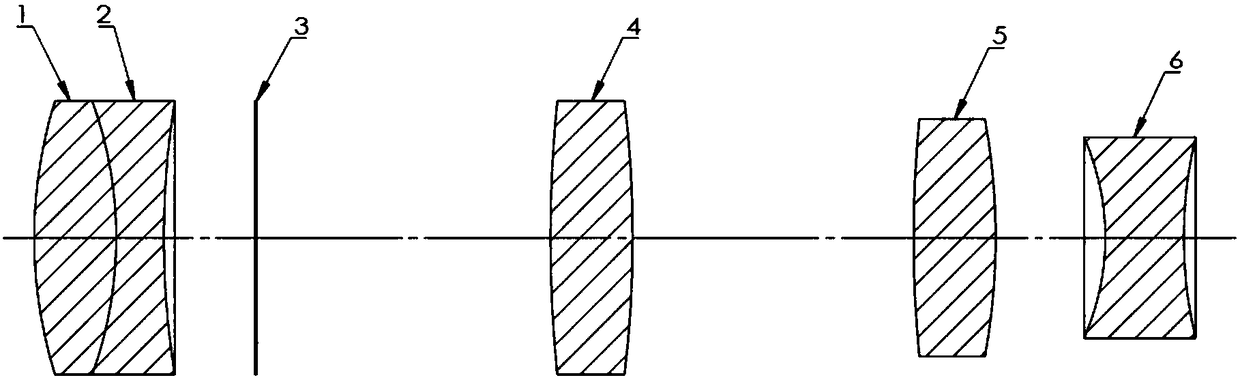

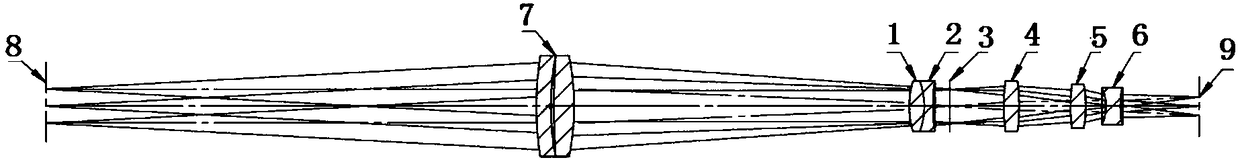

Coaxial machine vision optical imaging system for laser processing head

InactiveCN108388009AEasy to processEasy to batchCondensersLaser beam welding apparatusMachine visionLaser processing

The present invention discloses a coaxial machine vision optical imaging system for a laser processing head. The system comprises a first biconvex mirror, a first biconcave mirror, an adjustable diaphragm, a second biconvex mirror, a third biconvex mirror, and a second biconcave mirror. The first biconvex mirror, the first biconcave mirror, the adjustable diaphragm, the second biconvex mirror, thethird biconvex mirror and the second biconcave mirror are spherical lenses; the first biconvex mirror, the first biconcave mirror, the adjustable diaphragm, the second biconvex mirror, the third biconvex mirror and the second biconcave mirror are circular and center axes of the first biconvex mirror, the first biconcave mirror, the adjustable diaphragm, the second biconvex mirror, the third biconvex mirror and the second biconcave mirror are coaxial. The coaxial machine vision optical imaging system employs a full spherical mirror optical path structure, is easy to process, easy for batch andconsistency based on the spherical mirrors, employs three optical materials and cooperatively uses focus lenses to obtain good optical imaging quality, is suitable for optical fiber output laser processing head coaxial machine vision optical imaging, and is especially suitable for all the optical fiber output laser processing head coaxial machine vision optical imaging by taking fused quartz as focus lens materials.

Owner:SHANGHAI EMPOWER AUTOMATION TECH CO LTD

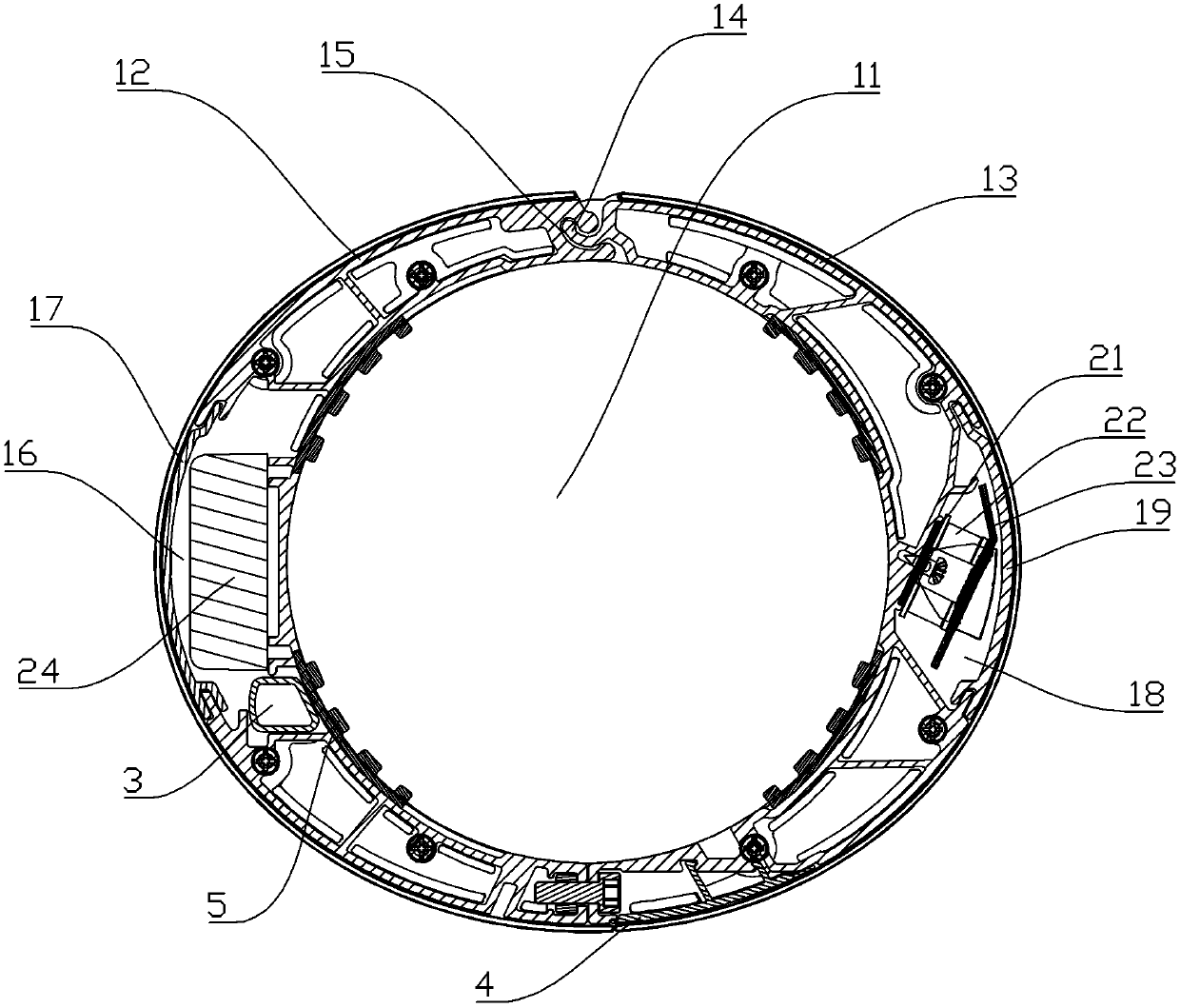

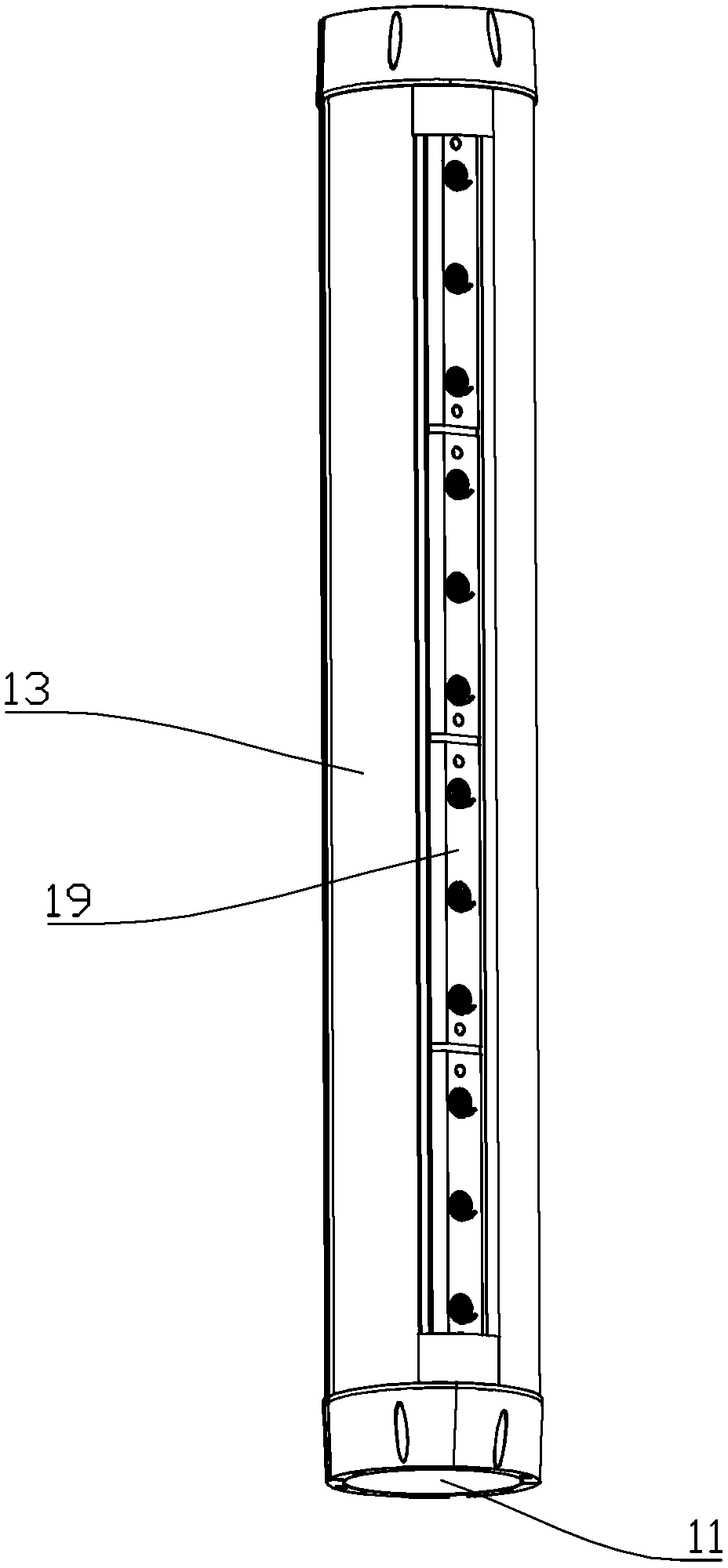

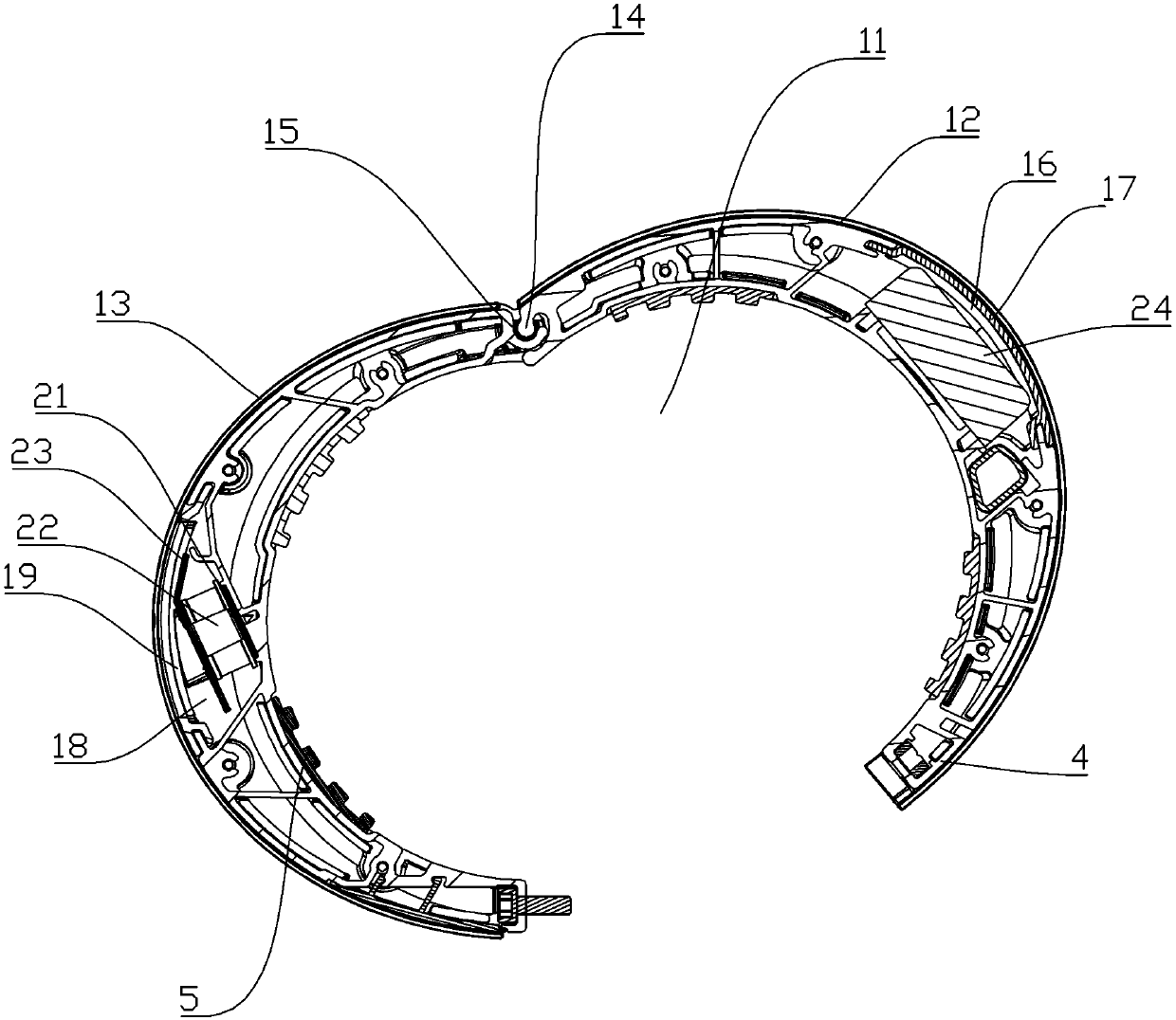

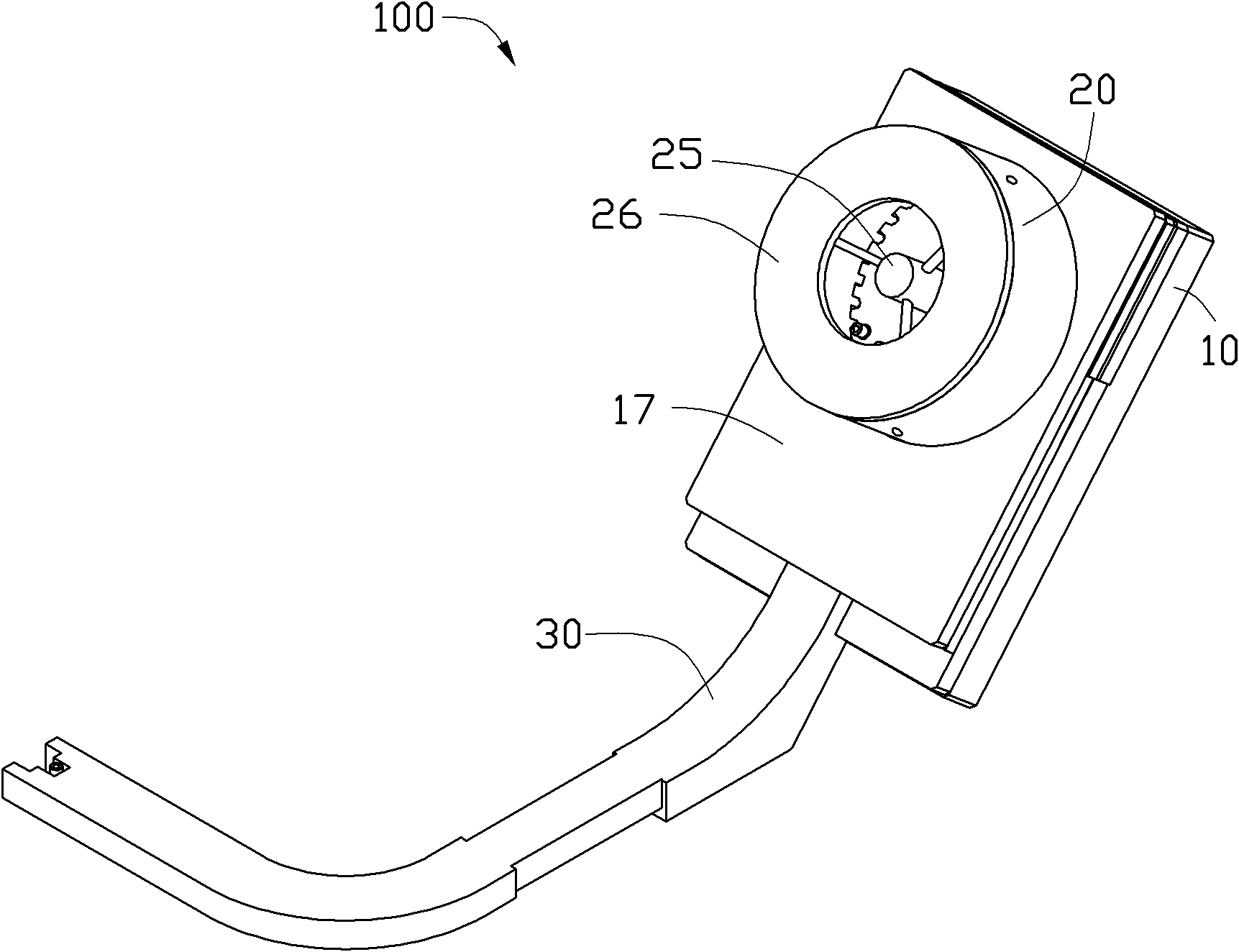

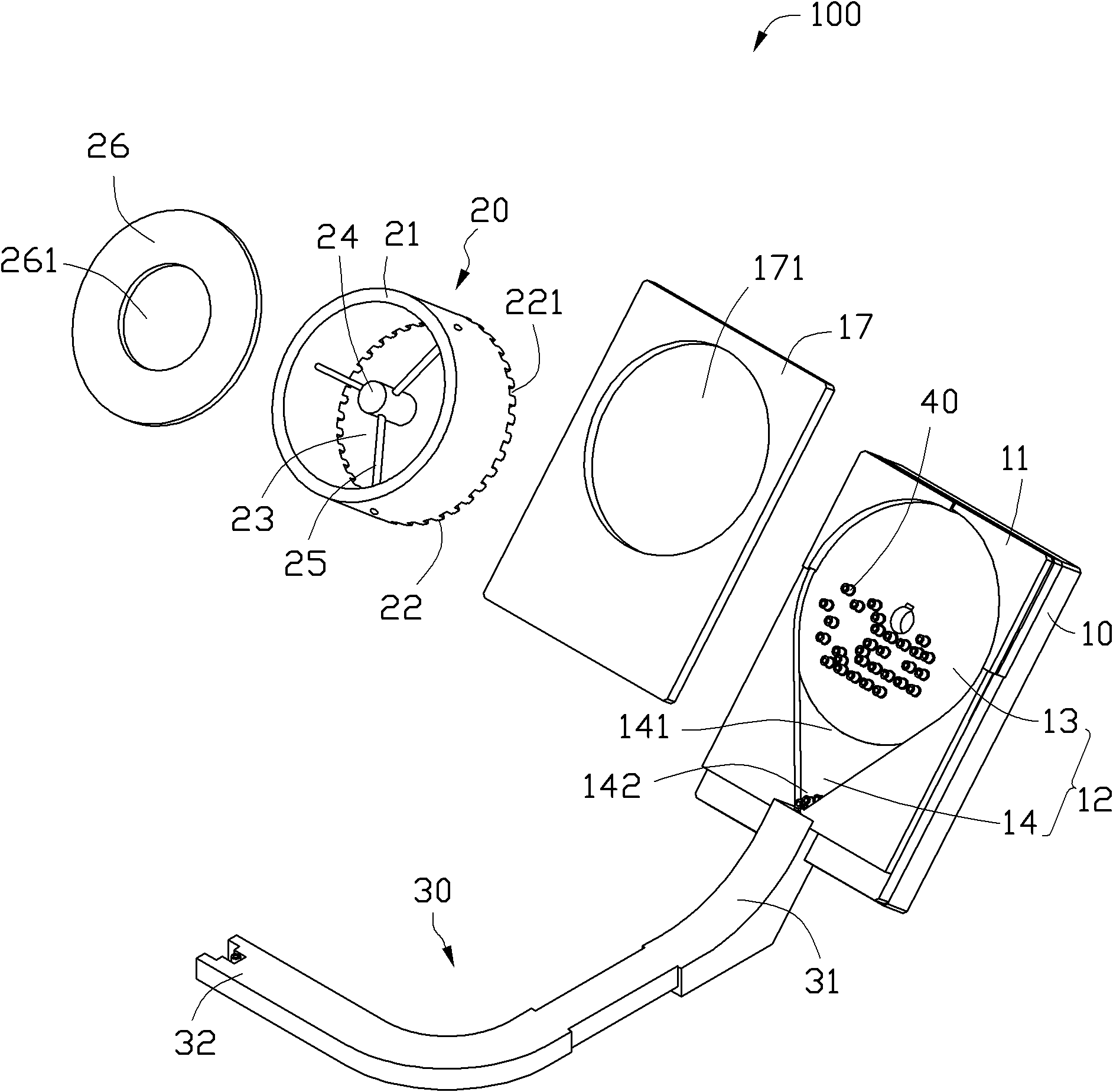

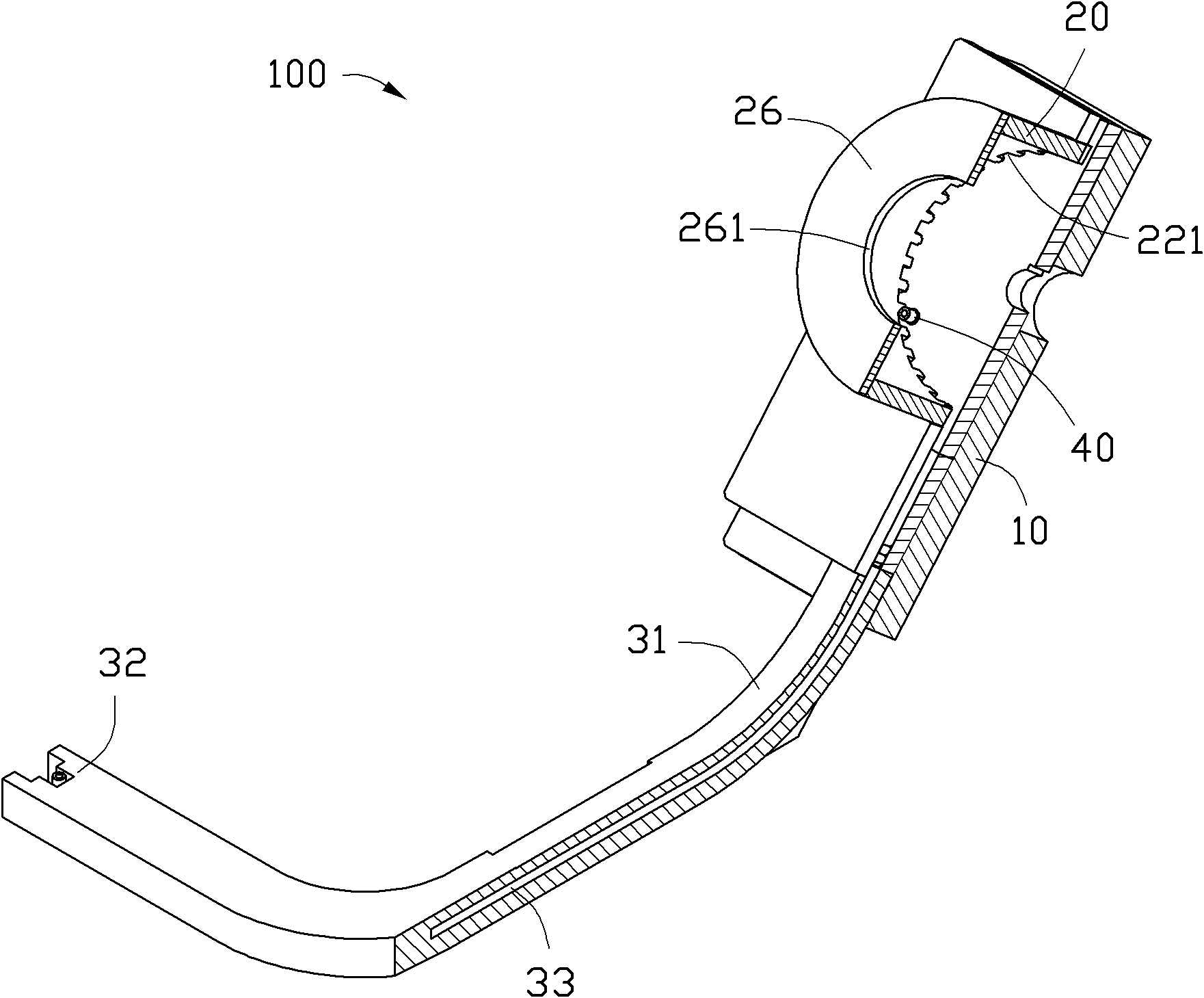

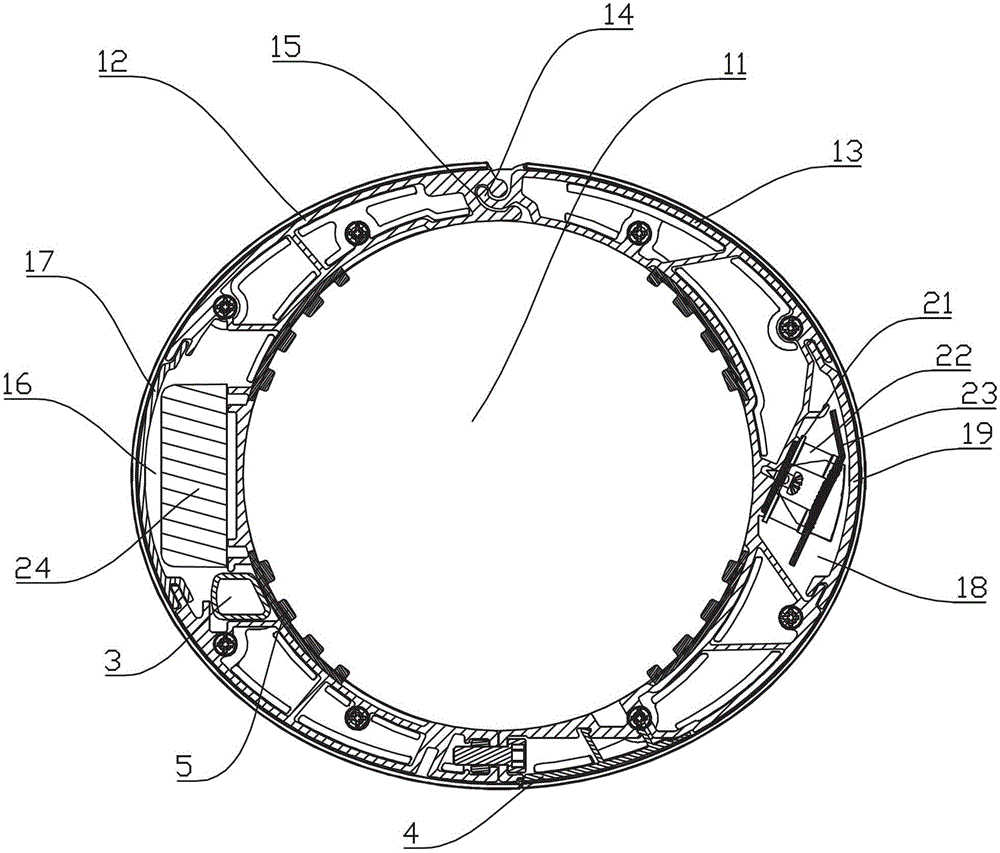

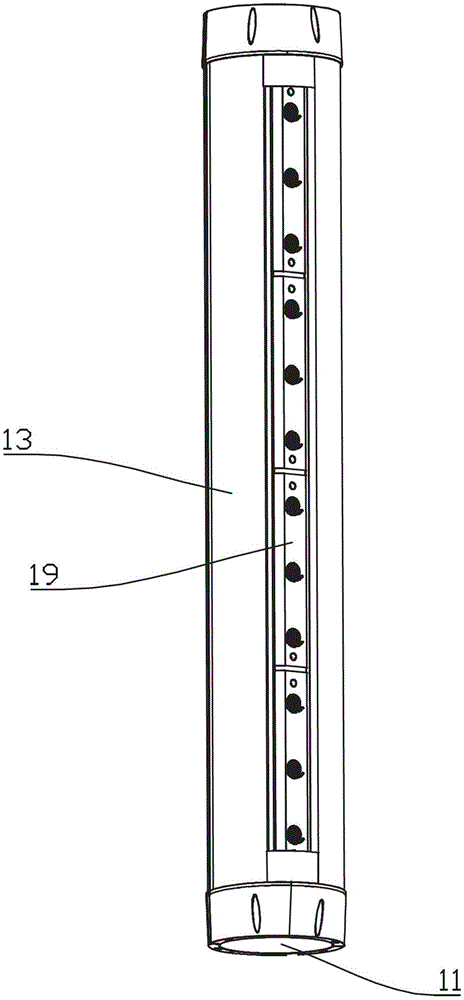

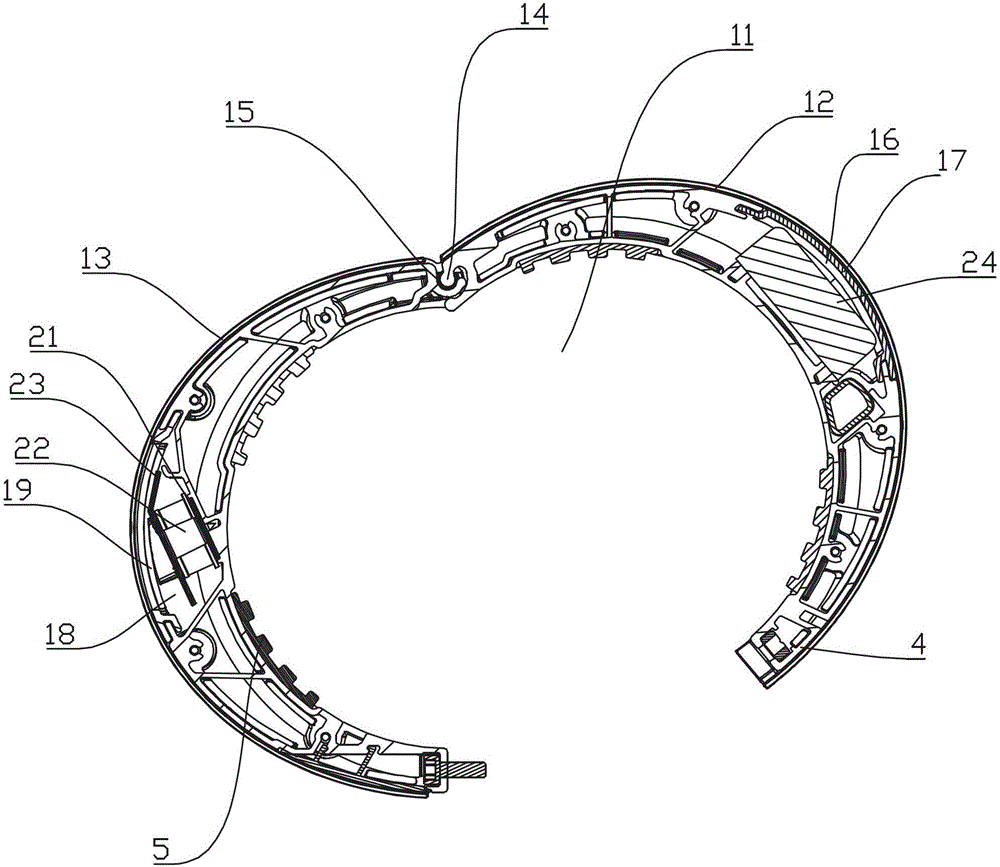

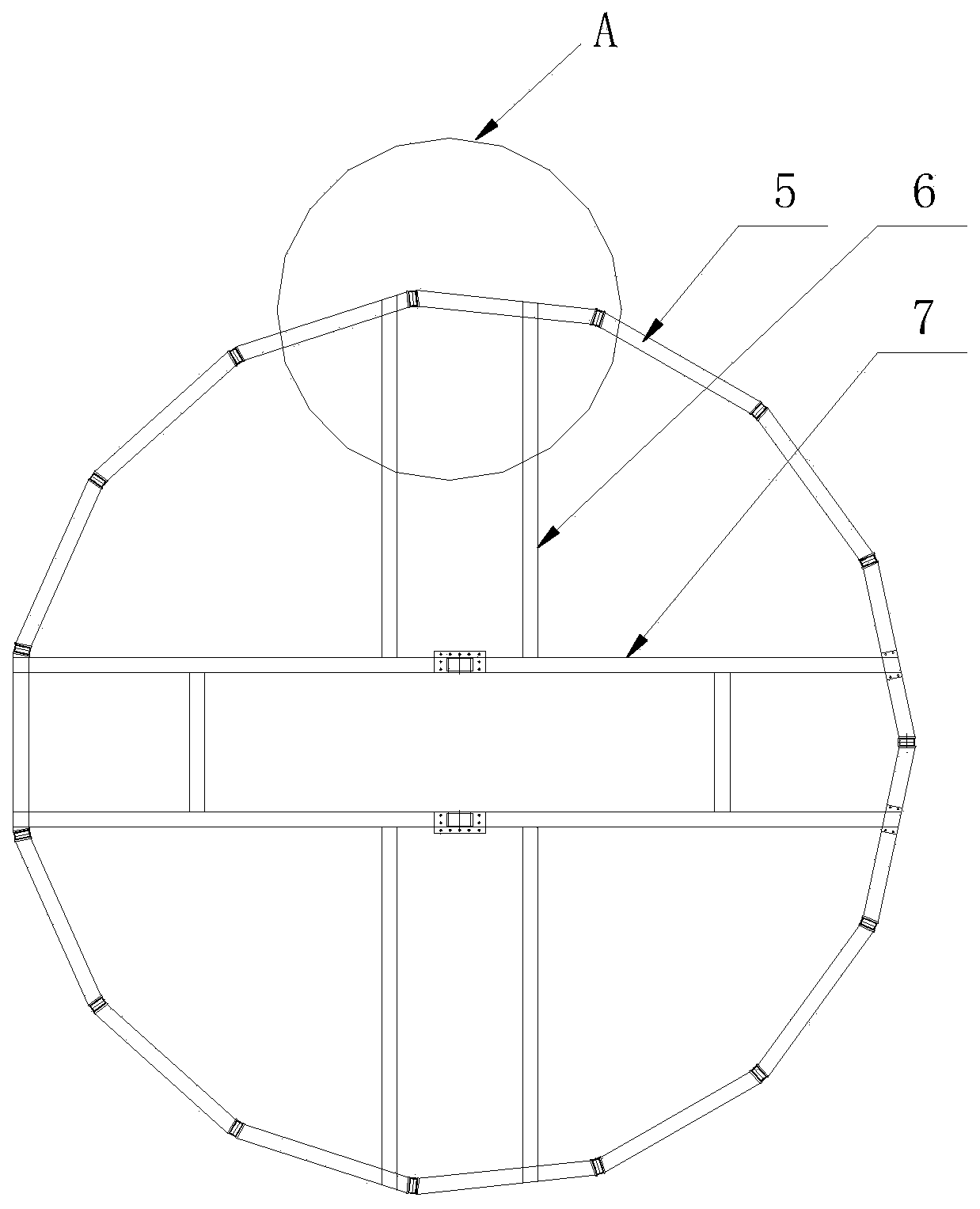

Encircling LED road bridge handrail lamp

ActiveCN103343920ALittle impact on appearanceCosmetic impact is minimizedLighting applicationsPoint-like light sourceManufacturing technologyEngineering

The invention discloses an encircling LED road bridge handrail lamp which comprises a tube-shaped outer shell and an LED assembly. The tube-shaped outer shell can be fixedly installed on a handrail, and an inner cavity of the tube-shaped outer shell is matched with the handrail in shape. The LED assembly is installed inside the tube-shaped outer shell. The tube-shaped outer shell comprises a first outer shell and a second outer shell. One end of the first outer shell and one end of the second outer shell are connected together through a connecting device in a pivoting mode, and the other end of the first outer shell and the other end of the second outer shell are fixedly connected through a bolt. The connecting device comprises a circular-arc-shaped clamping hook and a circular-arc-shaped clamping hole, wherein the circular-arc-shaped clamping hook is arranged at the end of the second outer shell, and the circular-arc-shaped clamping hole is formed in the end of the first outer shell and matched with the circular-arc-shaped clamping hook. The encircling LED road bridge handrail lamp is independent of the handrail, in other words, only the LED road bridge handrail lamp needs to be provided, and the handrail needs not to be manufactured. Therefore, different installation requirements of an old bridge and a new bridge can be met at the same time. The encircling LED road bridge handrail lamp is easy to install on site, and meanwhile uniformity of the installation angle of the LED road bridge handrail lamp is easy to ensure. After the LED road bridge handrail lamp is installed, influences on the appearance of the handrail are minimized and the manufacturing technology is simple.

Owner:广东迪艾生光电技术有限公司

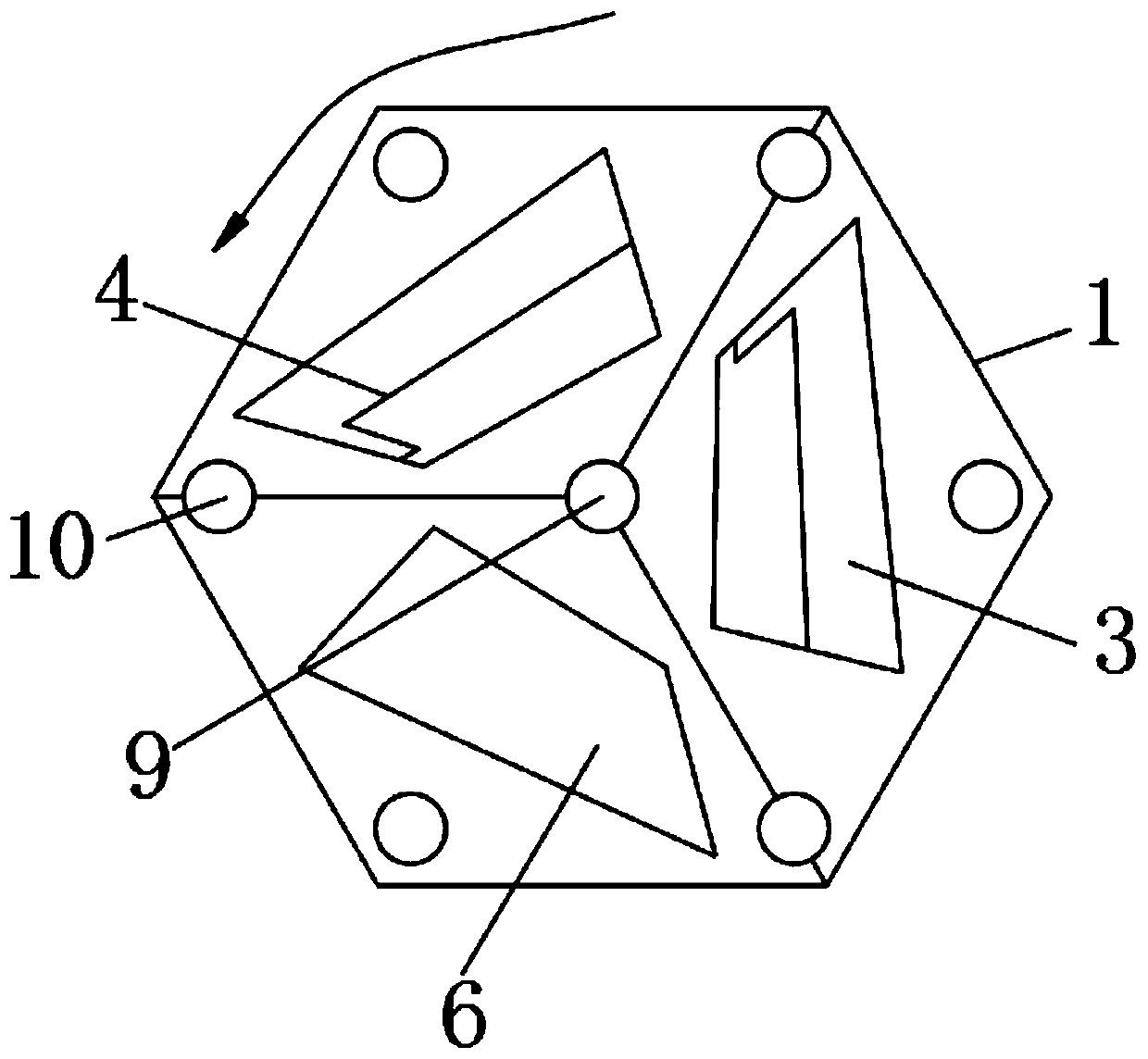

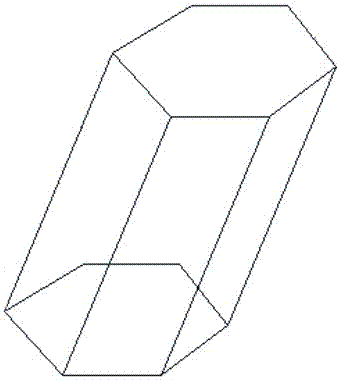

Vehicle tail lamp injection mold

ActiveCN110091474AReduce clearance tolerance requirementsReduce difficultyDomestic articlesWork in processEngineering

The invention relates to the technical field of mold equipment, and discloses a vehicle tail lamp injection mold. The vehicle tail lamp injection mold comprises a fixed mold frame and a movable mold frame with regular hexagon type cross sections; a semi-finished product side small insert, a finished product side small insert and a taking-out groove are arranged on the upper surface of the fixed mold frame in sequence; and the cross sections of the semi-finished product side small insert, the finished product side small insert and the taking-out groove are in rotational symmetry with the rotating angle being 120 degrees. In the vehicle tail lamp injection mold, the cross section adopts the regular hexagon design, so that the mold closing precision is improved, the design and production requirements are reduced, the smaller area is occupied, the manufacturer investment cost is reduced, meanwhile, the damage to finished products during taking out can be prevented, the lamp cover production yield is improved, finally, the moving and waiting time of taking out abrasive tools can be prevented, the production continuity is guaranteed, the waiting time of an injection molding valve is shortened, liquid-state materials not meeting the temperature requirement are reduced, the emptying is reduced, the material utilization rate is increased, and the lamp cover production cost is reduced.

Owner:常州宏创车辆部件有限公司

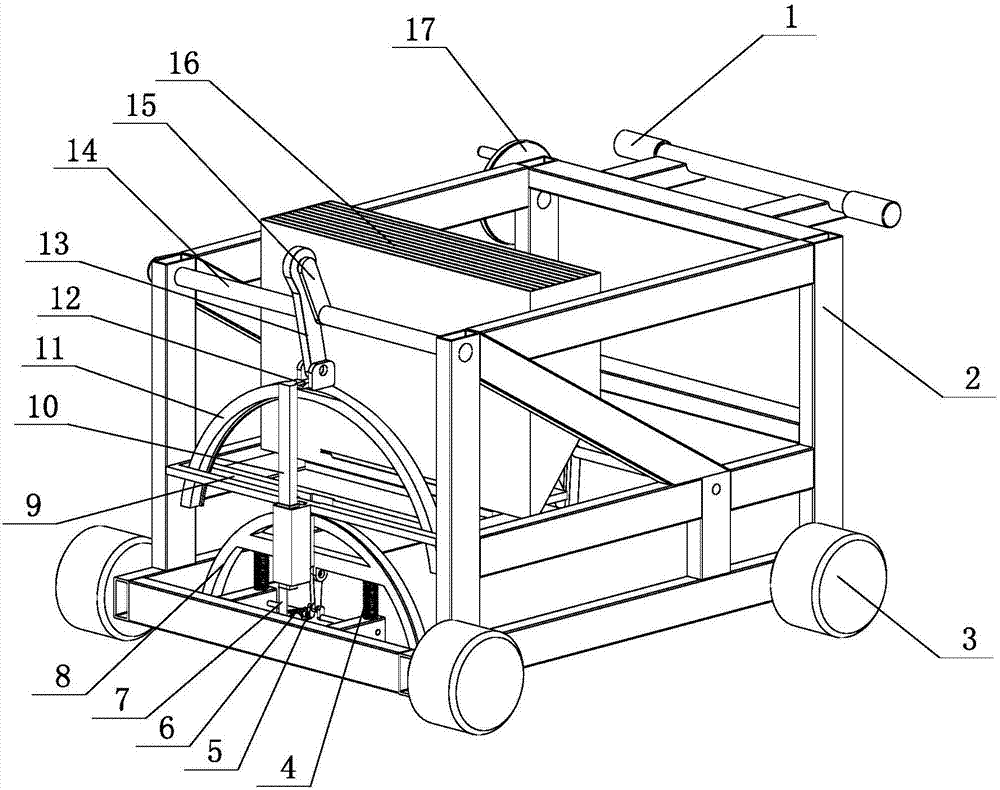

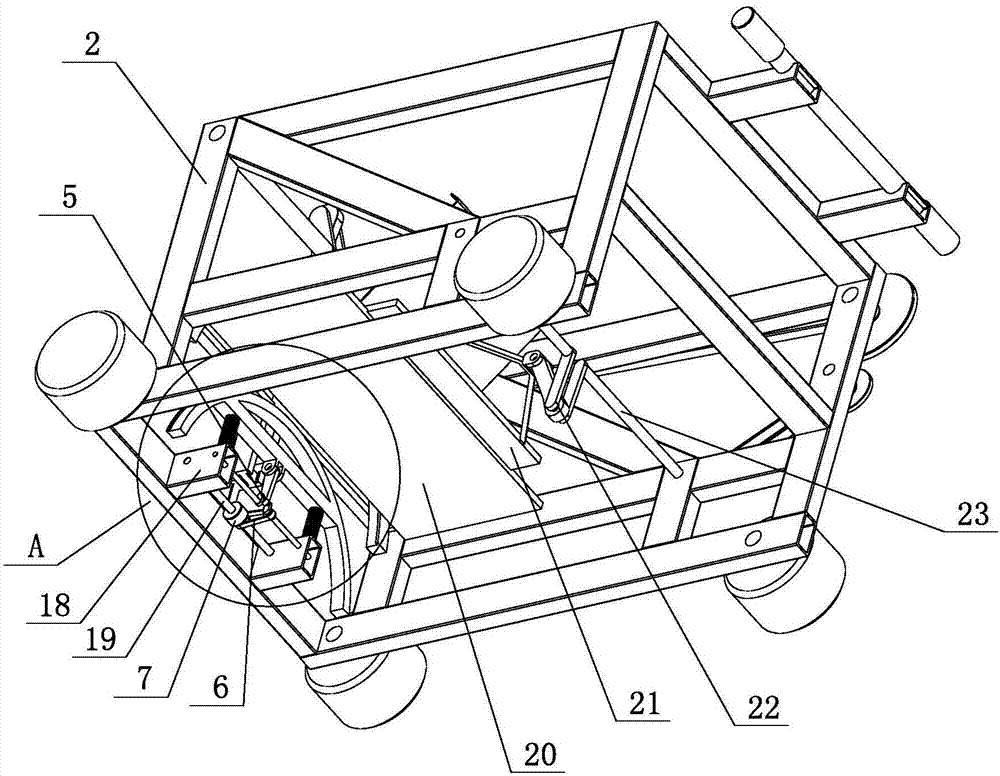

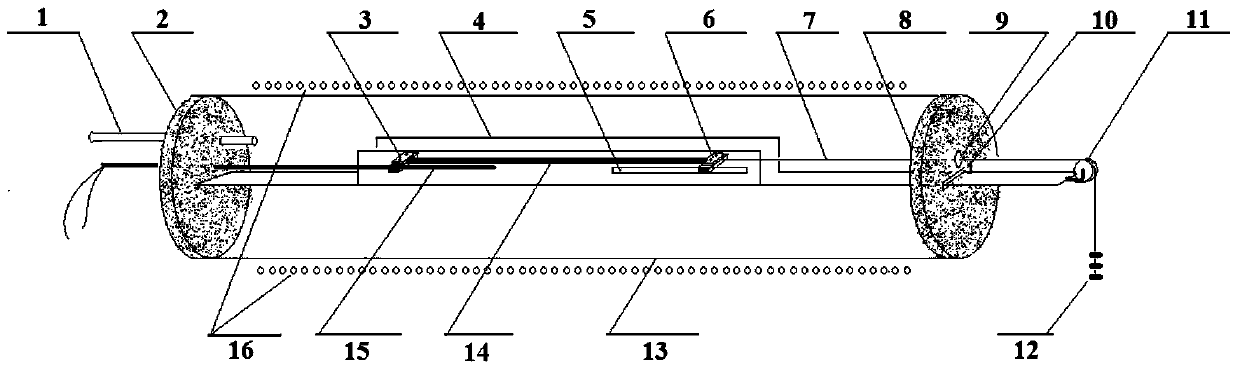

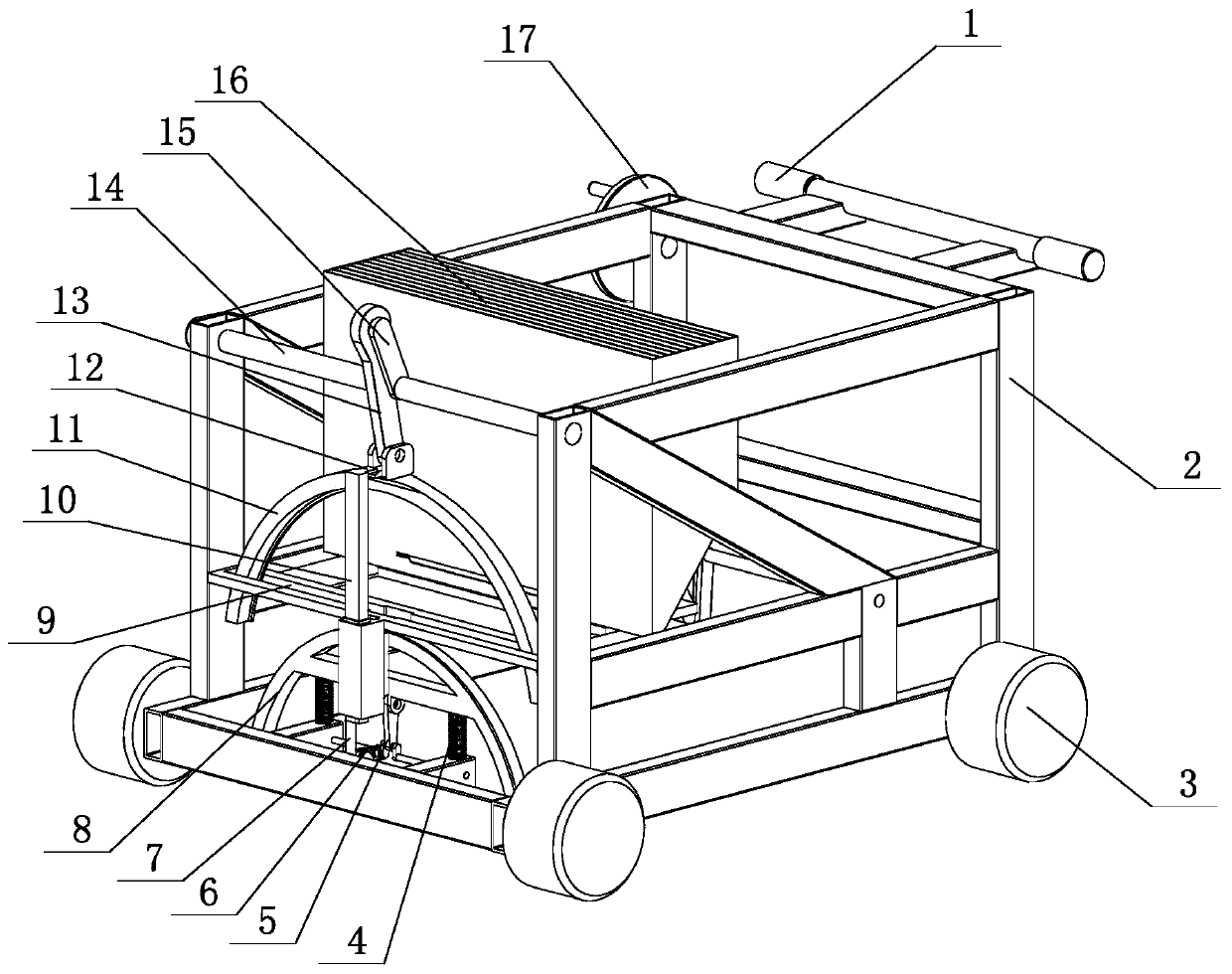

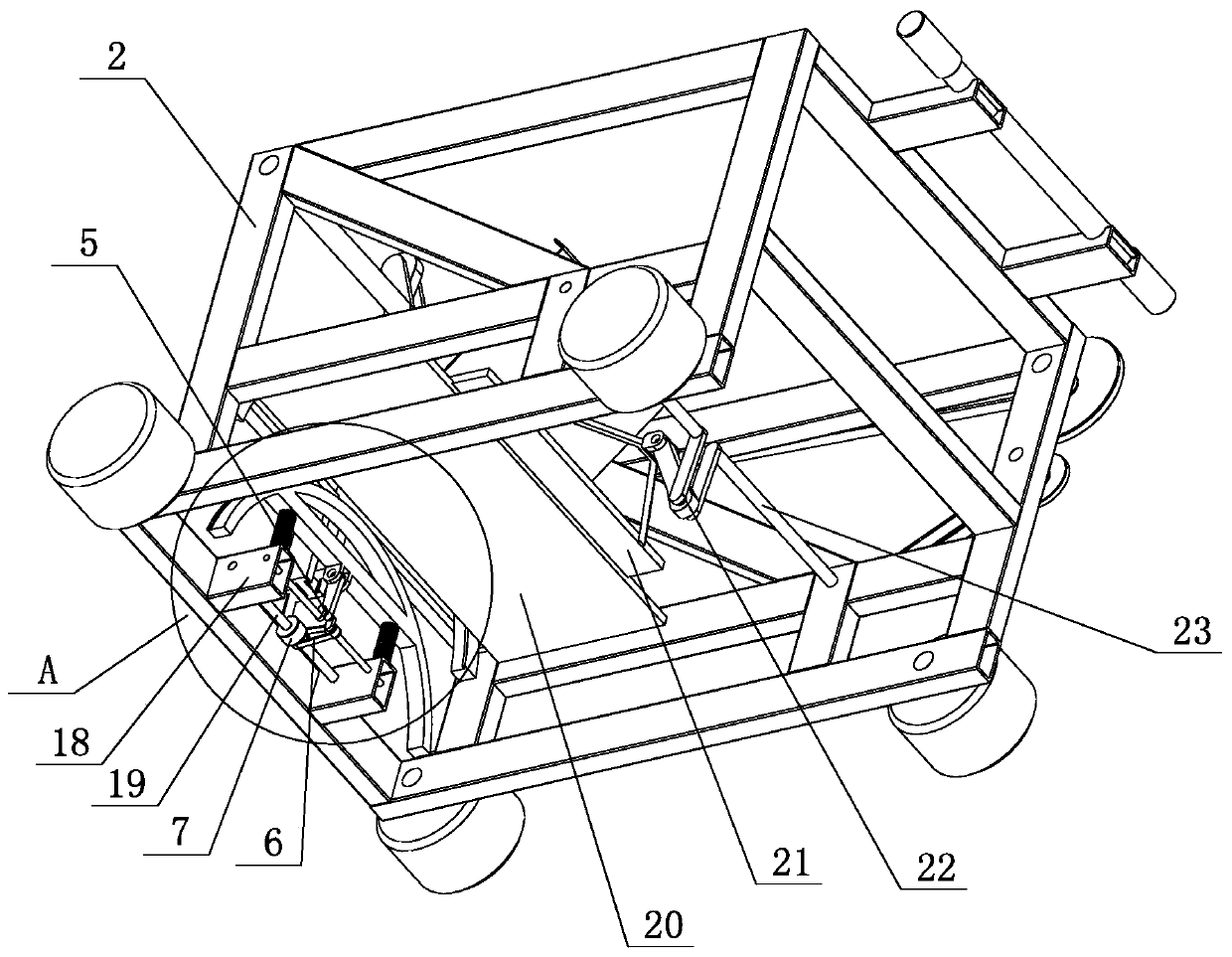

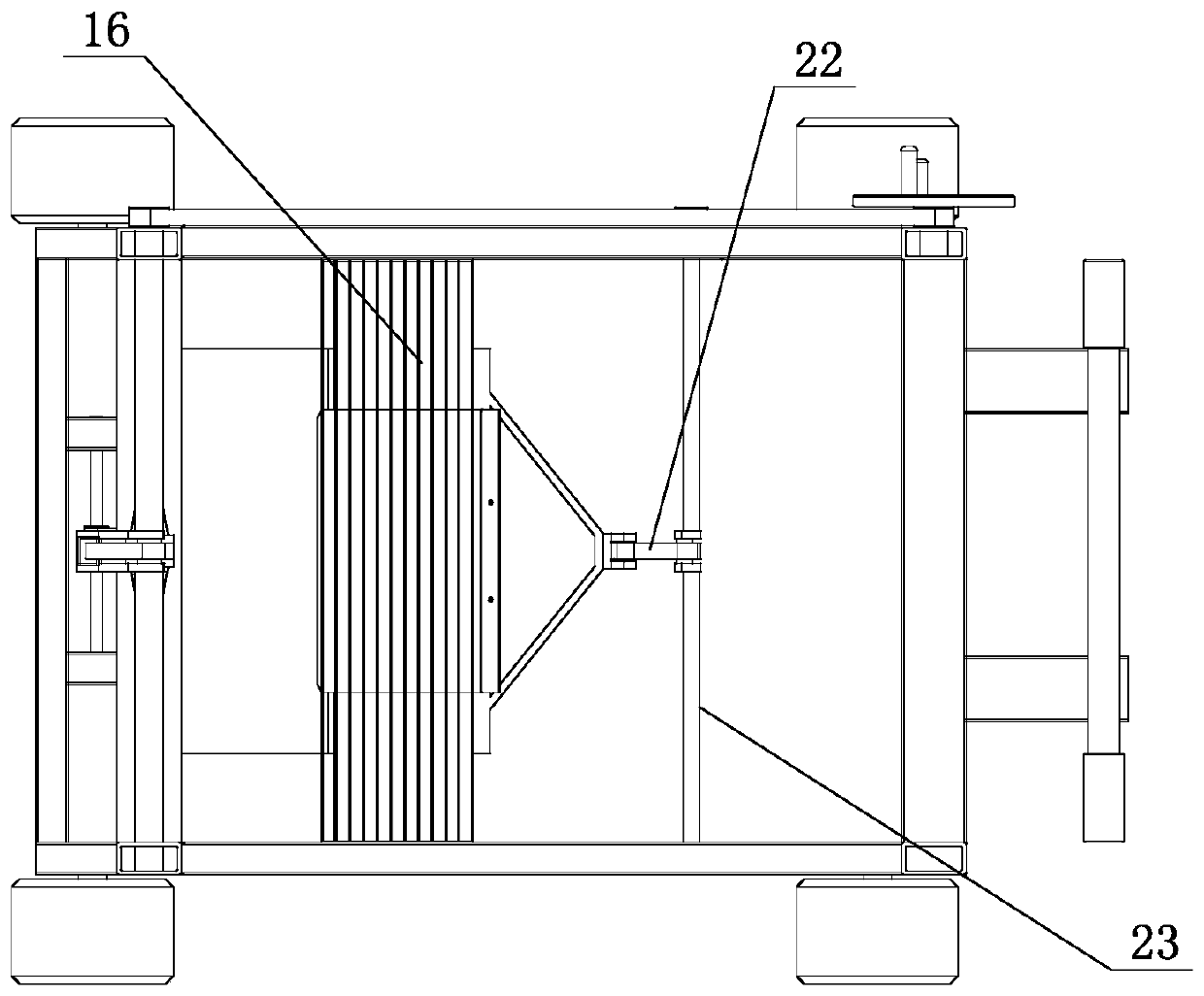

Hand-pushing type miniature automatic arch strip feeding machine

ActiveCN107439278AStable performanceGood insertion effectPlant protective coveringsTruckGinger Rhizome

The invention relates to the technical field of trestle truck loading technologies, and in particular relates to a hand-pushing type miniature automatic arch strip feeding machine comprising a rack, wherein a work bin, an arch strip conveying device, an arch strip inserting device and a separation device are arranged on the rack; the machine provided by the invention is high in production efficiency and low in manufacturing cost, can be widely applied to planting furrow crops such as ginger in common farmer families; one machine can replace the work of five persons, and the production cost is relatively low, so that the machine is a first choice for people to plant the ginger, and has an extremely high market promotion value.

Owner:WEIFANG VOCATIONAL COLLEGE

Gear pressing device for drill bit and hot inserting equipment using the device

InactiveCN104014982BSo as not to damageEasy to ensure consistencyMetal working apparatusEngineeringWell control

The invention relates to a drill bit tooth pressing device and thermal tooth inserting equipment with the drill bit tooth pressing device. The drill bit tooth pressing device comprises a rack. A base body positioning base used for fixing a drill bit base body and a telescopic tooth pressing device corresponding to tooth holes in the drill bit base body are arranged on the rack. The telescopic tooth pressing device is provided with pressing heads extending forwards in the axial direction of the corresponding tooth holes and pressing tooth heads into the corresponding tooth holes in the drill bit base body. A base body positioning base has the axis extending in the axial direction of the drill bit base body fixed to the base body positioning base. The telescopic tooth pressing device is rotationally assembled on the rack around the axis of the base body positioning base or the base body positioning base is rotationally assembled on the rack around the axis of the base body positioning base. After the drill bit base body is fixed, the base body positioning base or the telescopic tooth pressing device is rotated so that the tooth holes in the drill bit base body can correspond to the pressing heads of the telescopic tooth pressing device respectively, and then the tooth heads are pressed through power of the telescopic tooth pressing device. According to the drill bit tooth pressing device and the thermal tooth inserting equipment with the drill bit tooth pressing device, alignment is easy, operation is convenient, production efficiency is high, and product quality can be well controlled.

Owner:HUANGHE S & T COLLEGE

Aeroengine compressor blade and processing method thereof

The invention belongs to the technical field of aero-engines, and discloses a compressor blade machining method. The compressor blade machining method includes the steps that step 1, three-dimensionalmeasurement is carried out, specifically, a crest curve and a trough curve are built by extracting actual curve crest points and trough points of cross sections according to a three-dimensional diagram of a compressor blade; virtual curves of a blade body and a jog are built; step 2, point cloud is extracted, specifically, curvatures of the actual curve, the crest curve and the trough curve of the step 1 are analyzed, and the curves of the crest curve and the trough curve are regulated according to actual curve curvatures; a center line is built according to the crest curve and the trough curve; step 3, a hook face is rebuilt, specifically, a mesh hook face is built with center lines of the cross sections to generate a three-dimensional digital model; step 4, procedures are regulated, specifically, the blade three-dimensional digital model is imported to a three-dimensional software and corrected compared with blade master body data scanned by the three-dimensional software; and step5, numerical control machining is carried out, specifically, numerical control programming is carried out according to the blade three-dimensional digital model of the step 4, and a blade is subjectedto numerical control milling with a ball end milling. According to the compressor blade machining method, the blade precision and the surface roughness of a compressor can be effectively ensured.

Owner:株洲丰发精工实业有限公司

Hierarchical clustering network topology generation method based on multi-task UAV swarm information interaction

ActiveCN112437502BImprove adaptabilityEasy to ensure consistencyNetwork topologiesPosition/course control in three dimensionsAlgorithmTheoretical computer science

The invention discloses a hierarchical clustering network topology structure generation method based on multi-task UAV cluster information interaction, which includes: the steps of determining the UAV cluster set and the position matrix of each cluster; constructing each The steps of the network topology structure of the information exchange within the cluster of the cluster; the steps of constructing the network topology structure of the information exchange between the clusters. The method of the present invention uses a hierarchical clustering structure to self-organize the UAV cluster, and adopts the method of performing different tasks in different clusters, so as to solve the problem that the scale of the UAV cluster is limited and the information interaction is only oriented to a single task. In the SCH topology of multi-task UAV cluster information interaction, centralized control is adopted in the cluster, and a minimum spanning tree is calculated with the cluster head as the root to construct the network topology of any independent cluster and complete the network topology in each independent cluster. For information interaction, the spatial interaction gravity model is introduced between clusters to construct the inter-cluster network topology and complete the information interaction between UAV clusters.

Owner:BEIHANG UNIV

Feeding device

InactiveCN102463319AFacilitate automatic operationAutomate operationEngineeringMechanical engineering

Owner:KANGZHUN ELECTRONICS TECH KUNSHAN +1

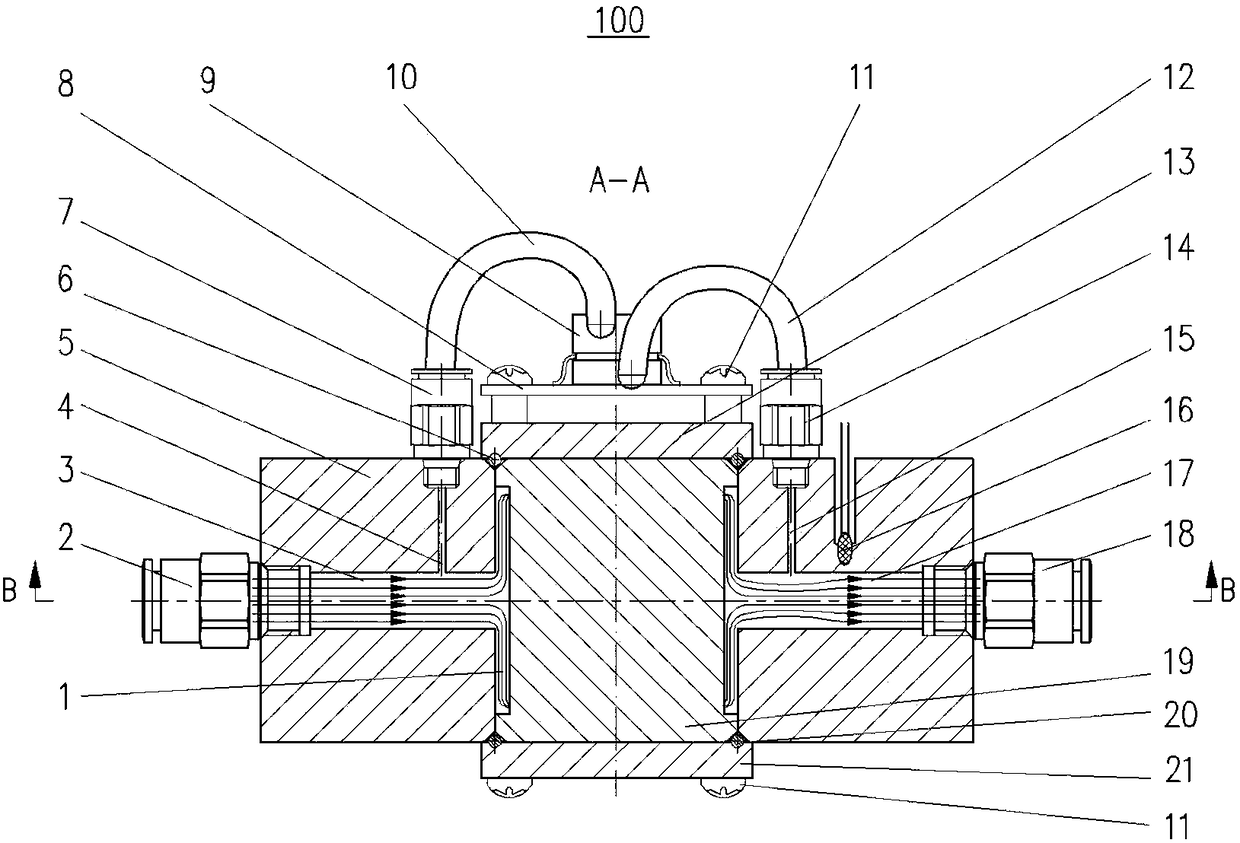

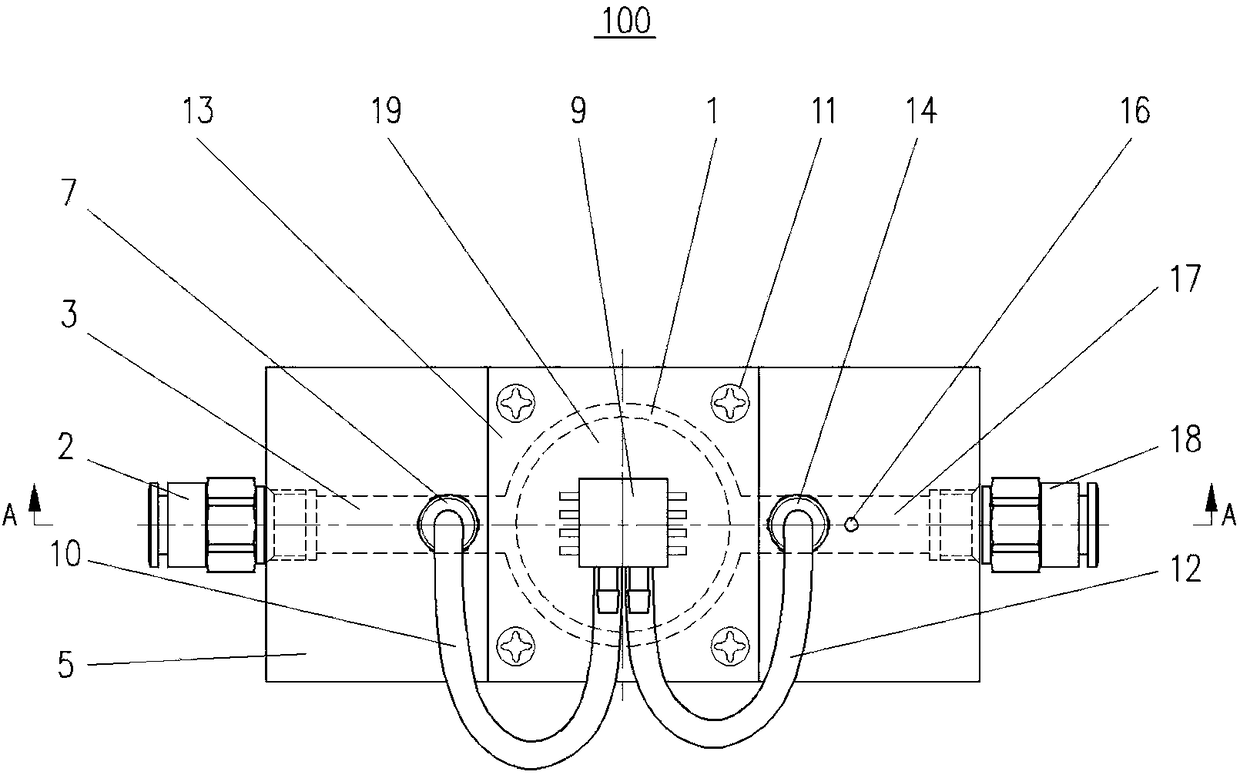

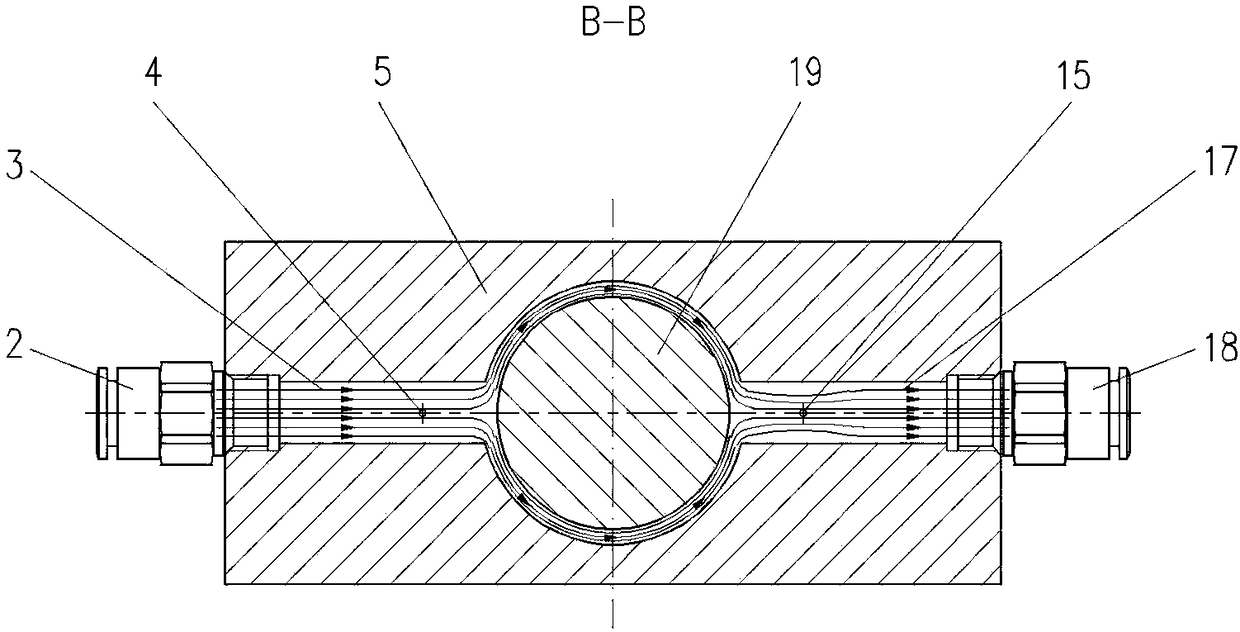

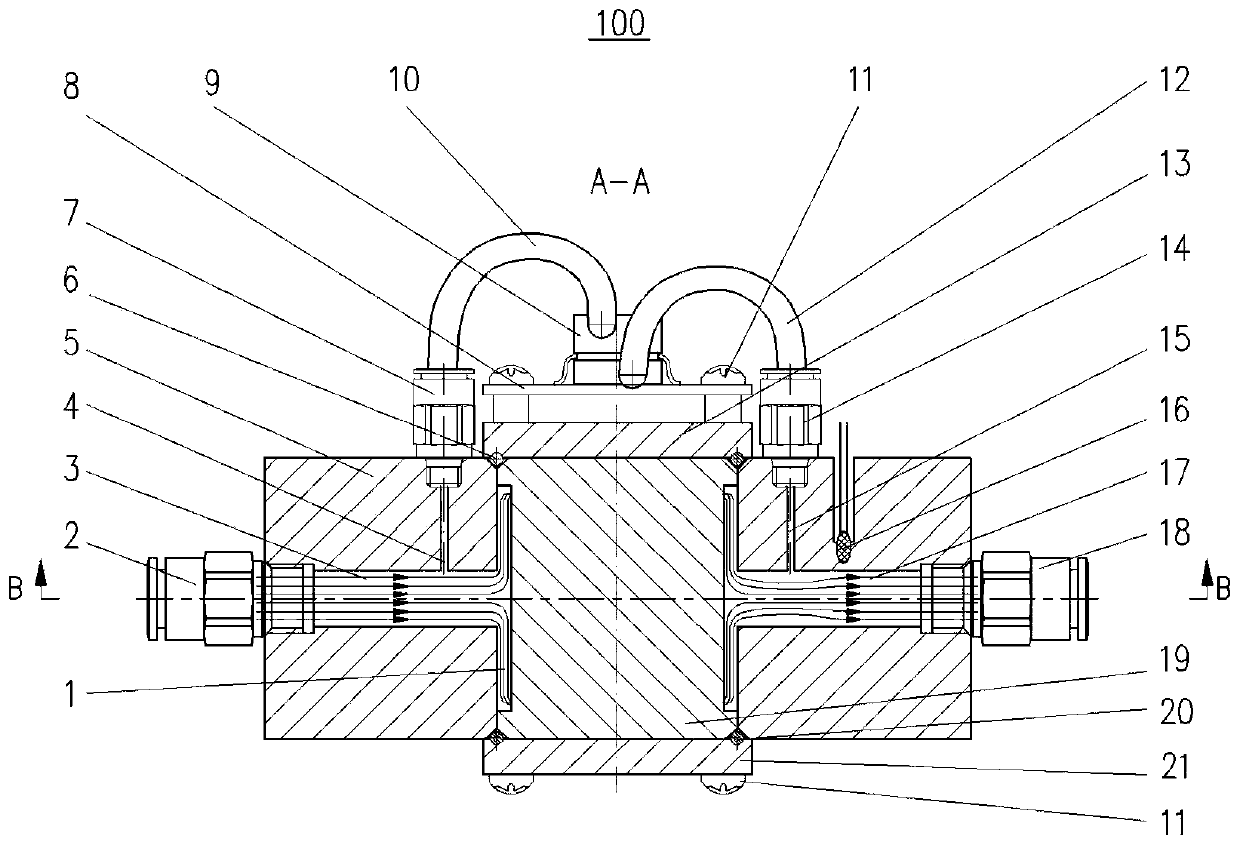

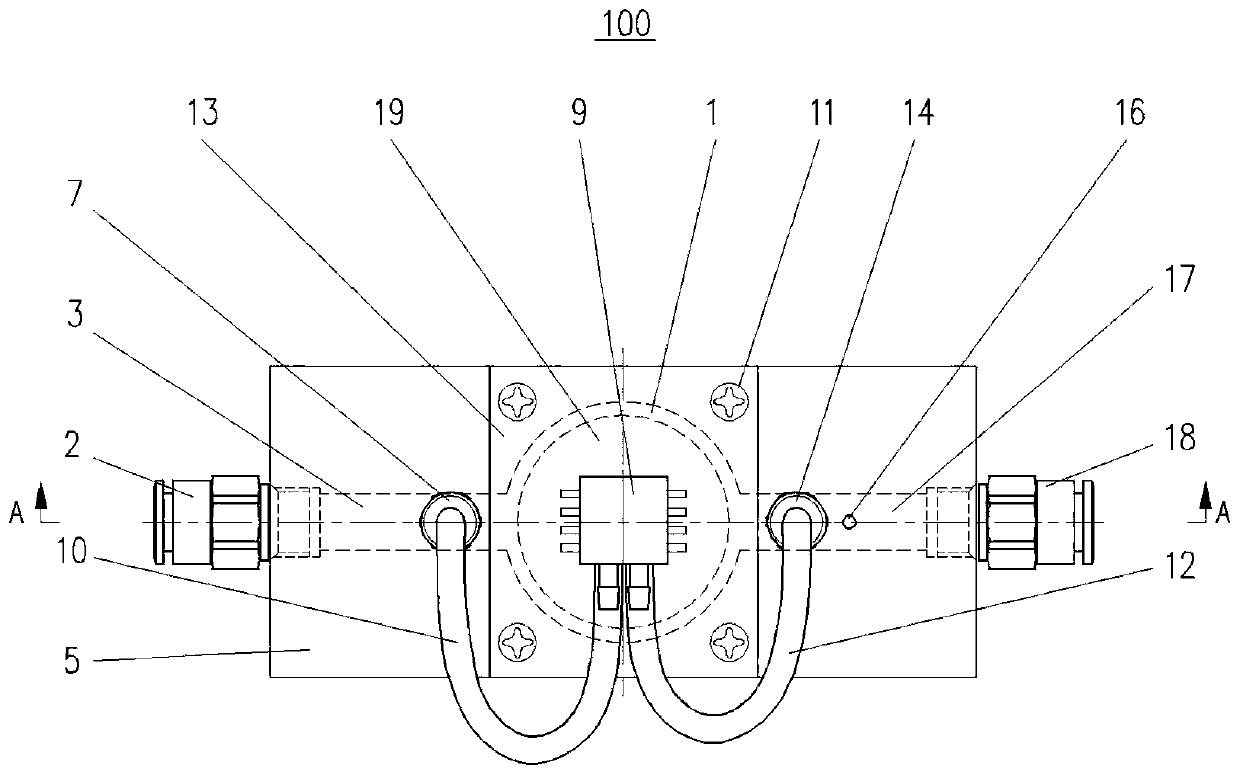

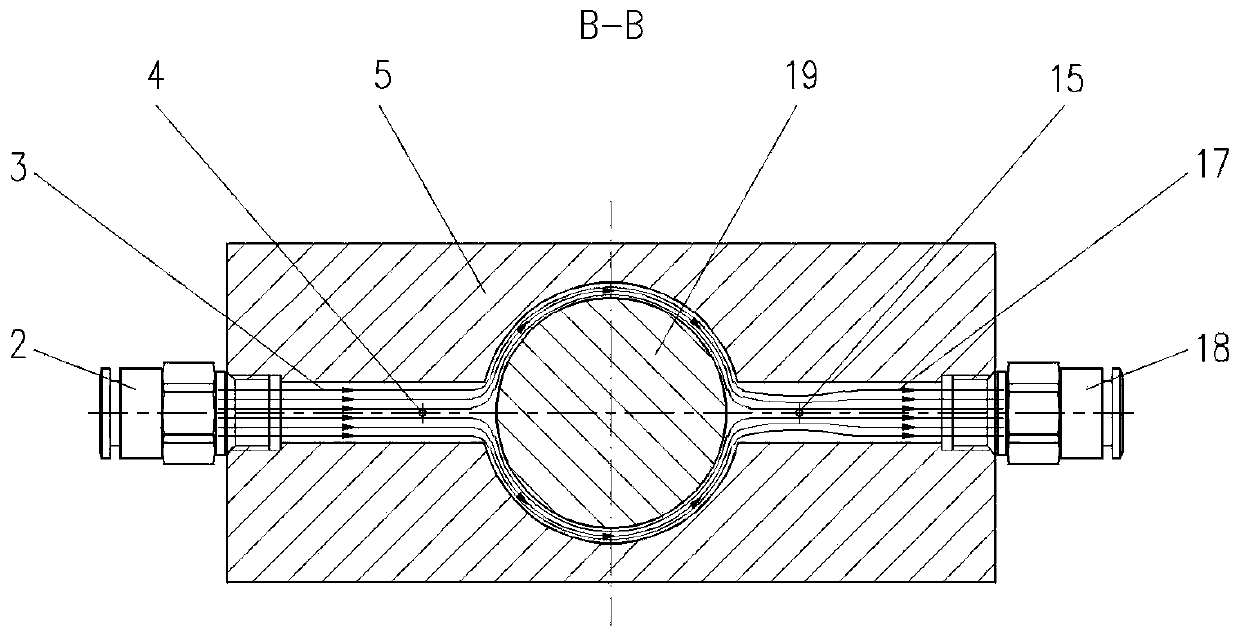

Thin-walled cylindrical centrifugal type gas mass flow meter

ActiveCN108088511AWill cause damageCause damageIndirect mass flowmetersDifferential pressureEngineering

The invention discloses a gas mass flow meter which comprises a flow meter body. A flow meter main body is arranged on the flow meter body and comprises a thin-walled cylindrical centrifugal type cavity (hereinafter referred to as cavity). The cavity comprises a gas duct body and a cylinder. The gas duct body is provided with a gas inlet, a front gas duct, a front pressure measuring point, a reargas duct, a rear pressure measuring point and a gas outlet. Centrifugal force is formed through the cylindrical cavity so that gas can make sufficient contact with the thin wall of the cavity, gas molecular kinetic energy is reduced, the pressure of gas flowing through the cavity is reduced, the variation of pressure before and after the gas flows through the cavity is measured through a differential pressure sensor, compensation is conducted through a temperature sensor, and the mass flow of the gas is calculated. The linear correspondence of the measured differential pressure value and the flow can be realized. The flow meter is high in repeatability, precision, durability and practicability and suitable for measuring various types of gases.

Owner:马宁敏

Producing system of internally-heating curing glass fibre reinforced plastic pipe controlled by program

InactiveCN100503213CLarge thermal inertiaHigh energy consumptionProgramme controlComputer controlComputer control systemSmall footprint

The invention relates to a glass fiber reinforced plastic pipe manufacturing device, in particular to a program controlled internal heating and curing glass fiber reinforced plastic pipe manufacturing system. It includes a support transmission mechanism, a mandrel, a thermal system, a yarn arrangement mechanism, a demoulding mechanism, and a computer control system; the mandrel is a double-layer metal tube, and steam is passed through the mandrel to heat and solidify the FRP pipe. The invention can heat and solidify uniformly, produce FRP pipes with few defects, high quality, and small footprint. The system adopts computer program control to realize production automation, improve product quality, and greatly increase production efficiency. The invention is used in the manufacture of glass fiber reinforced plastic pipes.

Owner:北京朗瑞达管道技术有限公司

Inverted liquid-phase acoustic surface wave detection device and array thereof

InactiveCN101968464BEasy to ensure consistencyOvercome the disadvantage of being volatileAnalysing fluids using sonic/ultrasonic/infrasonic wavesIsolation layerSurface acoustic wave sensor

The invention discloses an inverted liquid-phase acoustic surface wave detection device, which comprises a substrate and a reaction tank, wherein the substrate is provided with at least one pair of interdigital transducers, and the input interdigital transducer, the output interdigital transducer and lead areas thereof are provided with waterproof isolation layers; and the substrate is verticallyinserted into the reaction tank so that the detection area is soaked into the reaction tank. The reaction tank with constant size for bearing reaction liquid is adopted in the device so as to ensure consistency of the injected liquid amount in repeated experiments and solve the problem that the consistency of the liquid dropping amount in the repeated experiments is difficult to ensure in liquid dropping detection of the traditional acoustic surface wave sensor in the detection area; the substrate is vertically inserted into the reaction tank to form a closed reaction area, so the liquid sample cannot be volatilized and the defect that the liquid sample is easy to volatilize in the liquid dropping detection of the acoustic surface wave sensor is overcome; compared with the conventional acoustic surface wave detection device for detection through microfluidic inlet liquid, the standing closed reaction structure avoids liquid flowing interference; and the inverted liquid-phase acoustic surface wave detection device is arranged in an array form to realize simultaneous detection of multiple detected liquid samples.

Owner:THE THIRD AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIV OF PLA

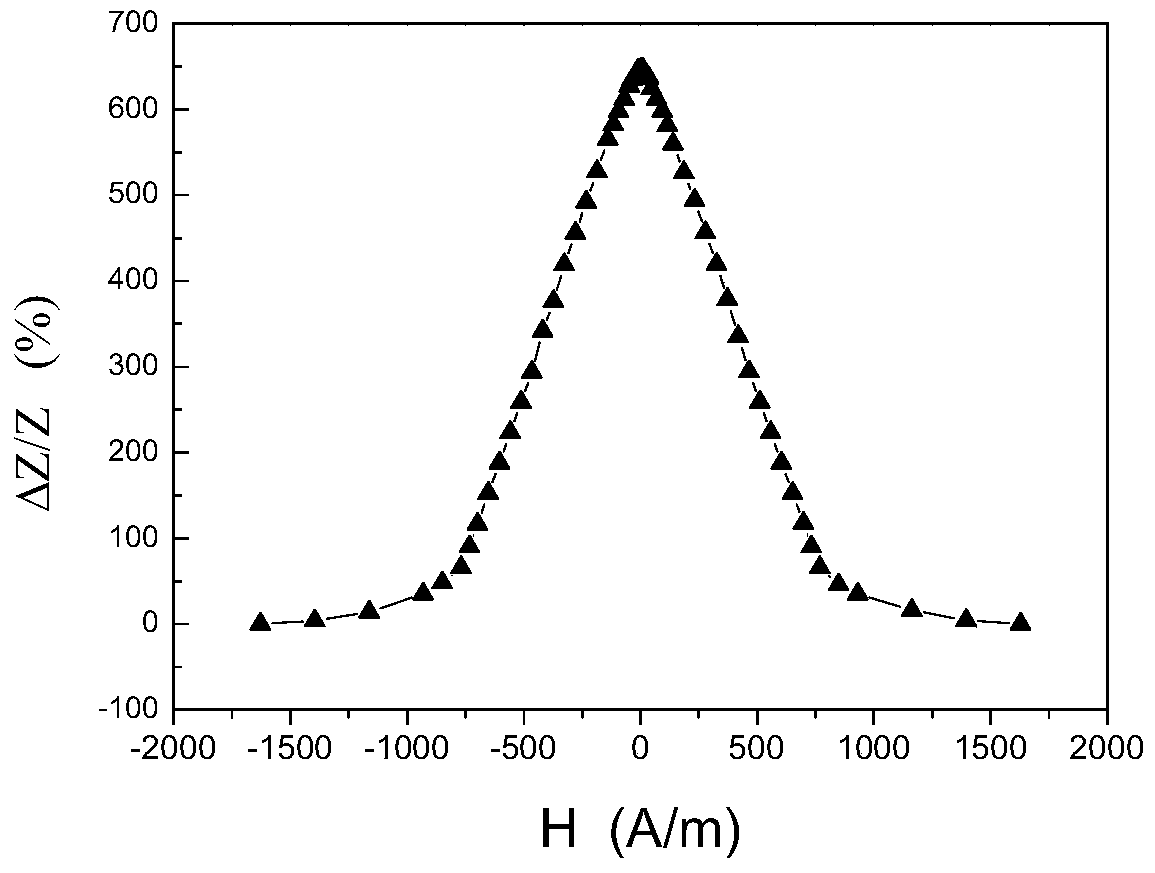

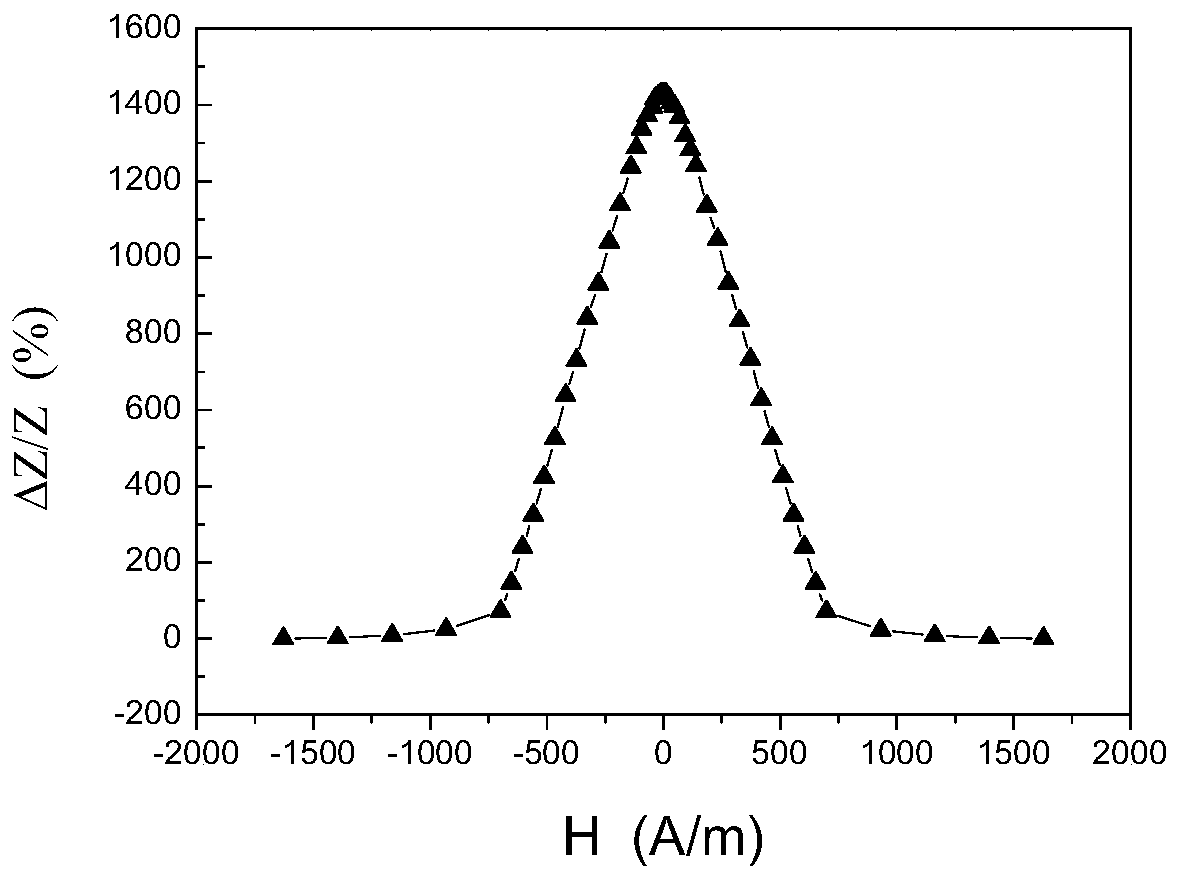

A method for preparing magnetically sensitive material with high sensitivity and wide linear region

ActiveCN105679486BSimple processEasy to controlMagnetic materialsProcess engineeringThermal treatment

The invention discloses a new method for preparing magnetically sensitive materials with high sensitivity and wide linear area. Compared with the existing technology, the technology of the present invention can be used to prepare magnetically sensitive materials with the advantages of wide linear area and high sensitivity at the same time. It has the advantages of simple process and easy control. There are few process parameters that need to be controlled, and it has the advantages of easy control of material properties and energy saving. There is no need to increase the processing temperature or increase the heat treatment time. Therefore, the present invention has significant energy saving advantages. Since the process is simple and easy to control, it requires The production equipment is simple, the cost is low, and it is easy to ensure the consistency of batch products. Therefore, it has the advantages of easy promotion and industrial transformation.

Owner:杭州仁才汇科技成果转化服务有限公司

Piezoelectric Sensor Vibrator

InactiveCN104538547BHigh sensitivityOvercoming the characteristics of difficult to make large-scale structuresPiezoelectric/electrostrictive device detailsLarge sizeCeramic

The invention discloses a piezoelectric ceramic sensor vibrator. The sensor vibrator includes a shell, several piezoelectric ceramic columns, a bracket, an upper pole plate, a lower pole plate, an upper cover plate, a lower cover plate, an upper terminal post, and a lower terminal post. , a pressure plate, a plurality of piezoelectric ceramic columns are fixedly arranged by brackets in the housing, an upper plate, an upper cladding plate, and a pressure plate are sequentially arranged above the plurality of piezoelectric ceramic columns, and the lower part of the plurality of piezoelectric ceramic columns is sequentially arranged The lower pole plate and the lower cover plate, the upper pole plate is connected with the upper terminal, and the lower pole plate is connected with the lower terminal. The present invention adopts a plurality of piezoelectric ceramic columns, which has high sensitivity. In terms of installation and production, in terms of low frequency, it overcomes the characteristics that piezoelectric ceramic sheets are difficult to make into large-scale structures, and it is easy to ensure the consistency of piezoelectric ceramic column parameters and improve Sensitivity to low-frequency signals to achieve a larger frequency response range.

Owner:XIAN TECH UNIV

Encircling LED road bridge handrail lamp

ActiveCN103343920BLittle impact on appearanceCosmetic impact is minimizedLighting applicationsPoint-like light sourceManufacturing technologyEngineering

The invention discloses an encircling LED road bridge handrail lamp which comprises a tube-shaped outer shell and an LED assembly. The tube-shaped outer shell can be fixedly installed on a handrail, and an inner cavity of the tube-shaped outer shell is matched with the handrail in shape. The LED assembly is installed inside the tube-shaped outer shell. The tube-shaped outer shell comprises a first outer shell and a second outer shell. One end of the first outer shell and one end of the second outer shell are connected together through a connecting device in a pivoting mode, and the other end of the first outer shell and the other end of the second outer shell are fixedly connected through a bolt. The connecting device comprises a circular-arc-shaped clamping hook and a circular-arc-shaped clamping hole, wherein the circular-arc-shaped clamping hook is arranged at the end of the second outer shell, and the circular-arc-shaped clamping hole is formed in the end of the first outer shell and matched with the circular-arc-shaped clamping hook. The encircling LED road bridge handrail lamp is independent of the handrail, in other words, only the LED road bridge handrail lamp needs to be provided, and the handrail needs not to be manufactured. Therefore, different installation requirements of an old bridge and a new bridge can be met at the same time. The encircling LED road bridge handrail lamp is easy to install on site, and meanwhile uniformity of the installation angle of the LED road bridge handrail lamp is easy to ensure. After the LED road bridge handrail lamp is installed, influences on the appearance of the handrail are minimized and the manufacturing technology is simple.

Owner:广东迪艾生光电技术有限公司

A thin-walled cylindrical centrifugal gas flowmeter

ActiveCN108088511BOvercome the shortcoming of short service lifeHigh measurement accuracyIndirect mass flowmetersDifferential pressureCentrifugal force

Owner:马宁敏

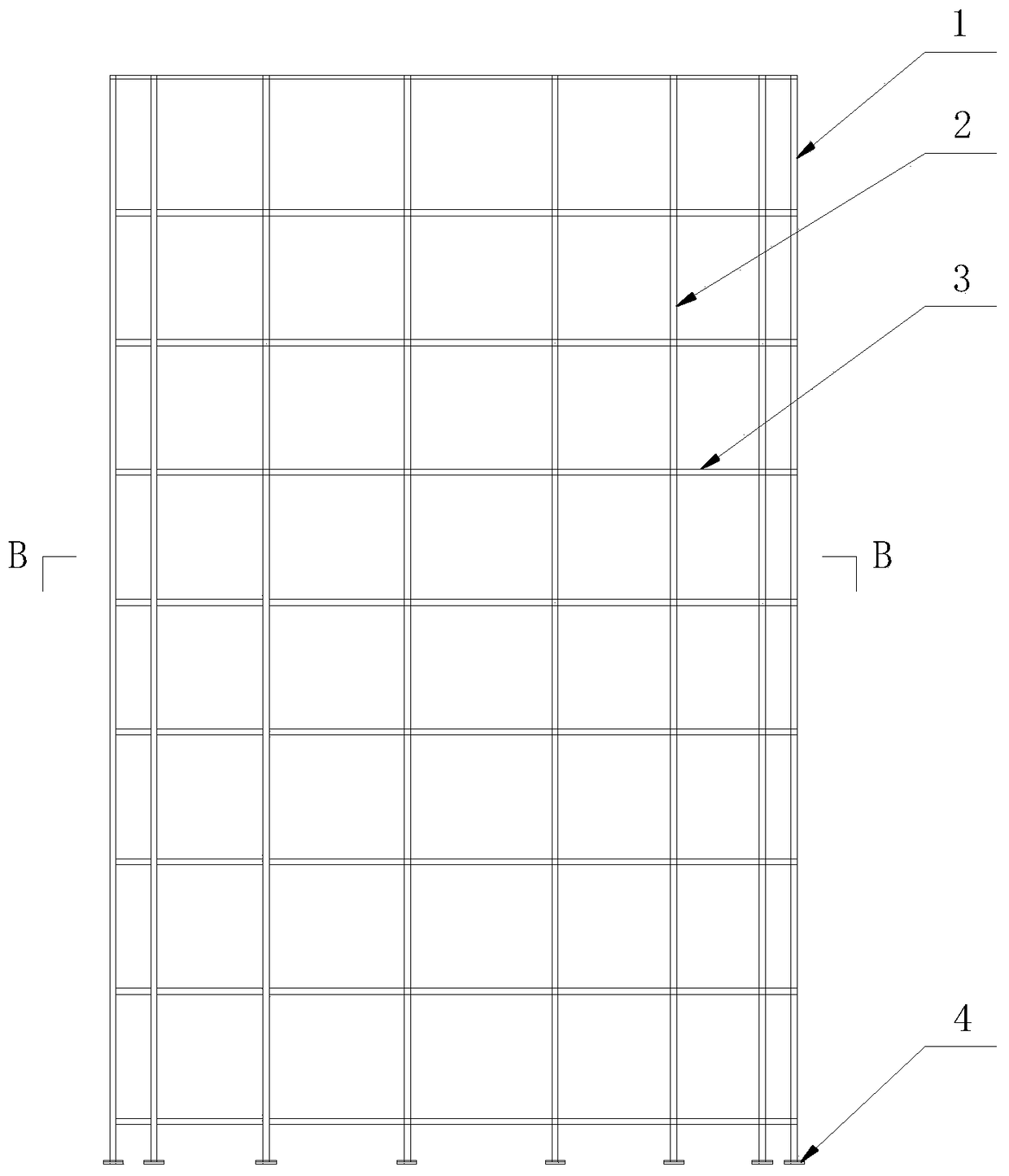

Assembled underground bicycle storage support tube

ActiveCN105201245BEasy to installLow costBuilding constructionsParkingsUltimate tensile strengthAssembly structure

The invention relates to an assembling type underground bicycle garage support cylinder, which is characterized by comprising a cage-type cylinder body composed of multiple stand columns and multi-layer polygon beam units, wherein each polygon beam unit is formed by connecting the multiple transverse beams to adjacent stand columns; and the distance between one polygon beam unit and the polygon beam unit at the adjacent layer is larger than the height of a bicycle. The assembling type underground bicycle garage support cylinder disclosed by the invention is scientific and reasonable in design, adopts a multiple-component assembly structure, and has the remarkable advantages of easiness in machining production and construction, short construction period, firm structure and high support strength.

Owner:TIANJIN YUANZHUO TECH DEV CO LTD

Hand-push small arch bar automatic insertion machine

ActiveCN107439278BImprove performanceGood insertion effectPlant protective coveringsTruckGinger Rhizome

The invention relates to the technical field of trestle truck loading technologies, and in particular relates to a hand-pushing type miniature automatic arch strip feeding machine comprising a rack, wherein a work bin, an arch strip conveying device, an arch strip inserting device and a separation device are arranged on the rack; the machine provided by the invention is high in production efficiency and low in manufacturing cost, can be widely applied to planting furrow crops such as ginger in common farmer families; one machine can replace the work of five persons, and the production cost is relatively low, so that the machine is a first choice for people to plant the ginger, and has an extremely high market promotion value.

Owner:WEIFANG VOCATIONAL COLLEGE

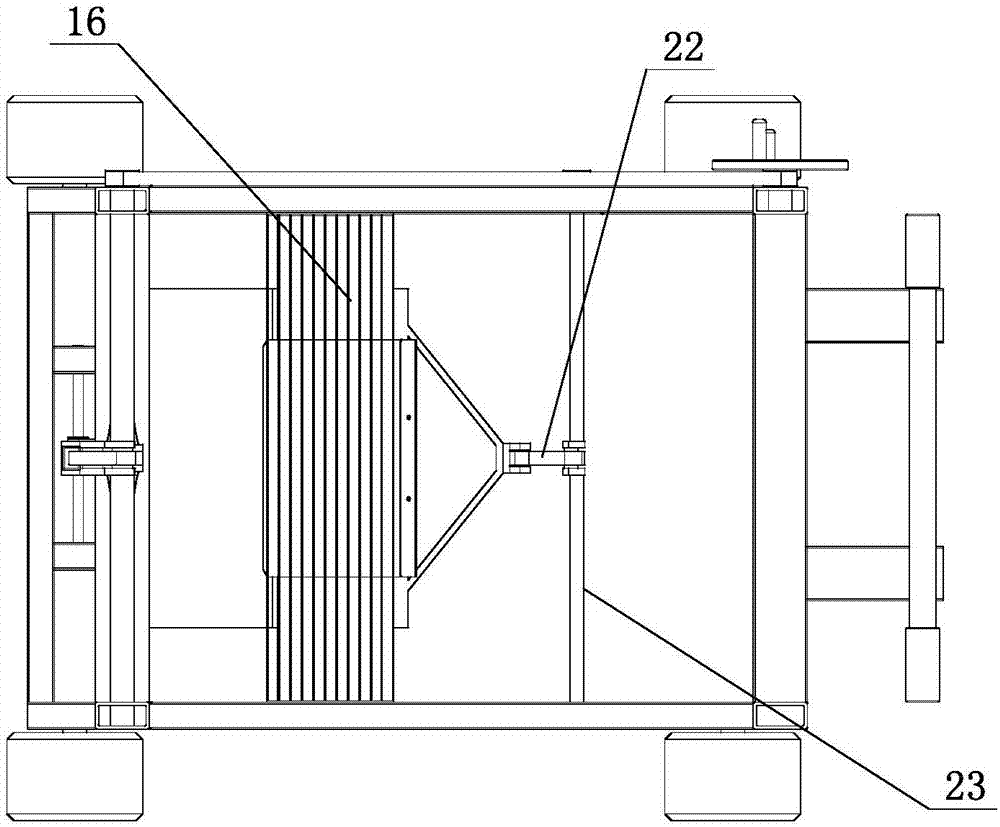

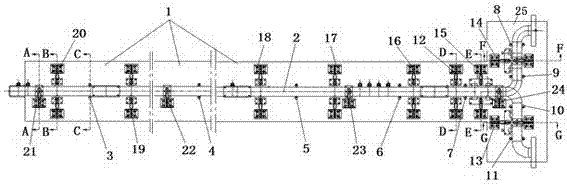

A cooling water row robot modular welding manufacturing method

ActiveCN105666027BEasy to ensure consistencyEnsure consistencyWelding/cutting auxillary devicesAuxillary welding devicesModularityStructural type

The invention discloses a modular welding-based and robot-based manufacturing method of a cooling hydraulic blower. The method comprises the following steps: firstly manufacturing various sub-components of the cooling hydraulic blower according to a determined product structural type; and then arranging the sub-components on a welding platform provided with fixtures, clamping and positioning by use of mold fixtures, performing modular operation, and assembling and welding the cooling hydraulic blower by use of a robot. Each single sub-component is placed on the multifunctional welding platform provided with the fixtures, all the single sub-components are fixed in a determined distribution mode in combination with a group of mold fixture used for multiple types of cooling hydraulic blowers according to the cooling hydraulic blower distribution rules, then all the components are assembled and welded according to a preset program and welding parameters by use of the welding robot, so that a needed cooling hydraulic blower is formed.

Owner:ZHUZHOU BOYA IND

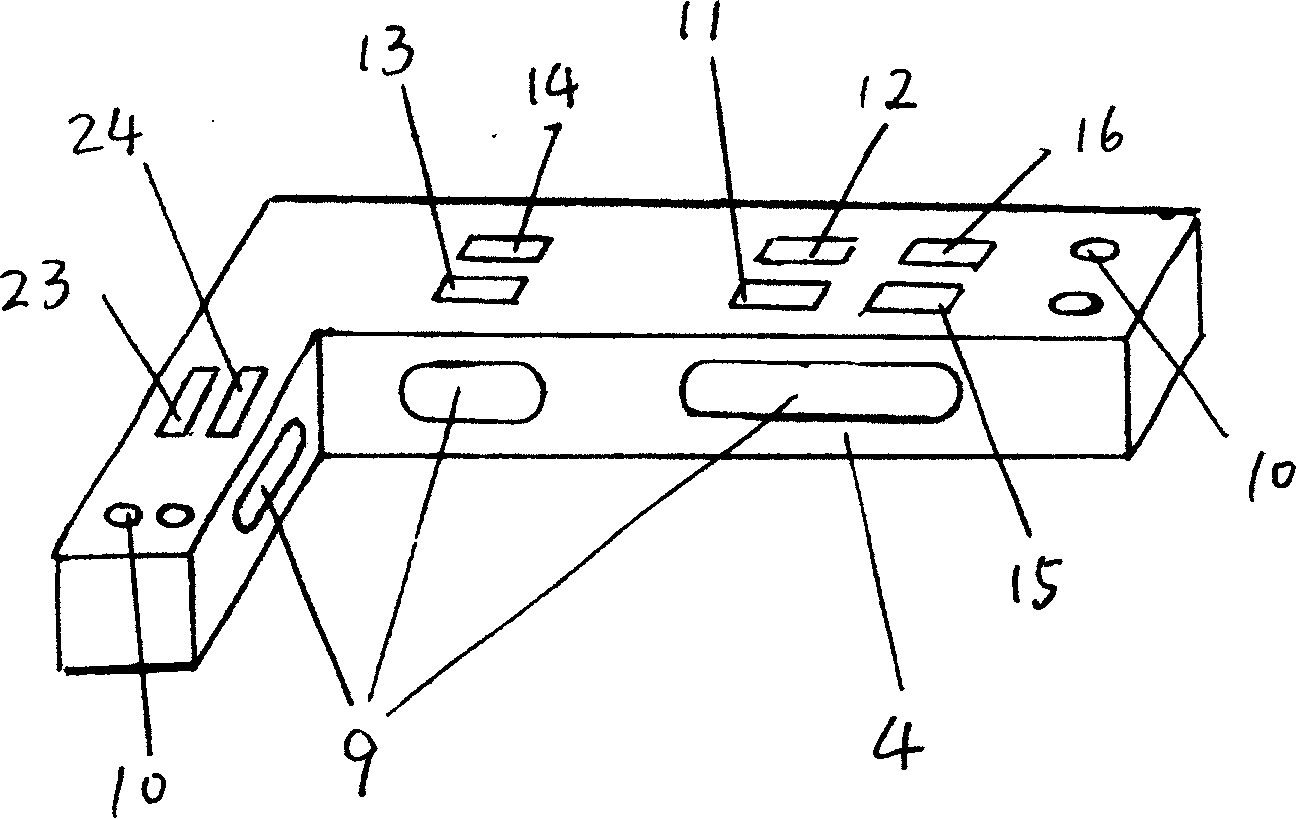

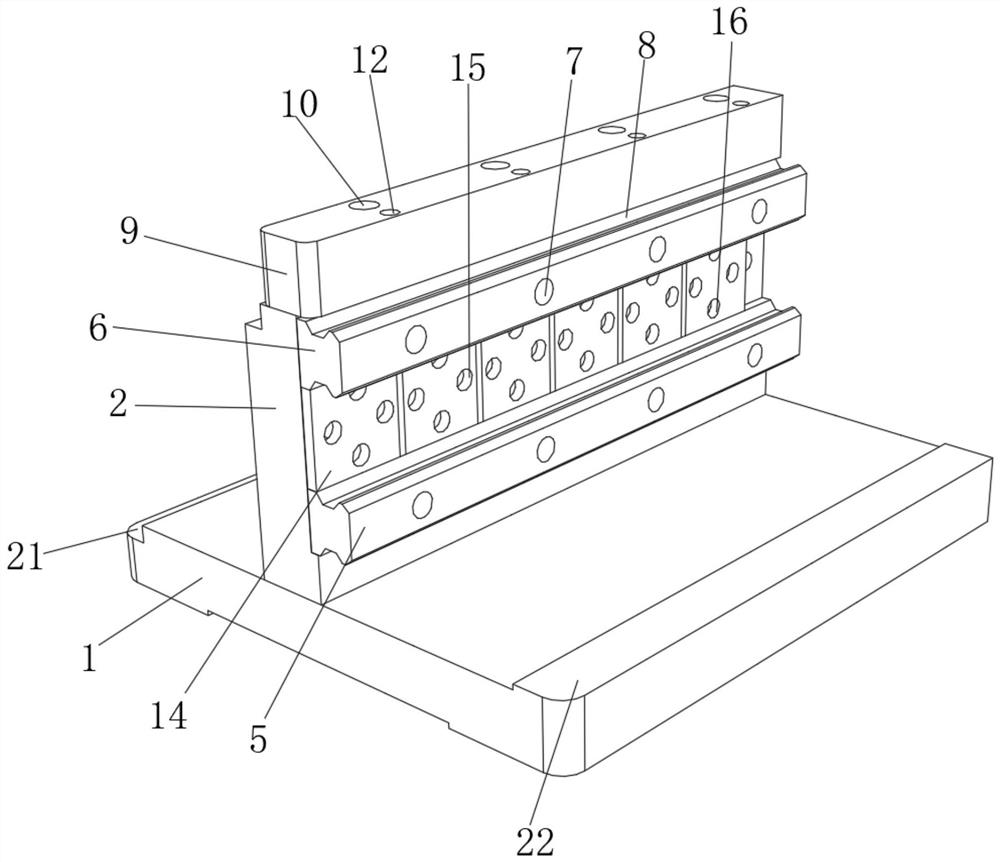

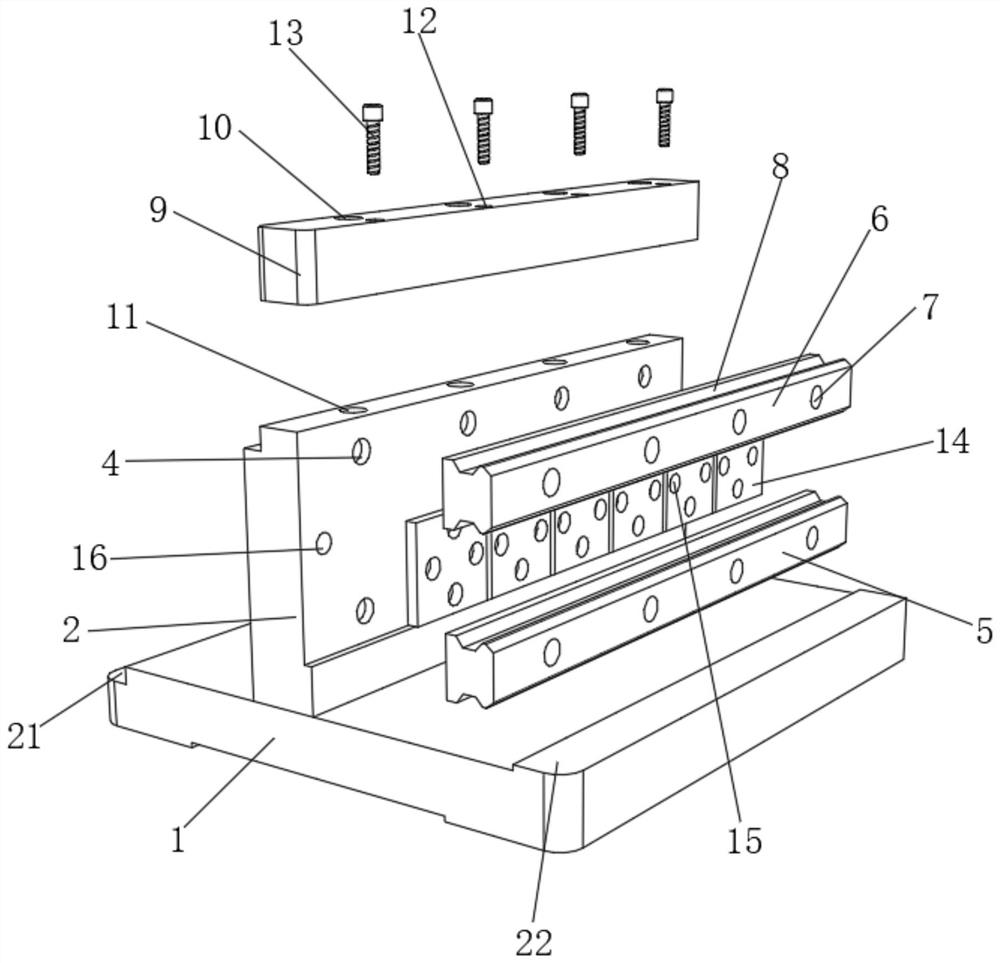

Splicing structure of linear motor carrying device

PendingCN113691096AEasy splicingEasy to ensure consistencyPropulsion systemsSupports/enclosures/casingsStructural engineeringClassical mechanics

The invention relates to the technical field of splicing structures, and discloses a splicing structure of a linear motor carrying device. The device comprises a base; a mounting plate is integrally formed at the top of the base, a first slide rail, a second slide rail and an adjusting support block are arranged on one side of the mounting plate, and the adjusting support block is located between the first slide rail and the second slide rail. First protruding blocks are integrally formed on the two sides of the first sliding rail and the two sides of the second sliding rail, the first protruding blocks at the bottom of the first sliding rail are connected with the clamping grooves in a clamped mode, a plurality of first through holes are formed in one side of the first sliding rail and one side of the second sliding rail, and a plurality of first fixing holes are formed in one side of the mounting plate. Assembling of the guide rails of the single modules is adjusted by adjusting the supporting blocks and the pressing blocks, so assembling is simpler, splicing of the linear conveying device with a sealing structure is facilitated, the consistency of assembling and splicing of the single conveying device is easier to guarantee, and the assembling and splicing device is suitable for splicing of the guide rails vertically installed.

Owner:AKRIBIS SYST SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com