Winding process of electronic current mutual inductor based on Rogowski coil

A current transformer, electronic technology, applied in the direction of coil manufacturing, etc., can solve problems such as difficult cross-section of wire turns, insufficient loop manufacturing process, excessive positioning gap, etc., to eliminate the influence of coil output accuracy and facilitate batch production Create and optimize the effect of electromagnetic parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

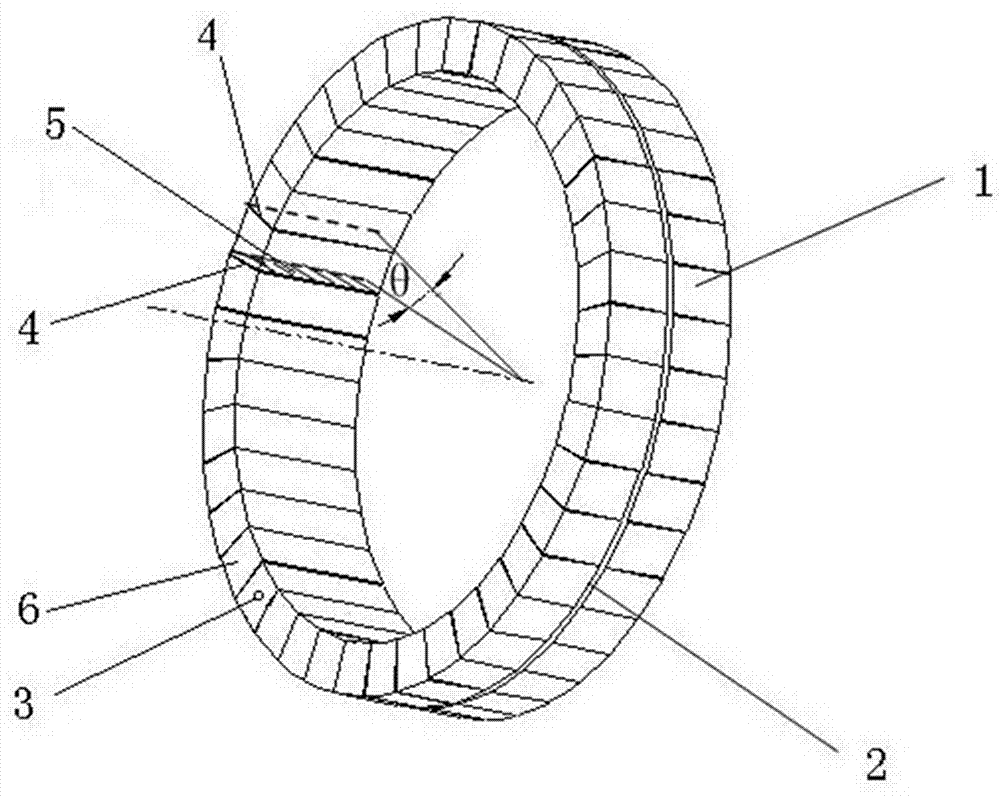

[0017] Such as figure 1 As shown, an electronic current transformer coil based on a Rogowski coil, the size of the coil bobbin 1 is as follows: the inner diameter is 160mm, the outer diameter is 180mm, the thickness of the coil bobbin 1 is 9.8mm, and the outer surface of the coil bobbin 1 has a loop groove 2; the winding diameter is 0.45mm. Coil winding steps are as follows:

[0018] (1) Use a 66-hole indexing disc to evenly draw the partition line 4 on the outer surface of the circular coil skeleton 1, and draw the line every 8 holes, and the central angle between adjacent partition lines 4 is θ=( 9 / 66)*8=1.09°, a total of 330 partition lines are drawn; the partition line 4 is an annular closed line formed around the cross section of the coil bobbin 1, and the closed section 5 formed by the annular partition line is in line with the circumference of the coil bobbin 1 The lines are perpendicular.

[0019] (2) On the outer surface 6 of the coil bobbin 1, open a process hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com