Drill bit tooth pressing device and thermal tooth inserting equipment with drill bit tooth pressing device

A drill bit and equipment technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of difficult control of product quality and low production efficiency, and achieve the effects of high production efficiency, convenient operation and guaranteed consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

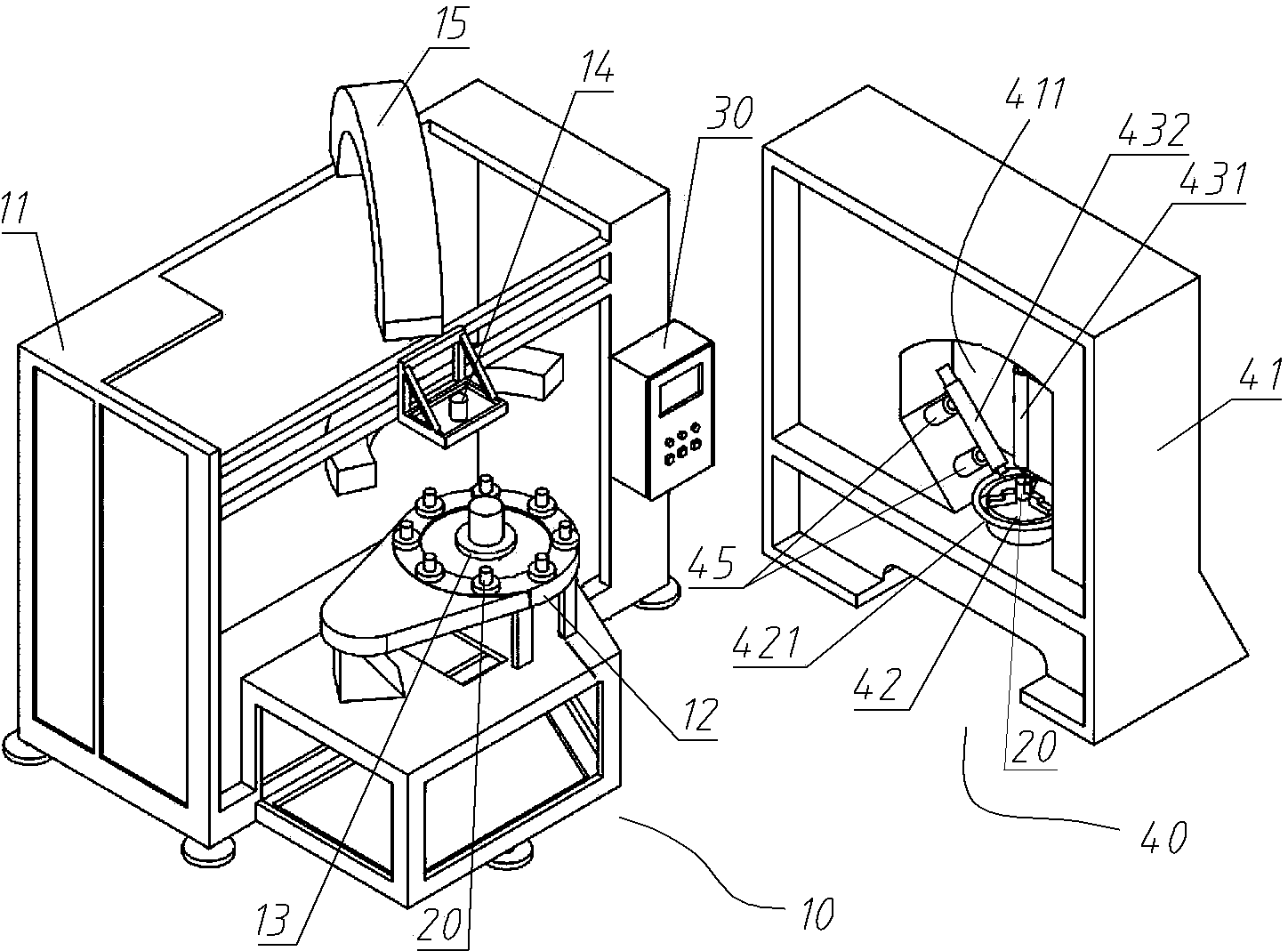

[0019] An embodiment of the hot cogging device in the present invention is as Figure 1~Figure 2 Shown is a thermal inserting equipment for down-the-hole drill inserts, including a rotary intermediate frequency heating device 10, a drill bit pressing device 40 for pressing the tooth head into the drill bit base 20, and An automatic controller 30 that controls the actions of the rotary intermediate frequency heating device 10 and the drill bit pressing device 40 .

[0020] The rotary intermediate frequency heating device 10 is used to heat the drill bit base body 20 to form a tooth head heating device. The device includes a heating device frame 11, and the heating device frame 11 is provided with a rotary heating table 12 with a plurality of stations. The infrared temperature measuring element 14 provided on the drill base 20 on the table 12 and the smoke and dust removal device 15 for discharging the smoke and dust during the heating process are also provided with an all-solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com