A cooling water row robot modular welding manufacturing method

A production method and cooling water technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as low welding accuracy, low operation efficiency, and unstable weld quality, and improve welding accuracy , improve work efficiency, and ensure the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

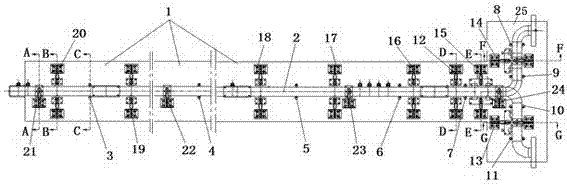

[0037] as attached figure 1 As shown, a cooling water row robot modular welding manufacturing method is a cooling water row welding method that needs to weld seven branch pipes on the main pipe. First, a single product is produced, and then the main pipe 1 of the cooling water row is placed On the welding platform, and according to the determined layout plan, each single piece is placed on a welding platform with a fixture, clamped and positioned by the mold fixture, and the modular operation is adopted, and the cooling water row is assembled and welded by the robot .

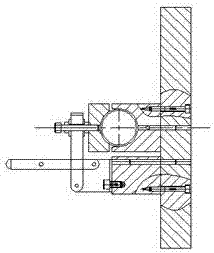

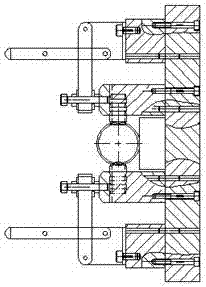

[0038] The above-described placing each single piece on a welding platform with fixtures is to design a multifunctional welding fixture platform 2 that can be used for various cooling water rows according to the arrangement of cooling water rows. 2 is installed with a combined mold fixture for assembling and fixing the cooling water row single pieces, using the combined mold fixture to fix and position each si...

Embodiment 2

[0054] The basic method of the second embodiment is the same as that of the first embodiment, and it is also a modular welding manufacturing method for cooling water row robots, except that there are only four branch pipes to be welded on the main pipe; the assembly welding method is still to make a single product first, Then put the main pipe of the cooling water row on the welding platform, and according to the determined layout plan, place each single piece on a welding platform with a fixture, clamp and position it by the mold fixture, and adopt modular operation. The welding of cooling water row is carried out by robot. Die clamps include pipeline positioning master mold 211, pipeline clamping molds 202, 203, 205, 208 and 209, and bilateral welding piece positioning molds 201, 204, 206 and 207; the cooling water row of different structures is realized by three kinds of mold assembly Positioning before welding.

[0055] The welding operation mode of the present embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com