Feeding device

A technology of feeding device and mounting plate, which is applied in the field of feeding device, can solve the problems that the processing procedure is easily affected by human factors, the processing efficiency is not easy to improve, and it is difficult to ensure the consistency of processing progress, so as to achieve simple structure and reduce human factors The degree of influence, the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution will be further described in detail below in conjunction with the accompanying drawings and embodiments.

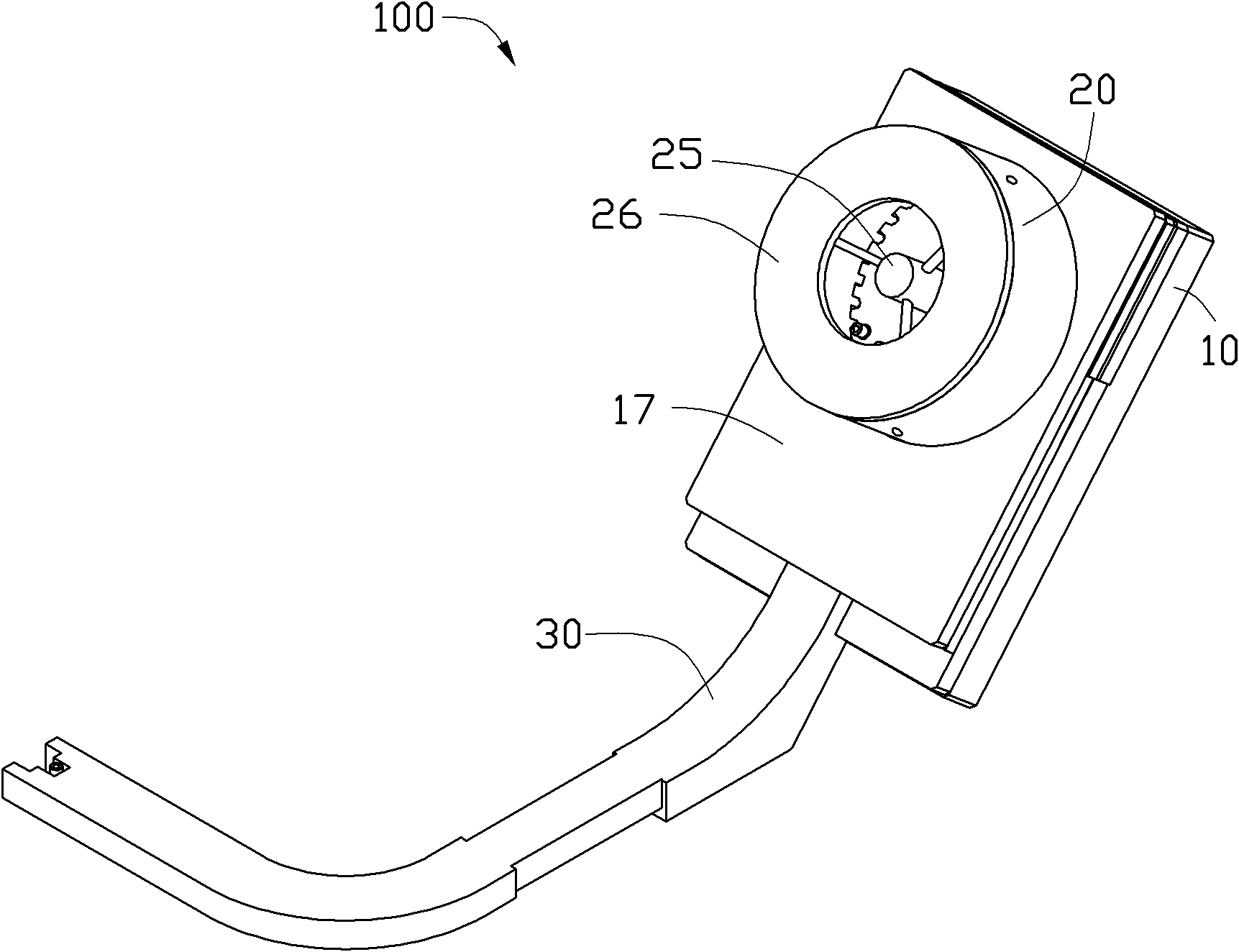

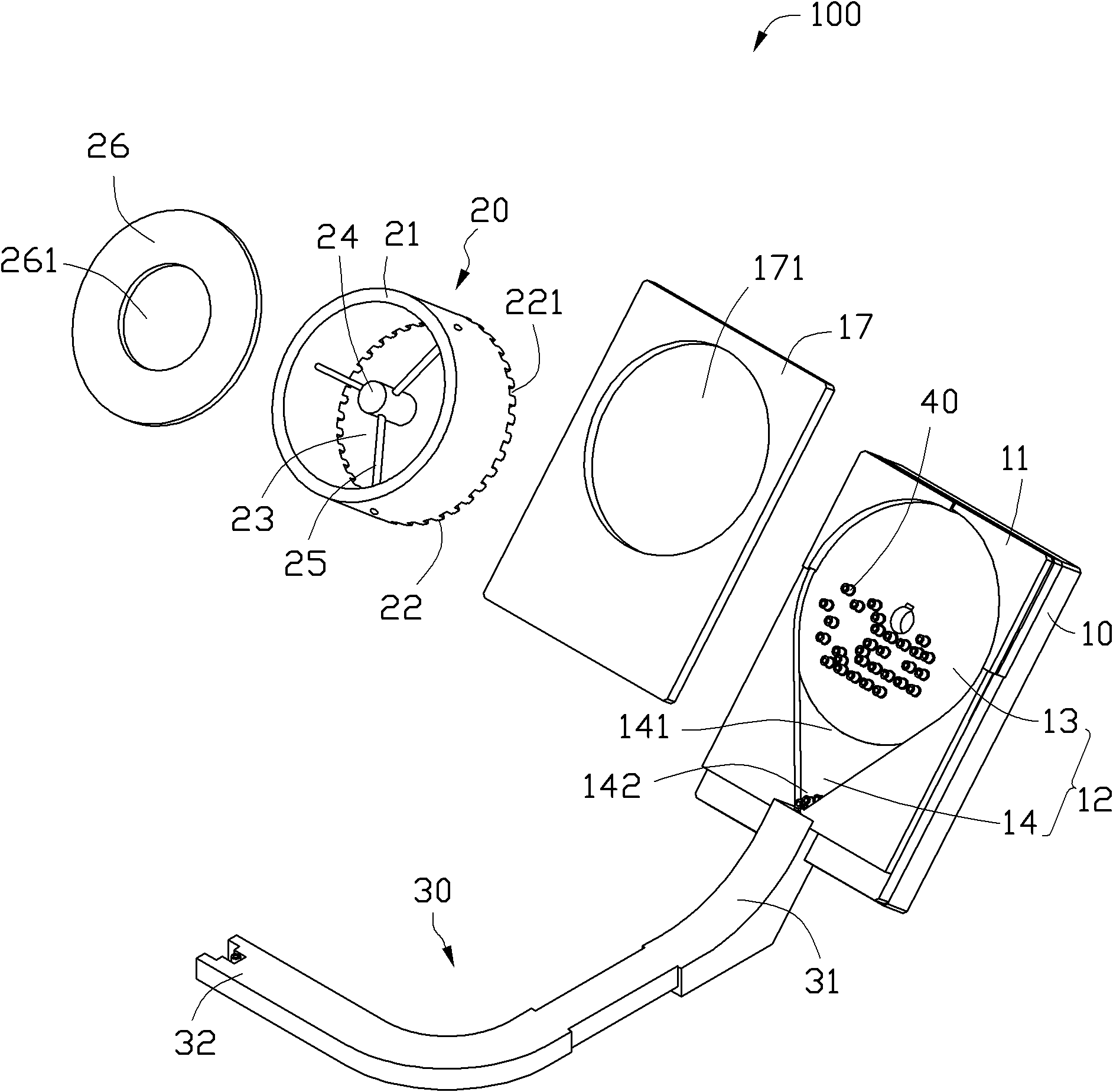

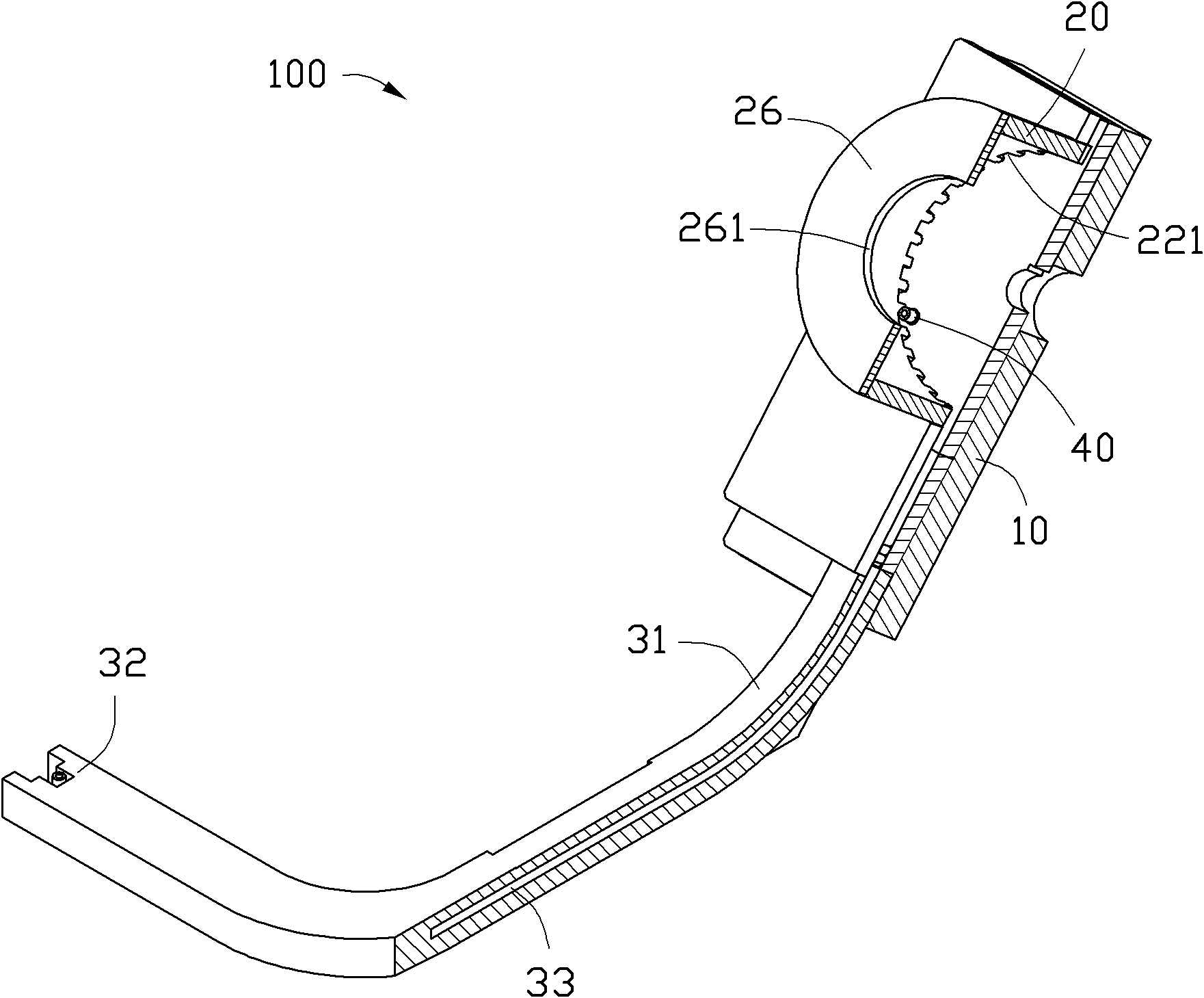

[0039] Please also refer to Figure 1 to Figure 3 , an embodiment of the present invention provides a feeding device 100, which is used for arranging and feeding parts in a predetermined direction, such as riveted studs, bolts, and rivets. The feeding device 100 includes a mounting plate 10 , a roller 20 , and a guide rail 30 .

[0040] The mounting plate 10 is used to set the feeding device 100 on corresponding processing equipment (not shown in the figure) at an angle greater than 0° but less than 90°, and is also used to support and set the drum 20 . The roller 20 is used to accommodate the parts, and turns the parts over by its own rotation, so that the direction of the parts matches the predetermined direction. The guide rail 30 cooperates with the drum 20 and is used to introduce the parts matching the predetermined direction, and gui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com