Gas-liquid isolated electronic atomizer

An electronic atomizer and gas-liquid isolation technology, applied in the field of tobacco, etc., can solve the problems of low production efficiency, short atomization airway, insufficient atomization, etc., and achieve convenient production and assembly, long atomization airway, and fog full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The gas-liquid isolated electronic atomizer of the present invention can be connected to a battery assembly (not shown in the figure) to form a complete electronic atomization device.

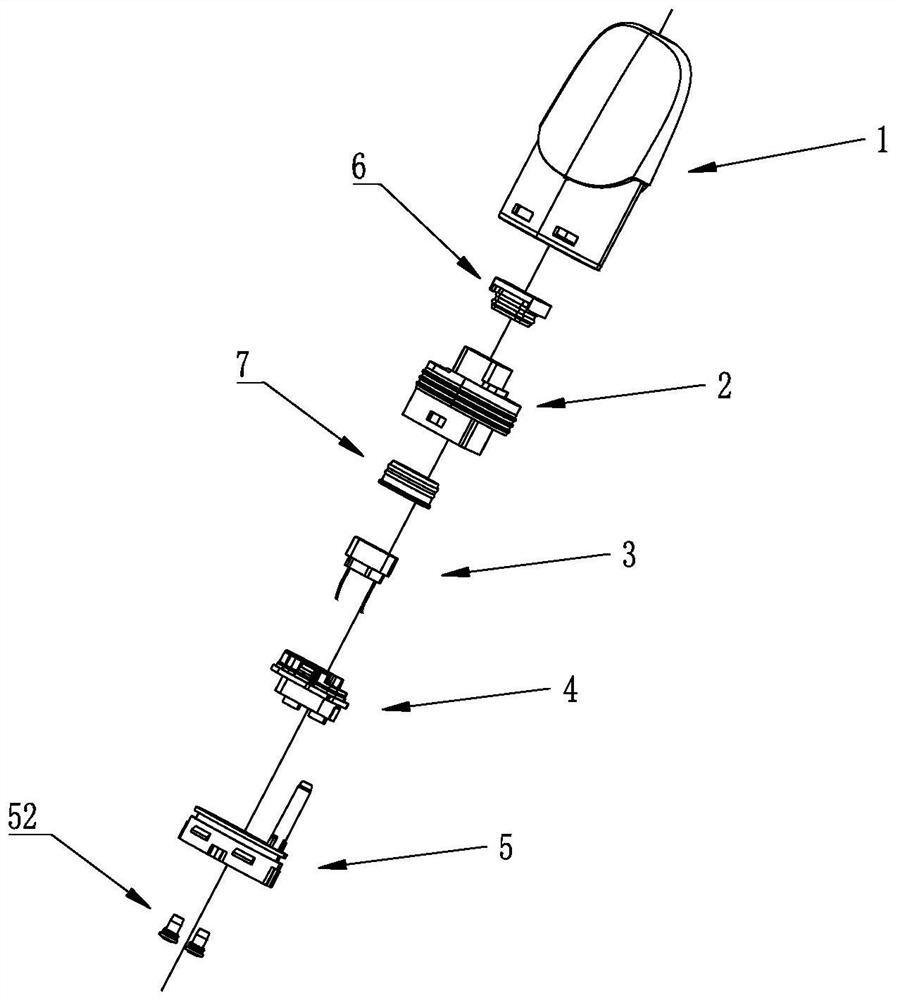

[0041] Such as figure 1 As shown, the electronic atomizer with gas-liquid isolation of the present invention is mainly composed of a housing 1 , a gas-liquid isolation bracket 2 , a porous atomizing core 3 , a supporting bracket 4 and a bottom cover 5 .

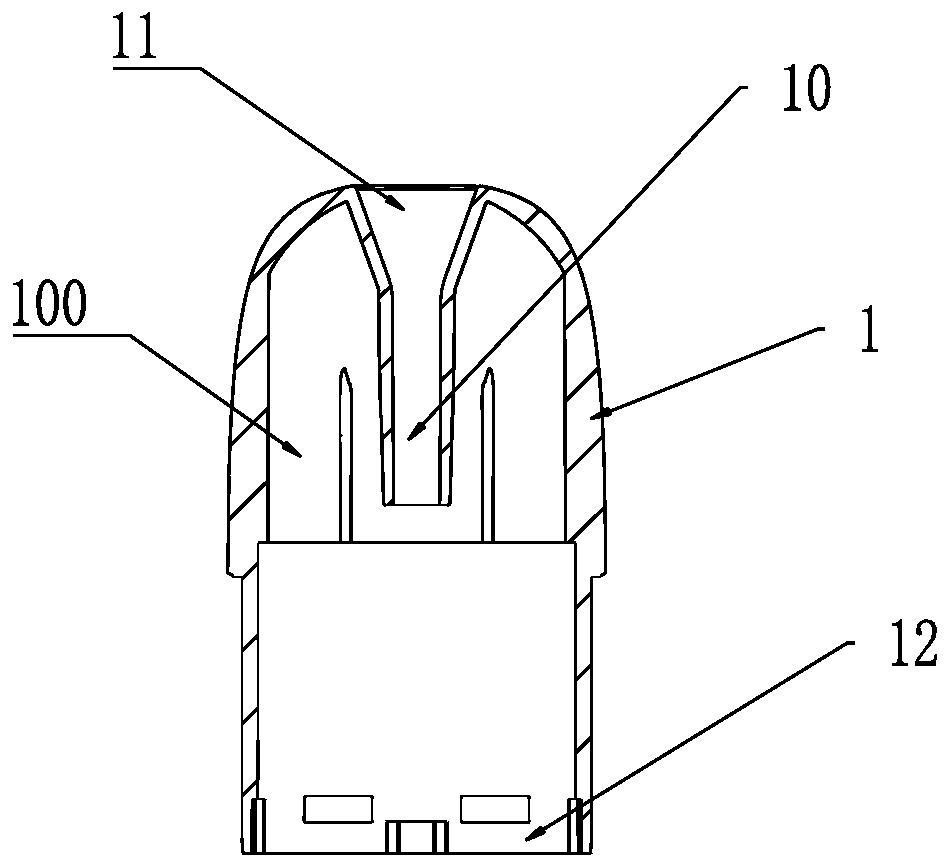

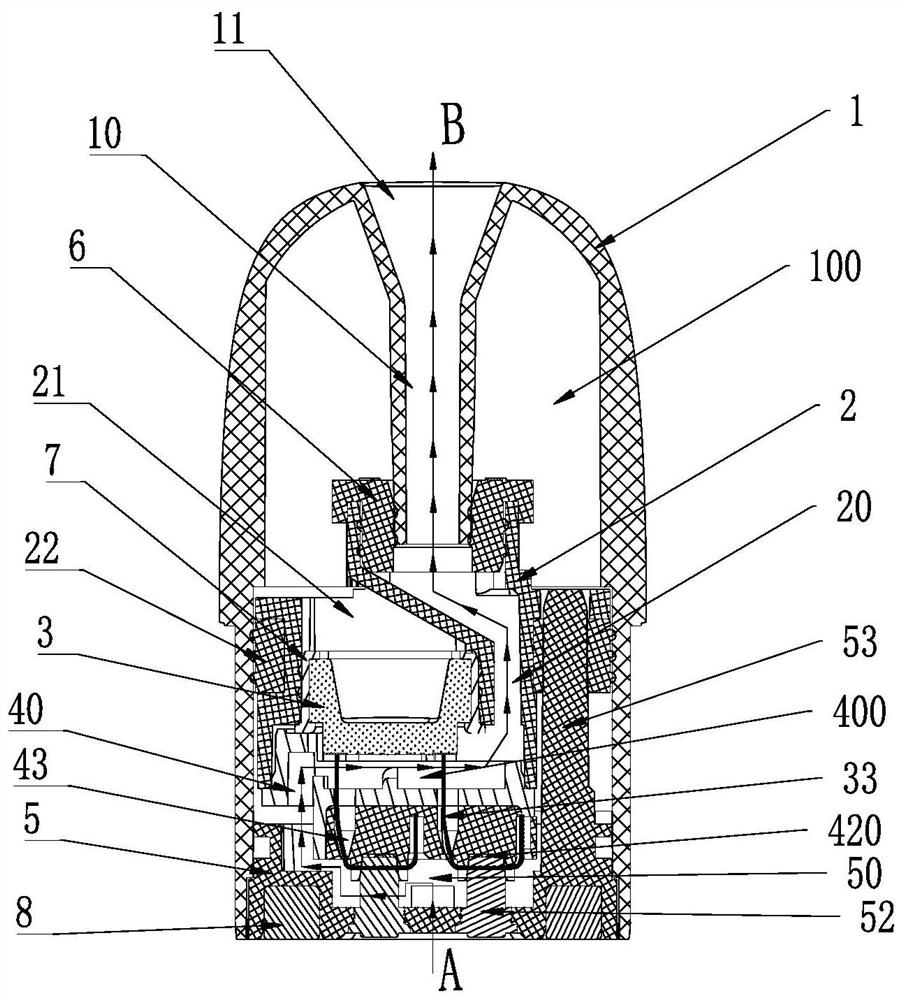

[0042] Such as figure 2 As shown, the upper center of the housing 1 is provided with a suction port 11 and the lower end is provided with a housing opening 12. The suction port 11 extends downward in the housing 1 and is provided with a central tube 10. The central tube 10 shrinks downward from the inner diameter of one end of the suction port 11. , so that the suction port 11 presents the shape of a trumpet mouth, which helps to slow down the flow velocity of the sucked steam and smoke, and makes the taste better. A liquid storage c...

Embodiment 2

[0055] On the basis of the first embodiment above, the difference from the first embodiment is that, as Figure 13-Figure 16 As shown, the supporting bracket 4 is only made of a hard material, the supporting bracket 4 is provided with a threading hole 43 and the bottom of the supporting bracket is provided with two upward concave electrode blind holes 420, and the pin 33 passes downward The threading hole 43 is bent and placed in the electrode blind hole 420 , and the bottom cover 5 is provided with two electrodes 52 , and the two electrodes 52 respectively upwardly contact the pin 33 in the two electrode blind holes 420 .

[0056] Such as image 3 , Figure 16 As shown, in the electronic atomizer with gas-liquid isolation of the present invention, when it works, the user inhales air through the suction port 11, and the internal air passage connected to the suction port 11 generates negative pressure, and the outside air enters the horizontal air intake channel from the air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com