Flushing method of nanofiltration and reverse osmosis water purifier

A technology of reverse osmosis water purifier and nanofiltration, applied in chemical instruments and methods, osmosis/dialysis water/sewage treatment, reverse osmosis, etc., can solve the problem of poor quality of the first glass of water, pollution, and TDS value change of pure water Advanced problems, to achieve the effect of good flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

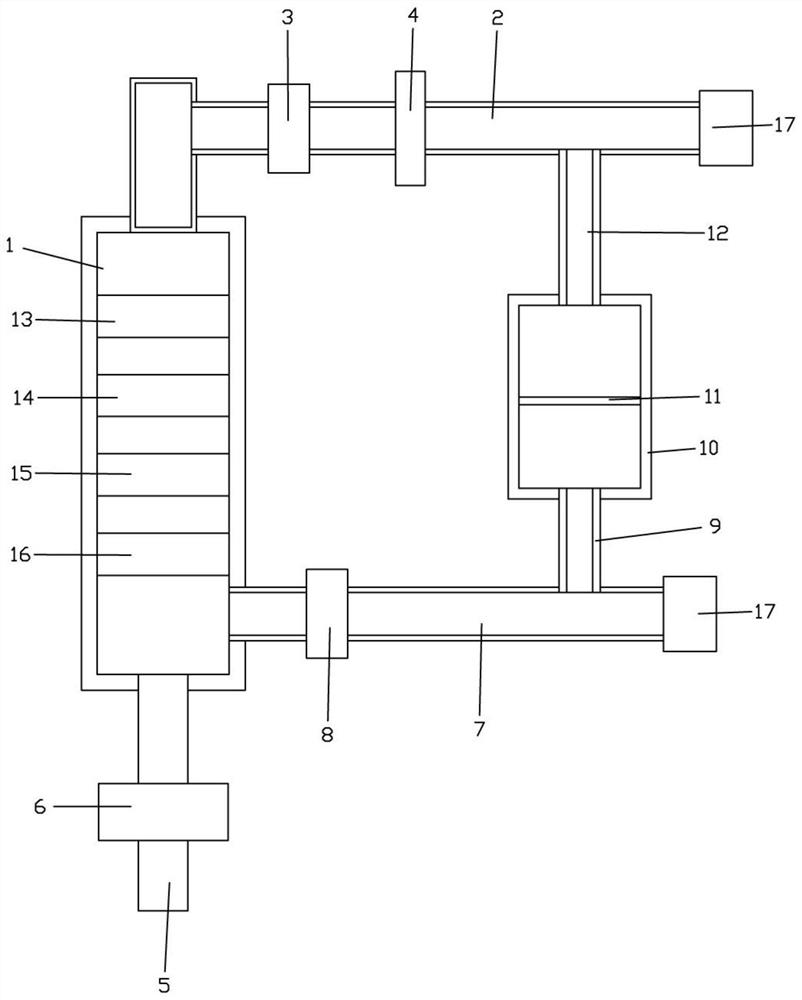

[0020] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] Such as figure 1 As shown, a nanofiltration and reverse osmosis water purifier of the present invention includes a filter element assembly 1 installed in the water purifier body, the upper side of the filter element assembly 1 is connected with a tap water inlet pipe 2, and the tap water inlet pipe 2 is connected with a water pump 3 and water inlet valve 4, the lower side of the filter element assembly 1 is connected with a waste water outlet pipe 5, the waste water outlet pipe 5 is connected with a waste water valve 6, the filter element assembly 1 is connected with a pure water outlet pipe 7, and the pure water outlet pipe 7 is connected with a flow meter 8. The pure water outlet pipe 7 is connected to the pure water storage pipe 9,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap