Leaf removing machine for rosemary processing

A defoliator and rosemary technology, which is applied in the field of defoliator for rosemary processing, can solve problems such as leaf breakage, and achieve the effects of avoiding leaf damage and improving defoliation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

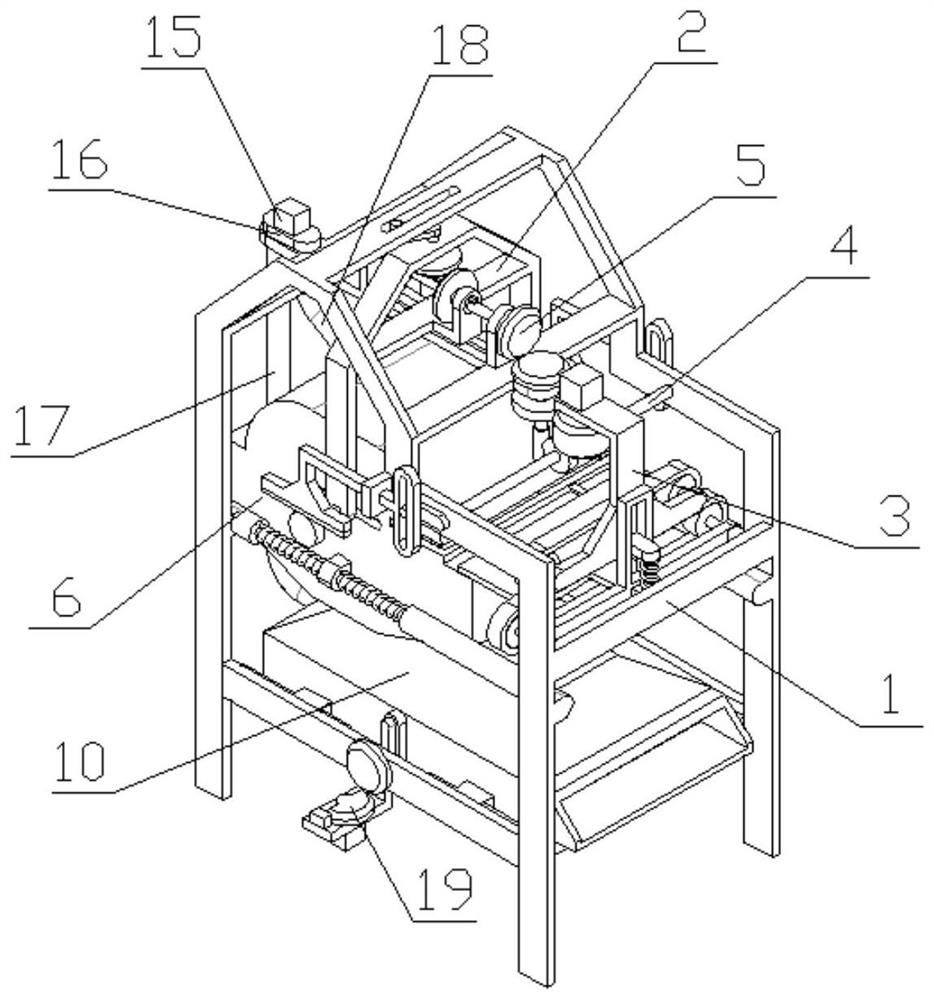

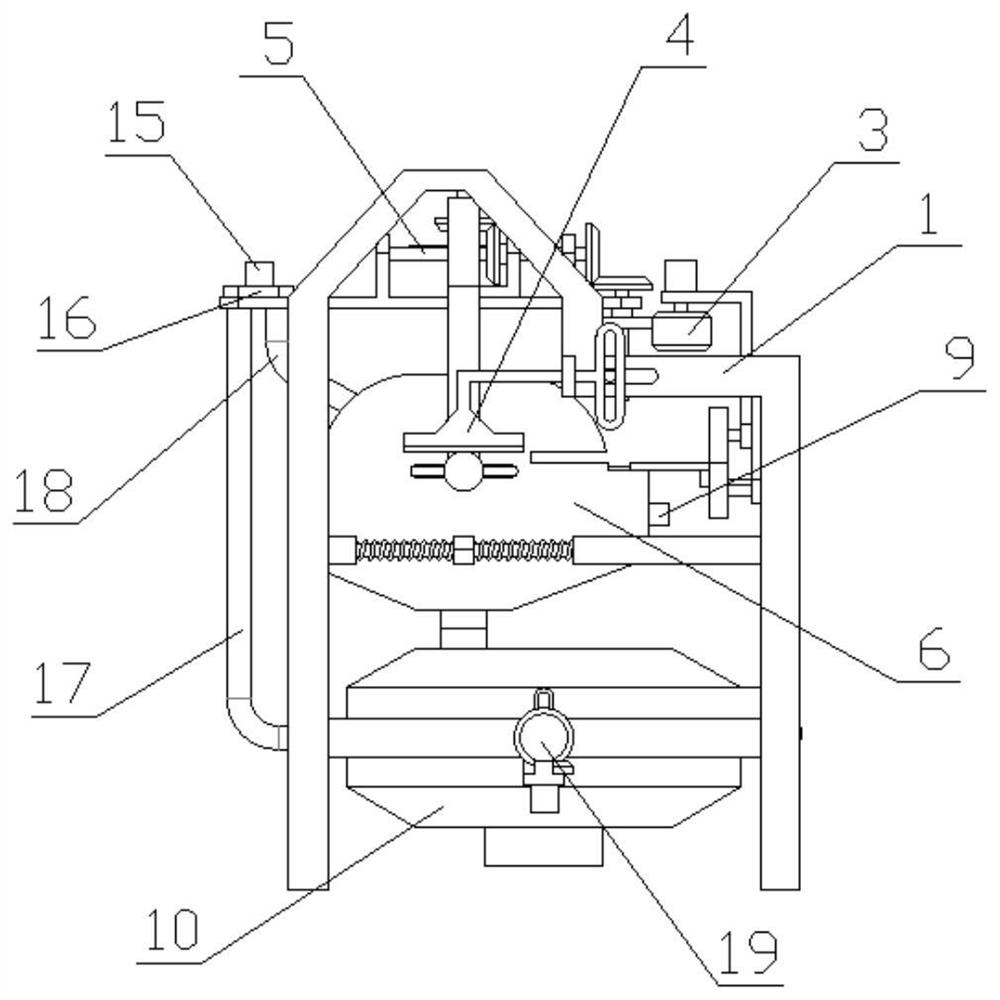

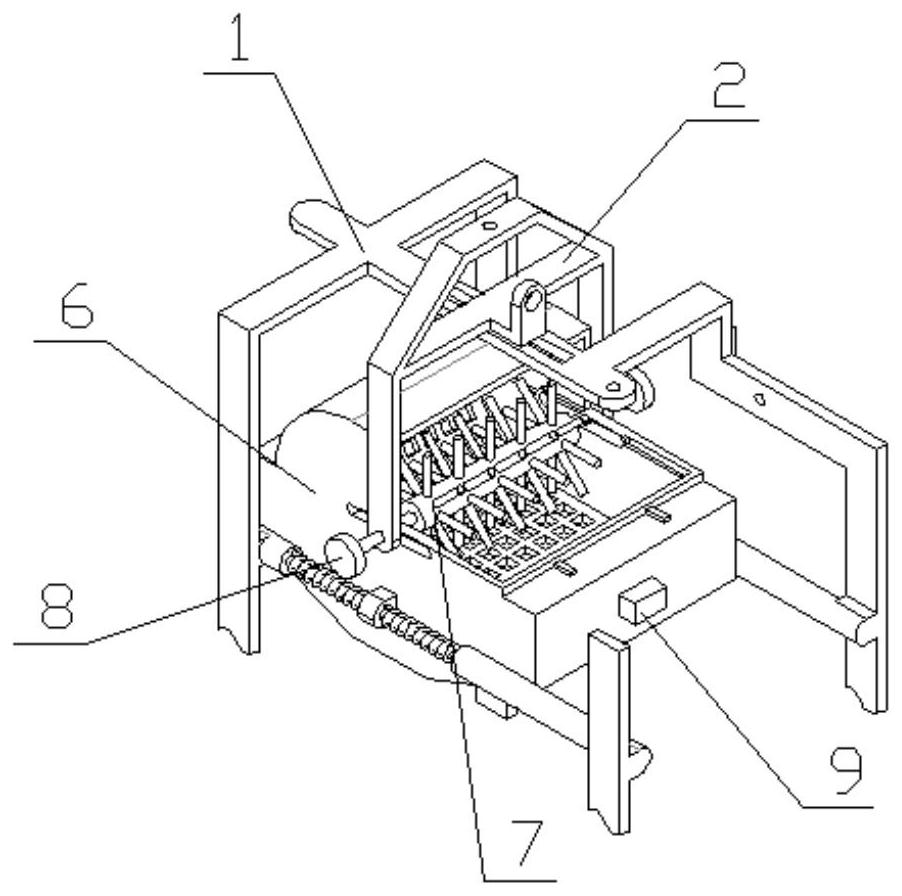

[0030] Combine below Figure 1-8 Illustrate the specific embodiment of the present invention, a kind of deleafing machine for rosemary processing, comprise support mechanism 1, the moving mechanism 2 that is slidably connected on the described support mechanism 1 successively from top to bottom, deleafing box body 6 and screening A box 10, the moving mechanism 2 is rotatably connected with a defoliating roller 7, the defoliating roller 7 is arranged inside the defoliating box 6, and one side of the supporting mechanism 1 is fixedly connected with a feeding mechanism , the feeding mechanism and the deleafing roller 7 are connected through a transmission combination, the deleafing box 6 and the screening box 10 are connected through a hose 12, and the support mechanism 1 One side is fixedly connected with fan 15, and described fan 15 is provided with electromagnetic valve 16, and described fan 15 is provided with first conduit 17 and second conduit 18, and described first condui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com