Combined filling unit based on modularization

A modular and filling technology, applied in the direction of threaded bottle caps, etc., can solve the problems of poor structural strength, inconvenient processing and circulation, and few reusable parts, so as to achieve the effect of improving design and high market application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

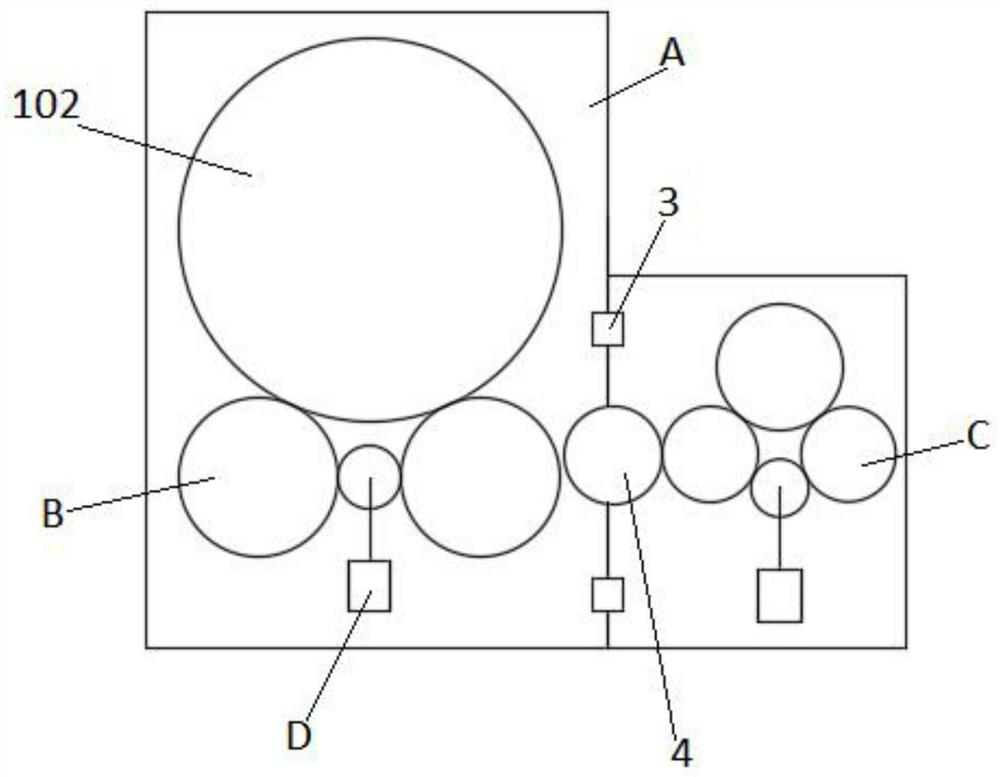

[0027] see figure 1 As shown, the present invention is a combination filling unit based on modularization, including a first functional module 1 and a second functional module 2 arranged side by side; the first functional module 1 includes a filling unit 102; the second functional module 2 Including a capping unit 201 or a capping unit 202; the filling unit 102, the capping unit 201 and the capping unit 202 all include a frame A, a bottle-in star wheel B, a bottle-out star wheel C and a drive Component D; the driving component D is composed of a drive motor and a conventional reducer in the field; the filling unit 102 is connected to the capping unit 201 or the capping unit 202 through a pair of positioning parts 3, and the filling unit 102 and the rotary The capping unit 201 or the capping unit 202 is connected through a transition star wheel 4; the filling unit 102 also includes a conventional filling mechanism in this field; the capping unit 201 also includes a conventional...

specific Embodiment 2

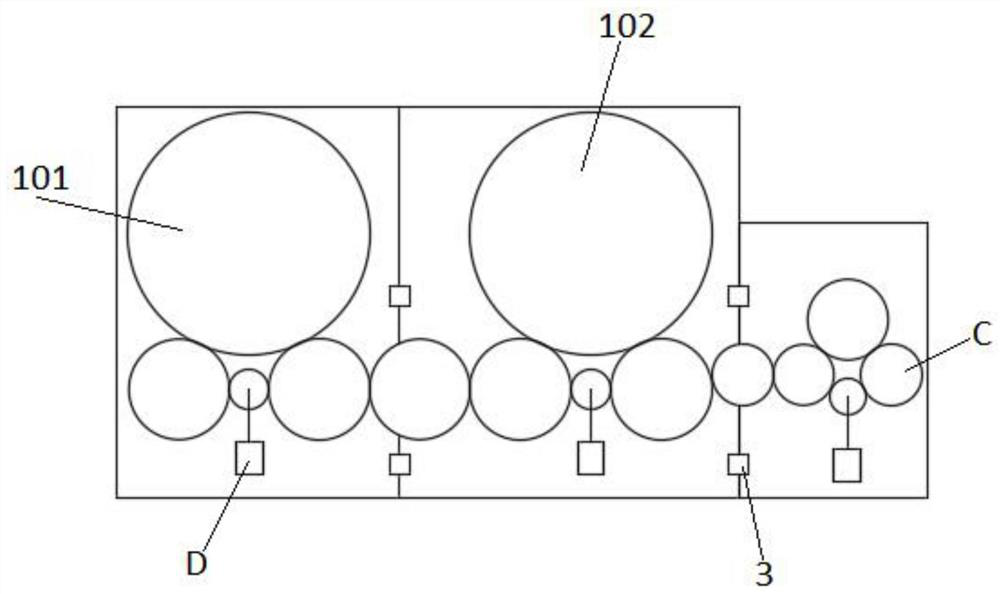

[0030] see figure 2As shown, the present invention is a combination filling unit based on modularization, including a first functional module 1 and a second functional module 2 arranged side by side; the first functional module 1 includes a bottle rinsing unit 101 and a filling unit 102 The second functional module 2 includes a capping unit 201 or a capping unit 202; the bottle rinsing unit 101, the filling unit 102, the capping unit 201 and the capping unit 202 all include a frame A, a star wheel for entering bottles B, a bottle-out star wheel C and a drive assembly D; the drive assembly D is composed of a drive motor and a conventional reducer in the field; between the bottle rinsing unit 101 and the filling unit 102 and between the filling unit 102 and the capping unit 201 Or the capping units 202 are respectively connected by a pair of positioning parts 3, and a transition The star wheel 4 is transmission connected; the bottle rinsing unit 101 also includes a conventiona...

specific Embodiment 3

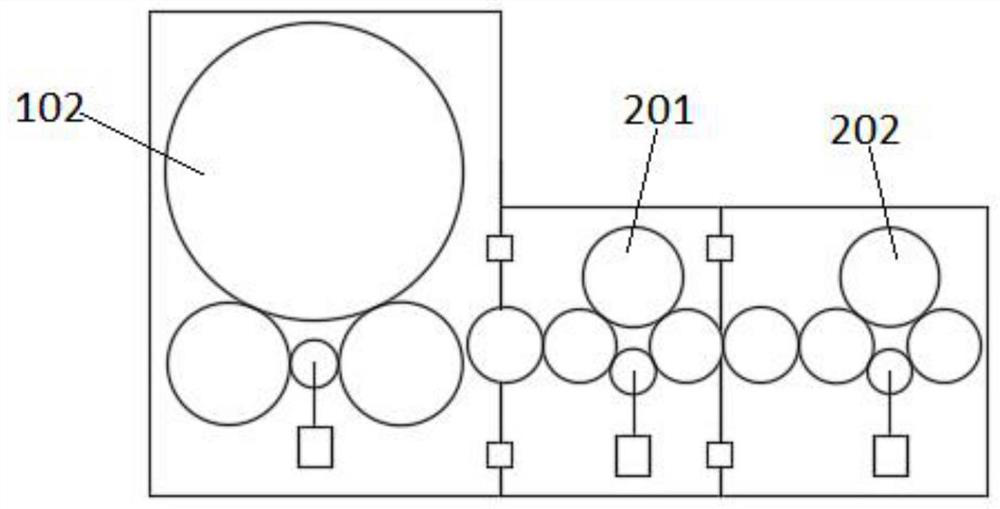

[0033] see image 3 As shown, the present invention is a combination filling unit based on modularization, including a first functional module 1 and a second functional module 2 arranged side by side; the first functional module 1 includes a filling unit 102; the second functional module 2 It includes a capping unit 201 and a capping unit 202; the filling unit 102, the capping unit 201 and the capping unit 202 all include a frame A, a bottle-in star wheel B, a bottle-out star wheel C and a drive Component D; the drive component D is composed of a drive motor and a conventional reducer in the field; the filling unit 102 and the capping unit 201 and the capping unit 201 and the capping unit 202 are respectively connected by a pair of positioning parts 3 , and between the filling unit 102 and the capping unit 201 and between the capping unit 201 and the capping unit 202 are respectively connected by a transition star wheel 4; the filling unit 102 also includes a conventional fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com