Bathroom decorative plate joint sealing structure

A technology for sealing structures and decorative panels, which is applied in building construction, covering/lining, construction, etc., and can solve problems such as short service life, poor sealing performance, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

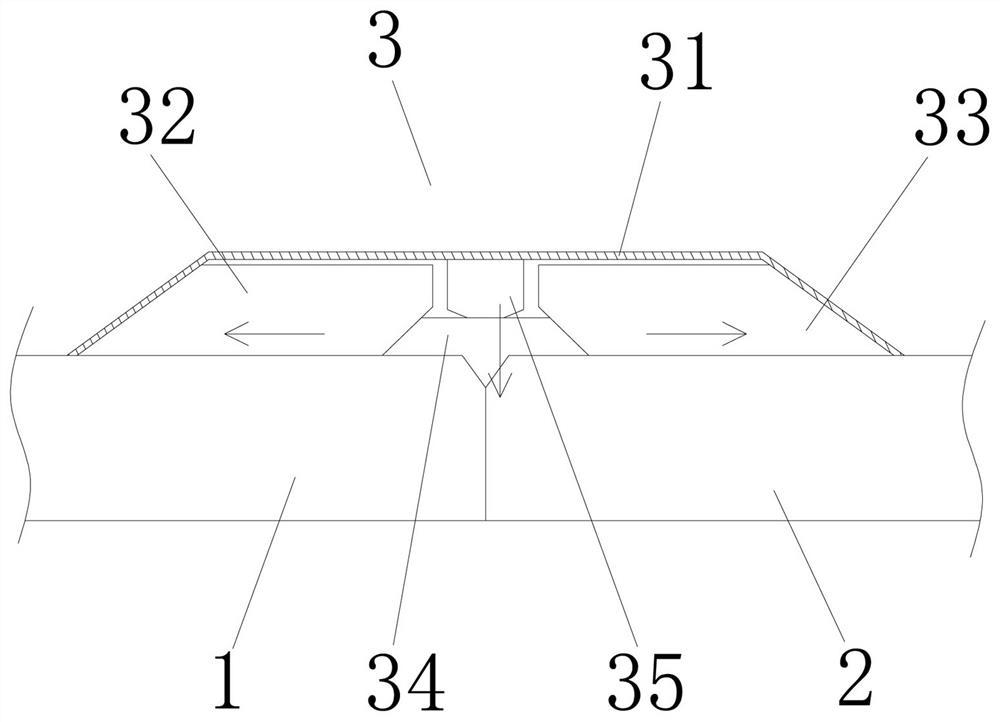

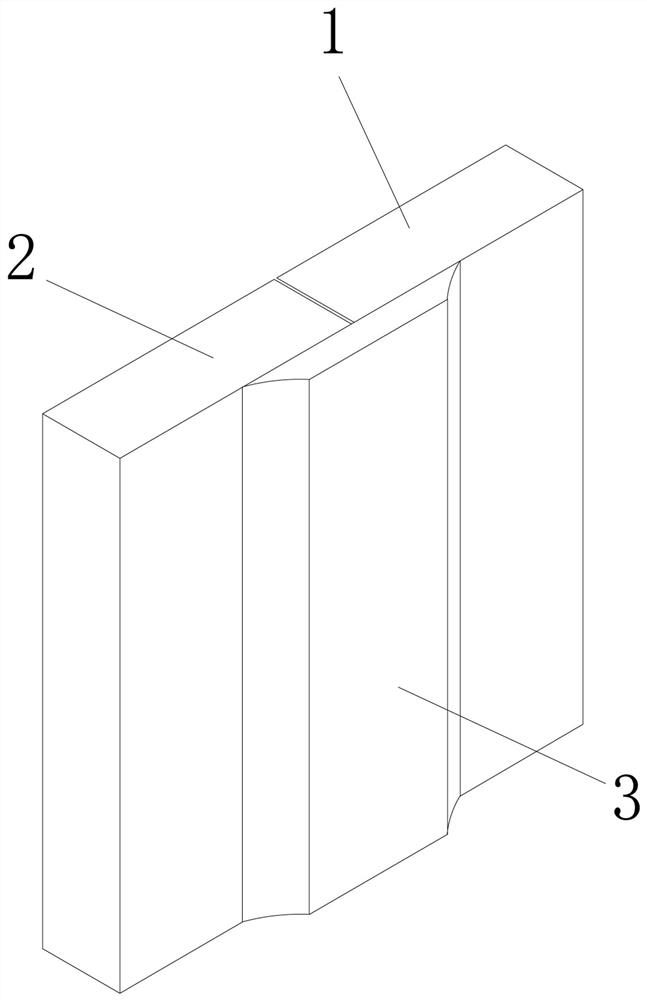

[0030] Embodiment one: if Figures 1 to 3 As shown, it is only one embodiment of the present invention, a seam sealing structure of sanitary decorative panels, including a first decorative panel 1, a second decorative panel 2, and The sealing part 3 at the joint of the board 2, the sealing part 3 includes a sealing shell 31, one end of the sealing shell 31 is fixedly connected with the side of the first decorative panel 1, and the sealing shell 31 is far away from the first One end of a decorative panel 1 is fixedly connected to the side of the second decorative panel 2, and the joint between the edge sealing shell 31 and the first decorative panel 1 is connected to the edge sealing shell 31 and the second decorative panel. 2 is less than the length of the edge sealing shell 31, so that the side of the edge sealing shell 31 close to the connection of the first decorative panel 1 and the second decorative panel 2 forms an installation cavity, the The installation cavity is pro...

Embodiment 2

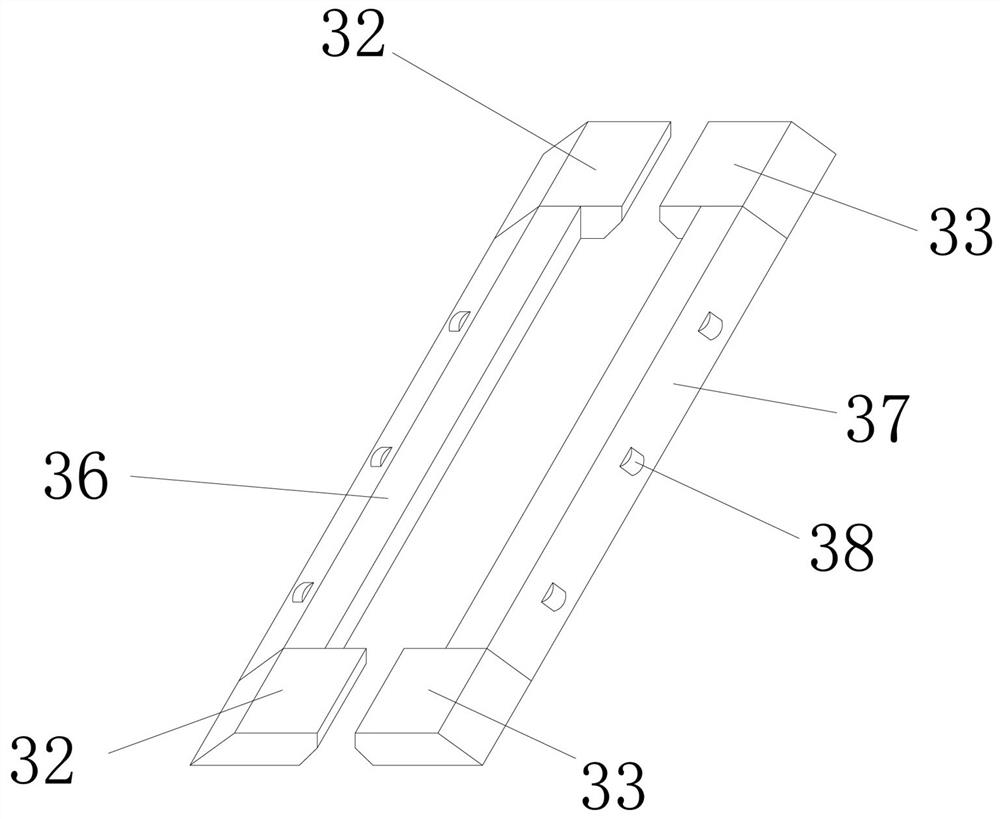

[0043] Embodiment two, still as Figures 1 to 3 As shown, it is only one of the embodiments of the present invention. On the basis of the first embodiment, in the seam sealing structure of the sanitary decorative panel of the present invention, the first slider 32 is far away from the second slider 33 One end and the end surface of the second sliding block 33 away from the first sliding block 32 are both inclined. In fact, these two inclined surfaces are inclined towards the gap between the two decorative panels as they move away from the decorative panel. ,like image 3 As shown, in this way, the first slider 32 and the second slider 33 can be pressed tighter against the first decorative panel 1 and the second decorative panel 2 under the limit of the edge sealing shell 31 .

[0044] Similarly, the end of the first slider 32 close to the second slider 33 and the end surface of the second slider 33 close to the first slider 32 are inclined. In fact, the first slider 32 The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com