A mounting base for installing and fixing a vacuum pump

A technology for installing a base and a vacuum pump, which is applied to the components, pumps, and pump components of a pumping device for elastic fluids, which can solve the problems of vibration at the joint connection, vacuum pump vibration, and affecting the sealing effect of the joint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

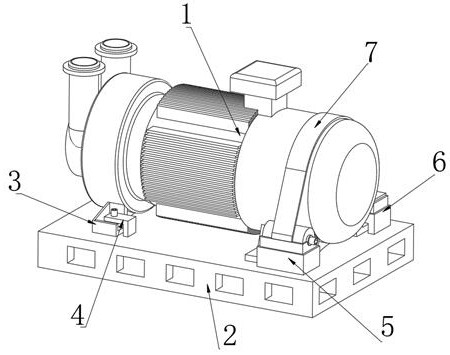

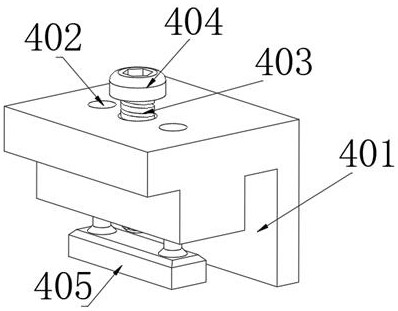

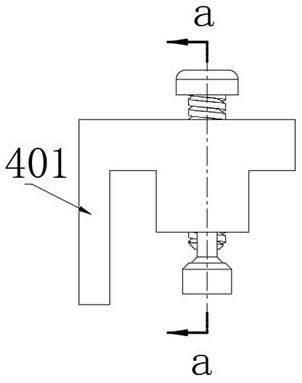

[0039] Such as Figure 1-15 As shown, the embodiment of the present invention provides a mounting base for vacuum pump installation and fixation, including a vacuum pump body 1, and the lower end of the vacuum pump body 1 is integrated and fixedly connected with four vacuum pump legs 3, two of which are under the vacuum pump legs 3. Two front outrigger fixing assemblies 4 are provided, and strap locking assemblies 5 and strap head fixing assemblies 6 are respectively arranged under the other two vacuum pump legs 3, and the front outrigger fixing assemblies 4, strap Both the locking component 5 and the strap head fixing component 6 are fixedly installed on the upper surface of the base mounting plate 2, and the strap locking component 5 and the strap head fixing component 6 are connected by a strap 7, and the strap The belt 7 is passed over the vacuum pump body 1 .

[0040]Through the above technical solution, the vacuum pump body 1 is firmly pressed against the upper surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com