Full-automatic test tube packaging machine and working method thereof

A packaging machine, fully automatic technology, used in packaging, packaging protection, transportation and packaging, etc., can solve problems such as black spots, affecting product use, air bubbles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

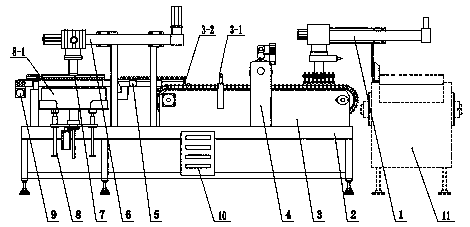

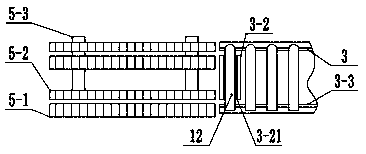

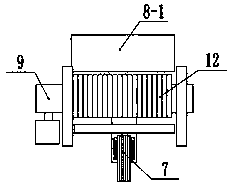

[0016] Depend on figure 1 Known, a kind of fully automatic test tube packing machine of the present invention, by suction pipe module 1, main frame 2, transfer pipe chain assembly 3, detection runner 4, code bottle mechanism 5, clamp bottle module 6, push tube mechanism 7, lifting mechanism 8. The collection belt 9 and the control box 10 are composed. The suction pipe module 1 is installed directly above the right side of the main frame 2, the pipe transfer chain assembly 3 is installed on the upper right side of the main frame 2, and the detection runner 4 is straddled and installed on the In the middle position of the pipe transfer chain assembly 3, the code bottle mechanism 5 is installed on the main frame 2 at the left end of the pipe transfer chain assembly 3. Installed on the main engine bracket 2 on the left side of the code bottle mechanism 5, the lifting mechanism 8 is installed on the outside below the tube collection belt 9, the tube pushing mechanism 7 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com