A transmission temperature oil level thermostat using a magnetically encoded angular displacement chip

A magnetic coding and angular displacement technology, applied in the field of transmission temperature oil surface thermostat, can solve the problem of easy deviation of detection results, and achieve the effect of improving cooling effect, expanding detection range, and speeding up flow speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

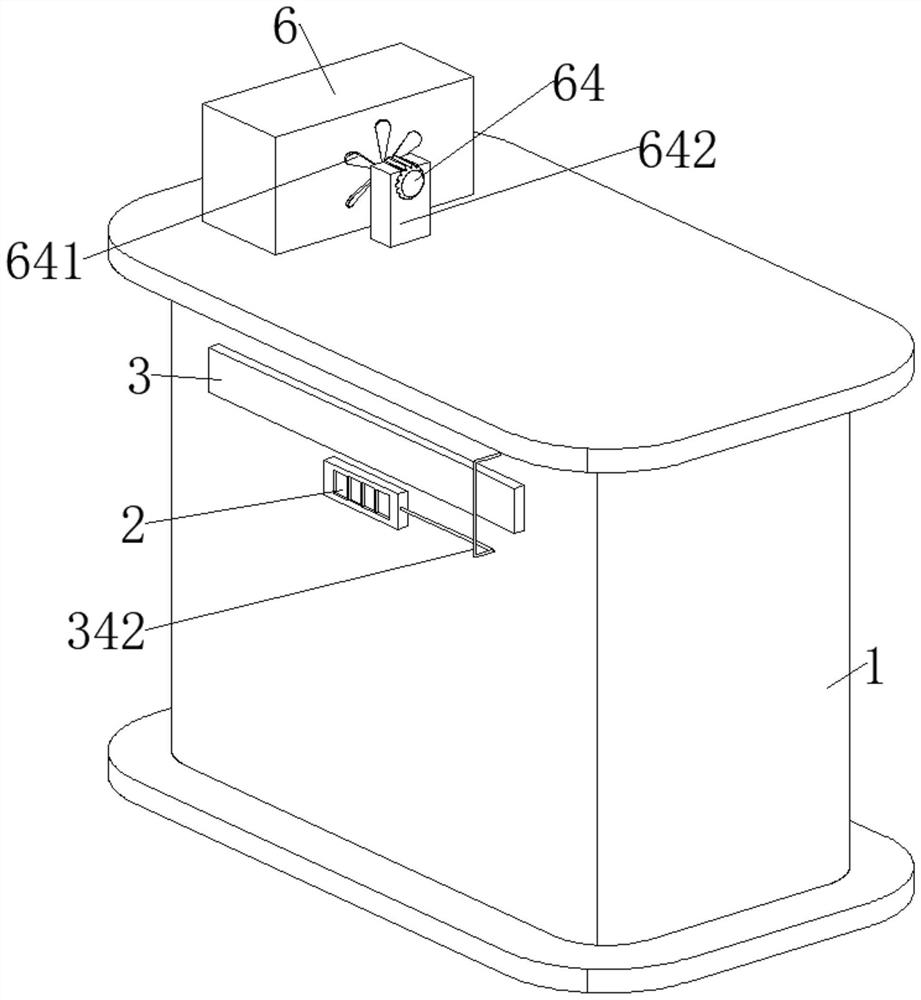

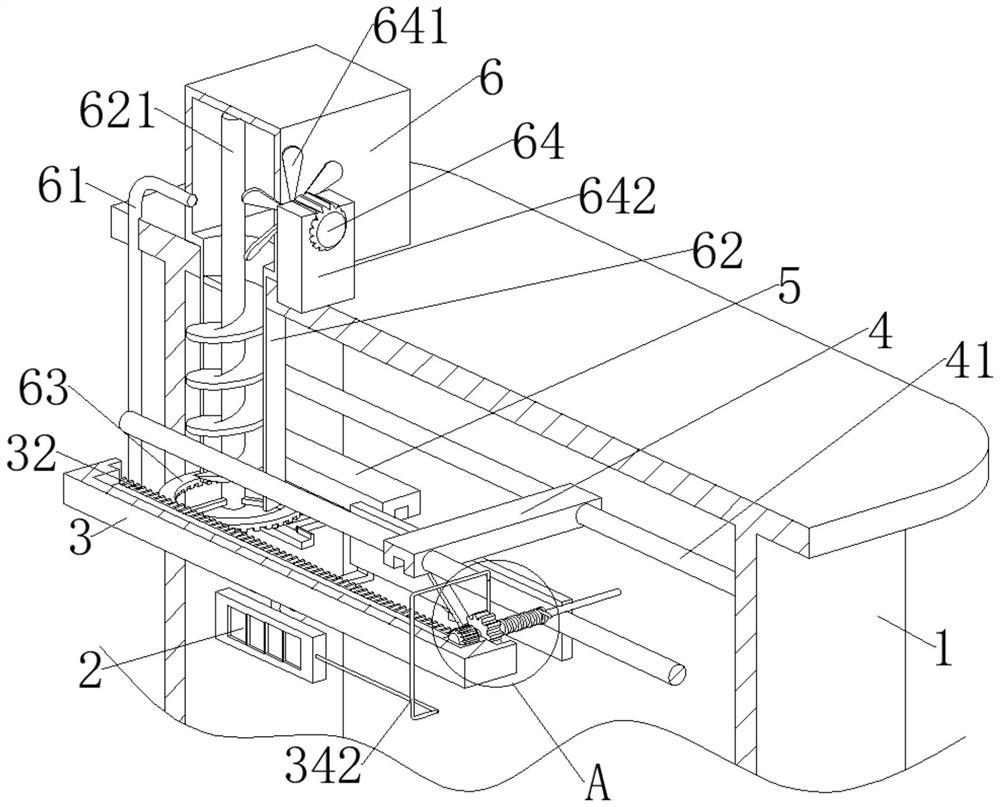

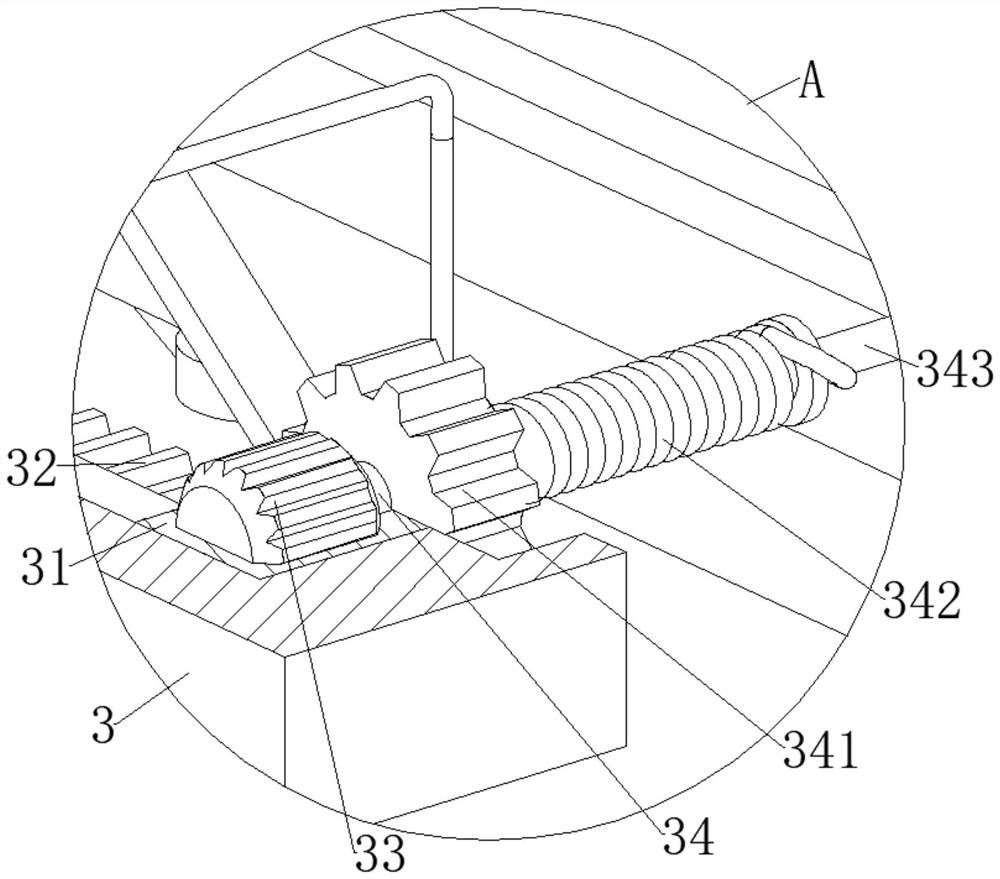

[0027] refer to Figure 1-Figure 4 , the present invention provides a technical solution: a transmission temperature oil level thermostat using a magnetically encoded angular displacement chip, including a transformer box 1 with built-in transformer oil and a magnetically encoded motor 33, and the outer wall of the transformer box 1 is fixedly connected with The temperature controller main body 2 is fixedly connected with the installation bar 3 on the transformer box 1, and the installation block 31 is slidably connected with the installation bar 3. There is a cavity for the installation of the magnetic encoding motor 33 in the installation block 31, and the output of the magnetic encoding motor 33 One end is fixedly connected with a rotating shaft 34, the rotating shaft 34 is coaxially fixedly connected with a first gear 341, the mounting bar 3 is provided with teeth 32 meshing with the first gear 341, and the end of the rotating shaft 34 away from the first gear 341 is coaxia...

Embodiment 2

[0040] refer to Figure 9 , is basically the same as Embodiment 1, the difference is that the drive mechanism includes a rack 72, the rack 72 is fixedly connected to the second slider 51, and the screw pump shaft 621 is fixedly connected with a one-way bearing 71, and the one-way bearing 71 The second gear ring 7 is fixedly connected to the top, the second gear ring 7 is located on the same axis as the screw pump shaft 621 , and the rack gear 72 meshes with the second gear ring 7 .

[0041] When the second slider 51 slides, the rack 72 fixedly connected to the second slider 51 slides synchronously. Since the rack 72 meshes with the second ring gear 7, the rack 72 that slides back and forth can drive the second ring gear 7. Reciprocating rotation, due to the setting of the one-way bearing 71, the second gear ring 7 can only rotate in one direction on the screw pump shaft 621, so that the second gear ring 7 that rotates when the second gear ring 7 rotates on the screw pump shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com