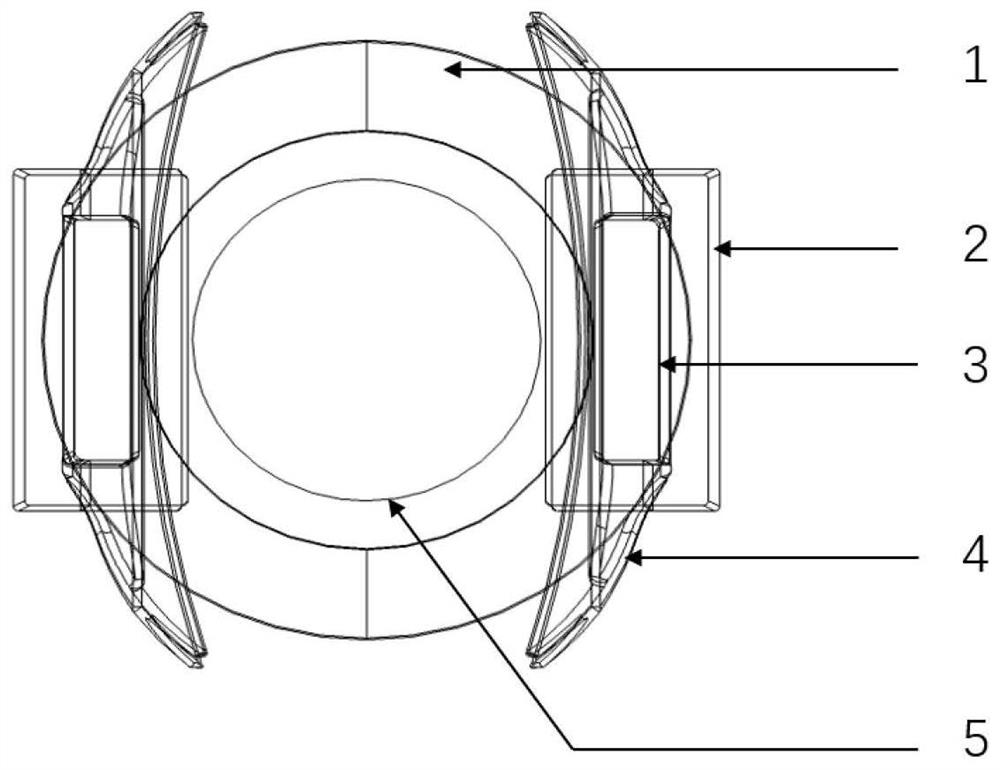

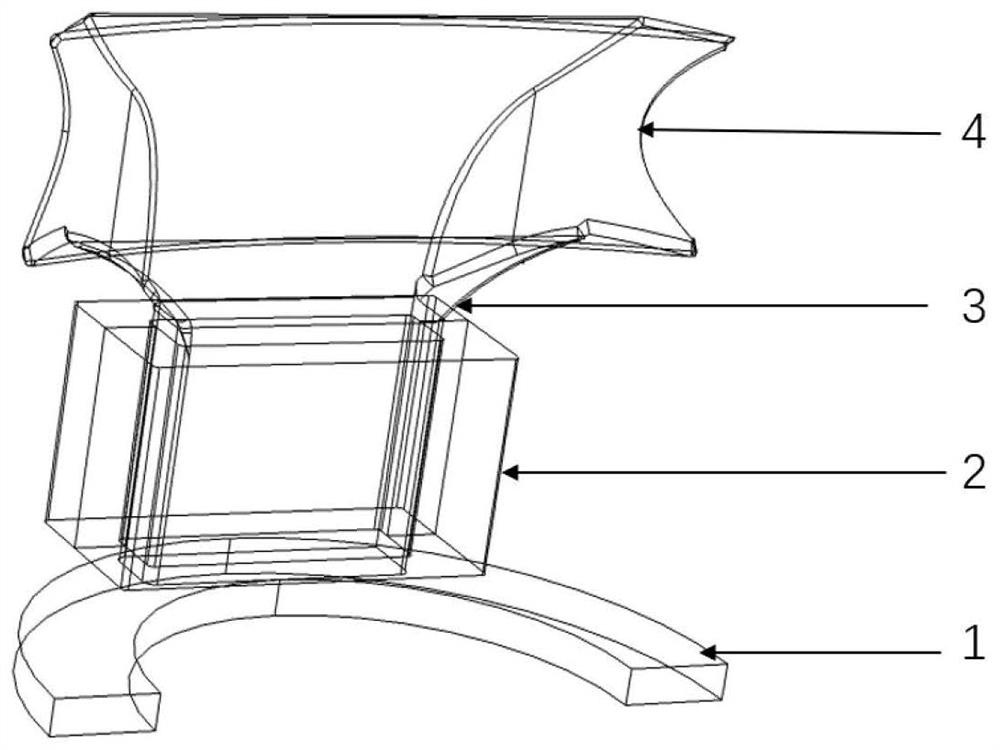

A magnetic field generator suitable for vacuum coating equipment

A magnetic field generating device and vacuum coating technology, applied in the manufacture/processing of electromagnetic devices, electromagnets, etc., can solve the problems of small uniform magnetic field space and low magnetic field strength, and achieve the effect of saving limited lateral space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] By simulating the internal structure of the vacuum coating equipment, a wafer 5 with a diameter of 4 inches is placed horizontally in the center area of a pair of spherically-cut pole heads (with a height of 60 cm). Among them, the shape of the pole head is made of a sphere with a diameter of 85cm, which is placed in the center of the wafer. By simulating an external excitation coil power supply, a magnetic field is generated in the central area. The excitation coil is a copper wire with a diameter of 2mm, and the number of turns is 400. By applying a current of 10A, a uniform magnetic field is generated in the center area of the pole head.

[0036] By simulating magnetic fields such as Figure 4 It can be obtained that the magnetic field strength obtained in the area of 4 inches is (23.463-26.337) mT, and the uniformity is 89.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| evenness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com