Rotary industrial robot spraying shielding device and spraying shielding method thereof

A kind of industrial robot and rotary technology, applied in the direction of coating, manipulator, spraying device, etc., can solve the problems of reduced service life of baffle, unfavorable work efficiency, lifting, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

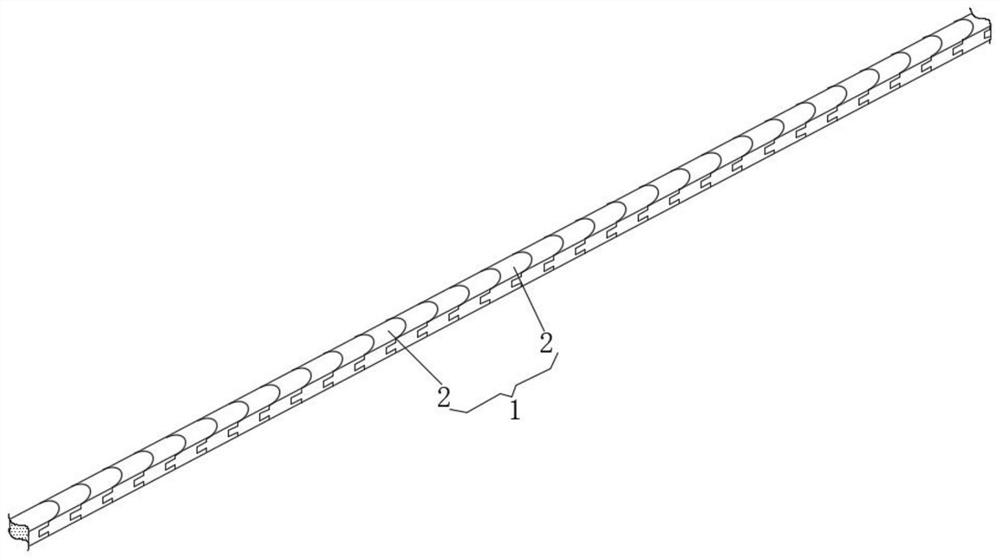

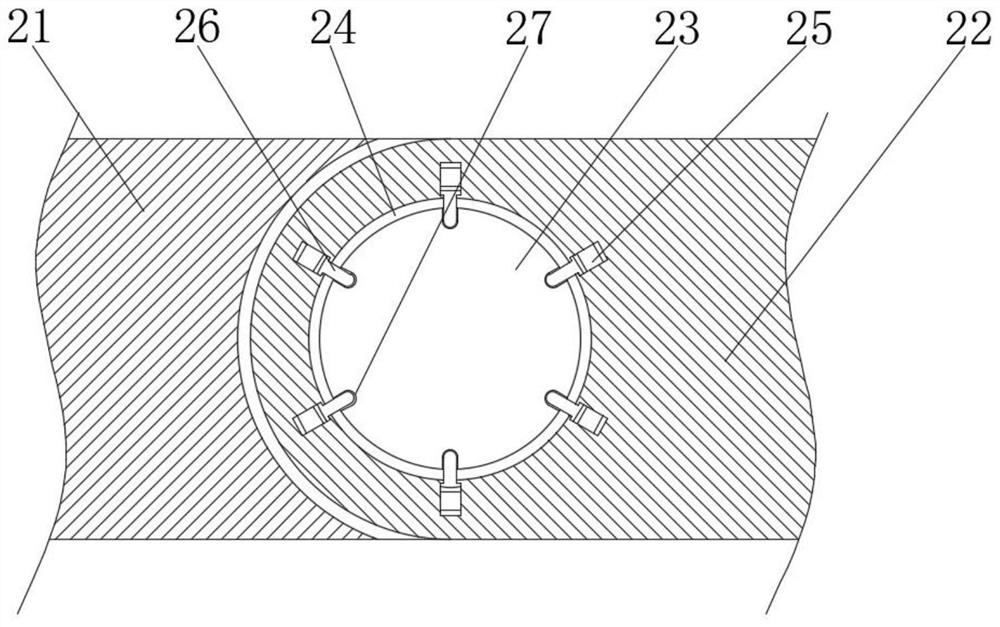

[0026] See Figure 1-3 This embodiment provides a rotary industrial robot spraying occlusion, including folding rod 1, folding rod 1 including a plurality of deflection block 2, and the folding rod 1 formed by assembling a plurality of deflection blocks 2 can be folded, so that it can be different The shape of the spray pattern is blocked, and the scope of the folding rod 1 blocks the spray coating.

[0027] In order to achieve the relative deflection between the deflection block 2, one end of the deflection block 2 is provided with the mounting groove 21 of the U-shaped structure, and the deflection block 2 is disposed from one end of the mounting groove 21, and the mounting groove 21 and the mounting plate 22 match. The adjacent deflection blocks 2 are hinged between the mounting grooves 21 and the mounting plate 22, and the deflection block 2 is hinged together by the mounting groove 21 and the mounting plate 22, and the deflection block 2 can be relatively rotated, and then by ...

Embodiment 2

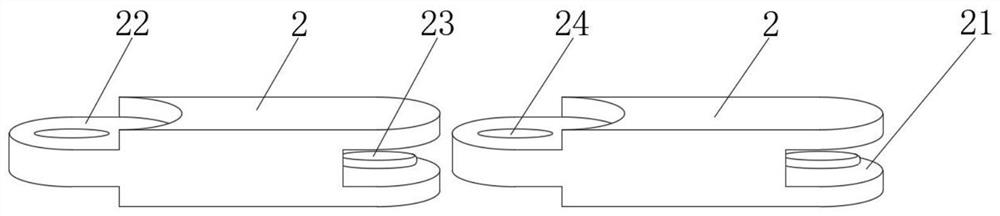

[0035] See Figure 4-5 Further improvements were made on the basis of Example 1: During the process of blocking the paint, since the size of the spray pattern cannot be achieved, it is necessary to modify the number of deflection block 2, that is, the deflection block 2 The number of increases and decreases.

[0036] The two ends of the deflection block 2 are separately opened, and the deflection block 2 is attached to the mounting groove 21 and the mounting plate 22, and the end portion of the mounting groove 21 is attached to the mounting groove 21, respectively. The end portion of the plate 22 is integrally provided with a plate 29 that matches the buckle groove 28, and is used by the mating between the plate 29 and the buckle groove 28, the mounting groove 21 and the mounting plate 22 can be implemented at the end portion of the deflection block 2. Disassembly and installation.

[0037] Among them, when the mounting groove 21 and the mounting plate 22 of the deflection block 2 ...

Embodiment 3

[0045] See Image 6 Further improvement is made in the basis of Example 2: A large metal material is present in the apparatus of the spray pattern, and the non-metallic material is fixed after the shape of the folded rod 1, and the support rod or bond is used to achieve the folding rod 1 and The fixation between the devices, but for the metal equipment, the effect of fixing the folding rod 1 and the device is better than the device.

[0046] The inside of the deflection block 2 is opened with a fixing chamber 4, and an electric suction cup 41 is mounted inside the fixing chamber 4, and the electric suction cup 41 uses the electromagnet in the prior art.

[0047] A iron plate 42 is fixed between the fixing chamber 4 and the deflection block 2, the iron plate 42 is separated from the electric suction cup 41 and is pair, the front panel of the iron plate 42 and the electrical chuck 41 is parallel to each other, wherein the iron plate 42 can convert the electric suction cup. The magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com