Metal building material surface polishing and derusting device

A technology for the surface of building materials and metal plates, which is used in grinding/polishing safety devices, metal processing equipment, grinding machines, etc. It can solve the problems that rust remover and debris mixture cannot be quickly discharged, and energy consumption is high, and achieve good grinding. Derusting, speeding up the discharge rate, and realizing the effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

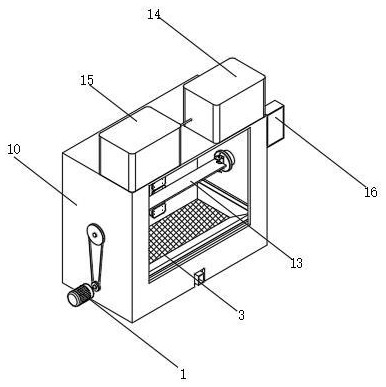

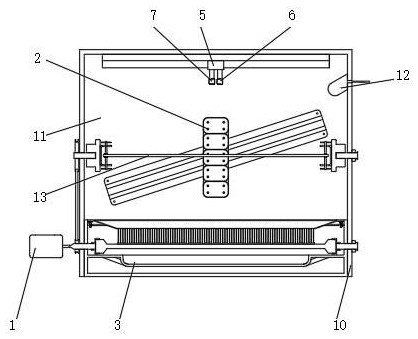

[0036] like figure 1 , 2 3, 4, 6, 8, and 9, a metal building material surface grinding device, including a casing 10, an operating bin 11, a detecting head 12, a driving device 1, a metal sheet 13, and a metal pipe 17, a box body The internal opening of the operating bin 11 is provided. The upper portion of the operation bond 11 is provided with a drive device 1, and the driving device 1 includes a second connecting head 104, a third connecting head 105, and a clamping member 106, one side of the casing 10. There is a second connecting head 104, and the other side of the casing 10 is provided with a third connecting head 105, the third connecting head 105 and the second connecting head 104 are placed in the end surface of the operating bin 11, which is provided with a clamp 106, operator warehouse 11. The inner two clamp 106 holds a metal sheet 13;

[0037]The drive device 1 further includes a first connecting head 101, a stepper motor 102, and a transmission belt 103, and a first...

Embodiment 2

[0041] like Figure 4 , 6 , 7, 8, a grinding rending mechanism of a metal building material surface grinding the rusting device, the grinding rear rust mechanism 2 includes a first slide direct, a linear driver 202, a first grinding piece 203, a second grinding piece 204, The third grinding piece 205, the fourth grinding piece 206, and the fifth grinding piece 207, the movable bin 11 is provided with a first slide guide 201, and the moving parts of the first slide rail 201 are connected to a straight drive 202, a straight drive The end of 202 is provided with a substrate, and the front end of the substrate is sequentially provided with the first grinding sheet 203, the second die-grinding piece 204, the third die mill 205, the fourth grinding piece 206 and the fifth grinding sheet 207;

[0042] The first grinding piece 203, the second grinding piece 204, the third grinding piece 205, the fourth grinding sheet 206, and the fifth grinding sheet 207 correspond to 100 mesh, 300 mesh, 5...

Embodiment 3

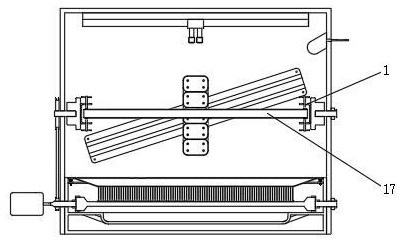

[0044] like Figure 5 As shown, a reinforcing vibration type waste collecting device of a metal building material surface is polished, and the vibration type waste collecting device 3 further includes a fixed frame 306, a spring 307, a shaped frame 308, and a filter film 309, a box 301. The upper portion is provided with a fixed frame 306, and a spring 307 is provided at the upper side angle of the fixed frame 306, and the upper portion of the cartridge 308, the shaped frame 308, and the spring 307 are connected in the upper end of the collecting box 301, and filter is provided in the frame of the shaped frame 308. Membrane 309;

[0045] The shaped frame 308 and the collecting cassette 301 are active, the collecting box 301 is fixed to the stationary frame 306, and the filter film 309 is fixed to the shaped frame 308, the cleaning brush 305 is rotated to contact the filter film 309 and the lower end of the shaped frame 308, the shaped frame 308 The cross section is set, the dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com