Hub cover with radar and infrared stealth functions

A hubcap and infrared technology, applied in the direction of wheel cover discs, wheels, coatings, etc., can solve the problem of improving the stealth function, and achieve the effects of high absorption rate, good radar stealth performance, and low reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

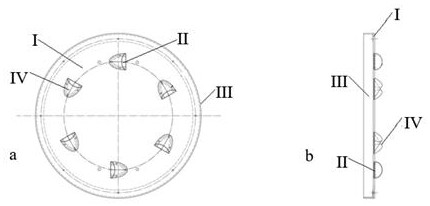

[0028] Such as figure 1 As shown, the hub cover with both radar and infrared stealth functions is composed of a disc plate I, a diversion groove II, an annular corner piece III, and a diversion ear IV. A diversion groove II is arranged on one side of the disc plate I, and a diversion ear IV is arranged above the diversion groove II; the other side of the disc plate I is covered with metal foil; the metal foil is sprayed with a thermal retroreflective coating. The annular corner piece III is connected with the disc plate I by riveting.

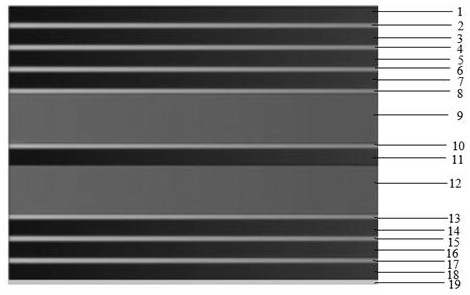

[0029] Such as figure 2 As shown, the disc plate consists of the first fiberglass layer 1, the first absorbing cloth layer 2, the second fiberglass layer 3, the second absorbing cloth layer 4, the third fiberglass layer 5, the third absorbing cloth layer 6, the fourth FRP layer 7, fourth absorbing cloth layer 8, first aramid honeycomb layer 9, fifth absorbing cloth layer 10, fifth FRP layer 11, second aramid honeycomb layer 12, sixth absorbi...

Embodiment 2

[0035] Such as figure 1 As shown, the hub cover with both radar and infrared stealth functions is composed of a disc plate I, a diversion groove II, an annular corner piece III, and a diversion ear IV. A diversion groove II is arranged on one side of the disc plate I, and a diversion ear IV is arranged above the diversion groove II; the other side of the disc plate I is covered with metal foil; the metal foil is sprayed with a thermal retroreflective coating. The annular corner piece III is connected with the disc plate I by riveting.

[0036] Such as figure 2 As shown, the disc plate consists of the first fiberglass layer 1, the first absorbing cloth layer 2, the second fiberglass layer 3, the second absorbing cloth layer 4, the third fiberglass layer 5, the third absorbing cloth layer 6, the fourth FRP layer 7, fourth absorbing cloth layer 8, first aramid honeycomb layer 9, fifth absorbing cloth layer 10, fifth FRP layer 11, second aramid honeycomb layer 12, sixth absorbi...

Embodiment 3

[0042] Such as figure 1 As shown, the hub cover with both radar and infrared stealth functions is composed of a disc plate I, a diversion groove II, an annular corner piece III, and a diversion ear IV. A diversion groove II is arranged on one side of the disc plate I, and a diversion ear IV is arranged above the diversion groove II; the other side of the disc plate I is covered with metal foil; the metal foil is sprayed with a thermal retroreflective coating. The annular corner piece III is connected with the disc plate I by riveting.

[0043] Such as figure 2 As shown, the disc plate consists of the first fiberglass layer 1, the first absorbing cloth layer 2, the second fiberglass layer 3, the second absorbing cloth layer 4, the third fiberglass layer 5, the third absorbing cloth layer 6, the fourth FRP layer 7, fourth absorbing cloth layer 8, first aramid honeycomb layer 9, fifth absorbing cloth layer 10, fifth FRP layer 11, second aramid honeycomb layer 12, sixth absorbi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com