A high-efficiency electroplating safety rack

A rack-mounting and safe technology, applied in the direction of electrolysis components, electrolysis process, drying gas arrangement, etc., can solve the problems of surface damage, collision, low efficiency, etc., and achieve the effect of improving electroplating efficiency and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

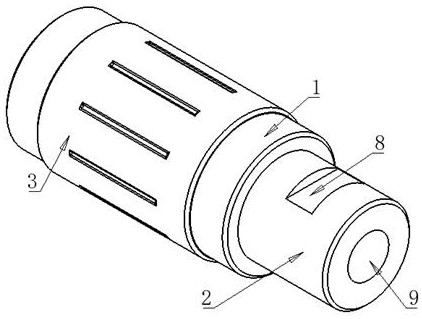

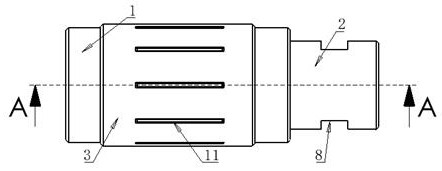

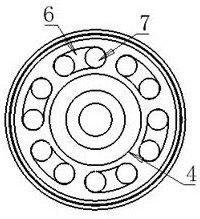

[0021] like Figure 1 to Figure 8 As shown in the figure, a high-efficiency electroplating safety placement rack, which adopts a new structural design, can be used in conjunction with automated electroplating equipment, and can be accurately placed with multiple bar-type electroplating products at the same time. The electroplating operation is carried out in cooperation with the electroplating solution container. During the electroplating process, the end position of the bar is fully and safely electroplated through the electroplating main area inside the placing rack. Combined with the drying fan to directly dry the surface, there is no need to operate a separate electroplating product during the overall electroplating process, which not only improves the overall electroplating efficiency, but also prevents the risk of collision between each other and improves the safety during the overall processing. It includes a cylindrical main body whose central axis is in the left-righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com