Conveying, overturning and skin removing device for shafts

A technology for shafts and turning disks, which is applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc., can solve the problems of large labor force, high price, low cost performance, etc. , the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

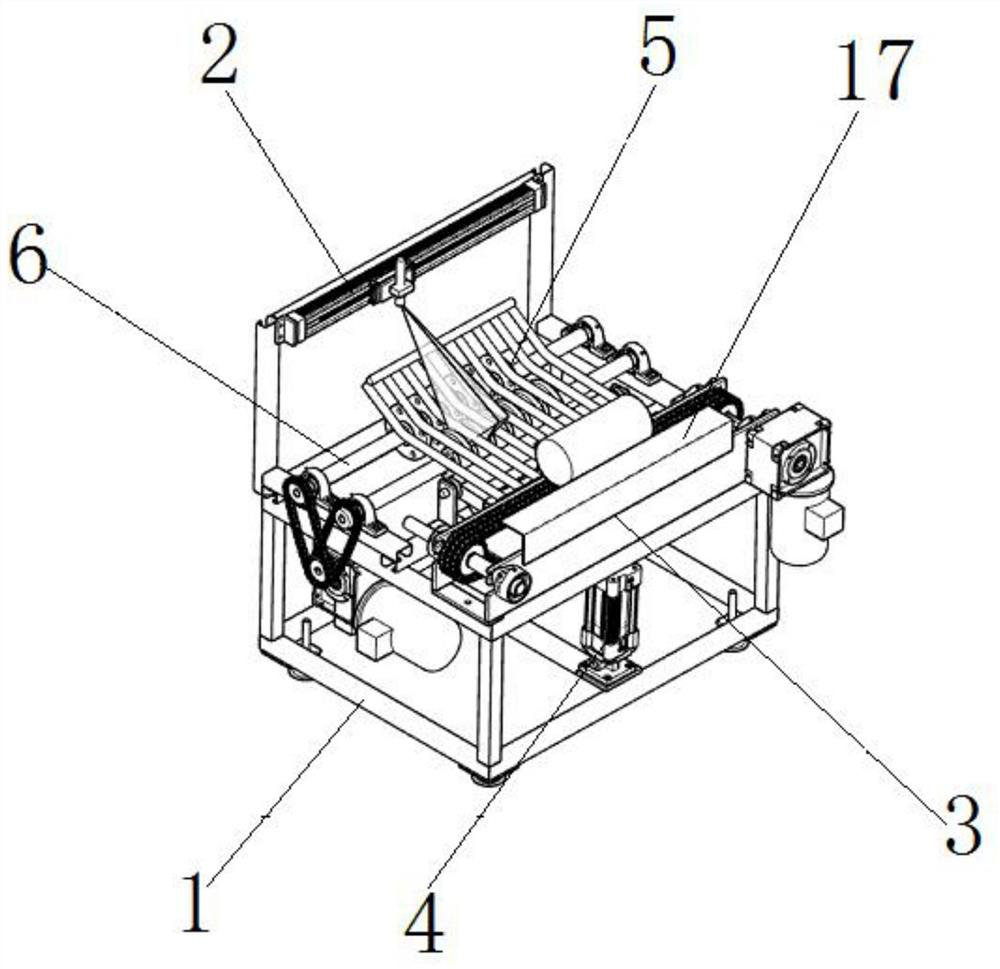

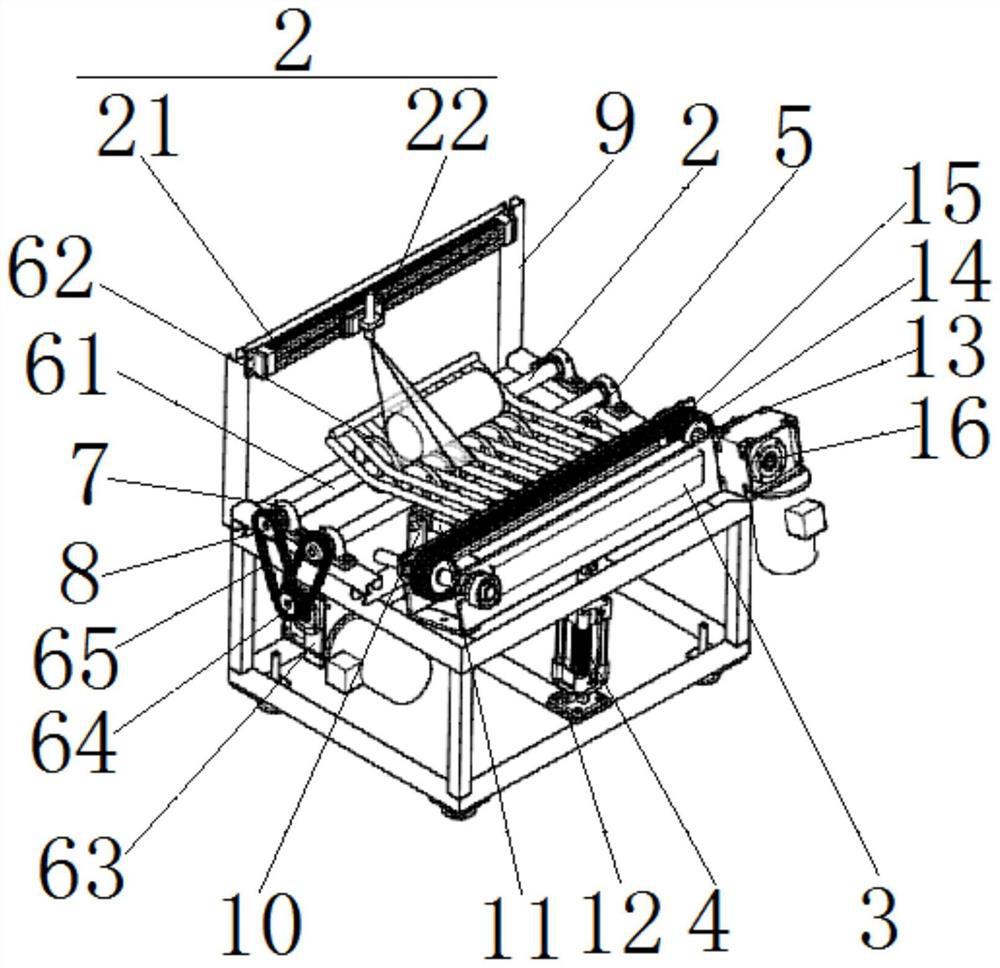

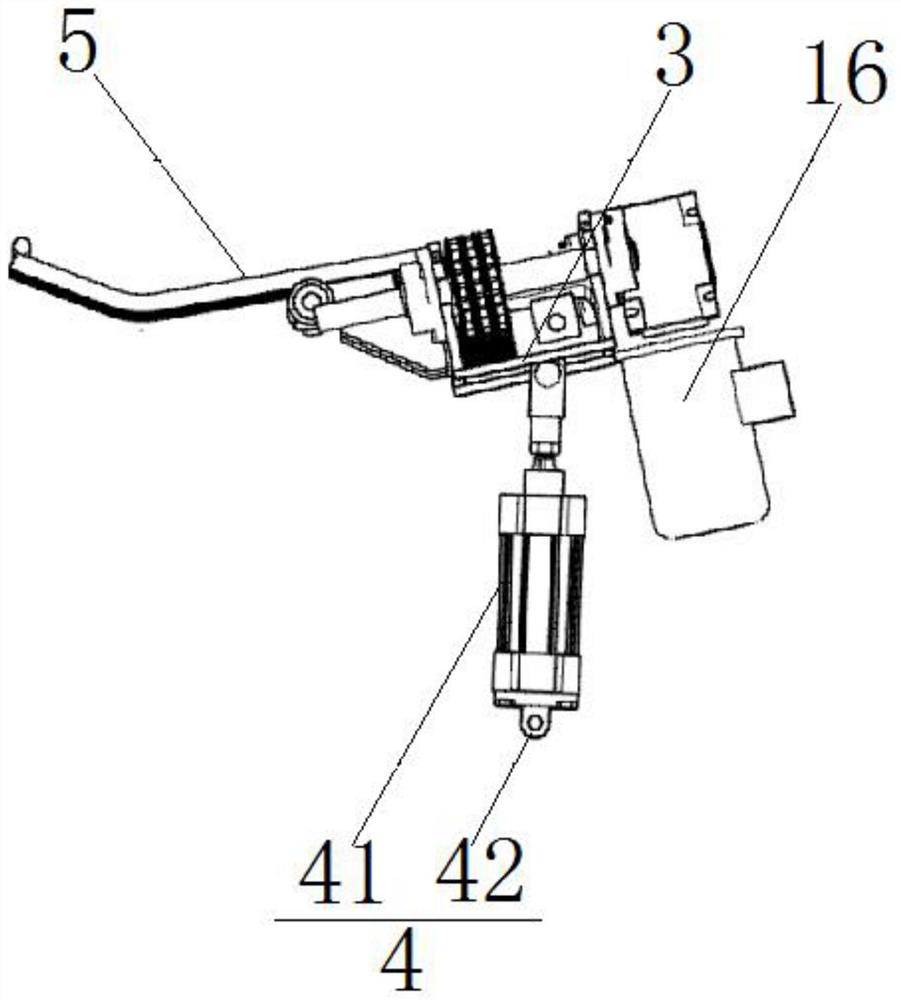

[0018] refer to Figure 1-Figure 4 , the present invention proposes a shaft transporting and flipping cleaning device, which includes a frame 1 on which a reciprocating spray mechanism 2 for workpiece cleaning is installed and a bearing frame 3 is rotatably connected. A support frame 9 is installed on the frame 1, and the reciprocating spraying mechanism 2 includes a rodless cylinder 21 and a shower head 22. Set toward the flip disk 62 .

[0019] In this embodiment, the frame 1 is equipped with a lifter 4 for driving the carrier 3 to turn over towards the reciprocating spraying mechanism 2 . A side of the carrier frame 3 close to the reciprocating spray mechanism 2 is connected with a plurality of fixed rods 5 and the plurality of fixed rods 5 are spaced apart from each other.

[0020] In this embodiment, a rotating mechanism 6 arranged between the reciprocating spraying mechanism 2 and the carrier 3 is also included. The rotation mechanism 6 includes two rotating rods 61 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com