Fixing and leveling device and method for repairing turbine blades through SLM

A technology of turbine blades and leveling devices, applied in the direction of turbines, process efficiency improvement, additive manufacturing, etc., can solve problems such as wear, cracks, defects, etc., to prevent deflection or movement, improve precise adjustment, and physical structure solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be described in further detail below in conjunction with specific embodiments.

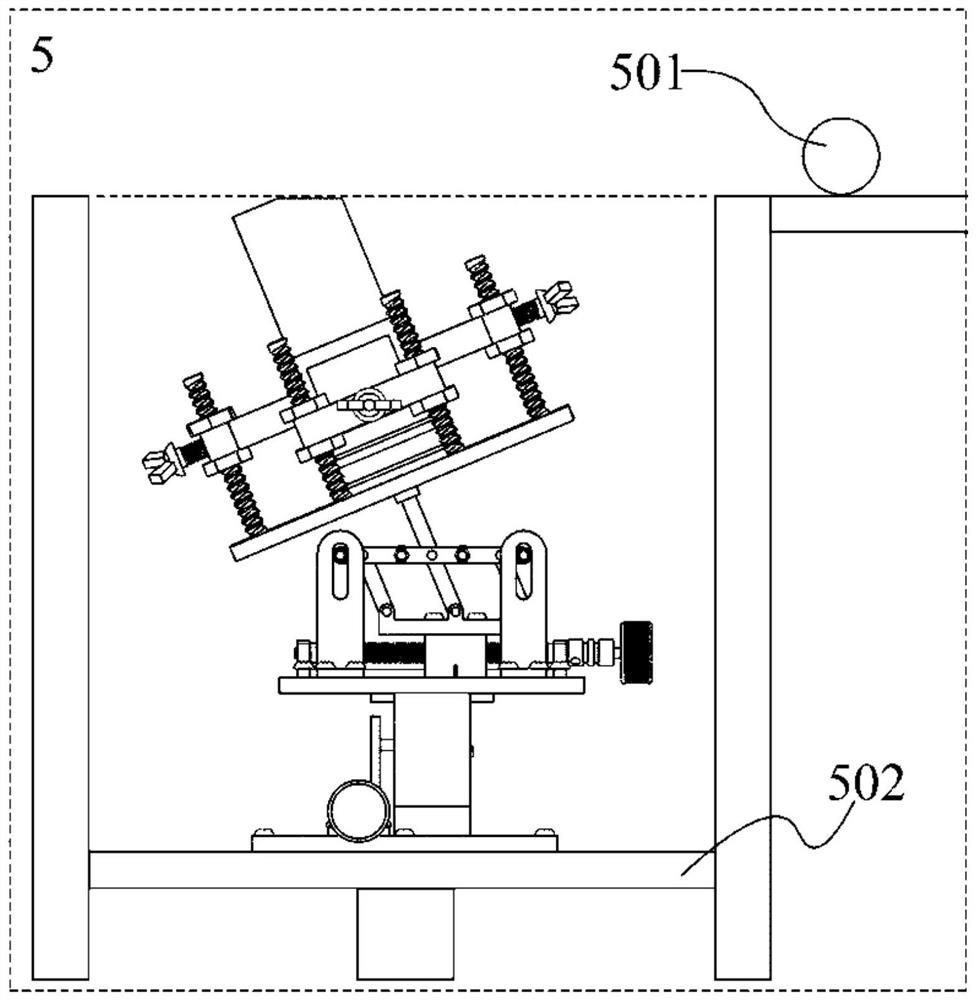

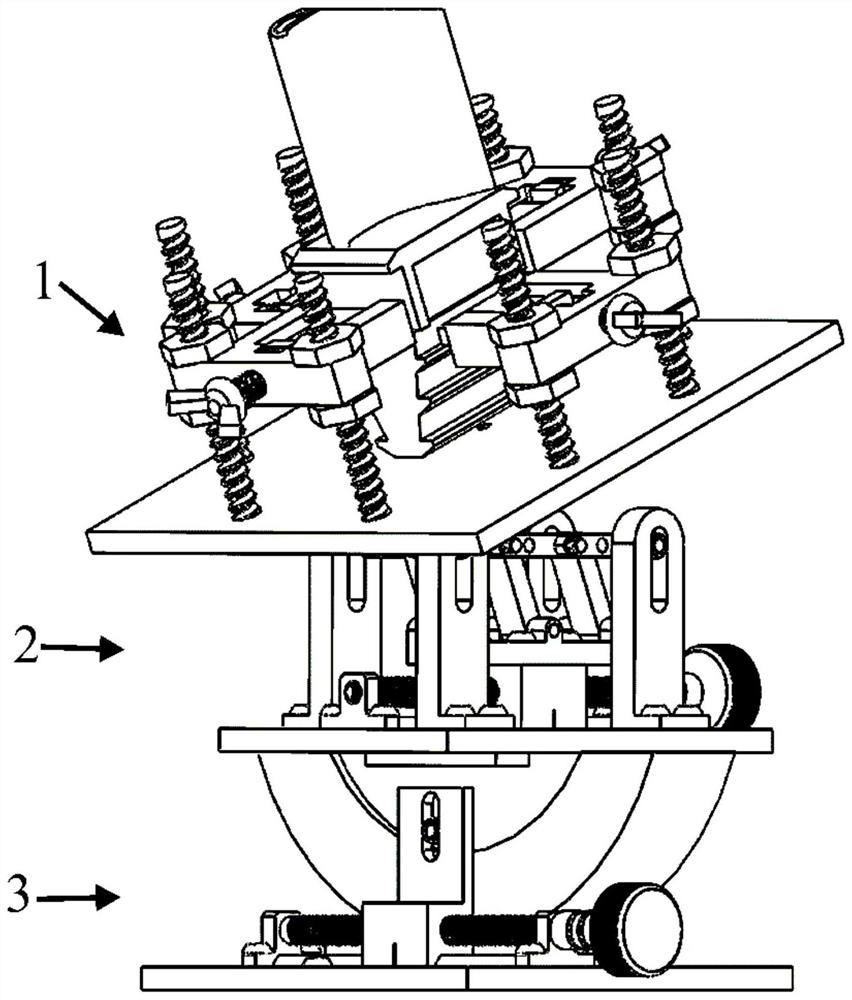

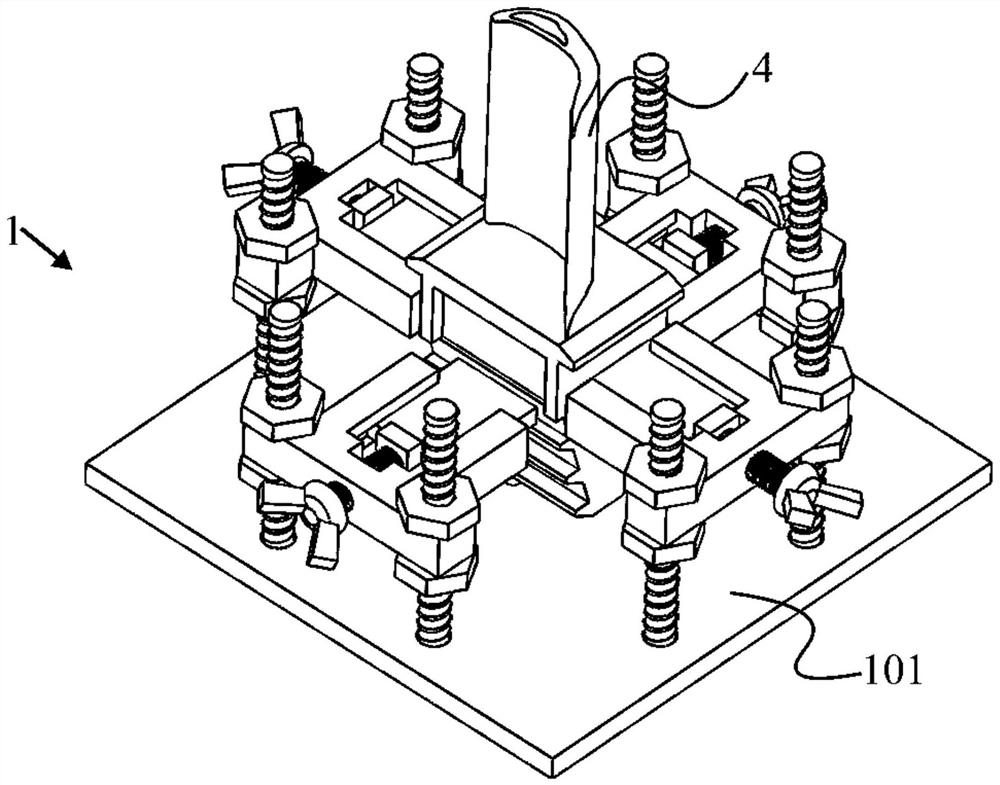

[0067] Such as Figure 1-7 shown. The invention discloses a fixed leveling device for repairing turbine blades by SLM, which includes a blade clamping mechanism 1, a first angle adjustment mechanism 2 and a second angle adjustment mechanism 3 connected sequentially from top to bottom;

[0068] The blade clamping mechanism 1 includes: a first platform 101 and four movable clamping mechanisms 102 symmetrically arranged on the first platform 101; the movable clamping mechanisms 102 are used to clamp the tenon root of the turbine blade 4;

[0069] Each movable clamping mechanism 102 includes: two screw rods 1021, a vertical movement guide block 1023;

[0070] Two screw rods 1021 are vertically spaced on the first platform 101, and the vertical movement guide block 1023 is sleeved on the screw rod 1021 through the guide holes 1023a at both ends;

[0071] On one side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com