Sand making process for machine-made sand and sand making device

A technology of machine-made sand and craftsmanship, applied in the direction of solid separation, filter screen, grille, etc., can solve problems such as reducing impact efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

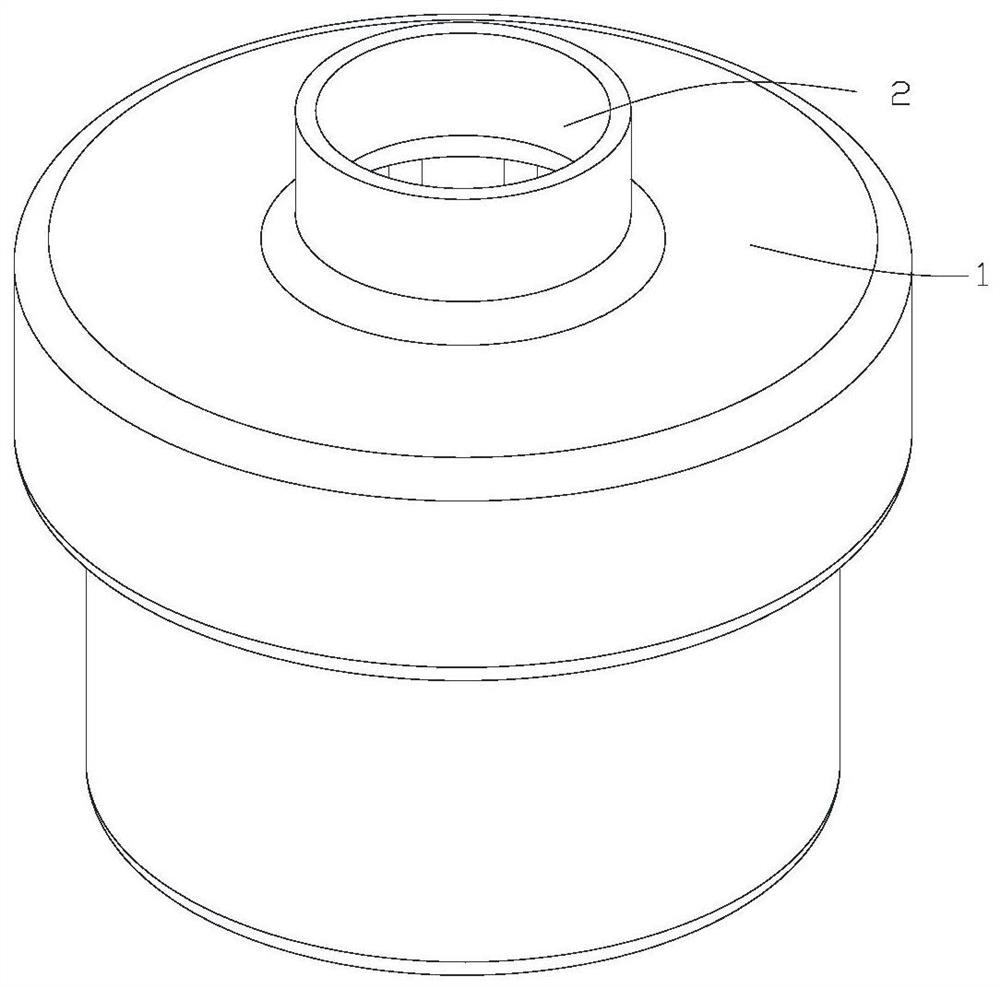

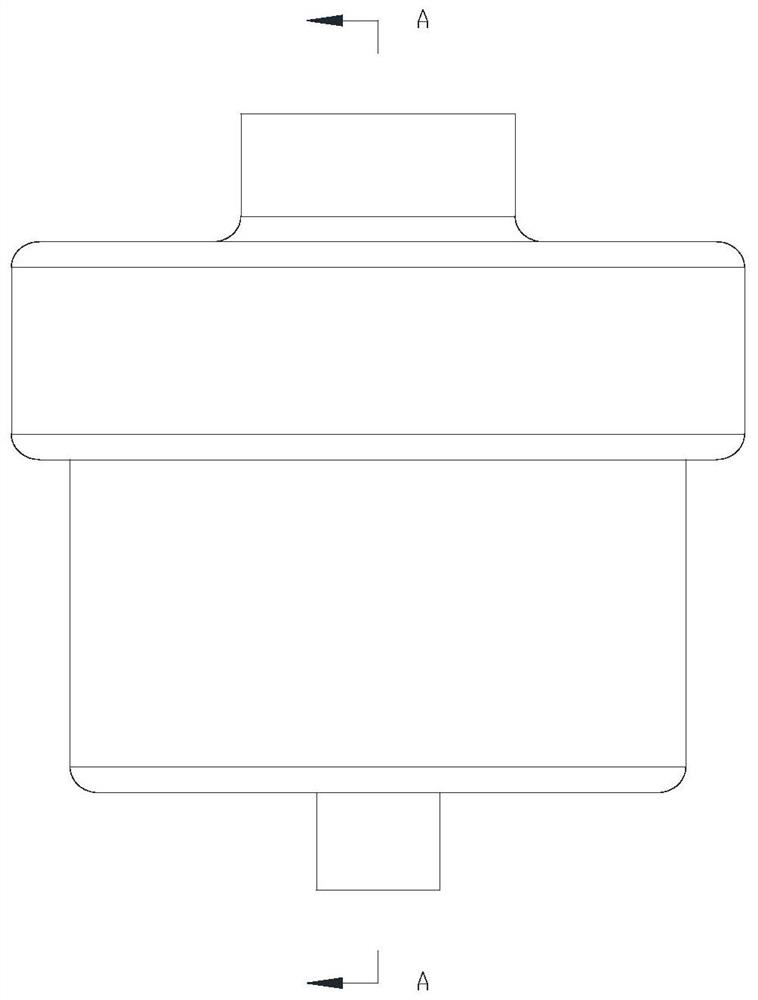

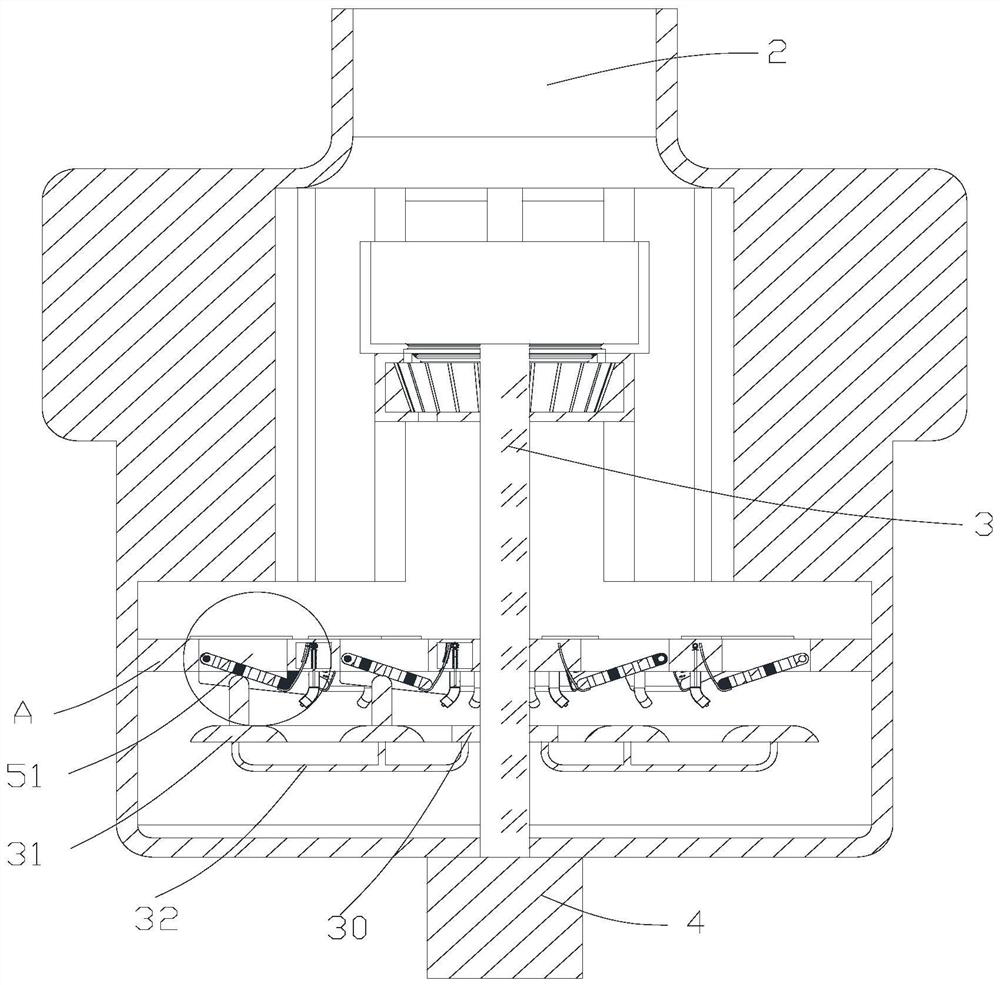

[0030] A sand making process of machine-made sand, characterized in that: comprising the following steps:

[0031] Step 1. The raw material stones enter the elevator through the feeding pit;

[0032] Step 2: The clean stones separated from the raw material stones through V-shaped sieve, linear vibrating sieve, and grading enter the impact sand making machine;

[0033] Step 3: There are many particles and powder in the stones impacted by the impact sand making machine, and they are screened again in multiple stages by the hoist.

[0034] Stones enter the body of the sand making machine from the feed port, and the finished sand will fall onto the screening plate, then fall into the feeding channel, and then be sent out from the sand leakage hole; after the sand making through the stones is completed, The screening plate realizes the screening of sand. During the screening process, one end of the turning plate will be turned upwards, and the turning plate will be turned upwards ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com