Sand making process for machine-made sand and sand making device

A machine-made sand and process technology, applied in solid separation, chemical instruments and methods, grain processing, etc., can solve problems such as reducing impact efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

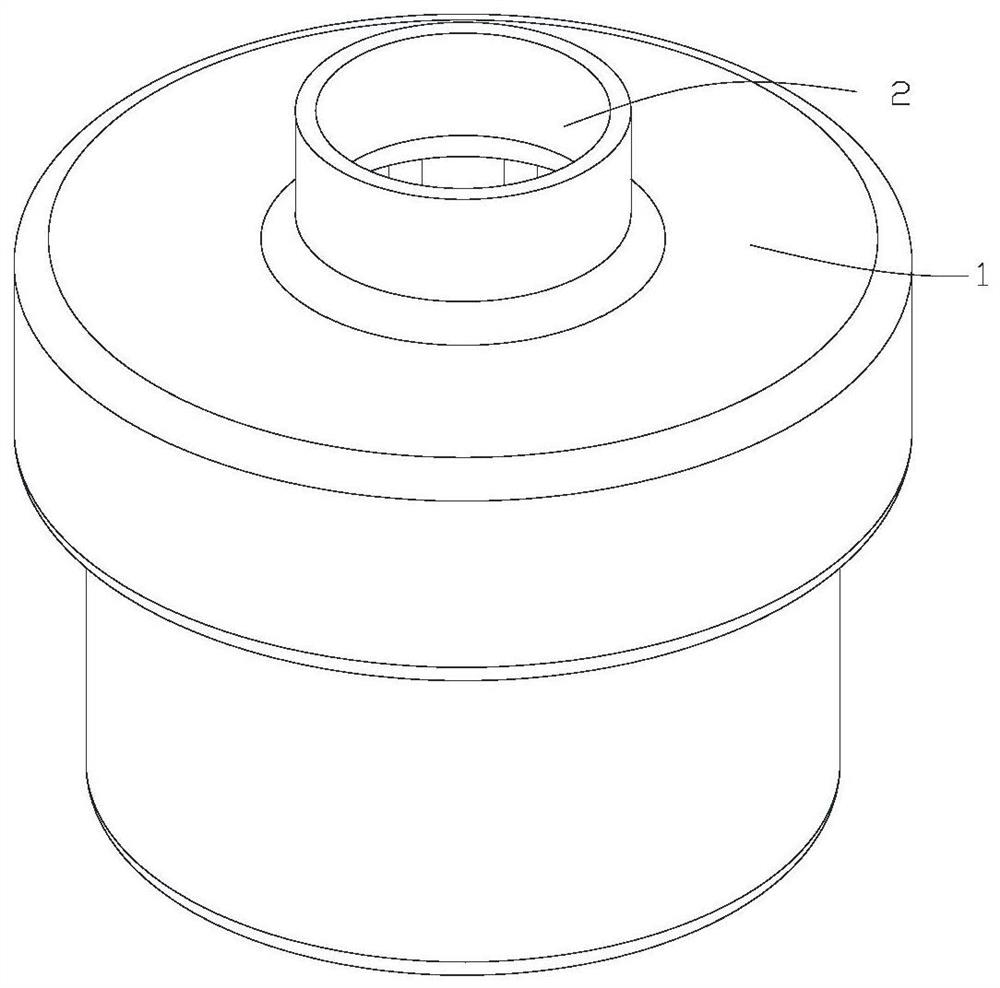

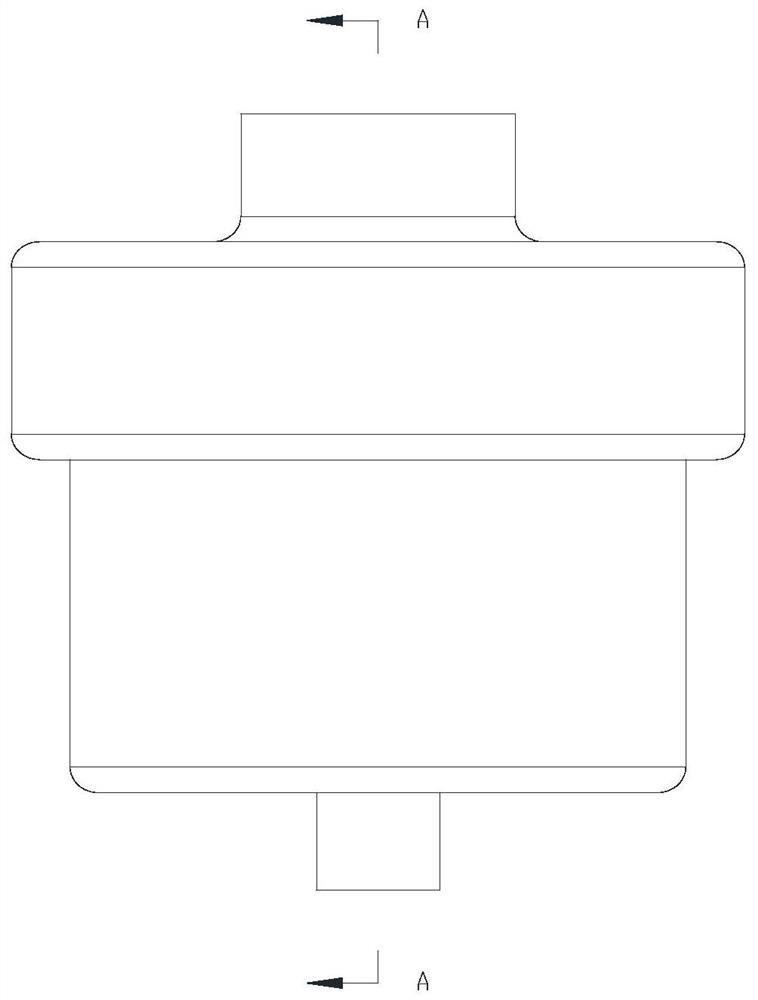

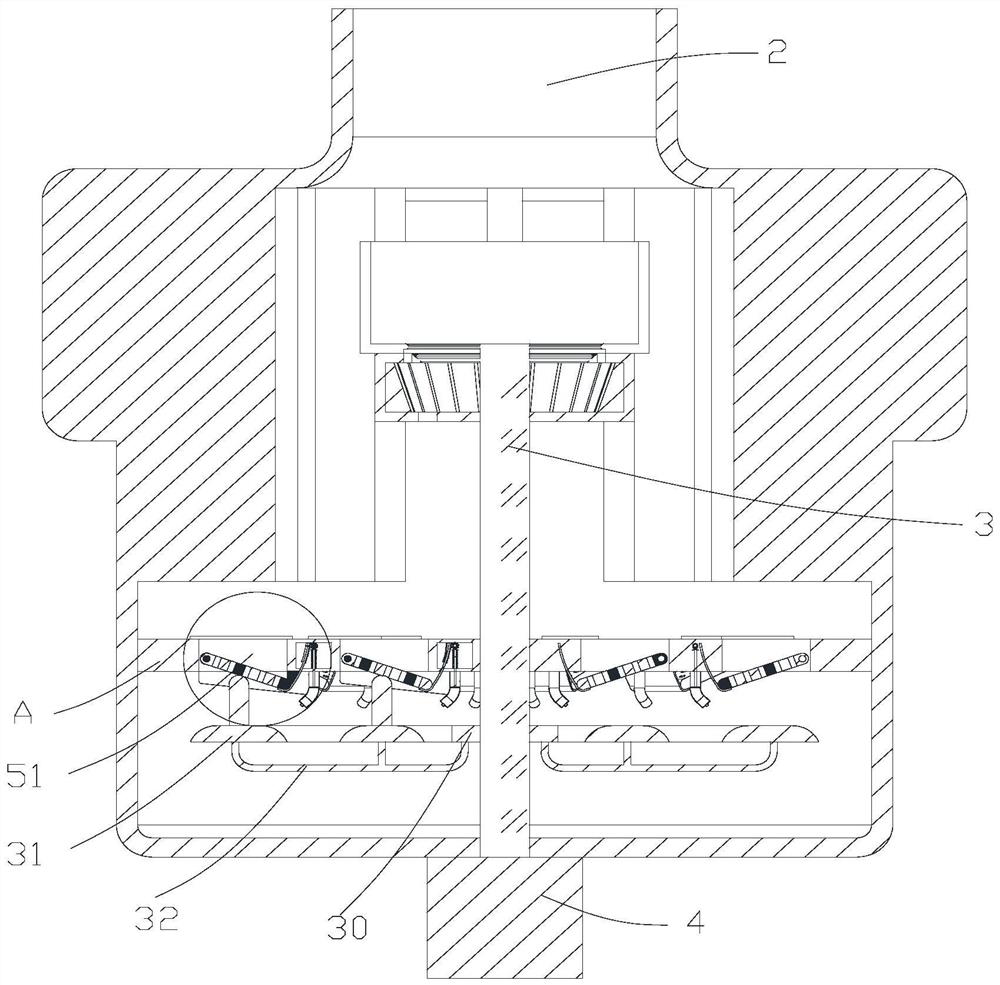

[0030] like Figure 1-10 As shown, a sand sheatting process of a mechanism sand, comprising the steps of:

[0031] Step 1, the raw stone enters the hoist through the pit;

[0032] Step 2, the raw stone passes through the V-shaped sieve, the straight-line vibration screen, and the clean stone separated after the level is adjusted into the impact sander;

[0033] Step 3, there is a multi-particle and powder in the stone after the impact molding machine, and multi-level screening is performed again through the hoist.

[0034] The stone enters the sander body from the feed opening, and the sandy scorpion will fall into the screening board, then fall into the lower oriented channel, then send it down from the leakage hole; after the stone sand is completed, The screening dish is implemented to the screen of the sand. During the screening process, one end of the flip plate will be turned upward, and the flip plate is turned upward, and the automatic dredging of the lower plate is realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com